Engine exhaust valve structure

A technology for exhaust valves and engines, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve the problem of exhaust valve rod and valve guide wear, exhaust valve rod rotation is not obvious, and exhaust valve rod cone burnt Damage and other problems, to achieve the effect of preventing fracture, obvious rotation effect and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

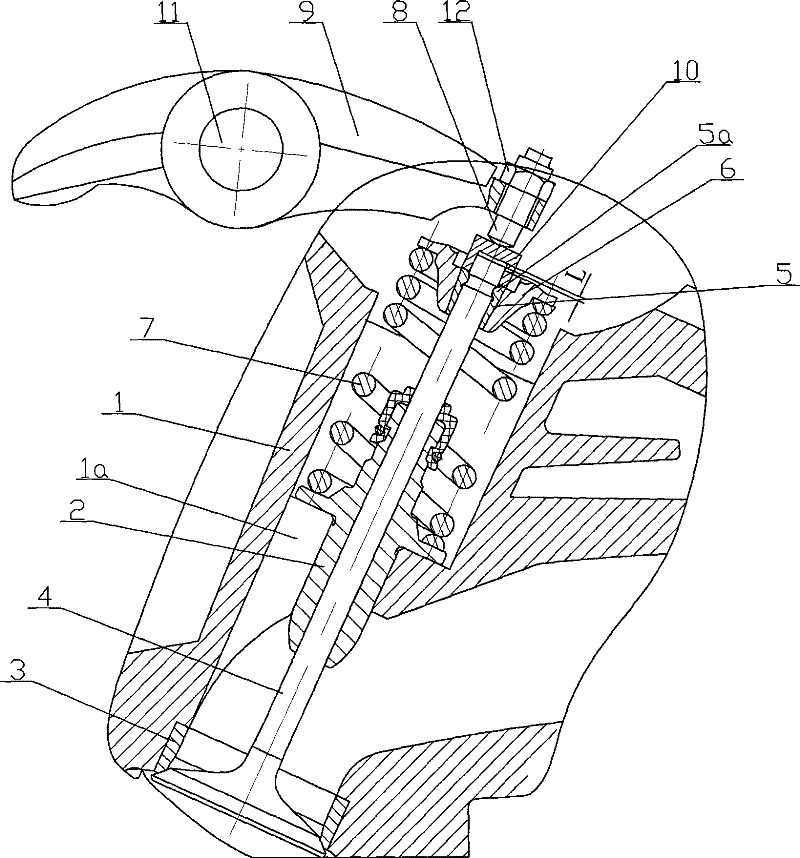

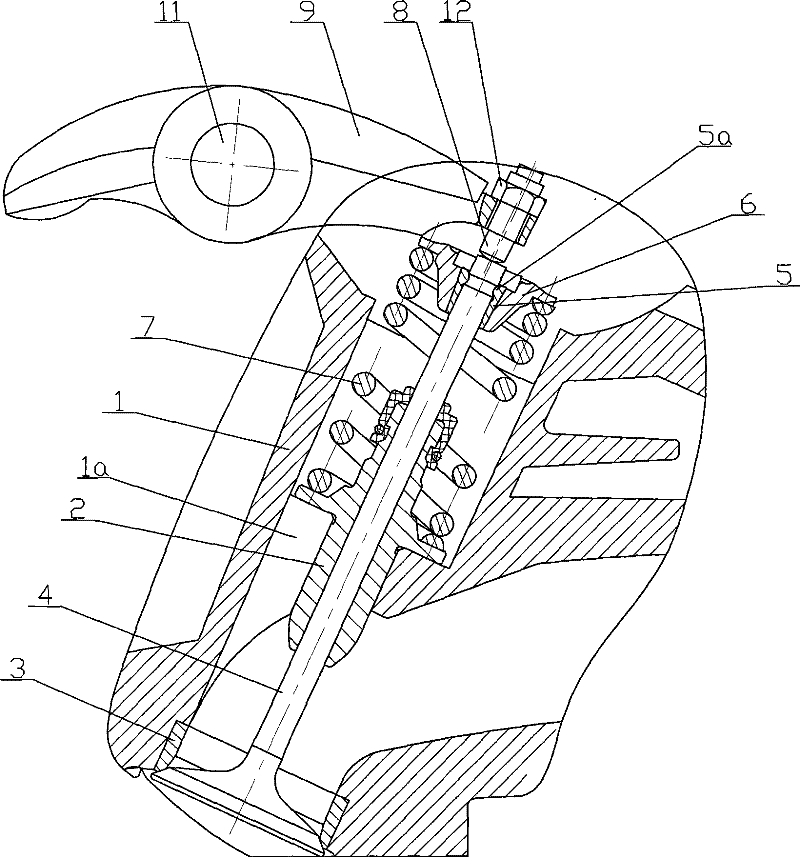

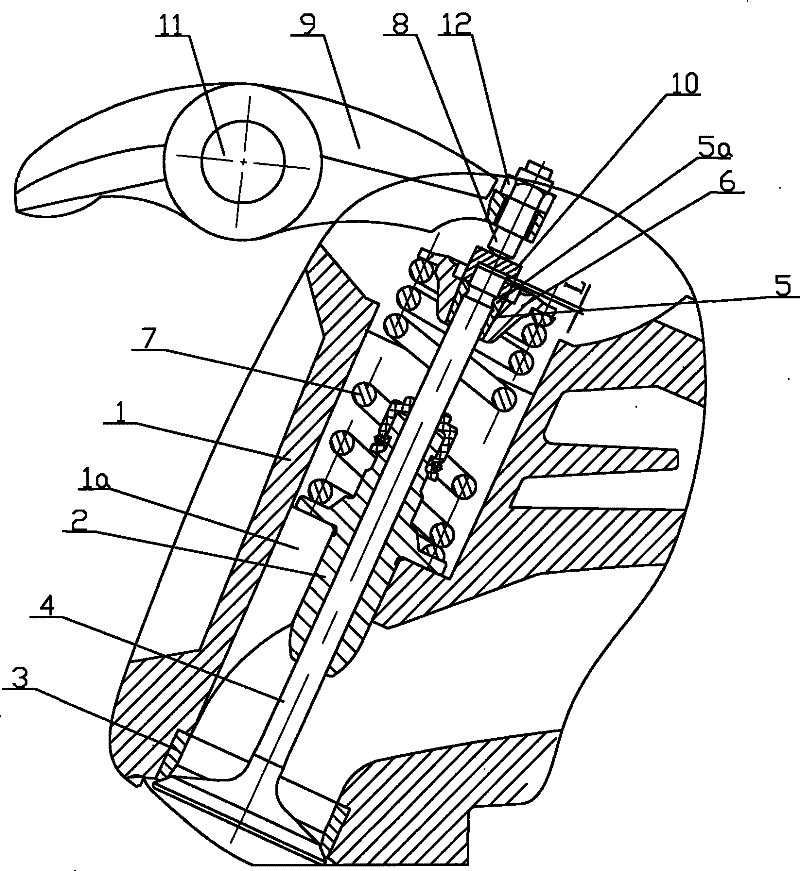

[0015] like figure 1 As shown, a valve guide 2 and a valve seat 3 are installed at the middle of the accommodation hole 1 a on the cylinder head 1 , and the valve guide 2 and the valve seat 3 are tightly fitted with the cylinder head 1 . The exhaust valve rod 4 passes through the valve seat 3 and the valve guide 2 from bottom to top, and the valve lock clip 5 is installed on the top of the exhaust valve rod 4, and the arc-shaped boss 5a on the inner wall of the valve lock clip 5 snaps into the row. The corresponding arc-shaped ring groove on the valve stem 4, and the arc-shaped boss 5a is slightly smaller than the arc-shaped ring groove matched therewith. The upper spring seat 6 is set on the outside of the valve lock clip 5, and the valve spring 7 upper end on the exhaust valve rod 4 is limited by the spring upper seat 6, and the lower end is limited by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com