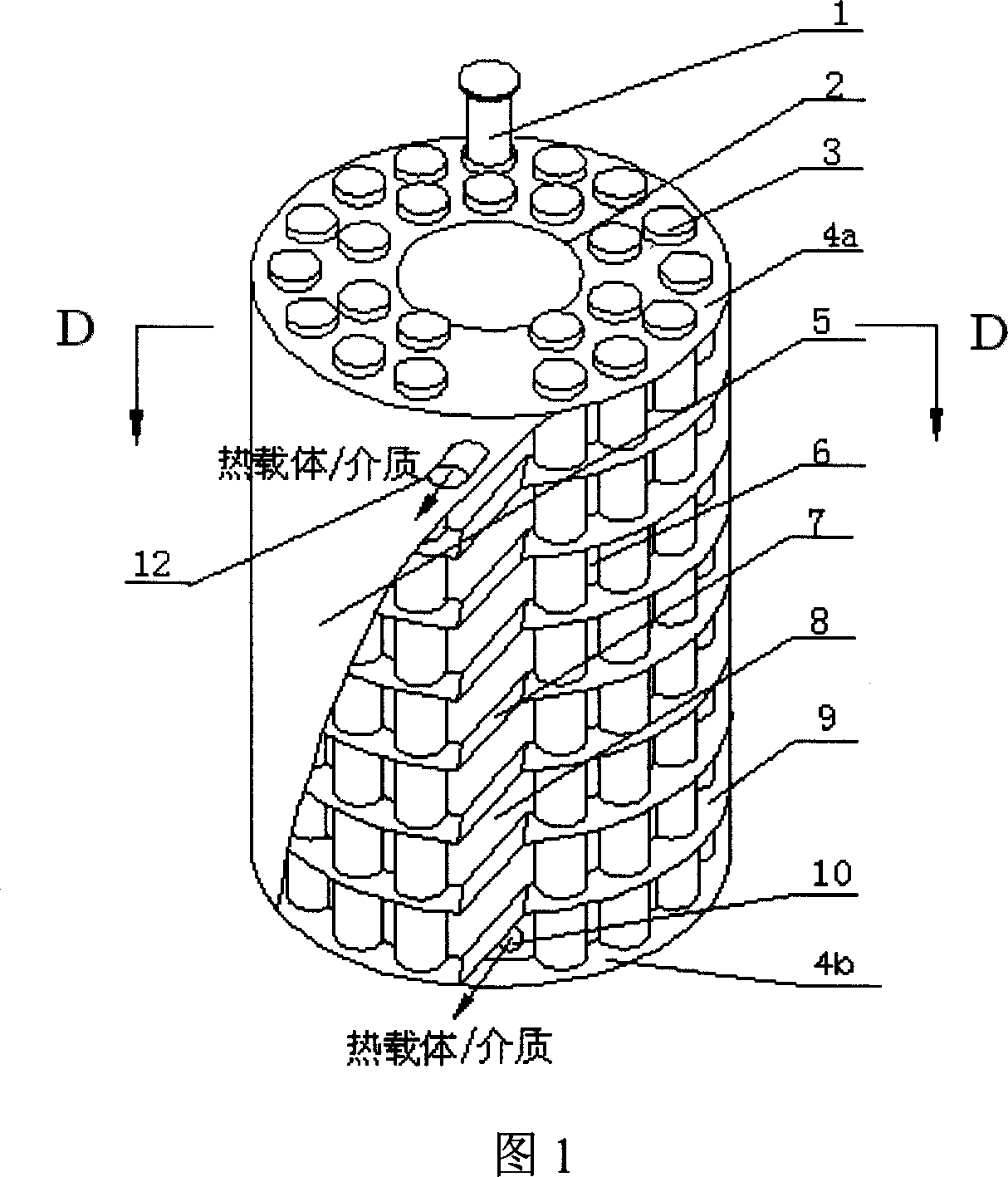

Multipurpose direct flow pipe shielded heat carrier boiler

A direct-flow tube, multi-purpose technology, applied in fluid heaters, water heaters, heat storage heaters, etc., can solve problems such as low flow rate, unreliable cooling of heating tubes, and easy carbon deposition and coking of heat carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

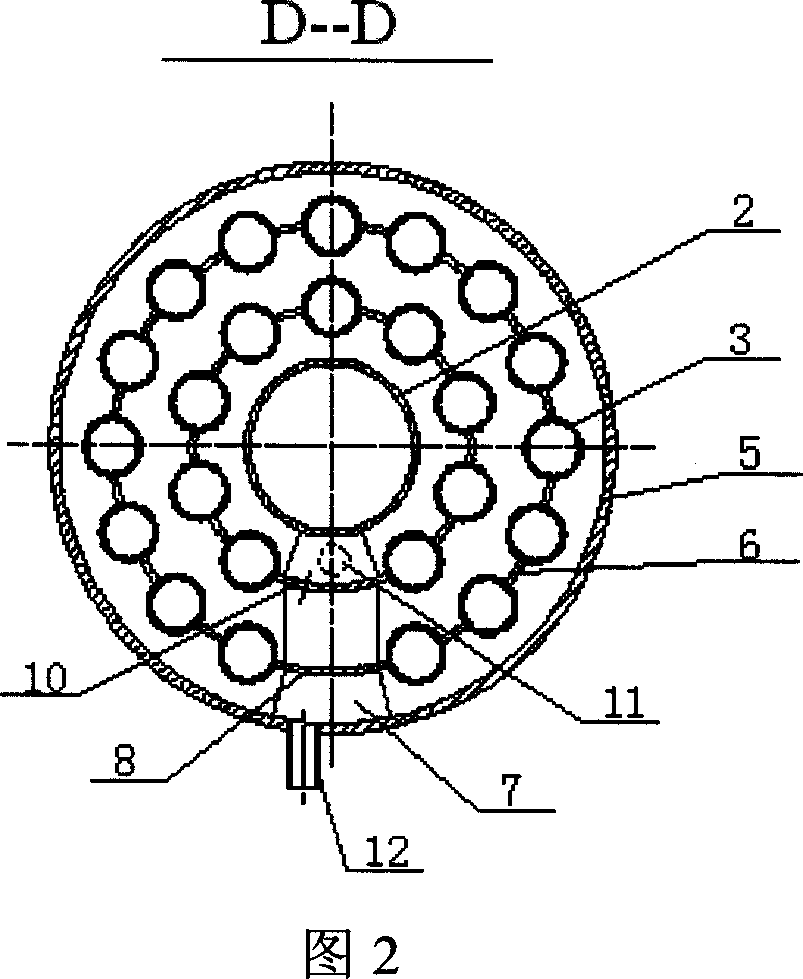

[0031]Referring to Figures 1 and 2, an electric heating rod 1 is installed in the casing 3 as a heat source, and the medium, that is, the organic heat carrier, enters from the medium inlet 11, and in turn, the inner, middle, and outer spiral flow channels are forced to change the cross-section. Flow, receive radiant heat release and convective heat exchange from the electric heating rod 1, flow out from the medium outlet 12, and flow to the heat user. The heat transfer coefficient is doubled due to the high-speed and variable-section lateral scouring turbulent flow of the organic heat carrier on the casing 3, and the connection of the fins 6, the baffles 9 and the casing 3 greatly expands the heat transfer surface and greatly improves the heat transfer coefficient. Heat transfer efficiency, so that the electric heating rod 1 and sleeve 3 can be rapidly cooled, and the heat transfer conditions are greatly improved, which effectively avoids the overheating, cracking, carbon depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com