Air gas primary heater unit of hot-air stove

A gas preheating and hot blast stove technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of not meeting the high air temperature of 1200°C and the flue exhaust gas temperature is not too high, so as to overcome the damage , improve the service life, the effect of low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

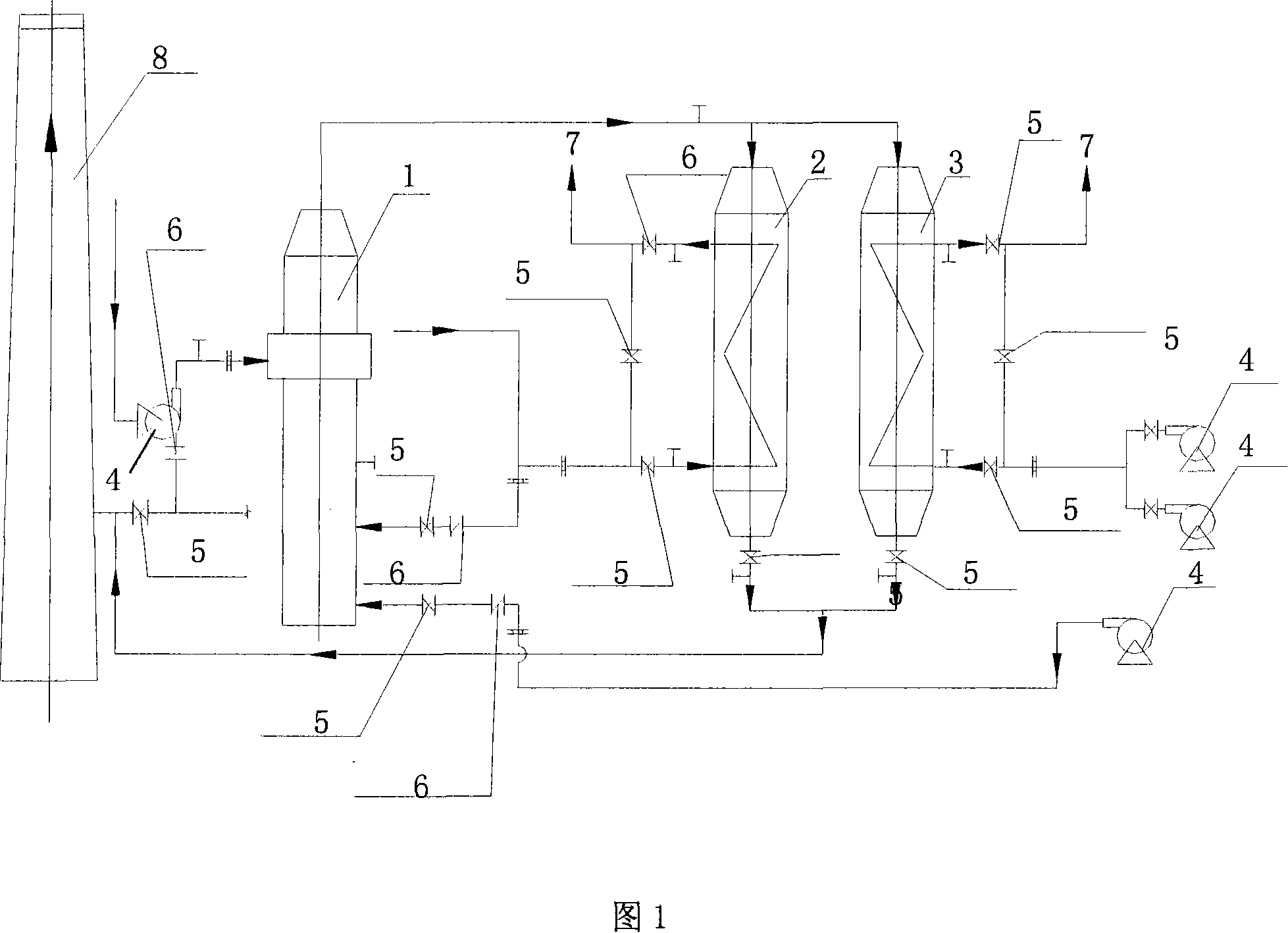

[0011] Embodiment 1: As shown in Figure 1, the preheating system is a one-time preheating device, wherein 1 is a combustion mixing furnace, 2 is a gas heat exchanger, 3 is an air heat exchanger, 4 is an induced draft fan, and 5 is a valve , 6 is a regulating valve, 7 is a hot blast stove, and 8 is a chimney. The air heat exchanger and gas heat exchanger of the preheating device are tube-type, and the flue gas of the hot blast stove is introduced into the mixing chamber on the upper part of the combustion mixing furnace by a high-temperature induced draft fan (see Figure 3), and the high-temperature flue gas produced by the combustion mixing furnace Mixing, so that the temperature of the mixed flue gas reaches 500-600°C, the mixed high-temperature flue gas enters the air heat exchanger and the gas heat exchanger respectively, and after heat exchange, the air and gas entering the hot blast stove are heated to 300°C, and the remaining exhaust into the chimney.

[0012] The combu...

Embodiment 2

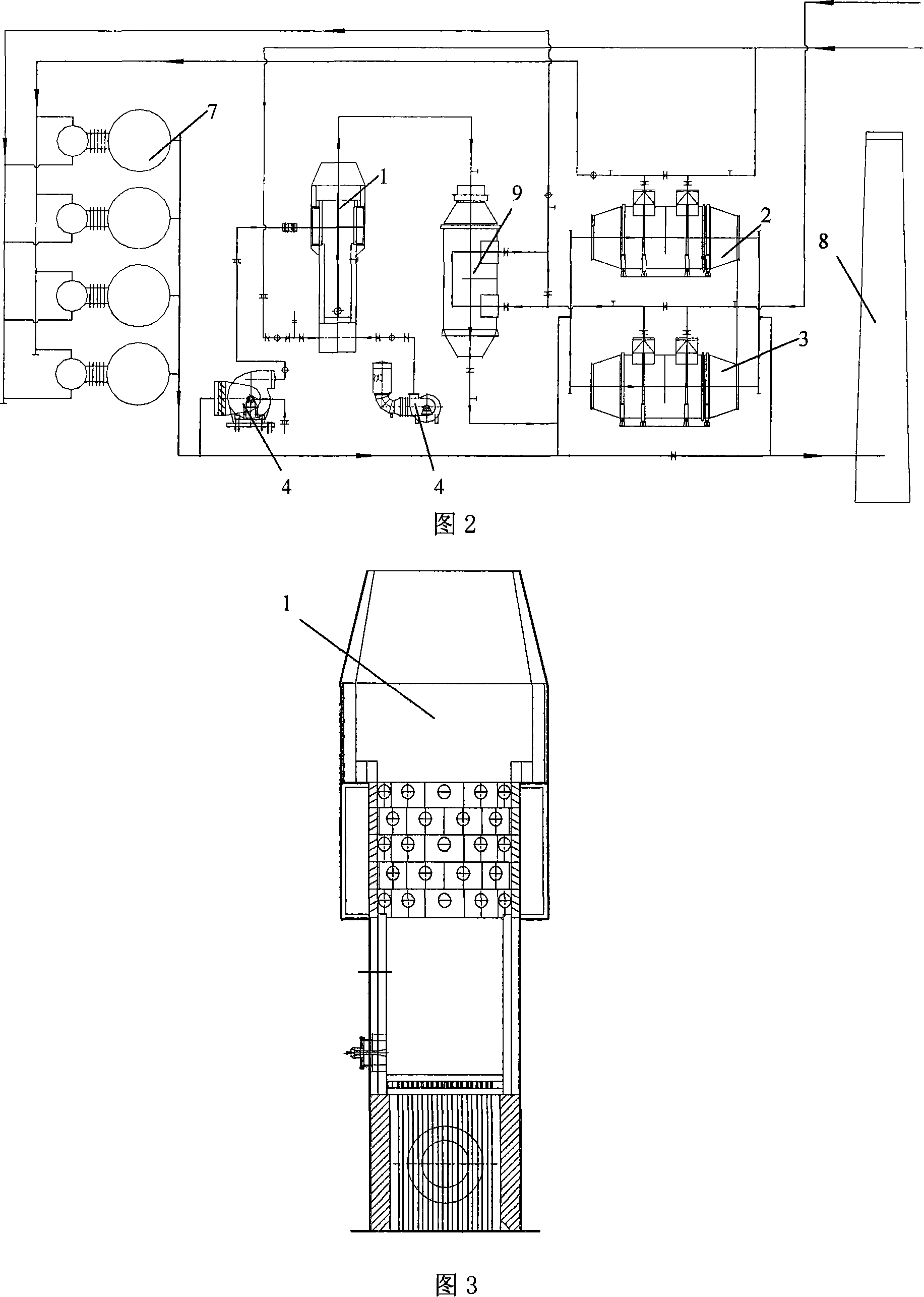

[0014] Embodiment 2: As shown in Figure 2, the preheating system is a secondary preheating device, or a segmented preheating device, wherein 9 is a high-temperature air heat exchanger, and the rest of the labels are the same as in Embodiment 1.

[0015] The segmented preheating device also adopts tube and tube type (the tube bundle is bare tube, after high temperature immersion aluminum, high temperature resistance, corrosion resistance) air heat exchanger and gas heat exchanger, first use the flue gas of the hot blast stove to preheat the air and gas to 200°C; then use the flue gas induced draft fan to introduce the flue gas of the hot blast stove into the mixing chamber on the upper part of the combustion mixing furnace (see Figure 3), and mix it with the high-temperature flue gas generated by the combustion mixing furnace, so that the temperature of the mixed flue gas reaches 550-700 ℃, use this flue gas to preheat the combustion air that has been preheated to 200 ℃ to 450 ℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com