A regenerative combustion system

A combustion system and regenerative technology, applied in the combustion method, control combustion, combustion equipment and other directions, can solve the problems of the waste heat of flue gas not being well utilized, the high temperature of industrial grate flue gas, and the low energy utilization rate, etc. Achieve significant effect of energy saving and emission reduction, improve energy utilization rate, and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

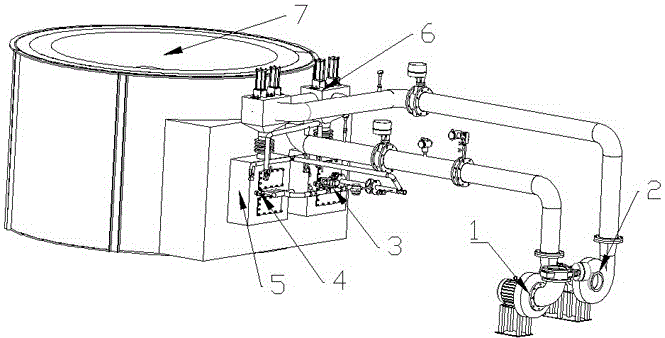

[0044] A regenerative combustion system, such as figure 1 As shown, it includes: air supply system 1, smoke exhaust system 2, fuel supply system 3, permanent flame system 4, regenerative burner 5, reversing system 6 and target kiln 7, wherein the air supply system 1 is arranged with Flow and pressure regulating devices, flue gas temperature monitoring devices are arranged on the smoke exhaust system 2, and shut-off valves are arranged on the corresponding regenerative burner pipelines of the fuel supply system 3 to control the supply of fuel.

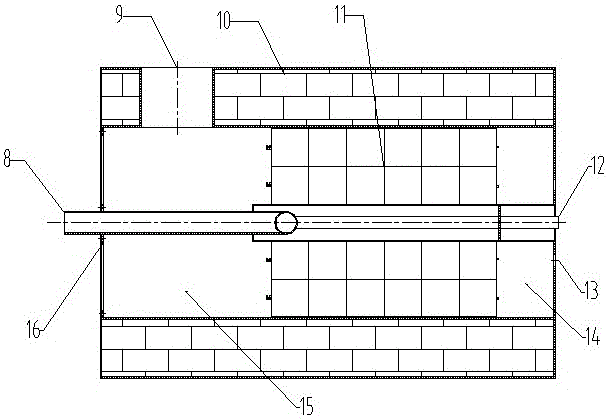

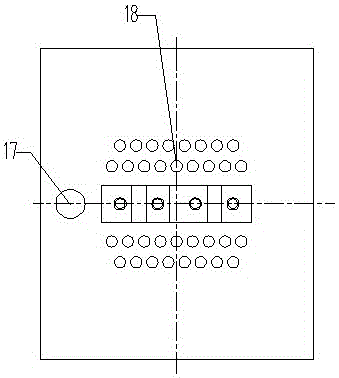

[0045] Sectional drawing of regenerative burner figure 2As shown, it includes: main fuel pipeline 8, combustion-supporting air inlet or flue gas outlet 9, regenerator 10, regenerator 11, fuel nozzle 12, front porous air distribution plate 13, front combustion-supporting air or flue gas buffer chamber 14, The rear combustion-supporting air or flue gas buffer chamber 15, the rear end plate 16, and the heat storage body are stacked in la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com