Converter repairing mass and preparation method thereof

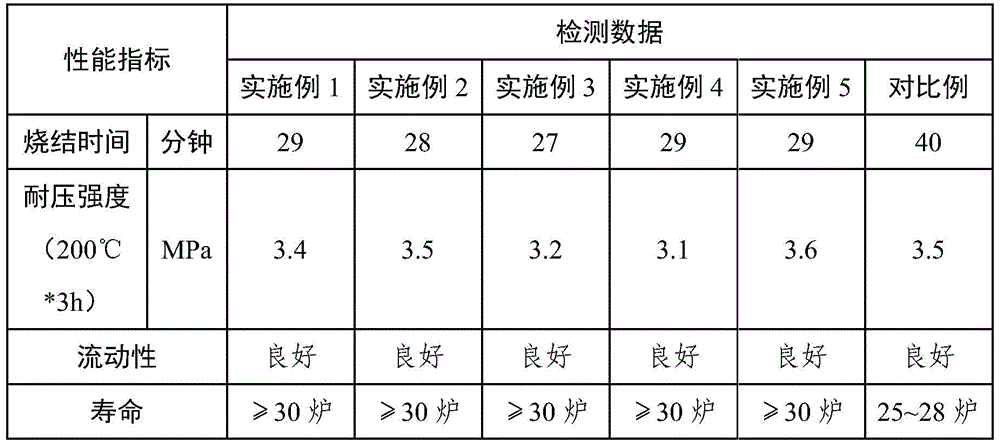

A technology for charging charging and converter, applied in the field of charging charging for converter and its preparation, can solve problems such as overall replacement of furnace shutdown, uneven damage to furnace lining, etc., and achieve high sintering strength, good protection effect, and good high temperature fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

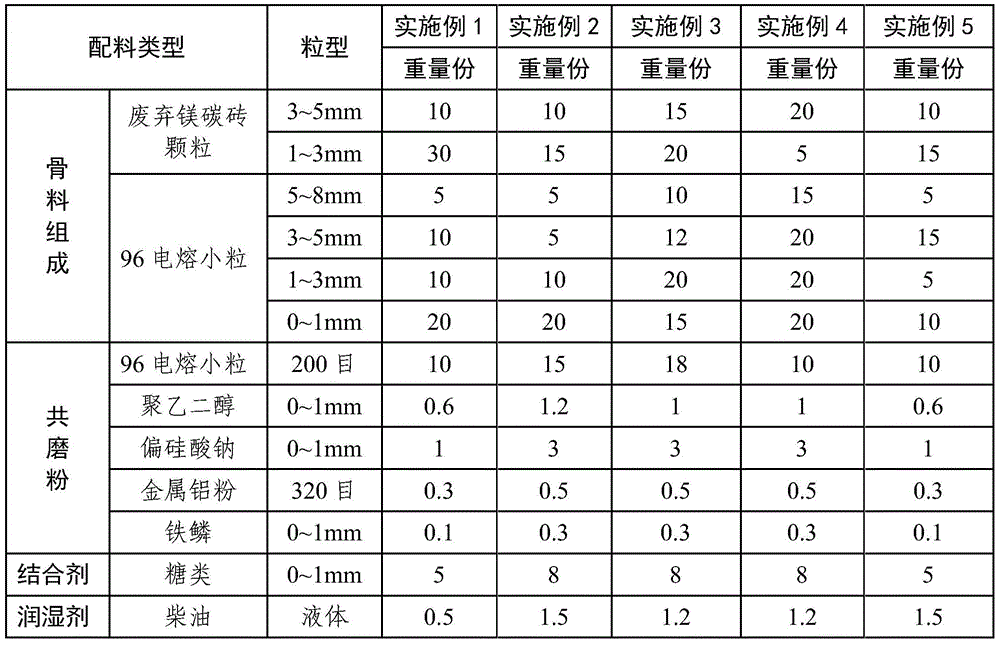

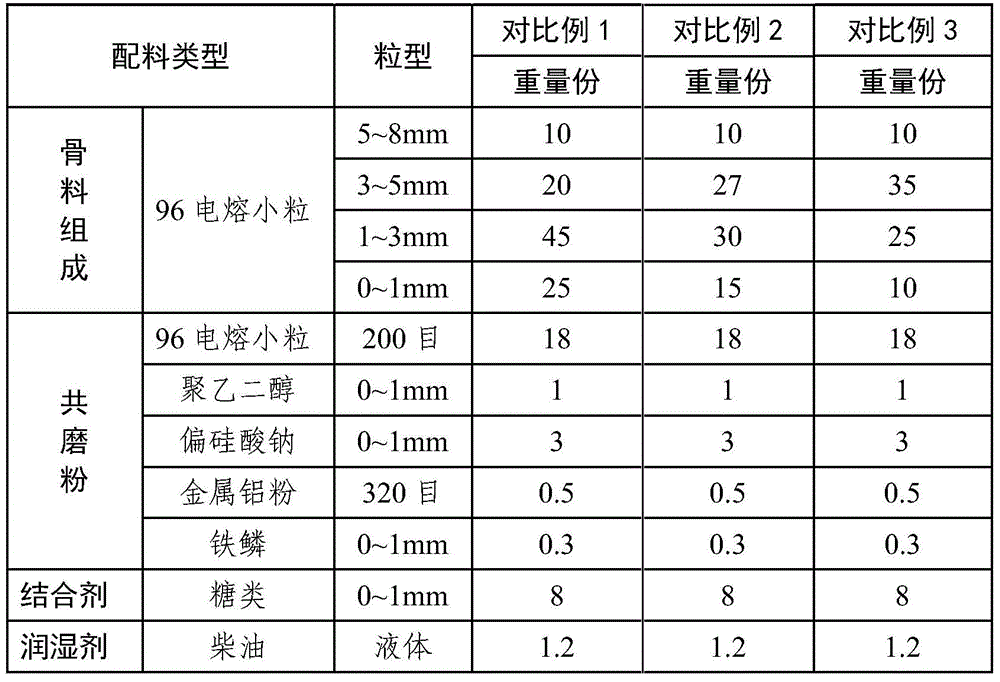

[0034] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0035] In order to avoid repetition, the raw materials used in this specific embodiment are first described in a unified manner as follows, and the specific examples will not be repeated: in the aggregate of the converter repair charge, the waste magnesia-carbon brick particles contained in the mixture of fused magnesia and waste magnesia-carbon brick particles It is waste magnesia-carbon brick particles after converter use or waste magnesia-carbon brick particles after ladle use, and its MgO content is ≥ 80%, wherein the weight ratio of components with a particle size of 5-3mm to components with a particle size of 3-1mm is 10-20 : 5-30.

[0036] In the aggregate, the fused magnesia contained in the mixture of fused magnesia and waste magnesia-carbon brick particles is 96 fused small-grain magnesia, and its MgO content is ≥ 94%. Among ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com