Aluminum silicon carbide castable for hot metal bottles and preparation method thereof

A technology for aluminum silicon carbide and molten iron cans, which is applied in the field of aluminum silicon carbide castables for molten iron cans and the field of preparation thereof, can solve the problems of high manufacturing cost, difficulty in environmental protection treatment of waste silicon carbide saggers, and high processing costs, so as to improve the sintering strength , The effect of good density and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

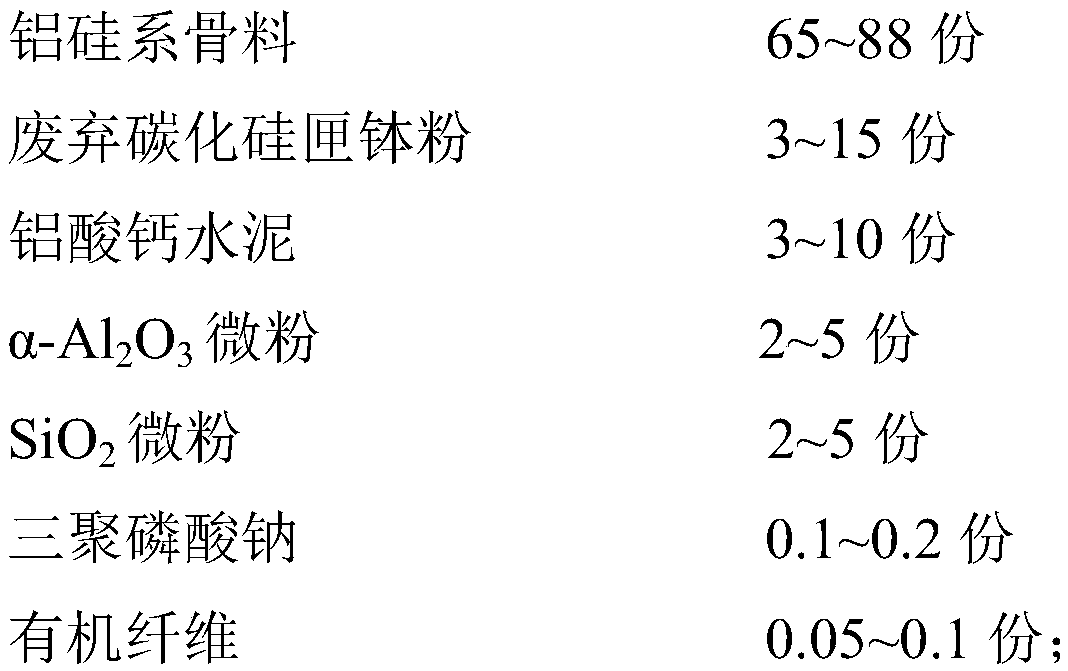

[0032] A kind of aluminum silicon carbide casting material for ladle, it is made of the raw material of following weight part:

[0033]

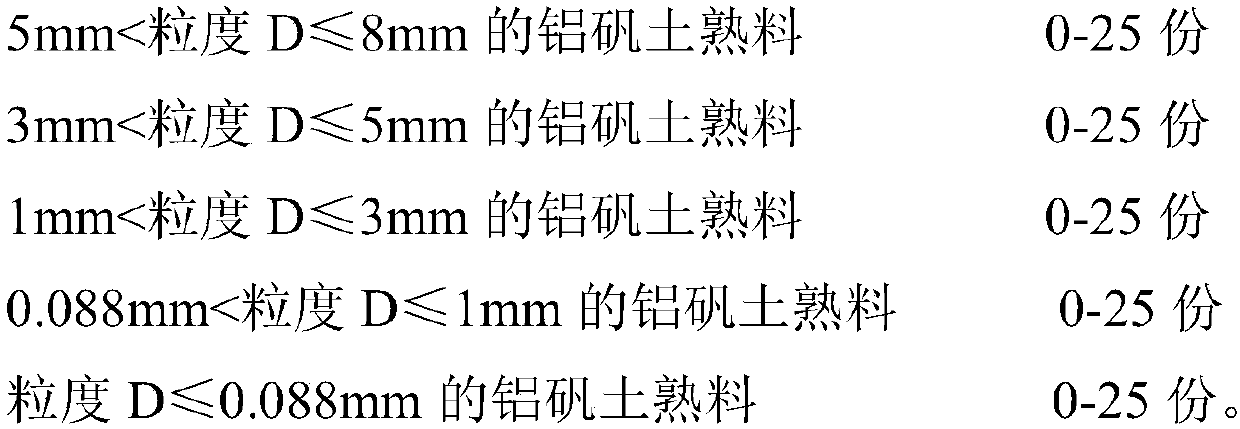

[0034] The aluminum-silicon-based aggregate consists of the following raw materials in parts by weight:

[0035]

[0036]

[0037] The waste silicon carbide sagger powder is obtained by crushing and finely grinding waste silicon carbide sagger powder; the particle size of the waste silicon carbide sagger powder is ≤180 mesh.

[0038] Al in the calcium aluminate cement 2 o 3 The CaO content is ≥69%, and the CaO content is 26-30%.

[0039] The α-Al 2 o 3 Al in micropowder 2 o 3 Content ≥98.5%, Fe 2 o 3 Content ≤ 0.3%; the SiO 2 SiO in fine powder 2 Content ≥ 92%, Fe 2 o 3 Content≤1.8%.

[0040] The organic fibers are polypropylene fibers with a length of 3-5 mm.

[0041] The above-mentioned method for preparing aluminum silicon carbide castables for molten iron tanks comprises the following steps: first, aluminum silicon...

Embodiment 2

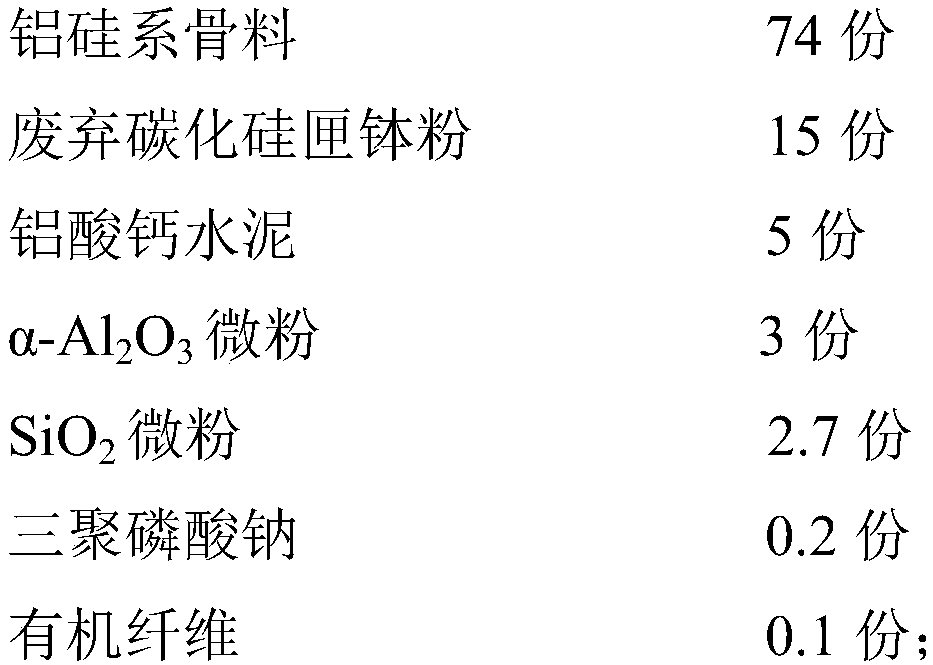

[0043] A kind of aluminum silicon carbide casting material for ladle, it is made of the raw material of following weight part:

[0044]

[0045] The aluminum-silicon aggregate is made of the following raw materials in parts by weight:

[0046]

[0047]

[0048] The waste silicon carbide sagger powder is obtained by crushing and finely grinding waste silicon carbide sagger powder; the particle size of the waste silicon carbide sagger powder is ≤180 mesh.

[0049] Al in the calcium aluminate cement 2 o 3 The CaO content is ≥69%, and the CaO content is 26-30%.

[0050] The α-Al 2 o 3 Al in fine powder 2 o 3 Content ≥98.5%, Fe 2 o 3 Content ≤ 0.3%; the SiO 2 SiO in fine powder 2 Content ≥ 92%, Fe 2 o 3 Content≤1.8%.

[0051] The organic fibers are polypropylene fibers with a length of 3-5mm.

[0052] The above-mentioned method for preparing aluminum silicon carbide castables for molten iron tanks comprises the following steps: first, aluminum silicon-based a...

Embodiment 3

[0054] A kind of aluminum silicon carbide casting material for ladle, it is made of the raw material of following weight part:

[0055]

[0056] The aluminum-silicon-based aggregate is selected from one or more of clay clinker, mullite, and bauxite clinker;

[0057]

[0058] The waste silicon carbide sagger powder is obtained by crushing and finely grinding waste silicon carbide sagger powder; the particle size of the waste silicon carbide sagger powder is ≤180 mesh.

[0059] Al in the calcium aluminate cement 2 o 3 The CaO content is ≥69%, and the CaO content is 26-30%.

[0060] The α-Al 2 o 3 Al in micropowder 2 o 3 Content ≥98.5%, Fe 2 o 3 Content ≤ 0.3%; the SiO 2 SiO in fine powder 2 Content ≥ 92%, Fe 2 o 3 Content≤1.8%.

[0061] The organic fibers are polypropylene fibers with a length of 3-5mm.

[0062] The above-mentioned method for preparing aluminum silicon carbide castables for molten iron tanks comprises the following steps: first, aluminum sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com