Method for low-temperature deironing by using mixed gas of air and sulfur dioxide (SO2)

A technology of sulfur dioxide and mixed gas, which is applied in the field of low-temperature iron removal with air and sulfur dioxide mixed gas for ore leaching liquid. It can solve the problems of less entrained metal ions, the impact of wet production stability, and large steam consumption, and achieve less entrained metal ions. , Low cost of auxiliary materials, significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

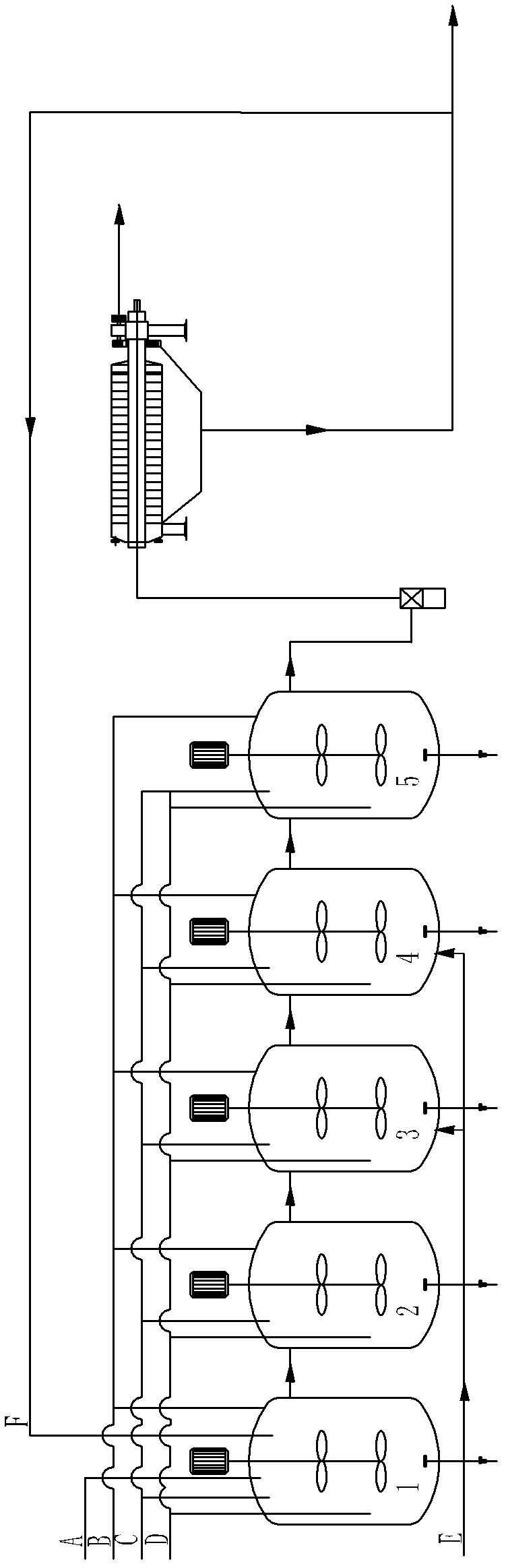

[0017] Such as figure 2 In the diagram of the iron removal equipment shown, above the five tanks, there are calcium carbonate solution C adding pipes, exhaust gas B absorbing pipes and compressed air D entering pipes, and above the carbon dioxide removal tank 1, there is also a pre-iron removal liquid A Feed tube and calcium sulfate F addition tube. Below the oxidation reaction tanks 3 and 4, a discharge valve and an intake valve for the mixed gas E are respectively provided. The five tanks are connected by a draft pipe, and the internal slurry overflows from the carbon dioxide removal tank 1 one by one, and finally flows to the middle tank 5 .

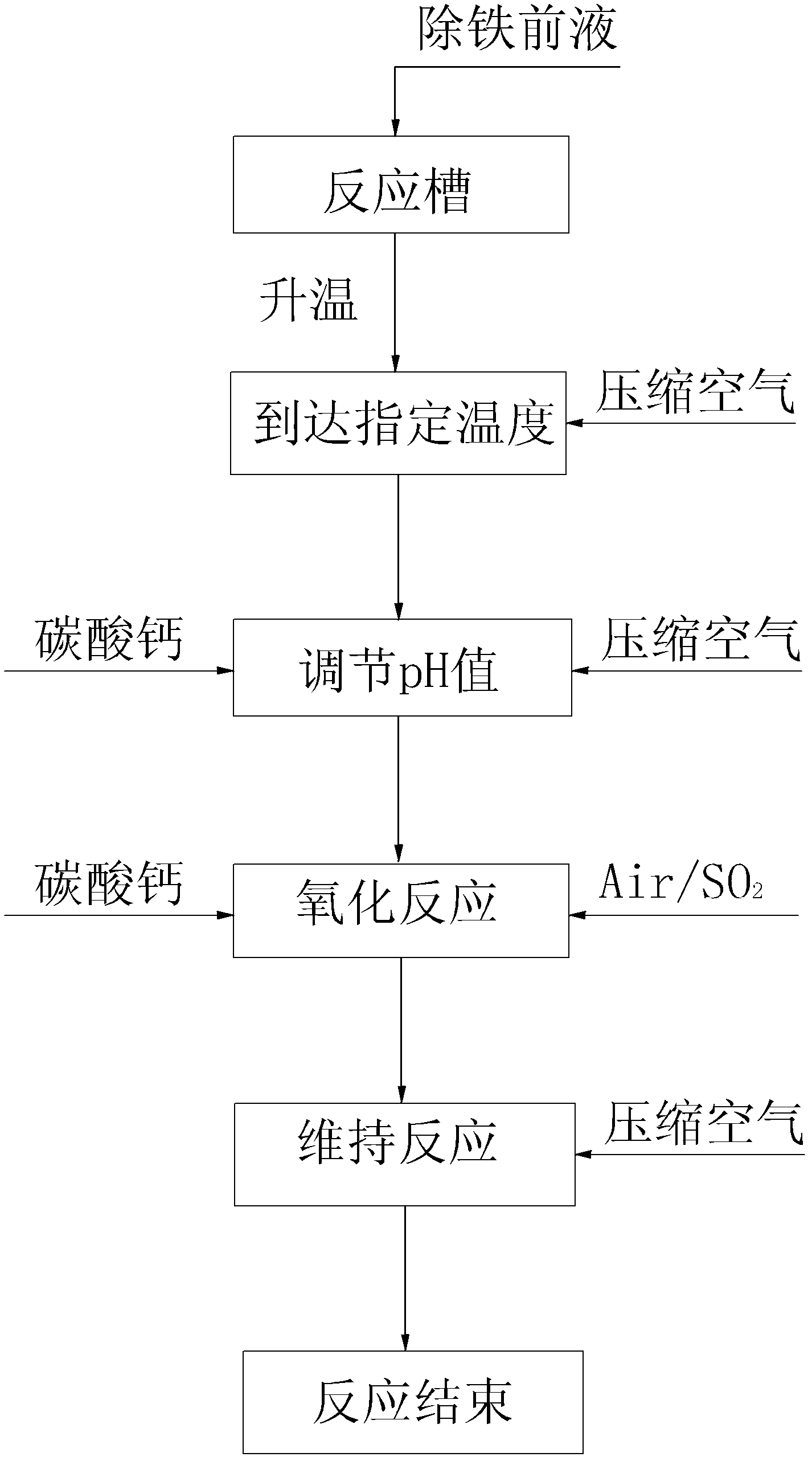

[0018] Such as figure 1 In the iron removal process shown, first put an appropriate amount of pre-iron removal liquid into the carbon dioxide removal tank 1, start stirring, heat up to 35 ° C ~ 80 ° C, and then keep it warm; then add an appropriate amount of calcium carbonate to adjust the pH of the solution between 2.5 ~ 4.5 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com