Replacing method of converter tap hole

A replacement method and tapping technology, applied in the direction of manufacturing converters, etc., can solve the problems of long time, poor replacement effect, and reduced success rate of slag blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] The materials in this example are all commercially available.

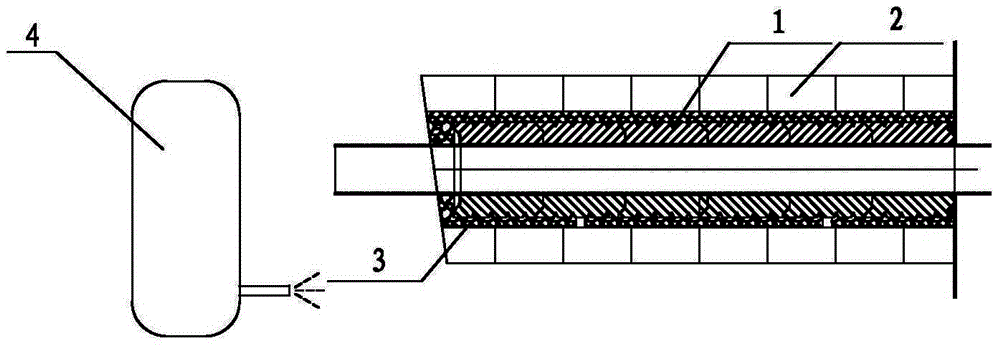

[0012] This embodiment is carried out according to the following steps: Step 1, put the whole set of bricks 1 into the channel 2 of the seat brick, and adjust the angle and position;

[0013] Step 2: Fix the overall set of bricks 1 on the furnace body of the converter by welding steel bars, use the gunning machine 4 to spray the tap hole grouting material 3 to the gap between the seat brick and the overall set of bricks, and use the waste heat in the converter to seal the The tapping hole grouting material can be sintered. Tap hole grouting material contains MgO, Cr 2 o 3 magnesium refractory castables.

[0014] The magnesia refractory castable used in this example mainly consists of MgO, Cr 2 o 3 Wait. The sintering strength is higher than that of Martin sand and furnace sand, and the fluidity of the grouting material is better. It can fill and fill the gaps around it. The waste heat in the converter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com