Method for preparing high-reliability optical fiber coupler

A fiber optic coupler, a reliable technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of high cost of packaging materials and complicated packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

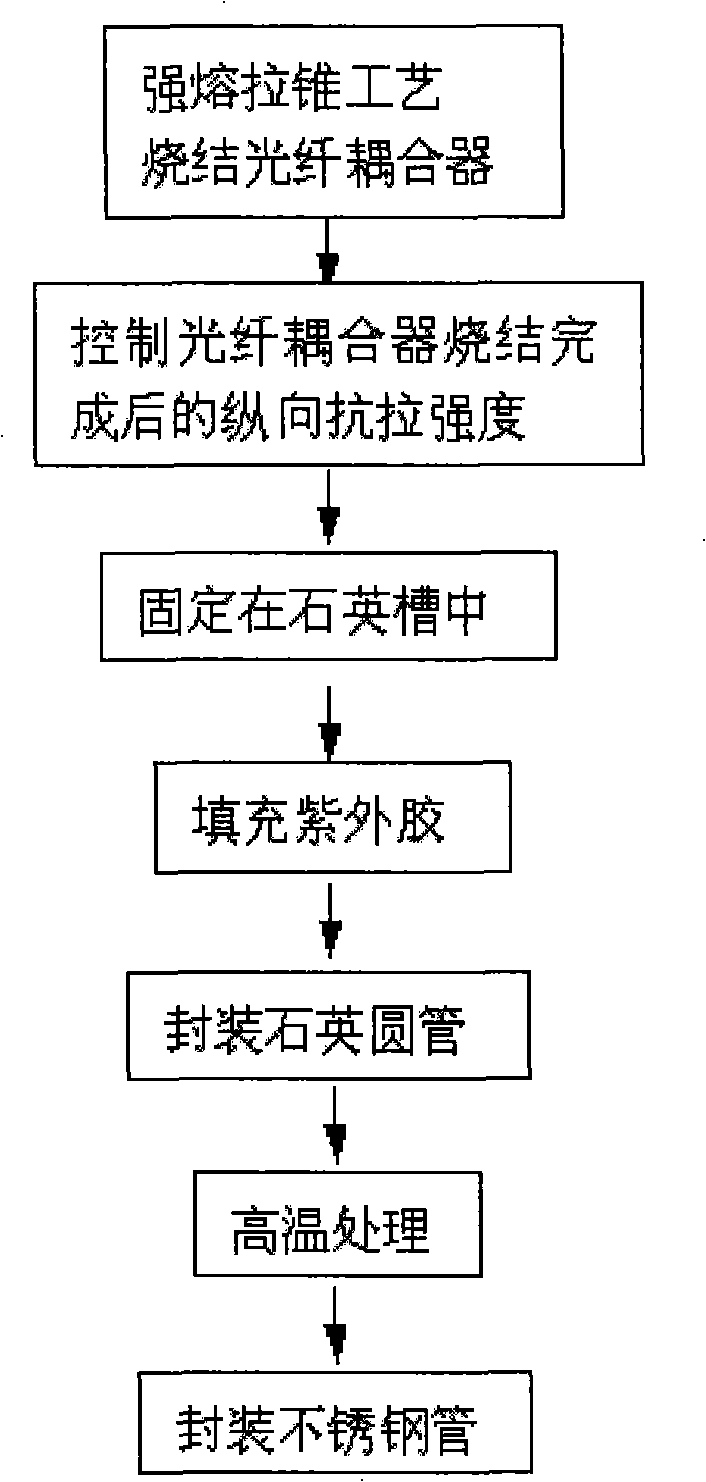

[0063] Such as image 3 Shown, be the method flow chart of the present invention, the preparation method of the present invention is introduced in detail below, and the realization process is:

[0064] (1) The optical fiber coupler is prepared by the parallel sintering strong fusion tapered process, and the longitudinal tensile strength of the optical fiber coupler after sintering is detected by tensile force, so that the longitudinal tensile strength is greater than 1N.

[0065] The optical fiber coating stripping of the optical fiber coupler needs to be treated by thermal stripping. The commonly used method of mechanically stripping the optical fiber coating is likely to cause surface defects in the optical fiber cladding, which reduces the strength and reliability of the optical fiber. The heating source of the fusion draw cone sintering process is a hydrogen-oxygen flame. There are two heating methods. One is to directly use hydrogen and oxygen in the air. The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com