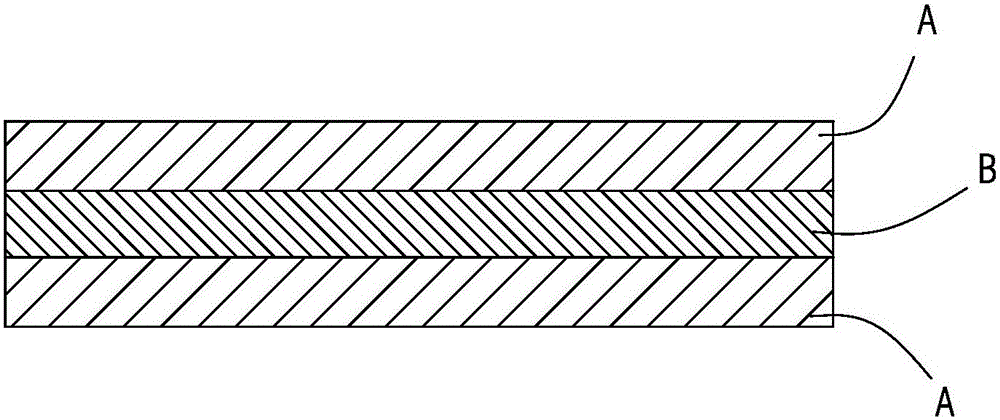

Solar battery backplane, and preparation method of film polyester used for backplane

A solar cell and polyester technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of heat and humidity resistance, low flame retardancy, polyester solar cell back film flame retardancy, poor heat and humidity resistance, and poor weather resistance, etc. problems, to achieve good weather resistance and heat and humidity resistance, excellent long-lasting flame retardant performance, simple and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] As mentioned above, in order to overcome the defects of the prior art, the present invention provides a method for preparing a polyester film for solar battery backsheets, comprising the following steps:

[0028] A, flame retardant and dispersant are uniformly dispersed in glycol to prepare flame retardant suspension;

[0029] B, mixing the fluorine-containing dibasic acid, dibasic alcohol, catalyst and the flame retardant suspension described in step A, and then carrying out the esterification reaction by direct esterification;

[0030] C. After the esterification reaction is finished, add a stabilizer to carry out polycondensation reaction.

[0031] The polyester used for the film of the solar cell backboard of the present invention uses fluorine-containing dibasic acid and dibasic alcohol as the main materials, adopts the direct esterification method to produce the polyester, and adds a suitable flame retardant during the esterification reaction Suspending agent, ca...

Embodiment 1

[0038] Add 1500ml of glass beads, 750g of magnesium hydroxide and antimony trioxide composite powder, 3000g of ethylene glycol, and 1.13g of sodium polyphosphate into a sand mill, and grind for 1 hour to prepare a flame retardant suspension, in which magnesium hydroxide The average particle size of the composite powder with antimony trioxide is 100nm. That is, the flame retardant in the above steps needs to be ground by high-speed dispersion or sand mill glass beads to make it uniformly dispersed in ethylene glycol, and then ground and dispersed into magnesium hydroxide and dioxygen trioxide with a mass concentration of 20-60%. Antimony composite powder-ethylene glycol flame retardant suspension, preferably the mass concentration of the composite powder is 30-50%.

[0039] Add 5.0kg of terephthalic acid, 0.8kg of ethylene glycol, 2.0 titanium dioxide, and 3600g of the above flame retardant suspension into a 20L general-purpose polymerization reactor, and carry out esterificati...

Embodiment 2

[0042] Add 1600ml glass beads, 1500g magnesium hydroxide and antimony trioxide composite powder, 1500g ethylene glycol, 2.50g sodium polyphosphate into a sand mill, and grind for 1.5 hours to prepare a flame retardant suspension, in which magnesium hydroxide and antimony trioxide composite powder with an average particle size of 150nm.

[0043] Add 5.0kg of terephthalic acid, 2.2kg of ethylene glycol, 1.10g of germanium dioxide, and 2020g of the above-mentioned flame retardant suspension into a 20L general-purpose polymerization reactor. Carry out the esterification reaction. When the water output reaches 1200ml, release the pressure to normal pressure, add 1.025g of triphenyl phosphate, stir for 10 minutes at normal pressure, raise the temperature and lower the pressure to 280°C and below 100Pa, and react for 1 to 3 hours. Obtain the desired polyester for film.

[0044] After the reaction is completed, it can be extruded through a melt pump, pelletized, and dried to obtain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com