High-strength biodegradable thermoplastic starch resin, and preparation method and use thereof

A thermoplastic starch, biodegradable technology, applied in the field of degradable resin, can solve the problems of poor transparency, poor mechanical properties of starch-degraded resin products, and can not be obtained, and achieves the effects of good transparency, good strength, and reduced biomass content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Described high-strength biodegradable thermoplastic starch resin, component is as follows by weight:

[0066] Food grade cornstarch 20Kg

[0067] Sorbitol 10

[0068] Diethylene glycol 5

[0069] Stearic acid 0.2

[0071] monoglyceride 1

[0072] Ethylene acrylic acid copolymer (EAA) 8

[0073] Ethylene-vinyl acetate copolymer (EVA) 4

[0074] Linear Low Density Polyethylene (LLDPE) 30

[0075] Very Low Density Low Polyethylene (VLLDPE) 15

[0076] High Density Polyethylene (HDPE) 12

[0077] Among them, the fineness of food-grade starch is 100 mesh, the water content is 12-14%wt; the monoglyceride density: 0.916g / cm3; the ester content> 30%; the melt index of the EAA is 6-15g / 10min, and : 0.93g / cm 3 , the melt index of the EVA is 2g / 10min, density: 0.94g / cm 3 , Food-grade starch is any one of corn starch, wheat starch, tapioca starch, sweet potato starch, and potato starch. The number average molecular weight of the HDPE is 300...

Embodiment 2-6

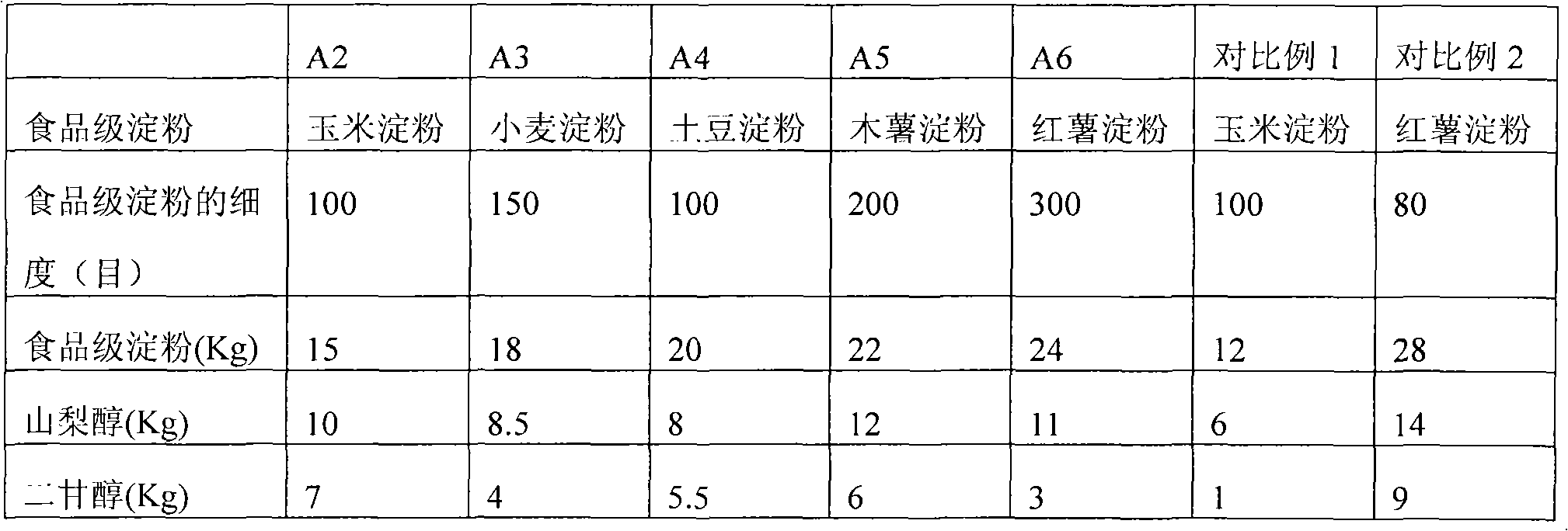

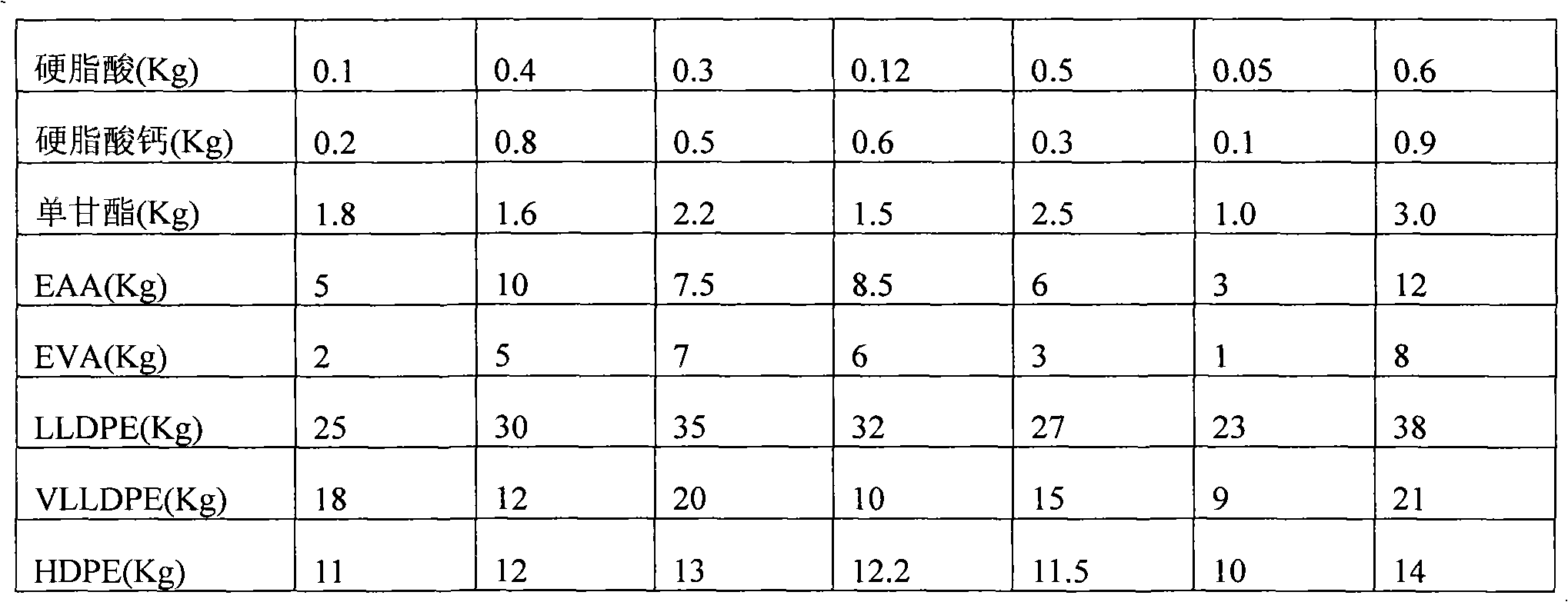

[0089] According to the formula in Table 2, the high-strength biodegradable thermoplastic starch resins of the present invention were prepared using the same method as in Example 1, which were respectively marked as A2-A6. The detection performance of the produced resin is shown in Table 3.

[0090] Table 2 The present invention and the formula of comparative example

[0091]

[0092]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com