Full biodegradable mulch material for crops in irrigated area and preparation method and application of full biodegradable mulch material

A technology for degrading mulch and crops, which is applied in the field of fully biodegradable mulch materials for crops in irrigation areas and its preparation, can solve problems such as incomplete degradation, affecting crop growth, and unclear secondary pollution, and achieves improvement in rigidity balance, The effect of low cost and good development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

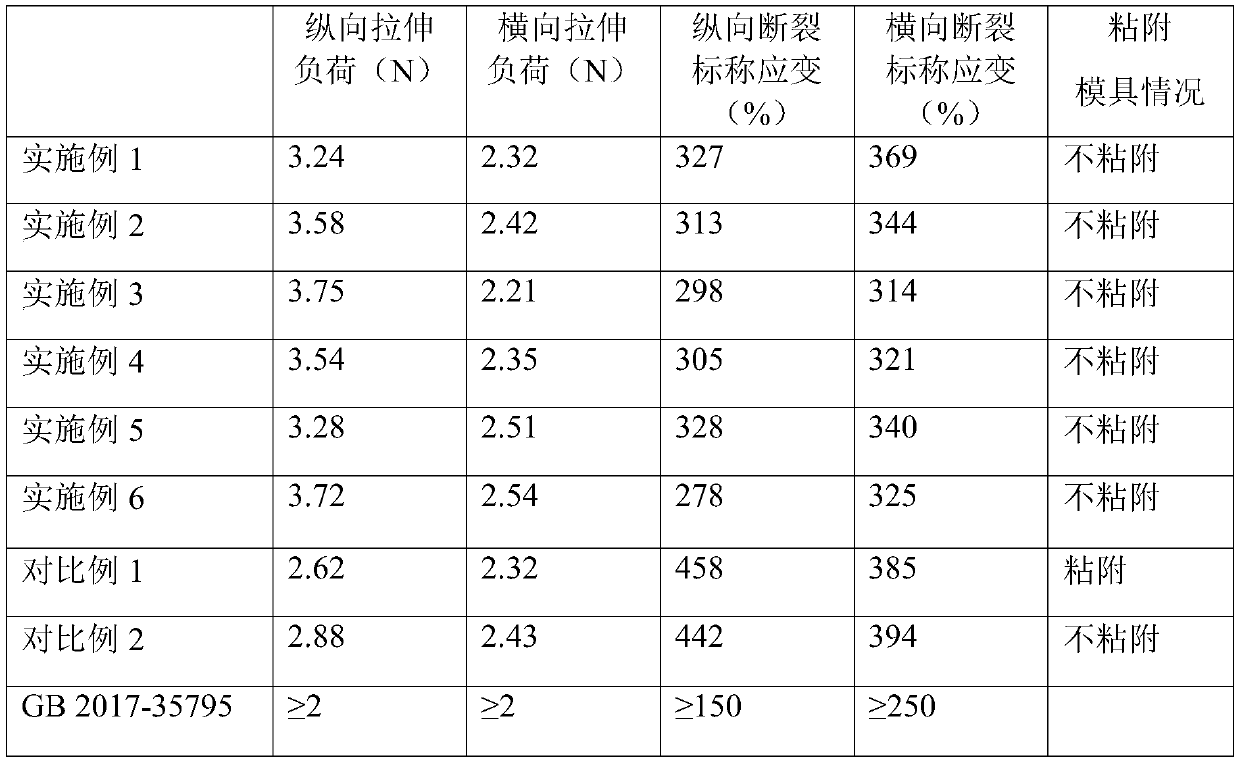

Examples

Embodiment 1

[0021] A fully biodegradable mulch material for irrigation area crops and a preparation method thereof, specifically comprising:

[0022] PBAT, molecular weight 80,000, 100 parts.

[0023] PEF, molecular weight 0.5 million, 5 parts.

[0024] 2-Methyl-2-oxazoline, 0.3 parts.

[0025] Zinc adipate, 0.5 parts.

[0026] Calcium Carbonate, 5 parts, Talc, 5 parts.

[0027] Antioxidant 168, 0.1 part, antioxidant 1010, 0.1 part.

[0028] UV-531, 0.5, UV-234, 0.5 parts.

[0029] Put PBAT and PEF in a desiccator at 60°C respectively, and dry for 6 hours, then add 2-methyl-2-oxazoline, zinc adipate, calcium carbonate, talcum powder, antioxidant 168, antioxidant 1010 , UV-531, UV-234, etc. are weighed according to the proportion, and added to the high mixer together with PBAT and PEF for mixing at a speed of 1000 rpm, and mixed for 2 minutes. Then the mixed material is put into a screw extruder for extrusion granulation, the melt temperature is set at 190° C., and the fully biodegra...

Embodiment 2

[0031] A fully biodegradable mulch material for irrigation area crops and a preparation method thereof, specifically comprising:

[0032] PBAT, molecular weight 80,000, 100 parts. .

[0033] PEF, molecular weight 0.5 million, 10 parts.

[0034] 2-Methyl-2-oxazoline, 0.3 parts.

[0035] Zinc adipate, 0.5 parts.

[0036] Calcium Carbonate, 5 parts, Talc, 5 parts.

[0037] Antioxidant 168, 0.1 part, antioxidant 1010, 0.1 part.

[0038] UV-531, 0.5, UV-234, 0.5 parts.

[0039] Put PBAT and PEF in a desiccator at 60°C respectively, and dry for 6 hours, then add 2-methyl-2-oxazoline, zinc adipate, calcium carbonate, talcum powder, antioxidant 168, antioxidant 1010 , UV-531, UV-234, etc. are weighed according to the proportion, and added to the high mixer together with PBAT and PEF for mixing at a speed of 1000 rpm, and mixed for 2 minutes. Then the mixed materials are put into a screw extruder for extrusion granulation, the melt temperature is set at 190° C., and the horse bi...

Embodiment 3

[0041] A fully biodegradable mulch material for irrigation area crops and a preparation method thereof, specifically comprising:

[0042] PBAT, molecular weight 80,000, 100 parts. .

[0043] PEF, molecular weight 0.5 million, 15 parts.

[0044]2-Methyl-2-oxazoline, 0.3 parts.

[0045] Zinc adipate, 0.5 parts.

[0046] Calcium Carbonate, 5 parts, Talc, 5 parts.

[0047] Antioxidant 168, 0.1 part, antioxidant 1010, 0.1 part.

[0048] UV-531, 0.5, UV-234, 0.5 parts.

[0049] Put PBAT and PEF in a desiccator at 60°C respectively, and dry for 6 hours, then add 2-methyl-2-oxazoline, zinc adipate, calcium carbonate, talcum powder, antioxidant 168, antioxidant 1010 , UV-531, UV-234, etc. are weighed according to the proportion, and added to the high mixer together with PBAT and PEF for mixing at a speed of 1000 rpm, and mixed for 2 minutes. Then the mixed material is put into a screw extruder for extrusion granulation, the melt temperature is set at 190° C., and the fully biode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com