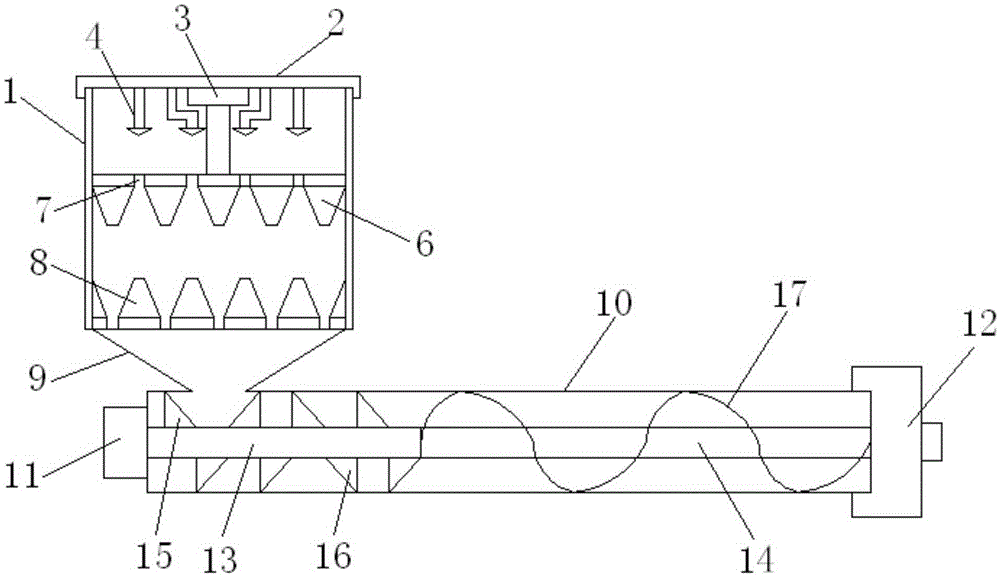

Blast-furnace anhydrous stemming and production device thereof

An anhydrous taphole mud and blast furnace technology, applied in the field of refractory materials, can solve the problems of poor slag erosion resistance, insufficient tapping time, and high smelting strength, so as to increase slag erosion resistance and improve slag iron erosion resistance , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention provides an anhydrous blast furnace clay, which is characterized in that it is prepared from the following raw materials according to their weight percentages:

[0031] 4-8% of super homogenized bauxite particles with a particle size of 1-3mm;

[0032] 17-20% brown corundum particles with a particle size of ≤1mm;

[0033] 180 mesh white corundum powder 3-7%;

[0034] 320 mesh tabular corundum powder 4-8%;

[0035] 320 mesh chrome sand powder 2-6%;

[0036] 9-18% of carbon materials with a particle size of 1-3mm;

[0037] 200 mesh high-purity silicon carbide 4-10%;

[0038] 5-7% of silicon carbide particles with a particle size of ≤1mm;

[0039] 260 mesh superfine powder 10-13%;

[0040] 200 mesh soft clay 8-12%;

[0041] 200 mesh sericite 2-5%;

[0042] 180 mesh metal silicon powder 2-4%

[0043] Compound oil 10-12%.

[0044] Al in the above-mentioned super homogenized bauxite 2 o 3 85-88%, Fe 2 o 3 1.5-2%, SiO 2 5-7%, the balance is impurit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com