Anti-static PE bag processing compound machine

An anti-static, compound machine technology, applied in the field of packaging bag processing, can solve problems such as difficulty in controlling the amount of adhesive applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail through specific implementation methods:

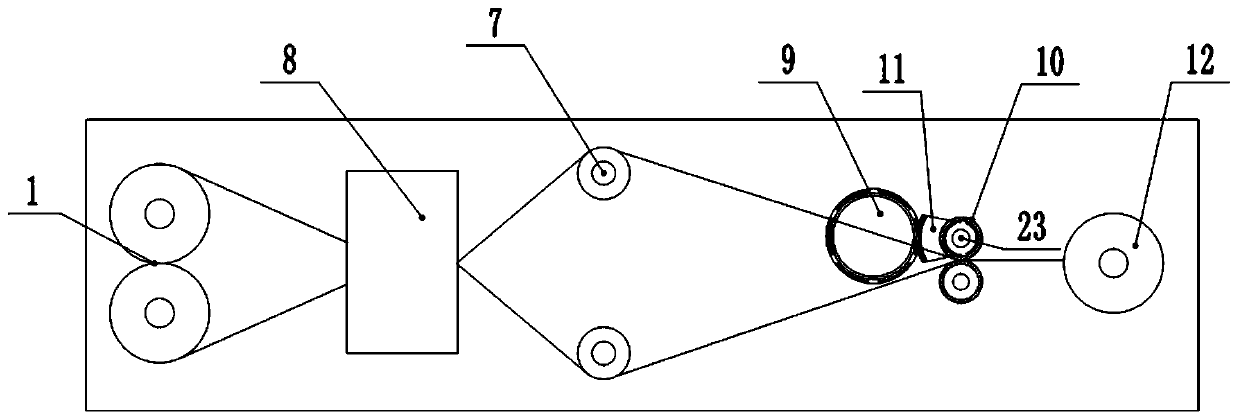

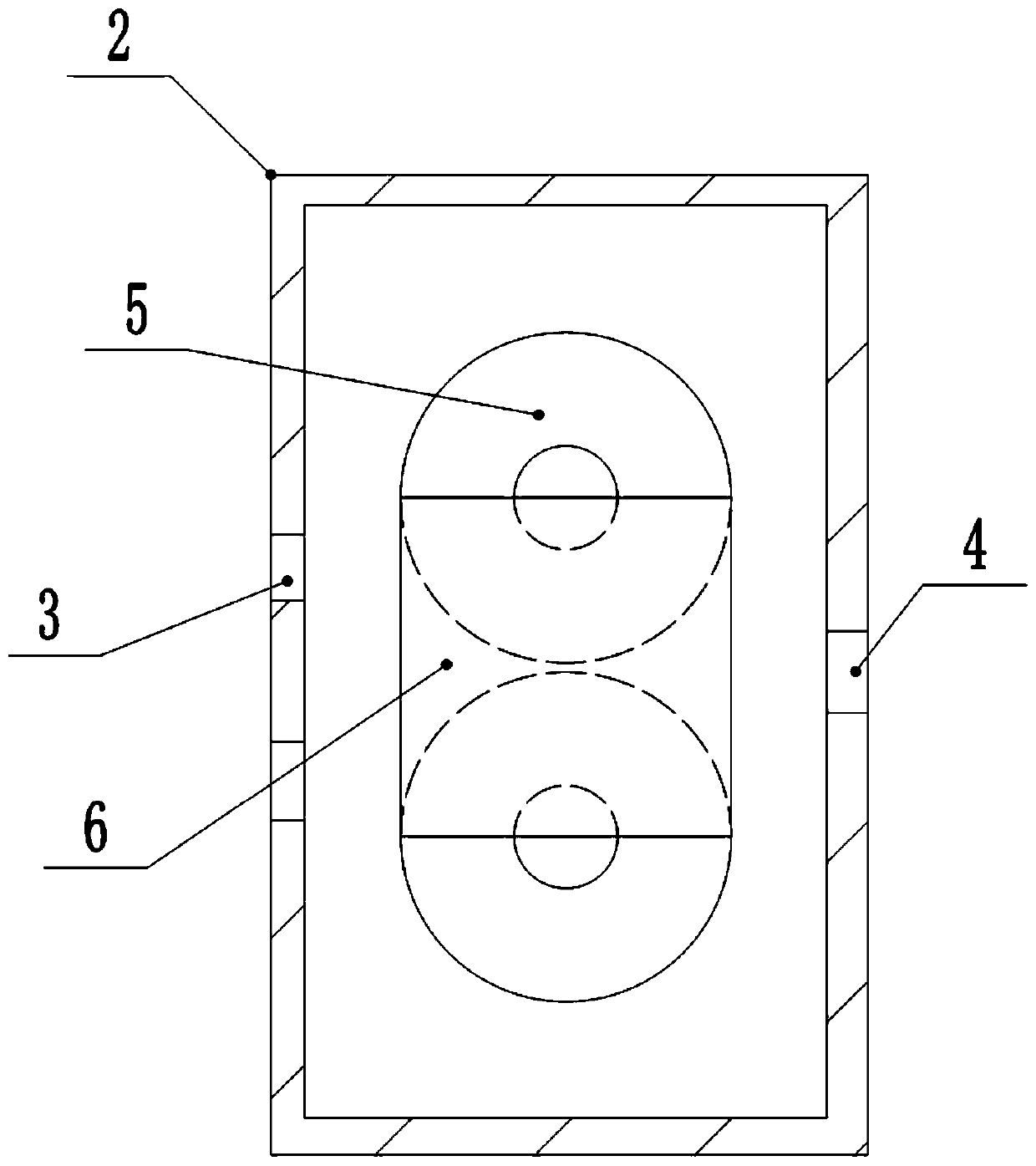

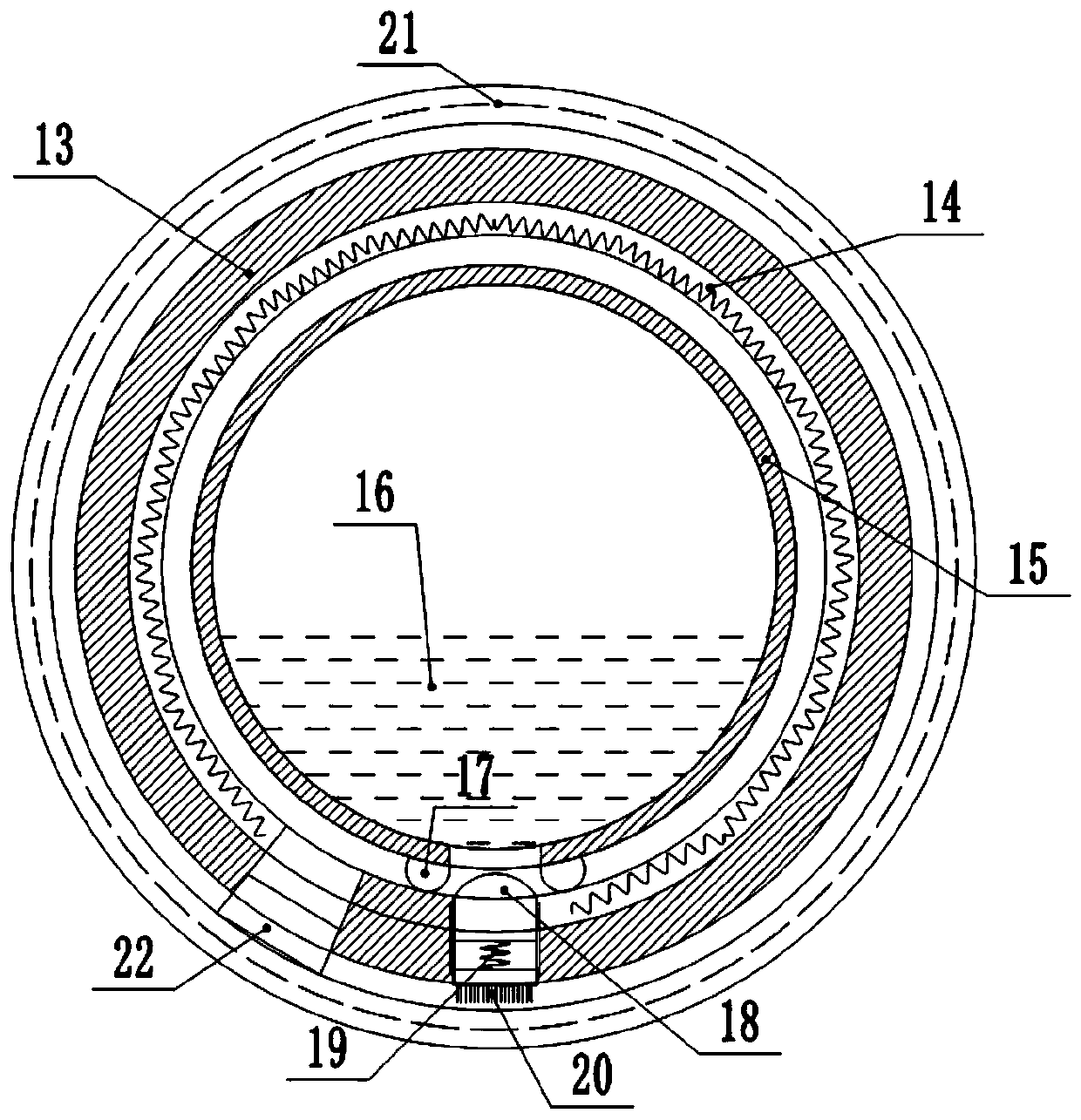

[0028] The reference signs in the accompanying drawings of the specification include: discharge unit 1, box body 2, feed port 3, discharge port 4, pressing roller 5, beating block 6, guide roller 7, alignment mechanism 8, gluing mechanism 9 , composite roller 10, fan gear 11, receiving unit 12, outer cylinder 13, heating wire 14, inner cylinder 15, adhesive 16, first protrusion 17, second protrusion 18, spring 19, brush 20, gear 21, rubber plug 22, ion wind rod 23.

[0029] like figure 1 The anti-static PE bag processing compound machine shown includes a frame on which, from left to right, there are a discharging unit 1, an alignment mechanism 8, a guiding unit, a gluing mechanism 9, a static elimination mechanism, and a receiving unit 12 . The discharge unit 1 includes two discharge rollers and a first motor for driving the discharge rollers to rotate. The two discharge rollers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com