Bottle shipping system

a shipping system and glass bottle technology, applied in the packaging industry, sustainable packaging industry, packaging types, etc., can solve the problems of reducing or eliminating the cushioning purpose of glass bottles, reducing or eliminating the use of glass bottles, and prone to shattering. , to achieve the effect of ensuring the ease of use and re-us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

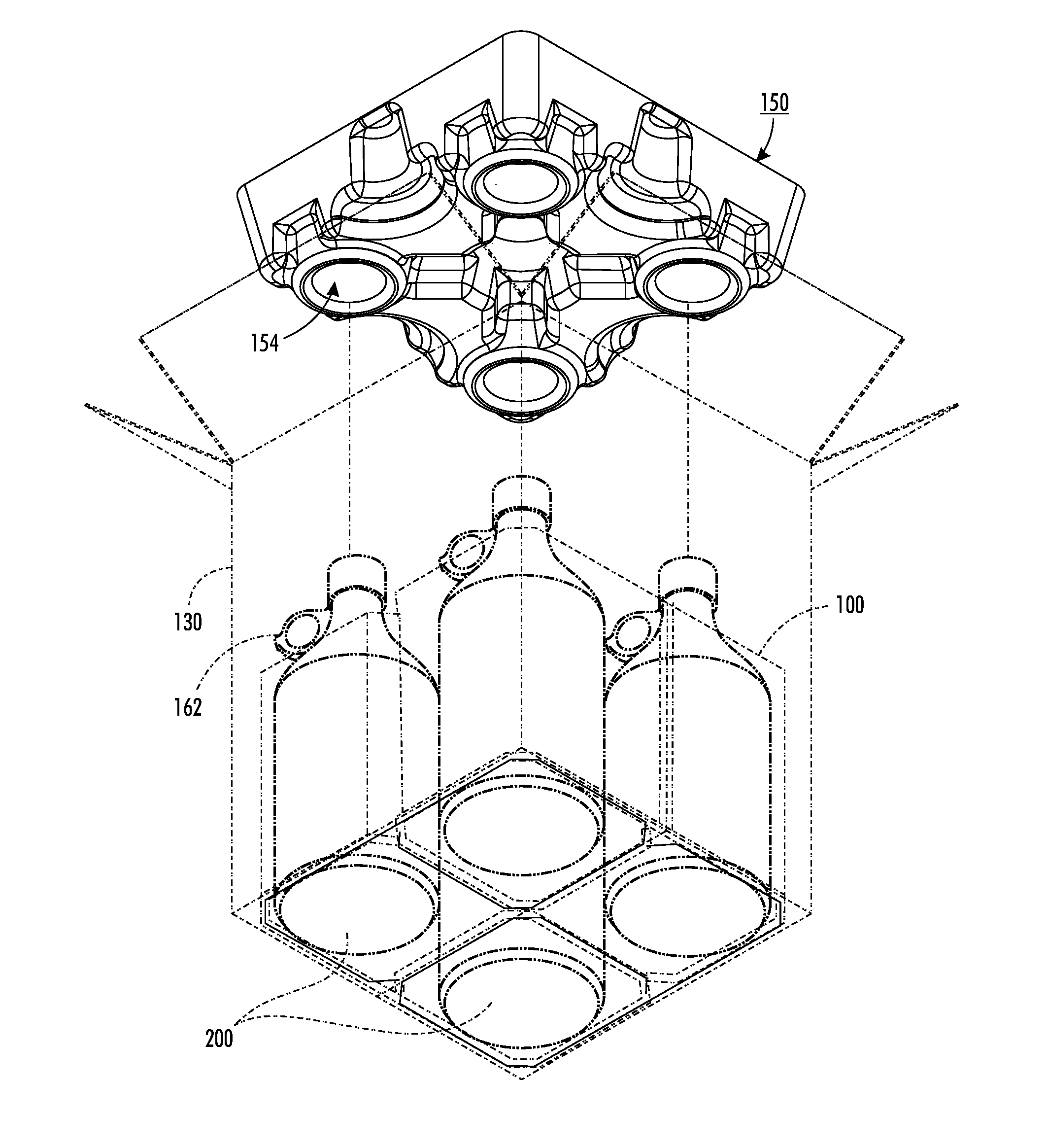

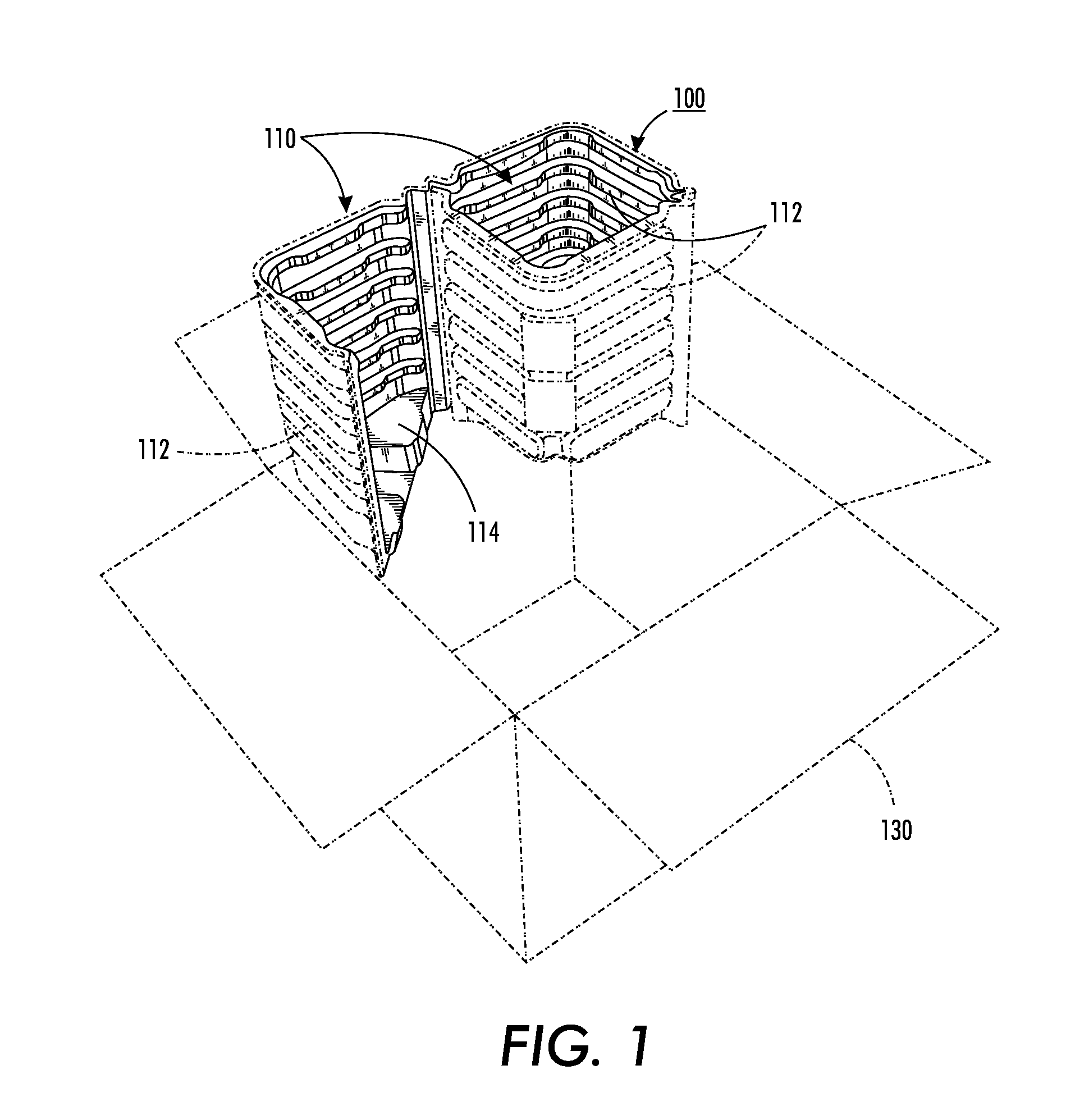

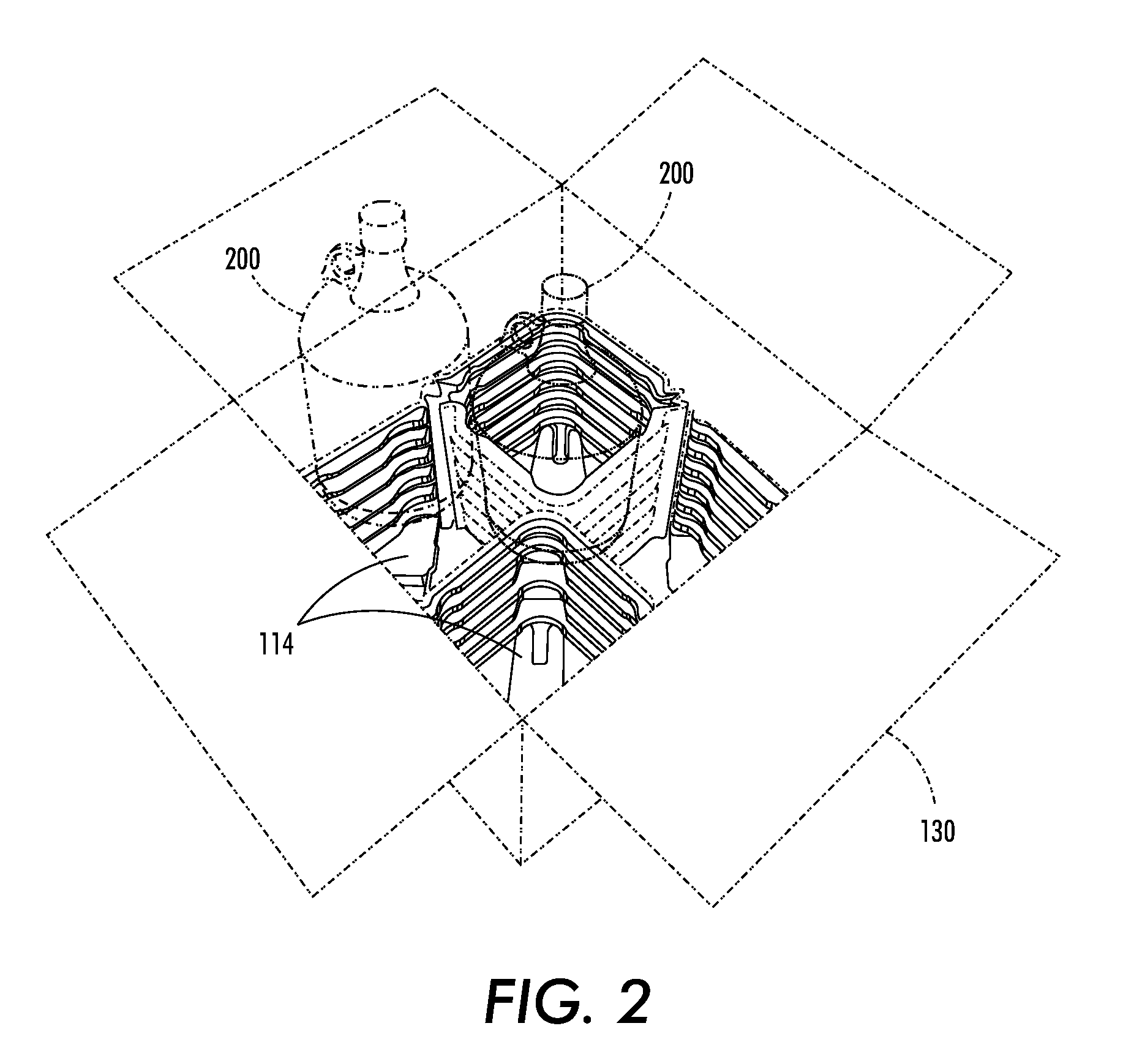

As more particularly set forth below, the disclosed system and methods are for assembling an improved bottle shipping container, specifically a container wherein a folding insert(s) or separator(s) is employed, in conjunction with a top cap insert to stabilize the bottle(s) and to provide padding during shipment and handling. As used herein the term bottle is intended to cover both a conventional glass bottle having a base, sides, shoulder, neck and re-sealable top, as well as other types of containers used for the storage and shipment of liquids and the like. The various embodiments described herein disclose several configurations for the shipping containers, and it is further contemplated that the shipping systems may also be used to ship containers other than traditional bottles. Accordingly, the use of the term bottles is not intended to limit the disclosure or claims to conventional bottles or bottle designs. The improved insert designs and associated packaging system permits s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| fragile | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com