Shipping and display system

a display system and product technology, applied in the field of product shipping display system, can solve the problems of product waste, over-all cost of merchandising such products, and increase the cost of using such units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

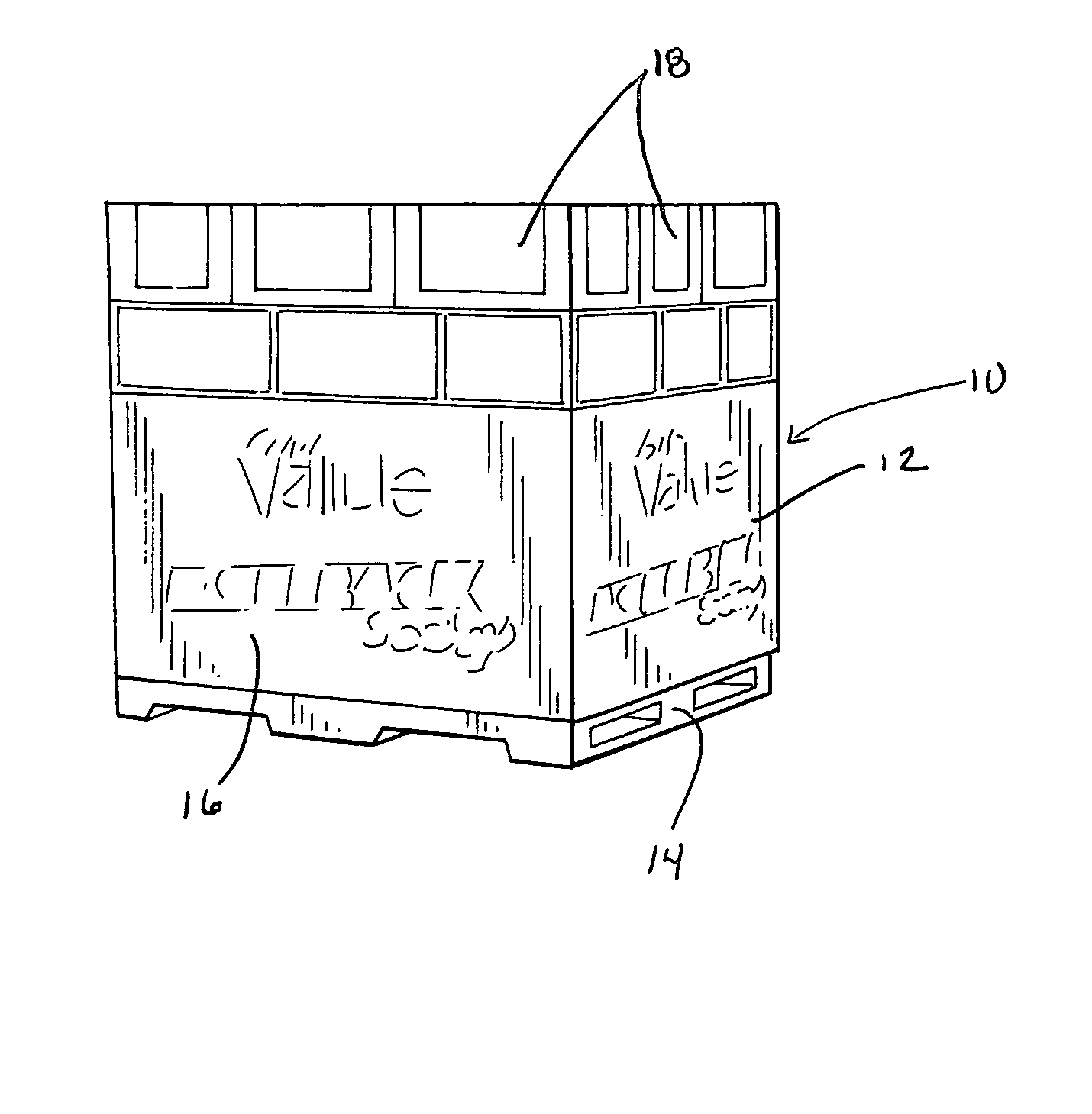

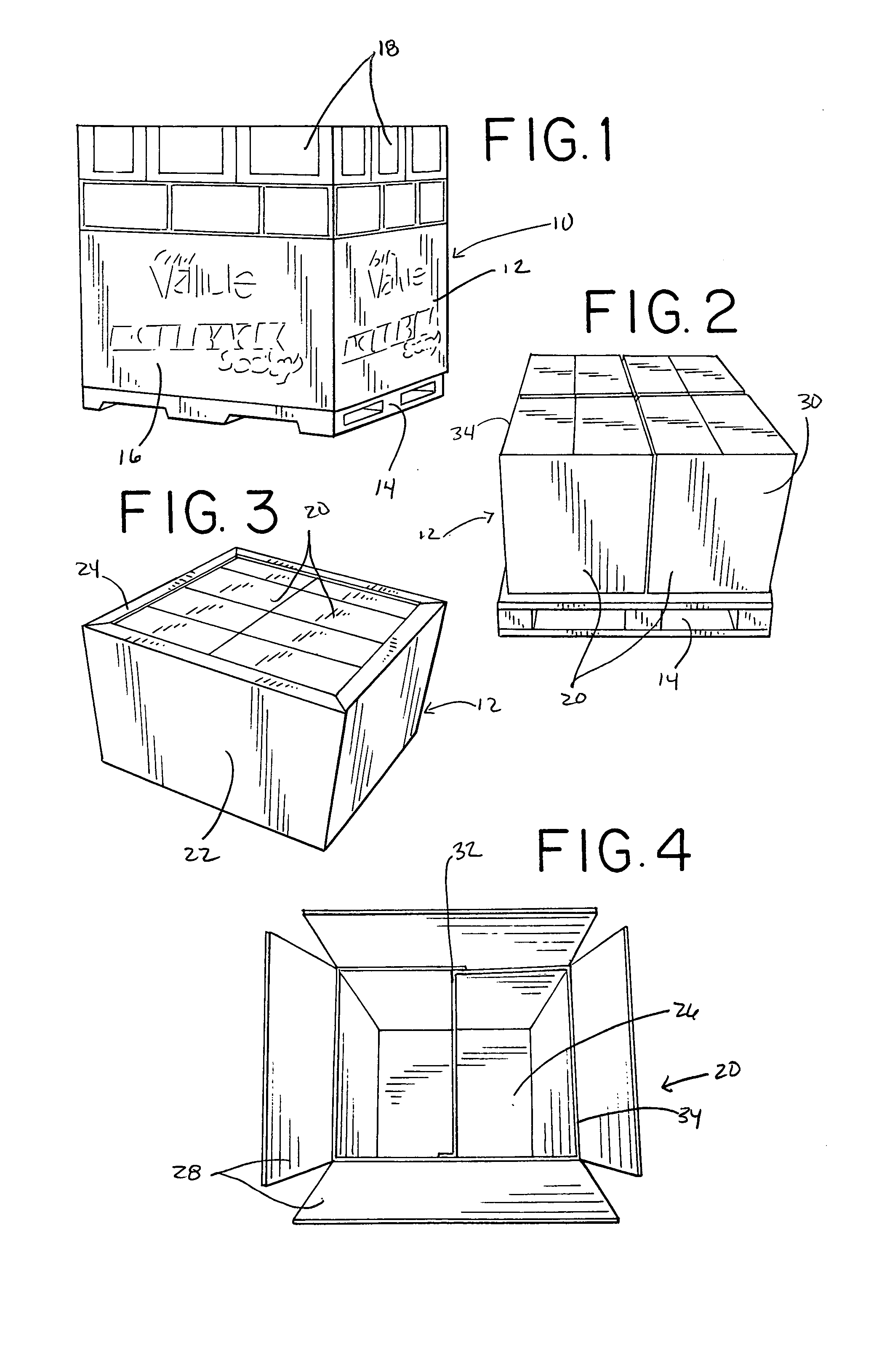

A support unit having an internal brace element, as shown in FIG. 4, comprising single wall, c-fluted, 44 ECT fiber board was tested for compression strength by the Compression Test Procedure by ASTM Standard D 642. The support unit had dimensions of 23-{fraction (1 / 16)}″ L×19-⅛″ W×23-⅞″ H. The internal brace element had four side walls co-extensive with the internal perimeter of the unit and a central divider separating the interior of the unit into two equal compartments. The side walls of the internal brace element had dimensions of 22-⅜″ L×18-½″ W×23-¼″ H. The divider was 18-{fraction (5 / 16)}″ in length. The support unit was placed between upper and lower platens of the test machine. The lower platen was raised to bring both platens in contact with the specimen and an initial pressure or pre-load 50 lbs / ft was applied. Pressure was increased in a continuous manner until failure of the unit (collapse) occurred. The maximum load was recorded at 2010 lbs.

example 3

A base comprising four support units as described in Example 2 above, and as shown in FIG. 3, was tested for compression strength by the Compression Test Procedure by ASTM Standard D 642 as described above. The base included a securing wrap secured to the outer perimeter of the base. The base had dimensions of 46-⅜″ L×38-{fraction (9 / 16)}″ W×23-¾″ H. The maximum load was recorded at 6000 lbs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com