Bag-breaking and liquid-taking machine for bagged product

A technology for breaking packages and products, which is applied in packaging, transportation and packaging, and unsealing by removing items, etc. It can solve the problems of slow extrusion efficiency, liquid splashing and overflowing, messy and messy, etc., to achieve reasonable structural design and improve recycling Efficiency, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

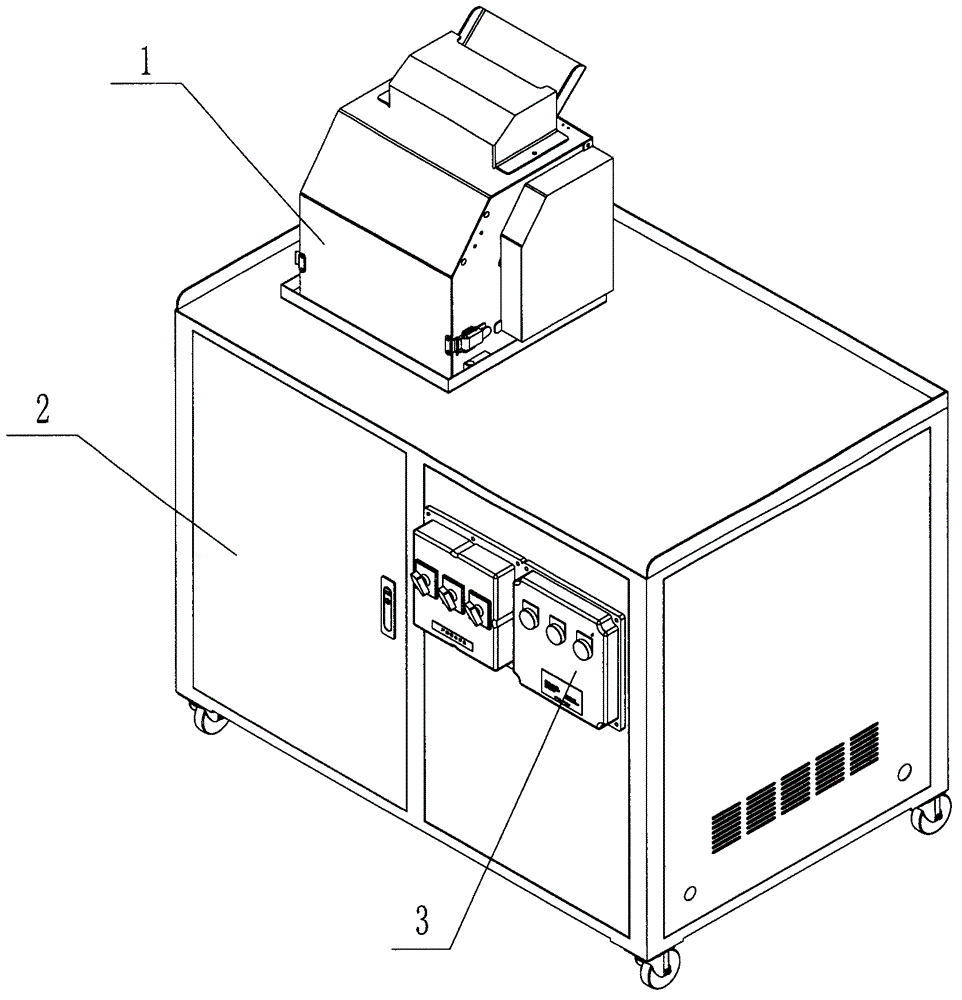

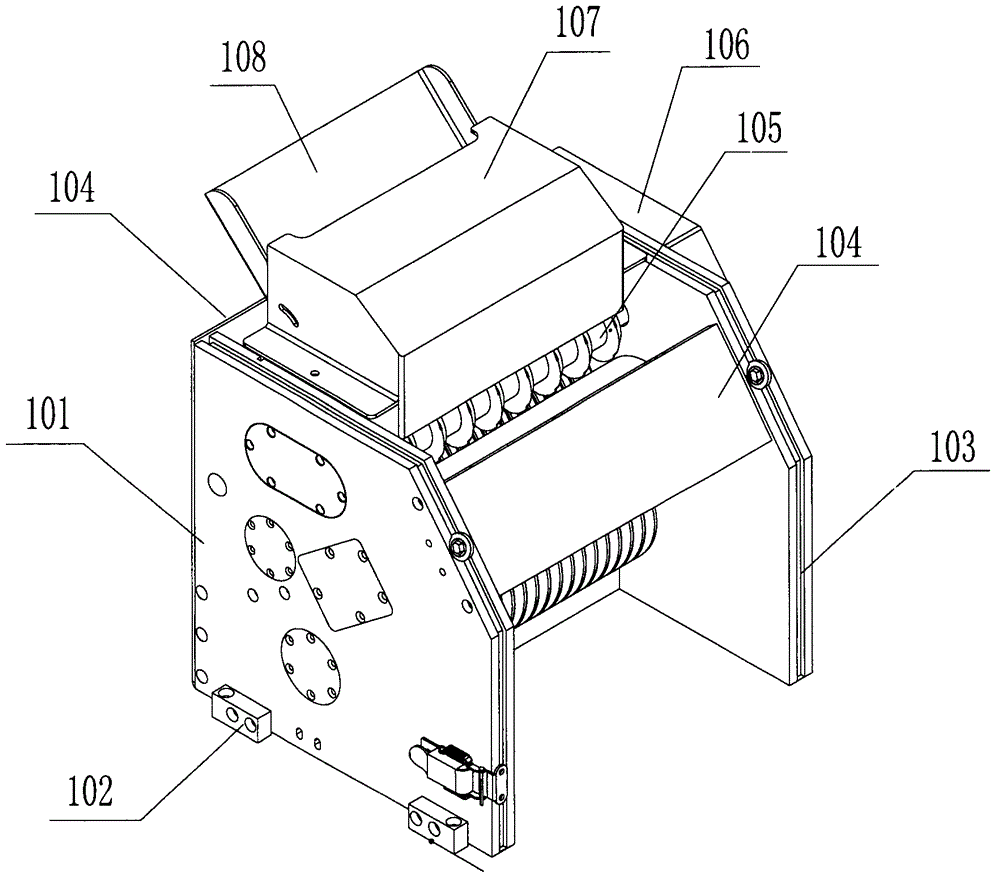

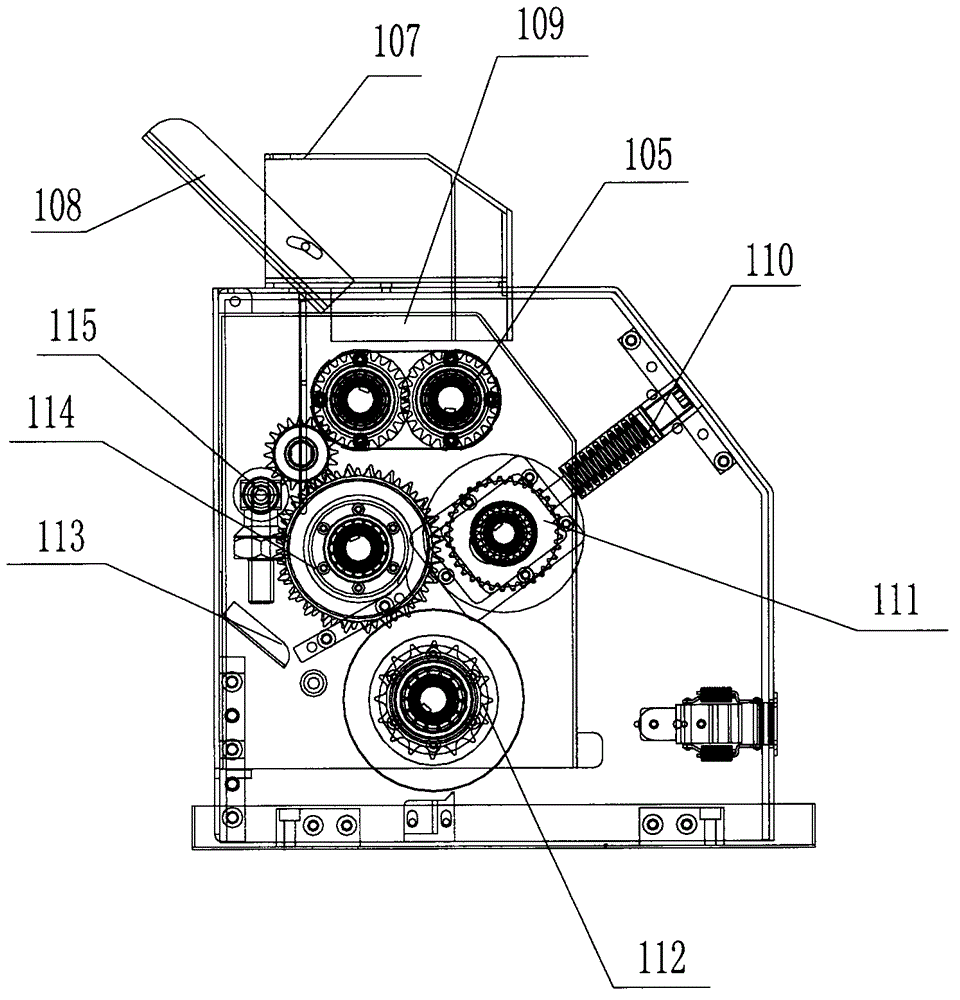

[0018] Such as figure 1 , figure 2 with image 3 Shown is a bagged product breaking bag liquid extraction machine, including a control cabinet 2 and a liquid separation device 1 installed above the control cabinet 2. The liquid separation device 1 includes a left wall panel 101 and a right wall panel 103. A wallboard fixing plate 104 is provided between the wallboard 101 and the right wallboard 103, a cutter group 105 is arranged on the upper part between the left wallboard 101 and the right wallboard 103, and above the cutter group 105 A feeding port 109 is provided, a squeeze roller 111 and a discharge roller 114 are arranged below the cutter group 105, and a squeeze roller 111 and a discharge roller 114 are arranged below the squeeze roller 111 and the discharge roller 114. Press the driving roller 112, and a liquid collection bucket 113 is provided below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com