Patents

Literature

46 results about "Bulk box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bulk box, also known as a bulk bin, skid box, pallet box, bin box, or octabin is a pallet-size box used for storage and shipping of bulk quantities. In the U.S. and Canada, the term gaylord is sometimes used for triplewall corrugated pallet boxes; this is due to the first bulk bins being manufactured by the original Gaylord Container Company of St. Louis, which was acquired by Crown Zellerbach of San Francisco in 1955.

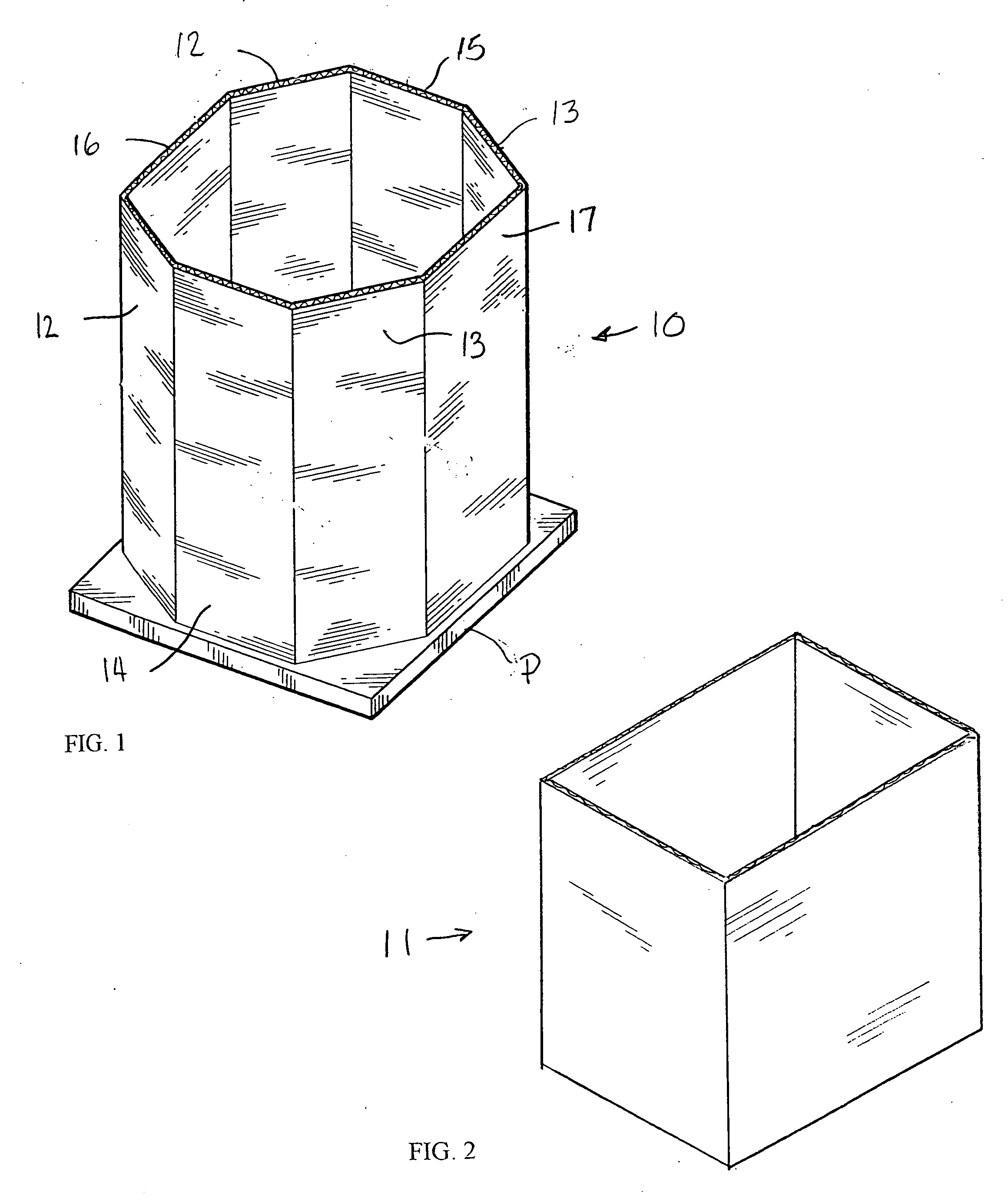

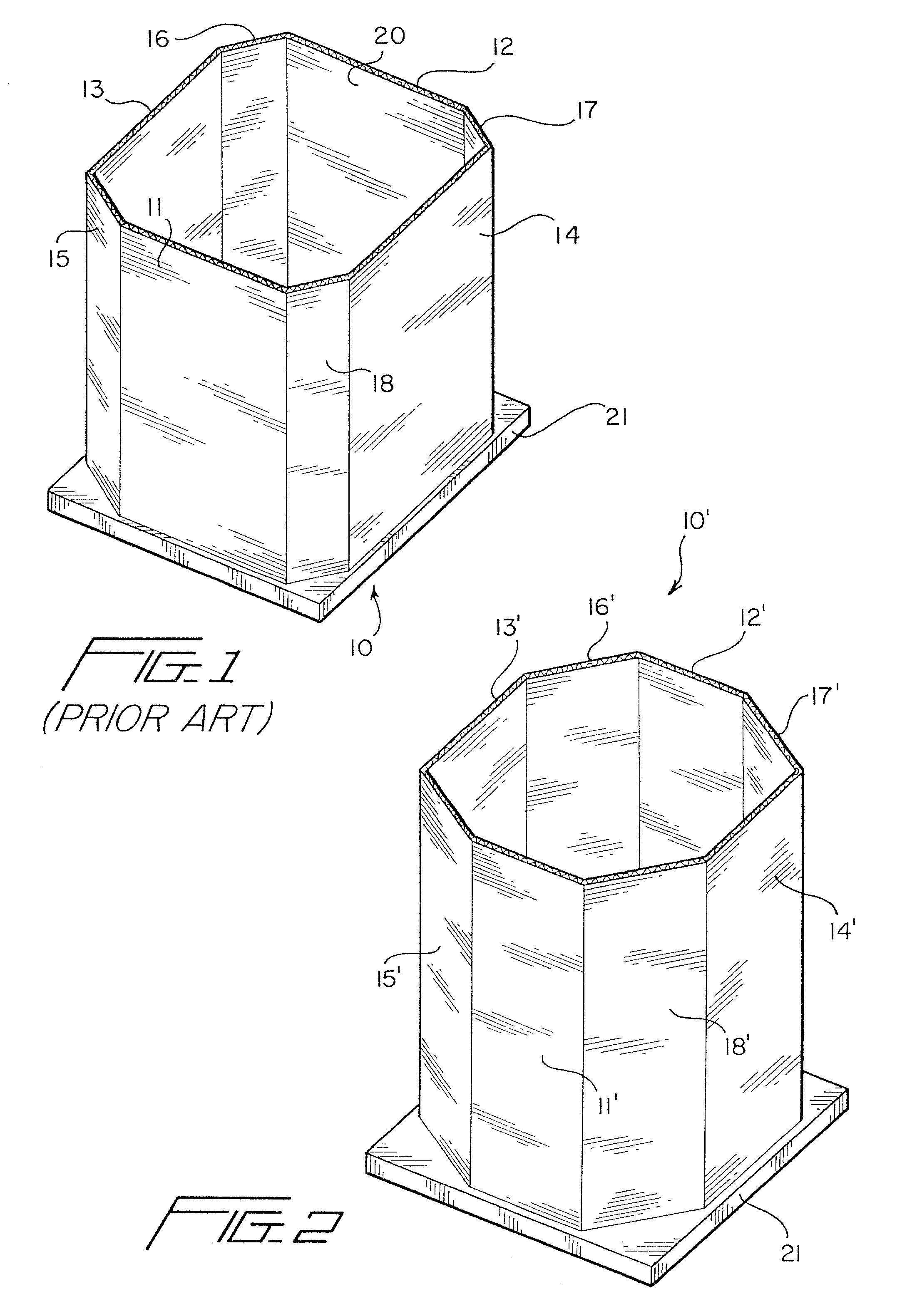

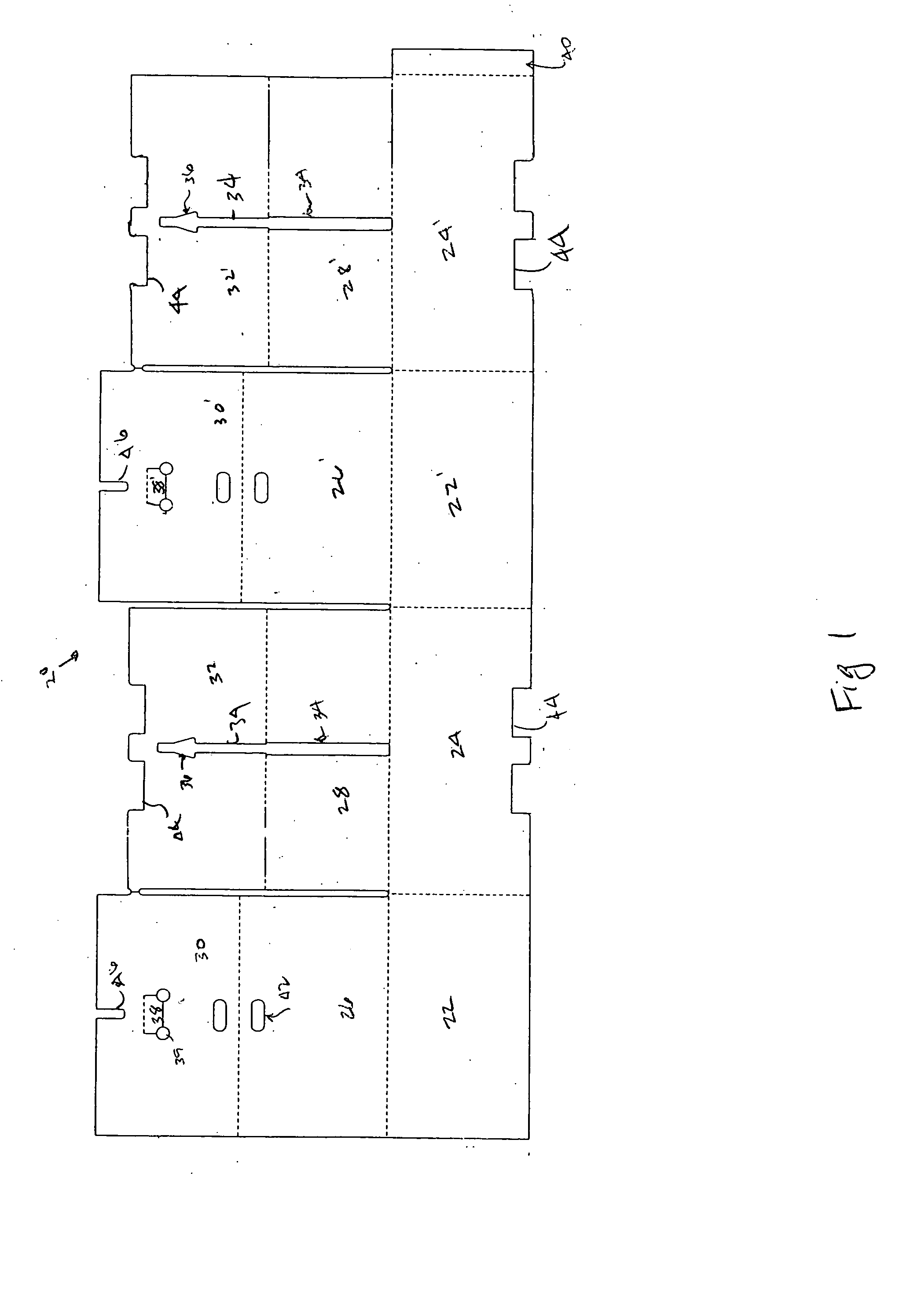

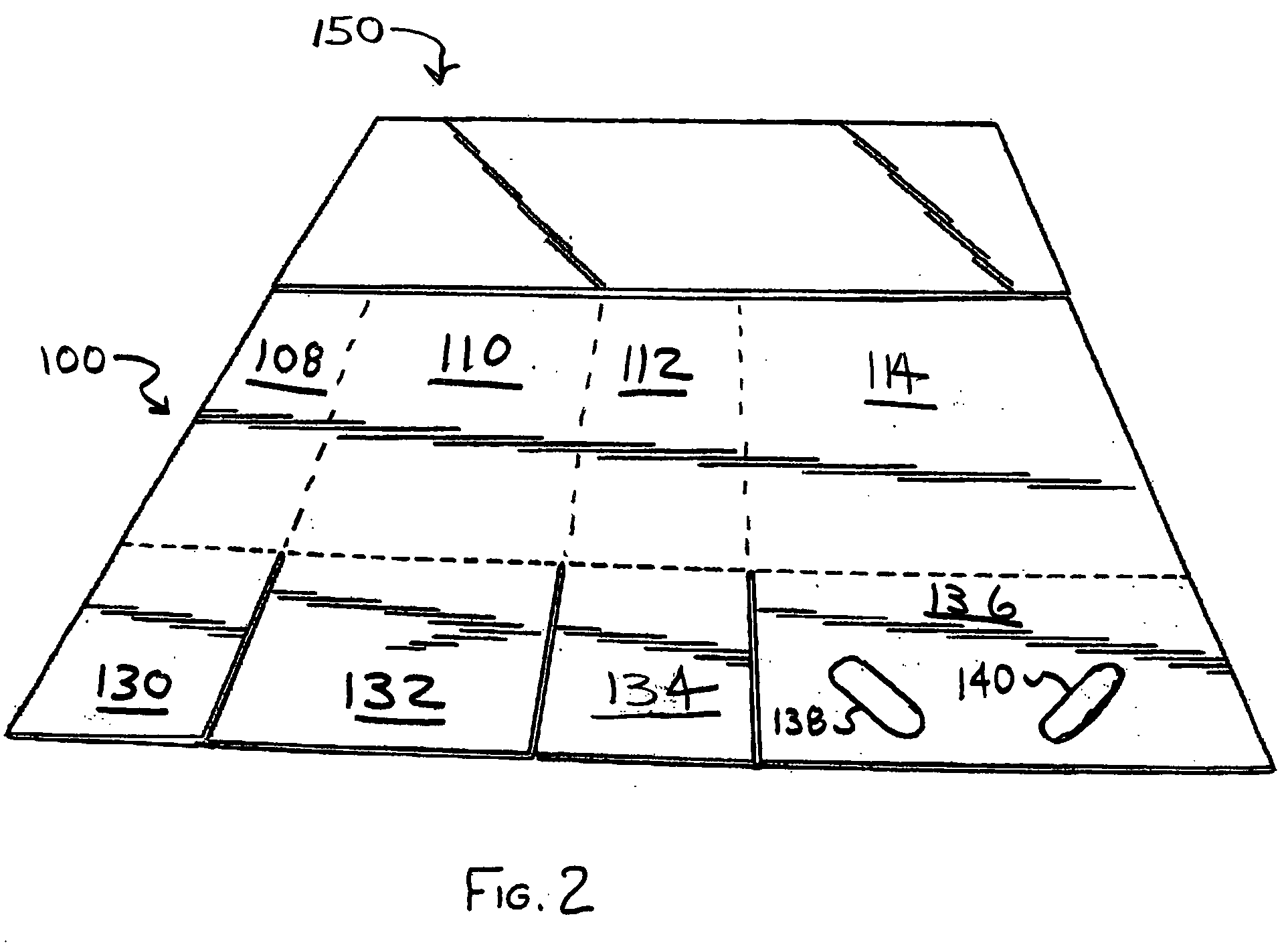

Polygonal collapsible bulk bin

Owner:WESTROCK SHARED SERVICES LLC

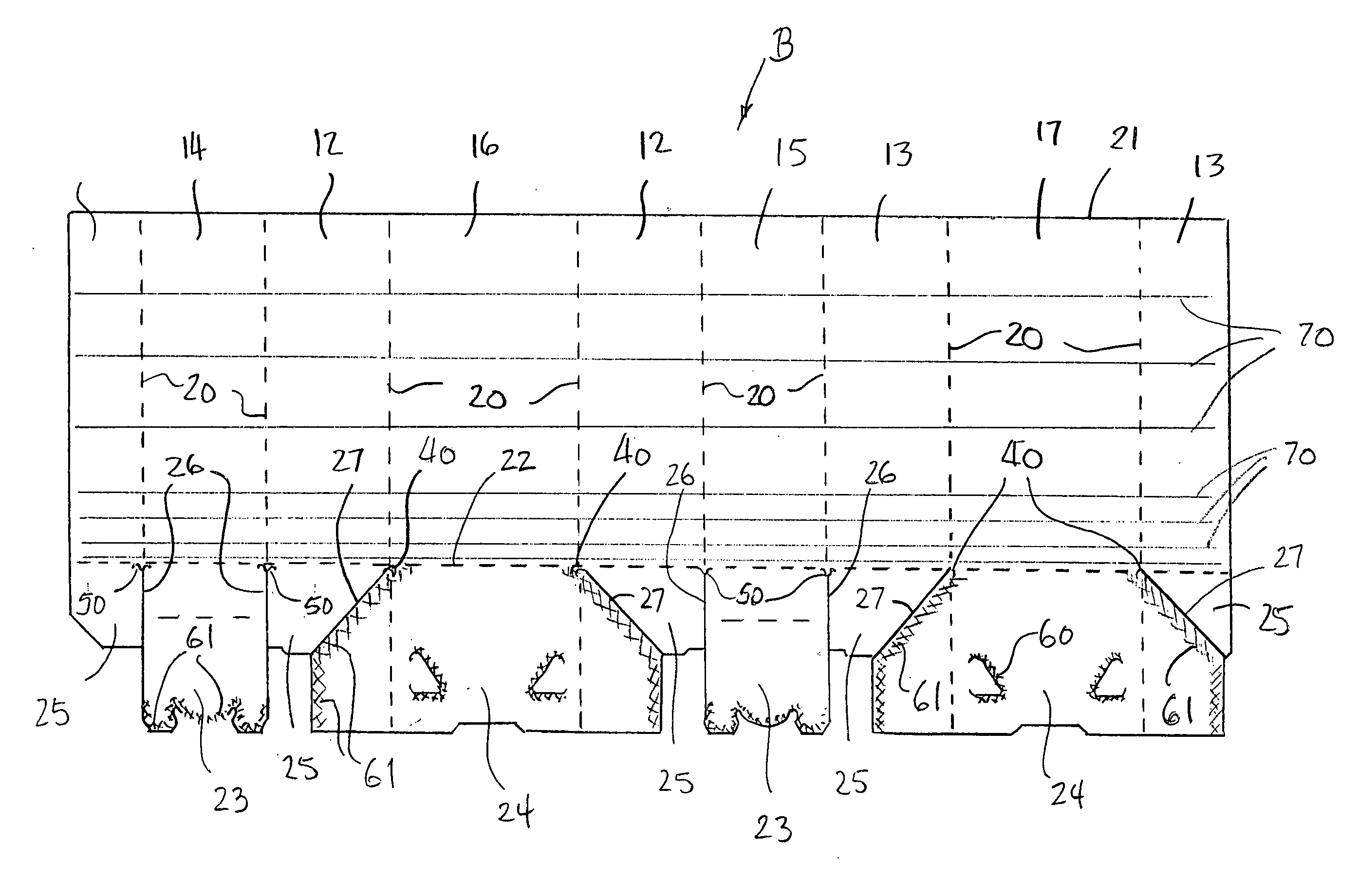

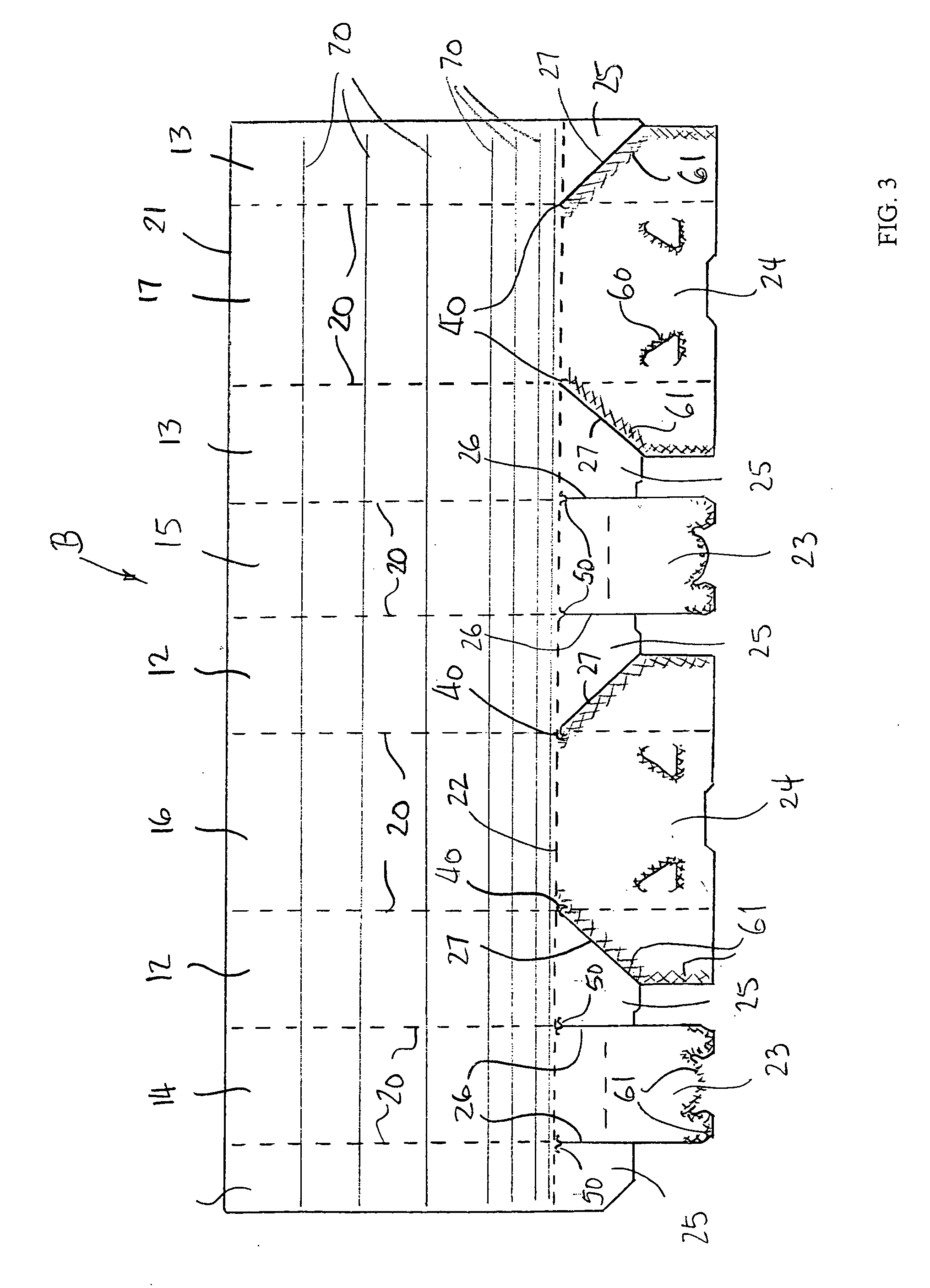

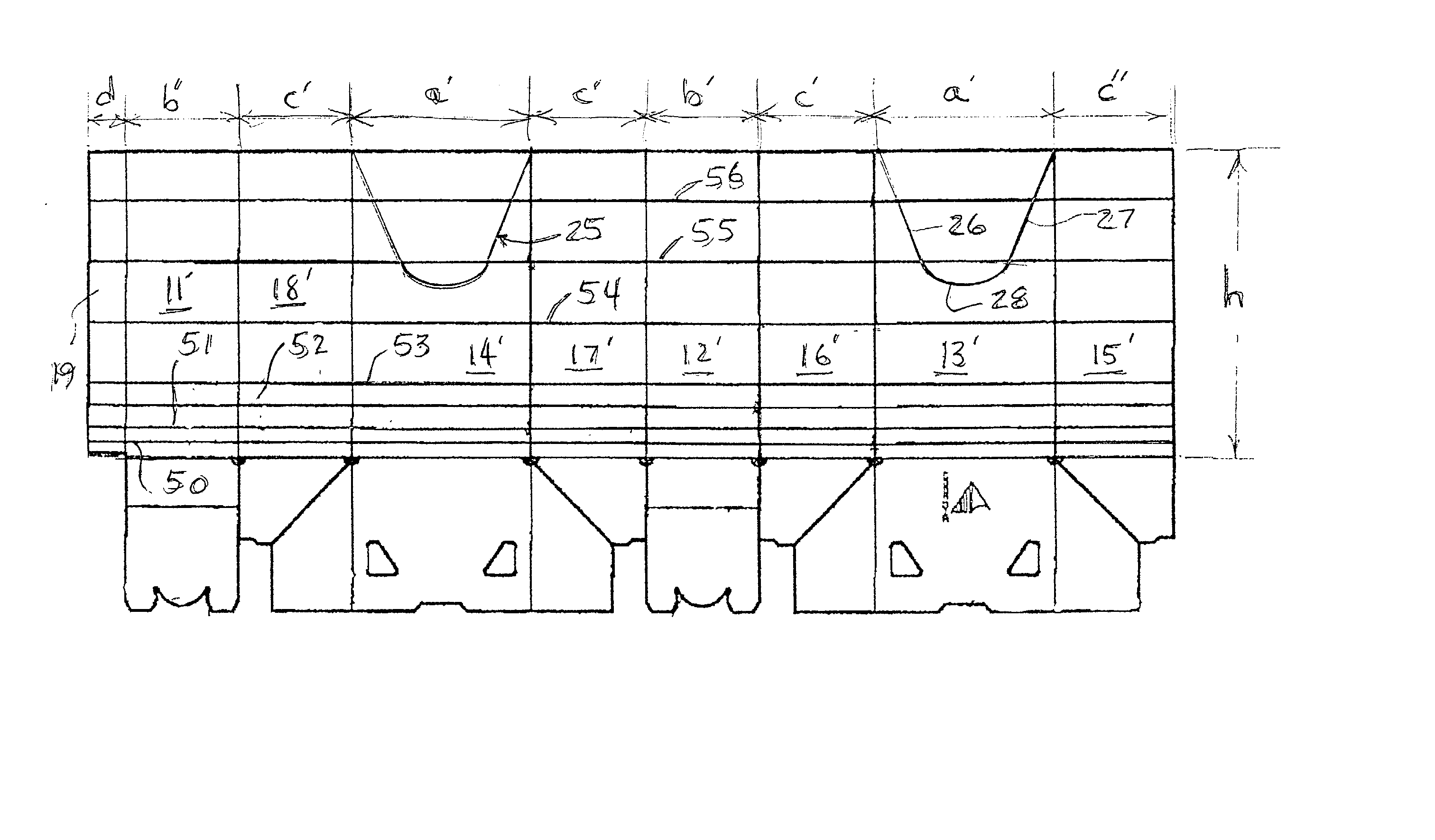

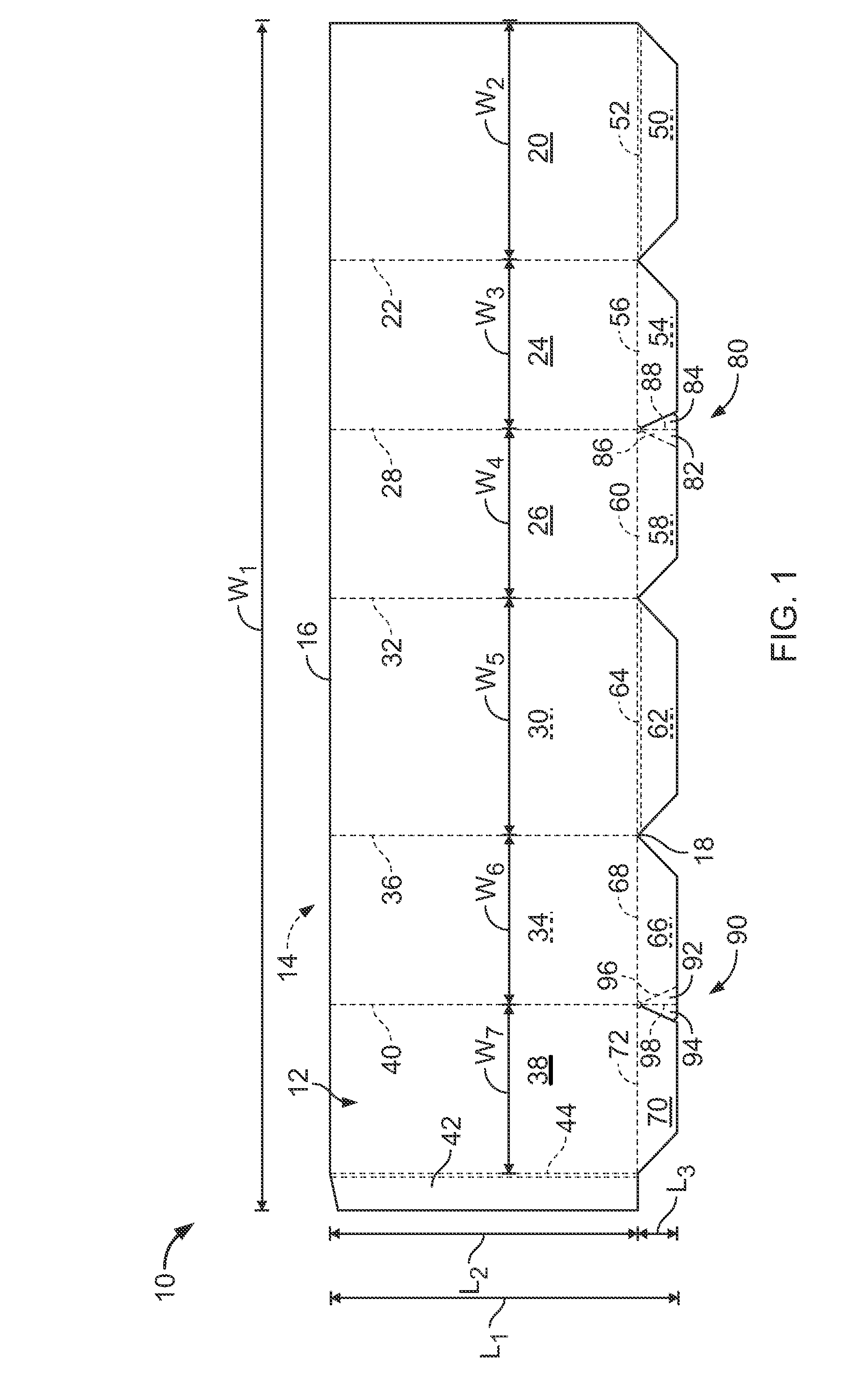

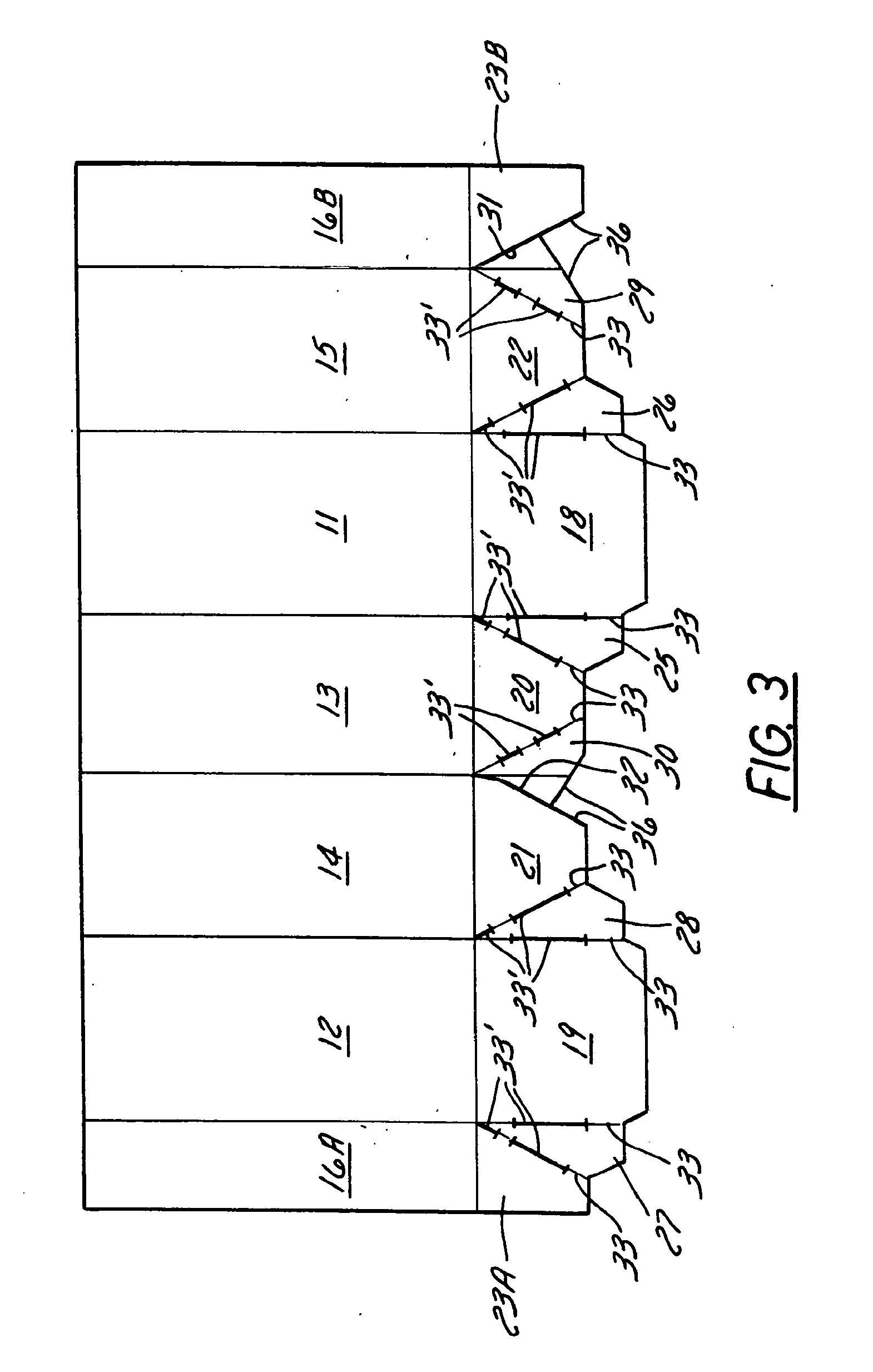

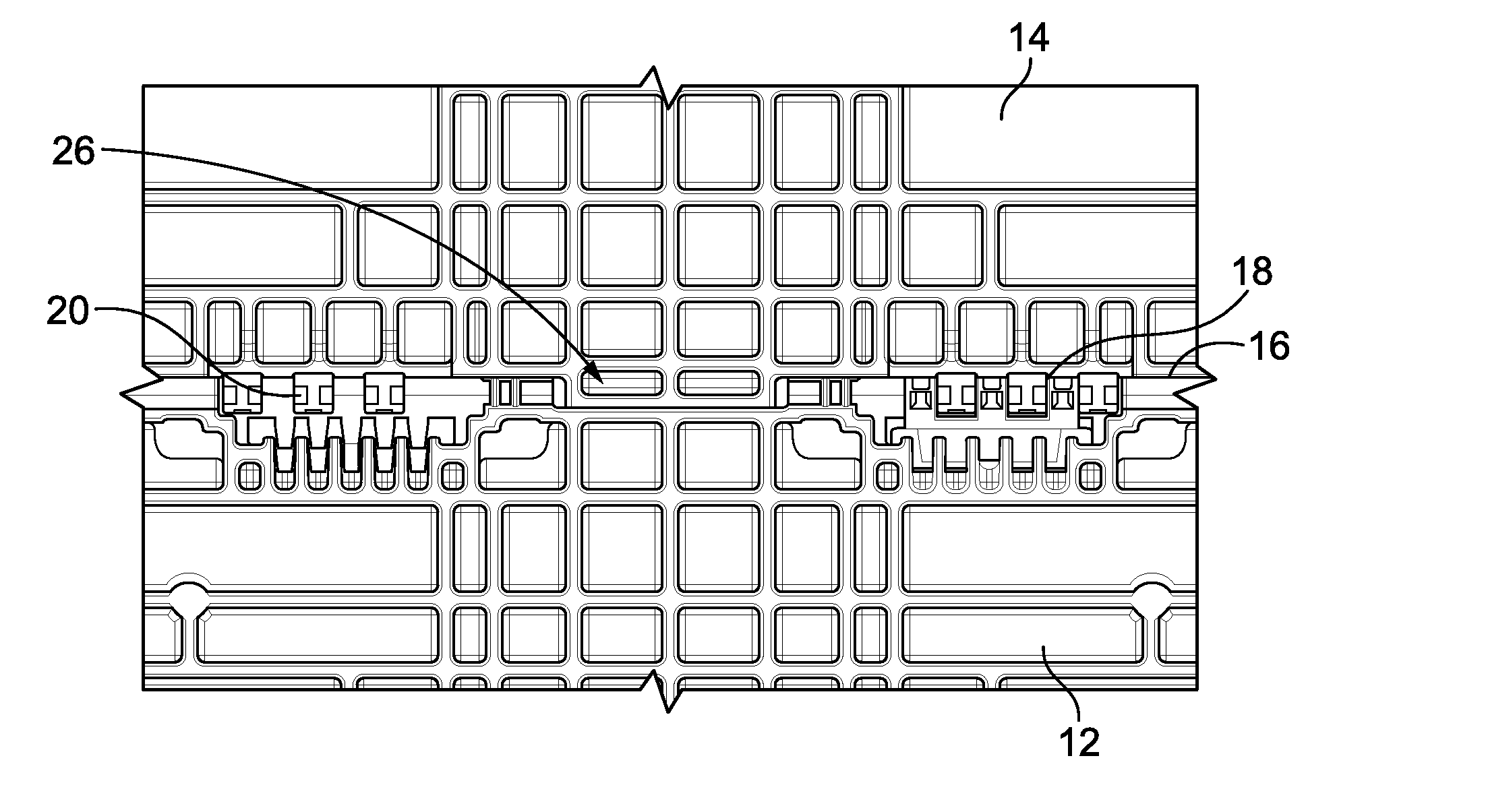

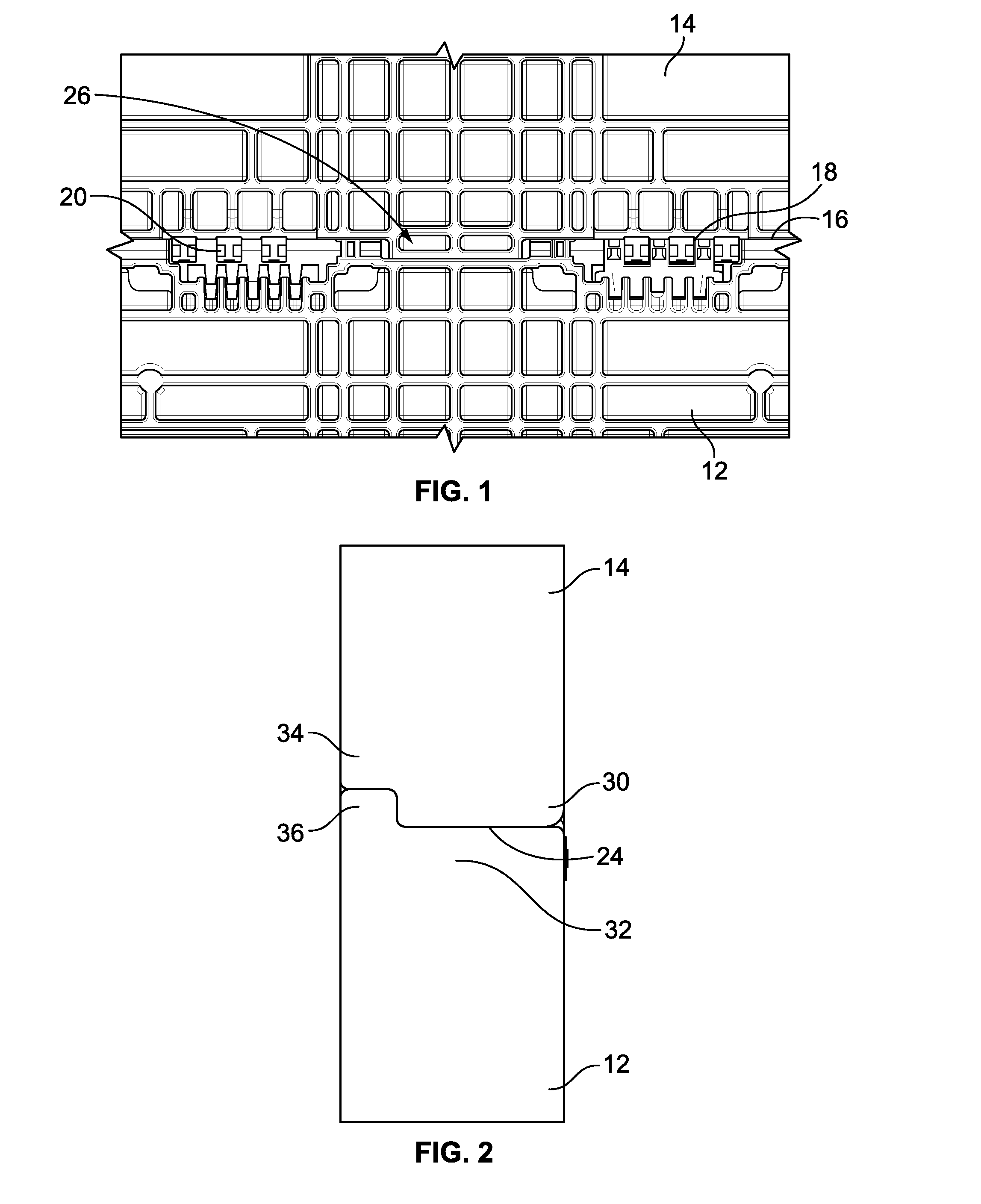

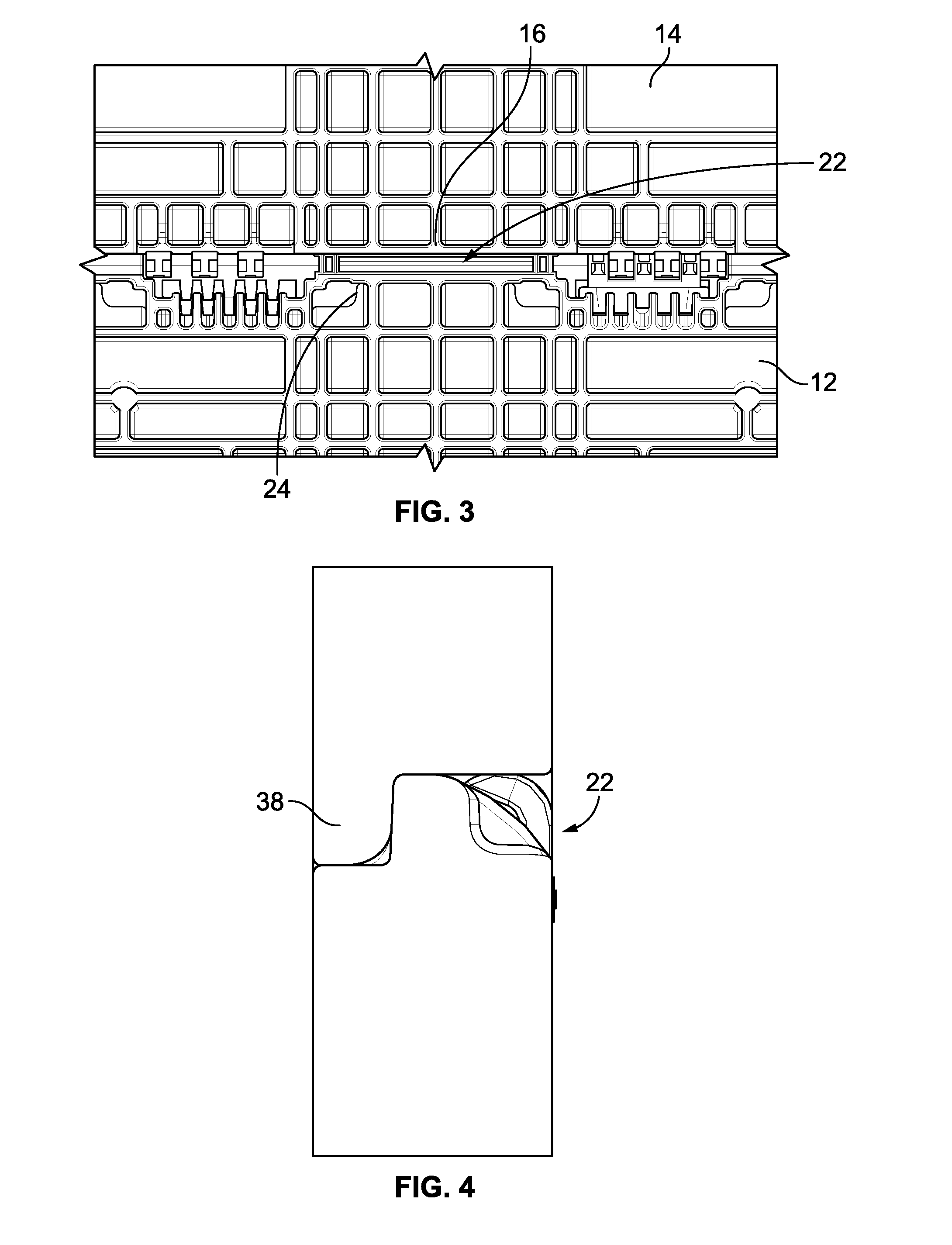

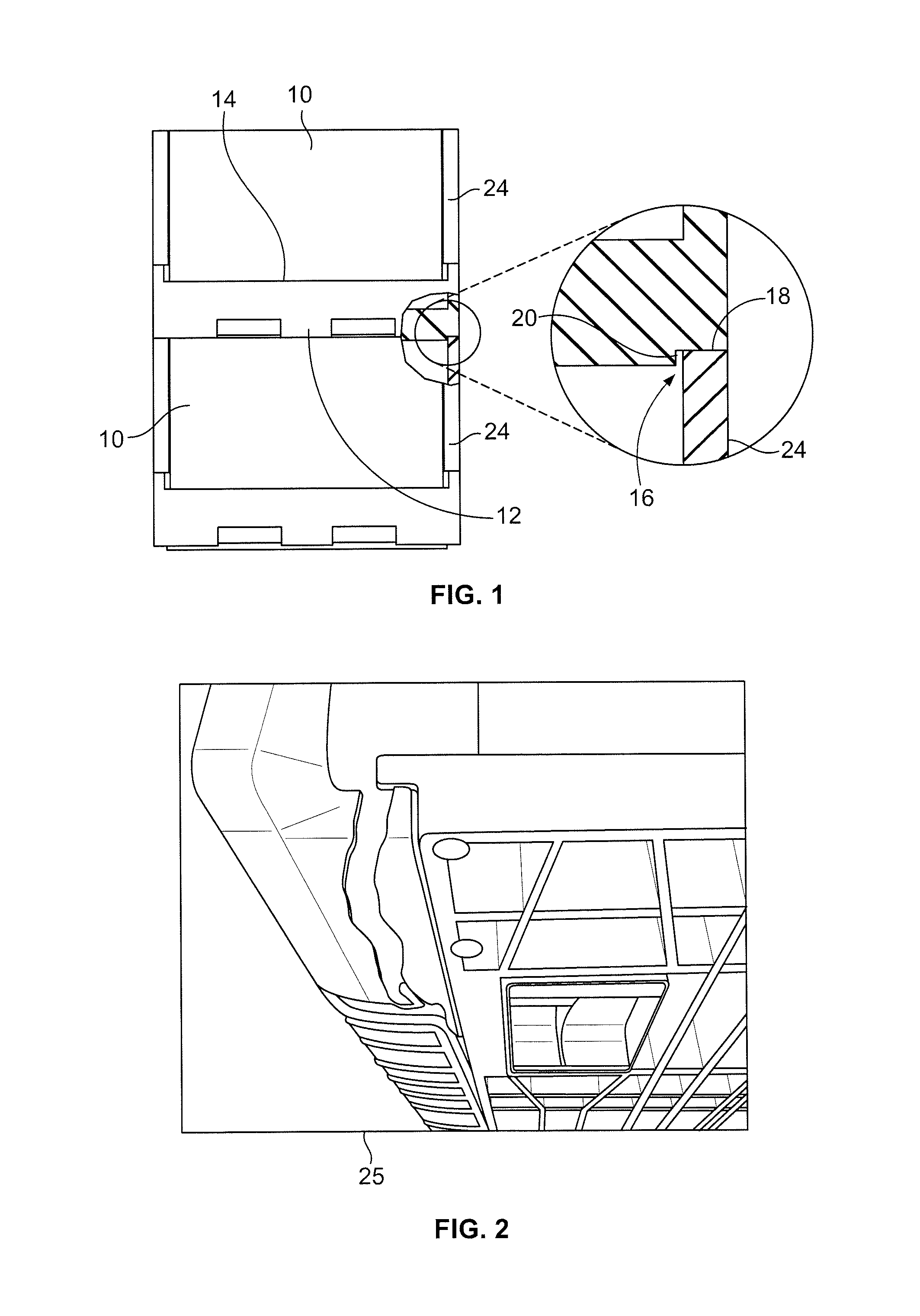

Octagonal bulk bin with means to resist initiation of failure of the vertical score in the bin

InactiveUS20070152027A1Redirect the stress awayEliminate pointPaper/cardboardRigid containersBulk boxGreek letter psi

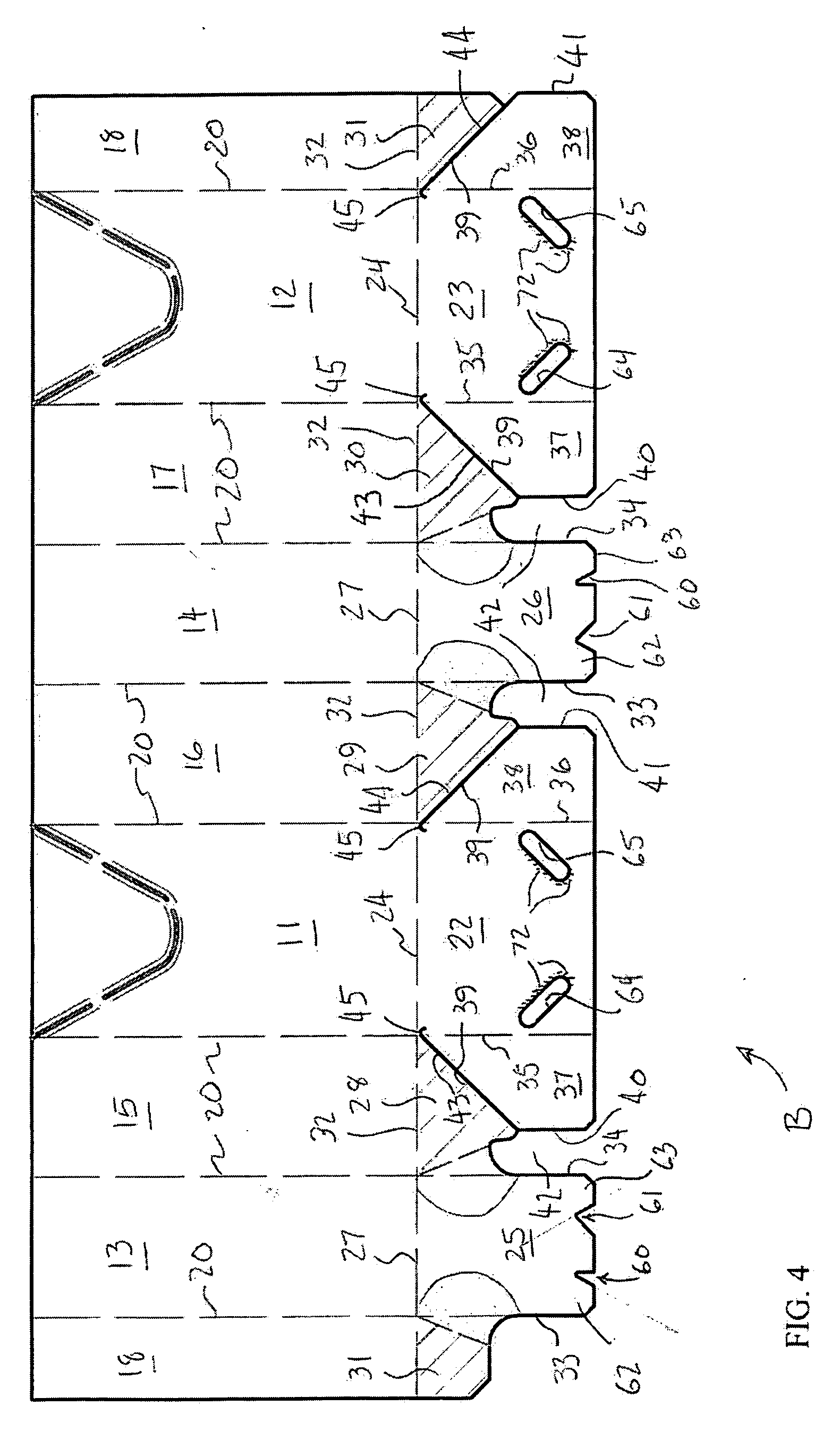

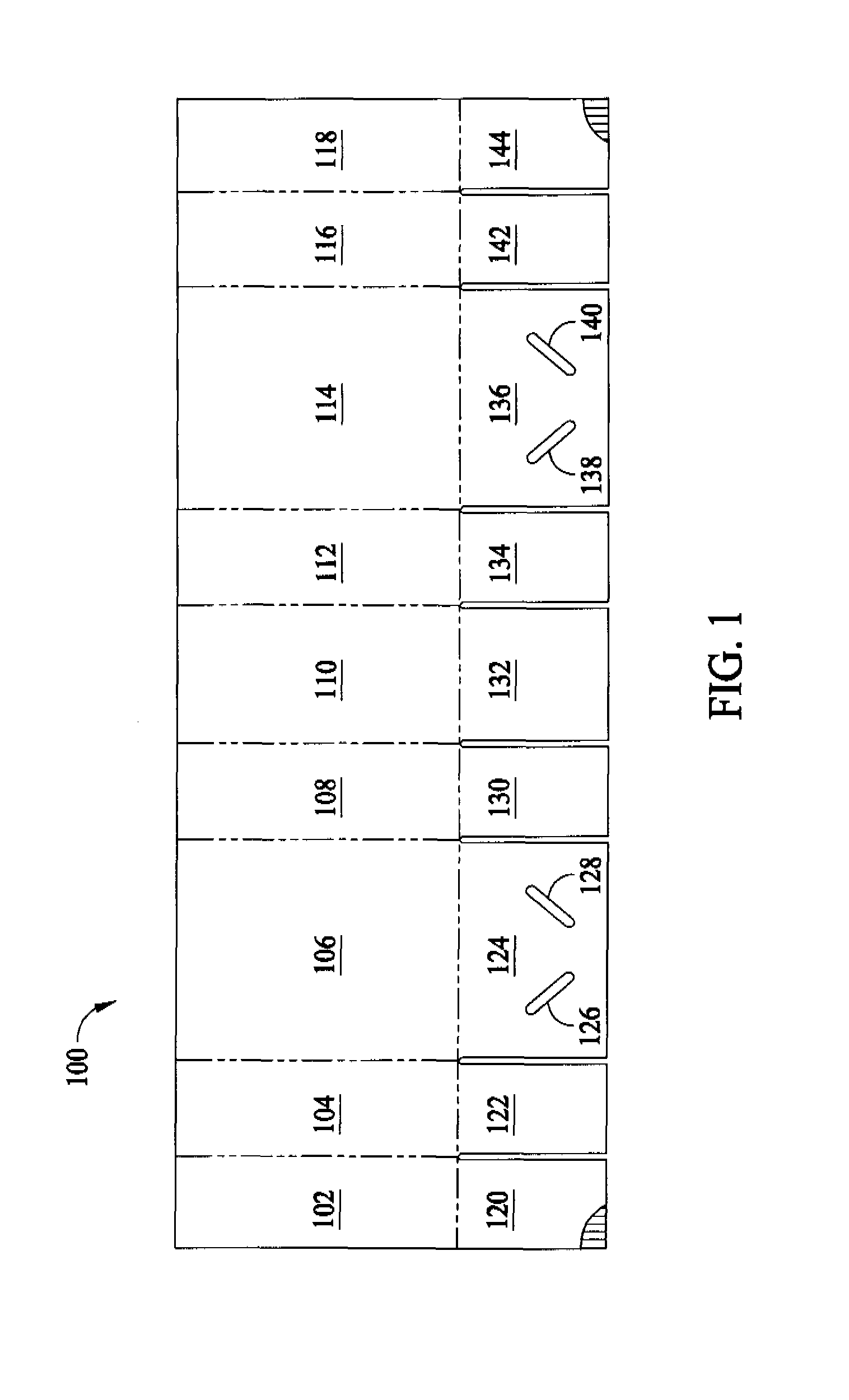

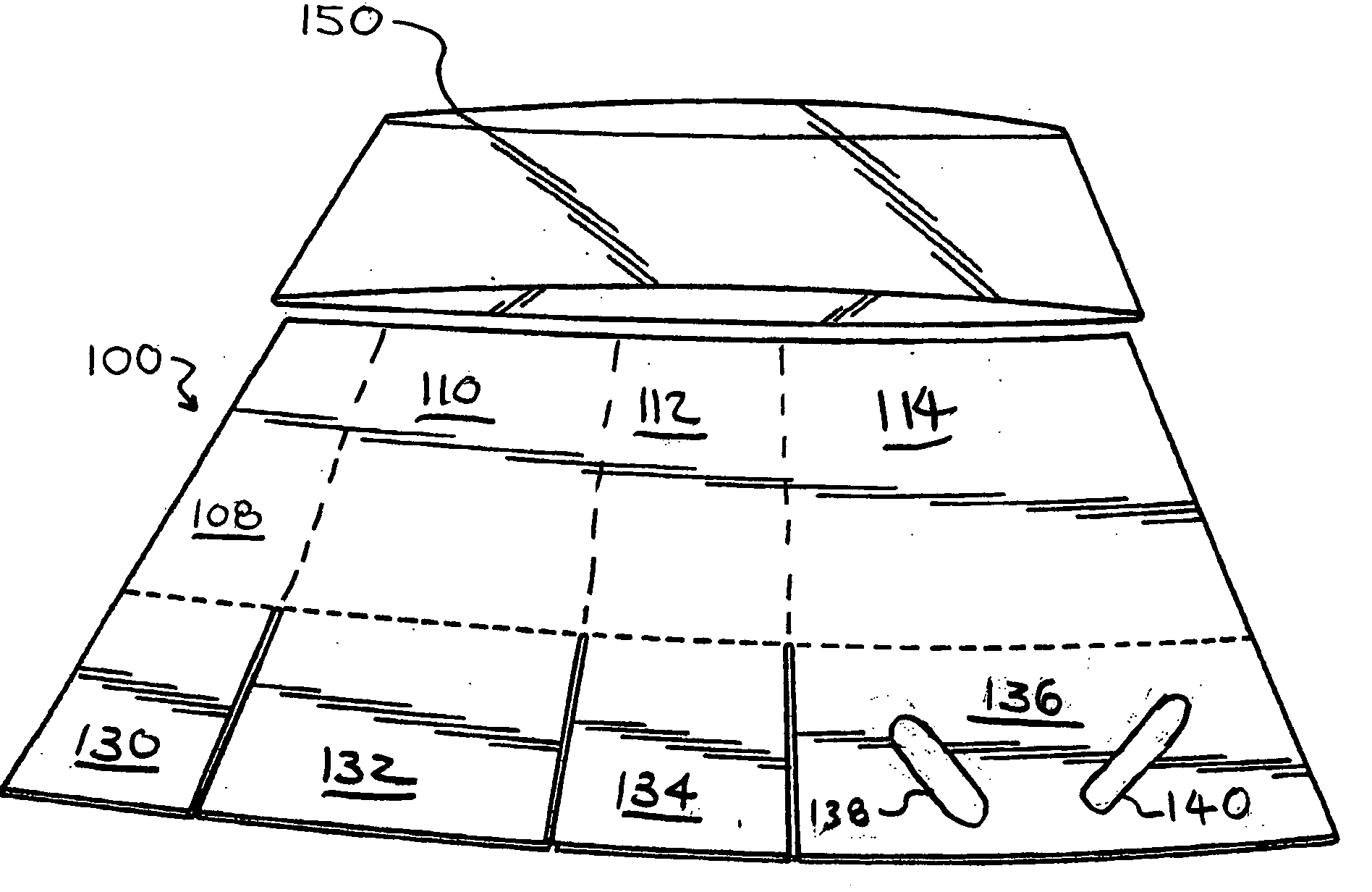

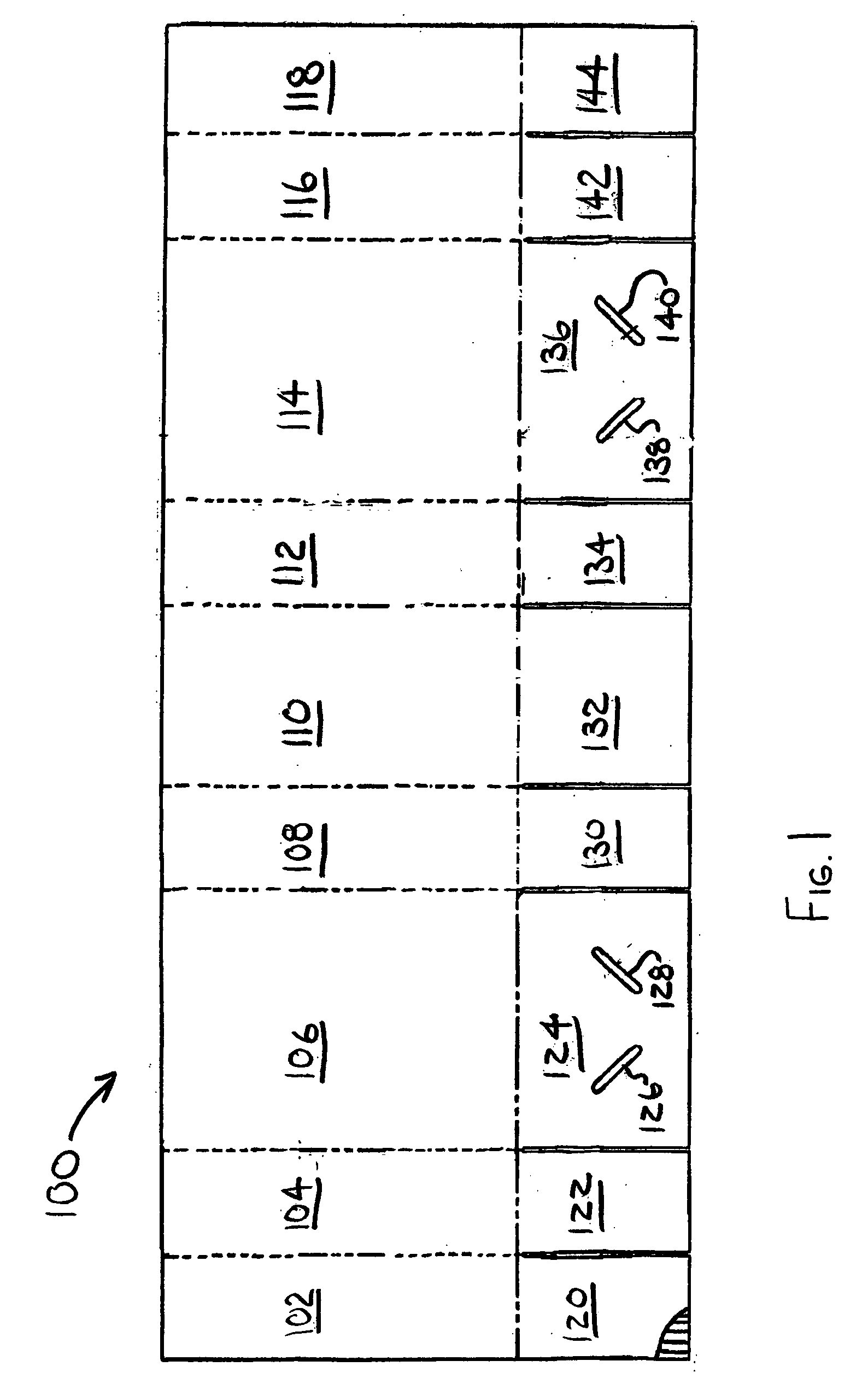

In a bulk bin having side walls joined to one another at adjacent edges along vertical scores, and bottom flaps joined to bottom edges of the side walls along a flap score, with adjacent flaps separated from one another by a flap slot, a shaped cut is made at the terminal end of the flap slot to redirect stress away from the bottom end of the vertical score and resist initiation of tearing of the vertical score at that point. In one embodiment, the shaped cut is a downwardly open hook shape which terminates in an end pointing laterally away from the vertical score and into the flap. In another embodiment, the shaped cut resembles a modified Greek letter psi (ψ), with the ends pointing laterally away from the vertical score, and in still another embodiment, the shaped cut is “T” shaped, with the ends of the “T” pointing laterally away from the vertical score.

Owner:INT PAPER CO

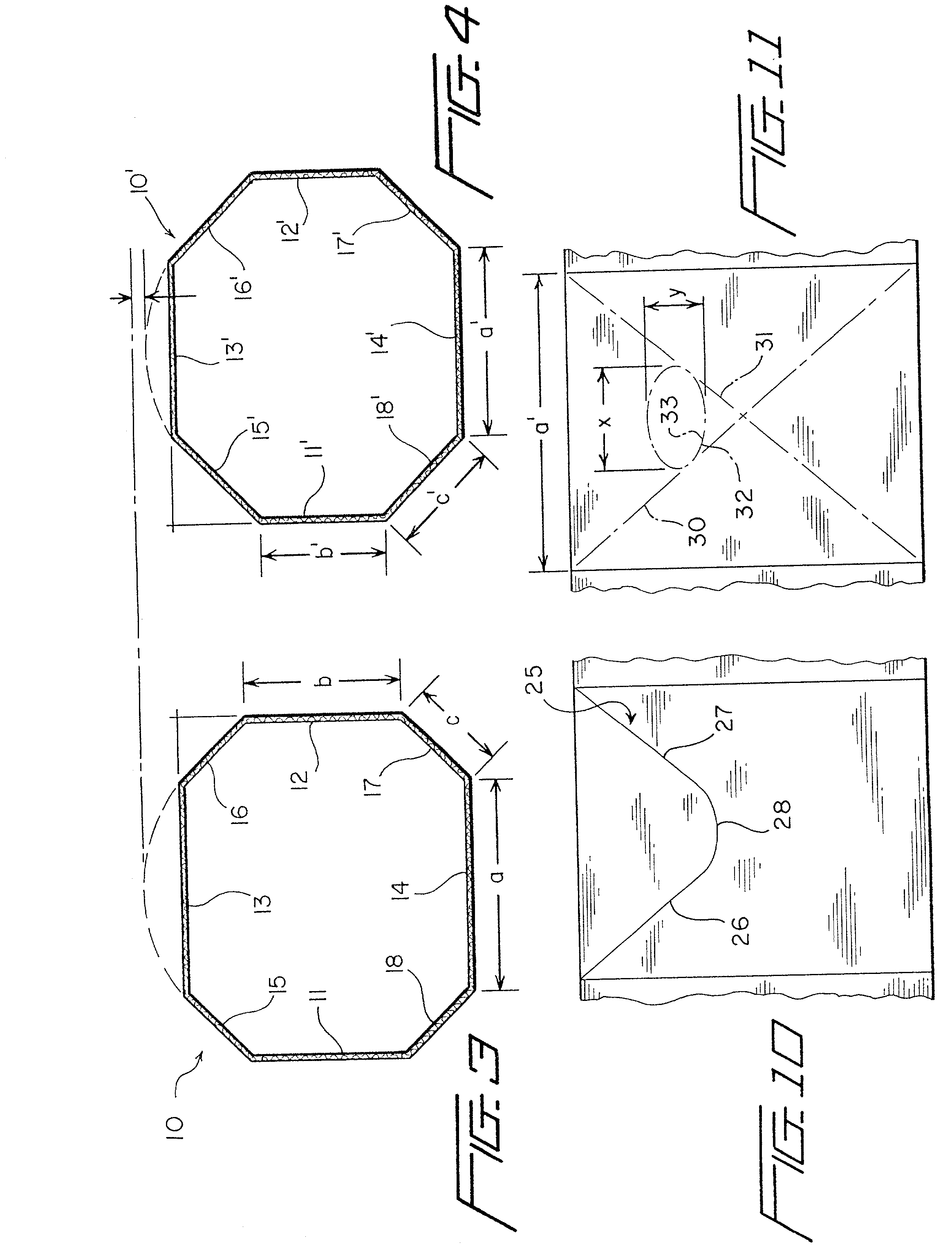

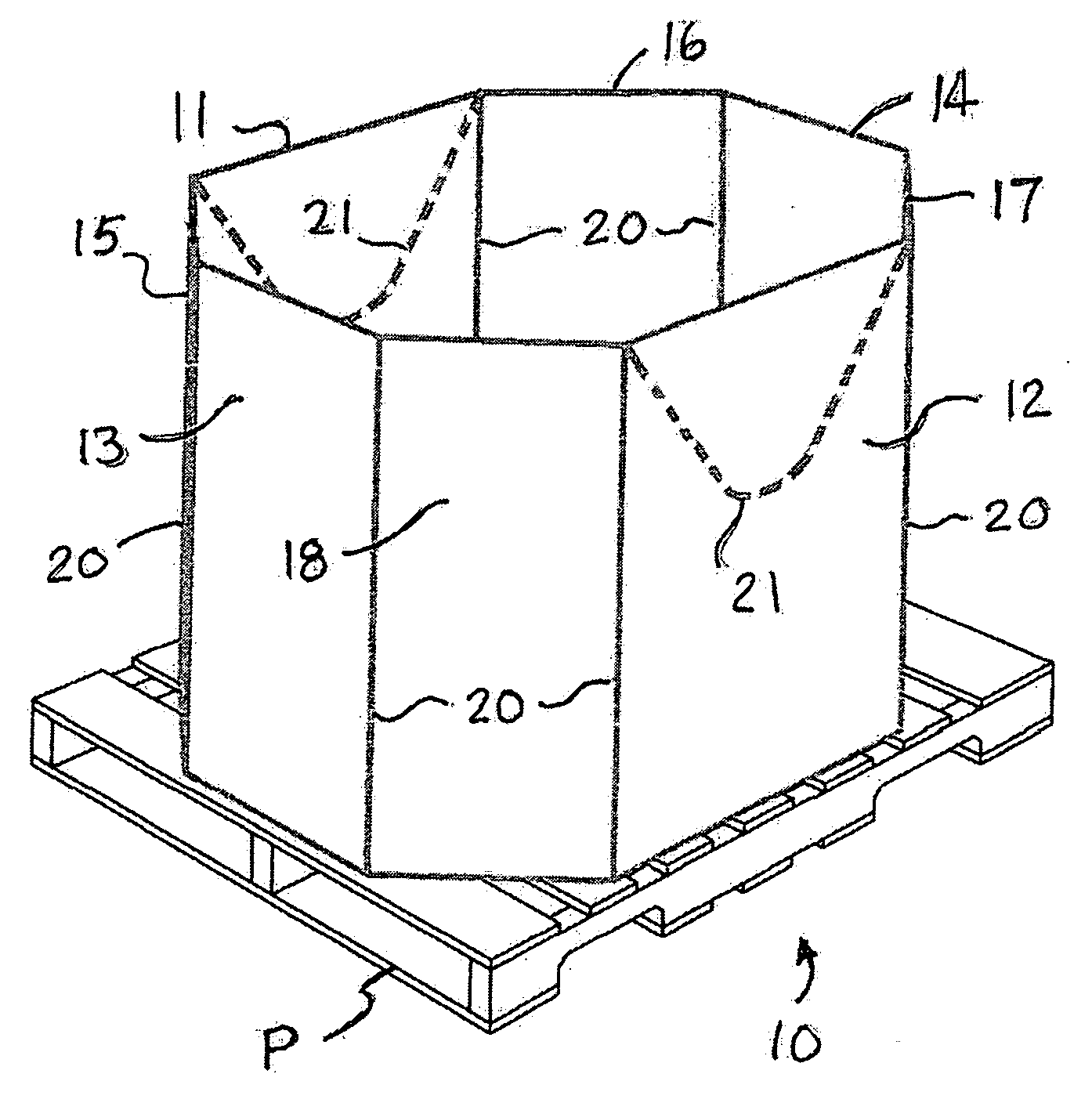

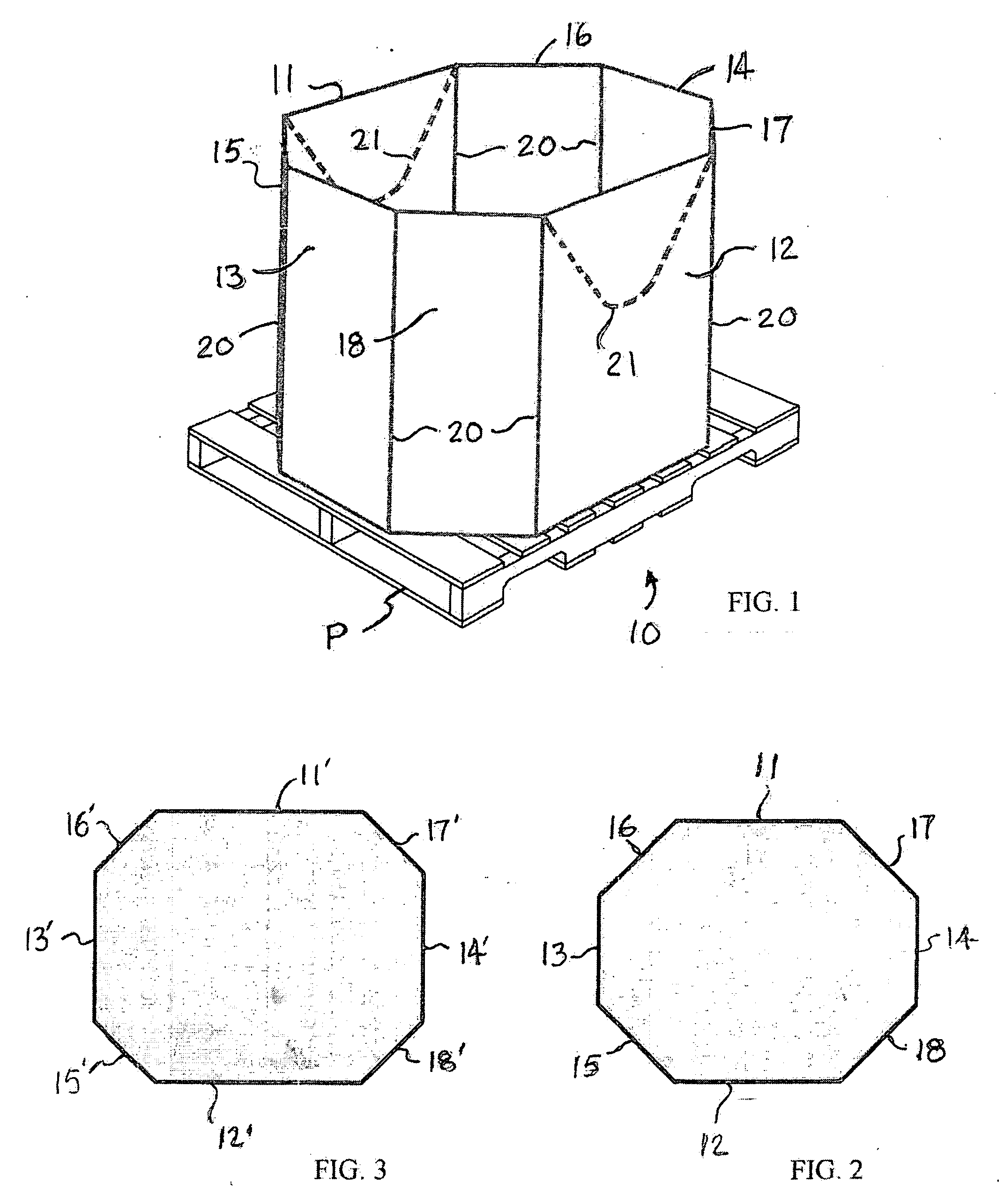

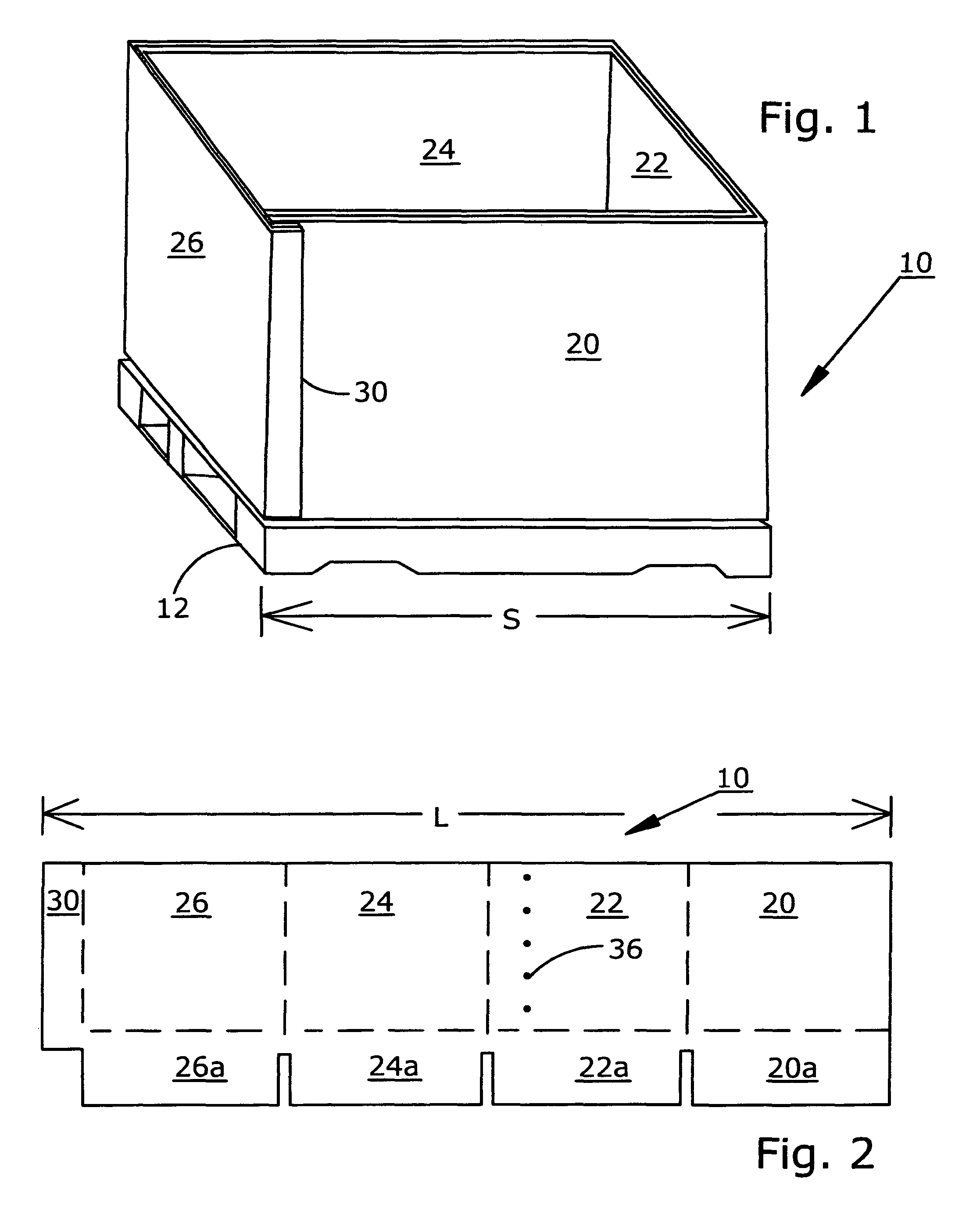

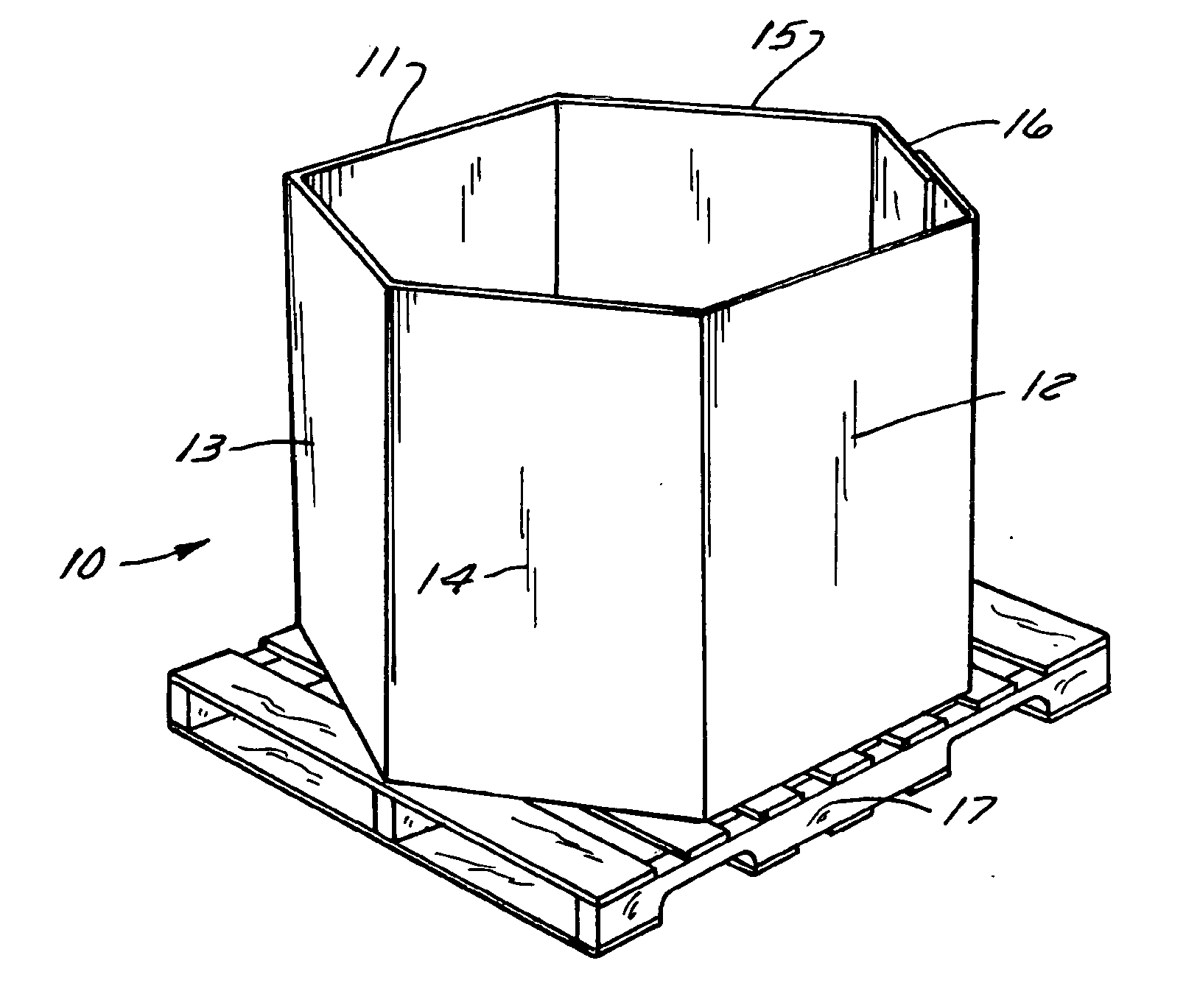

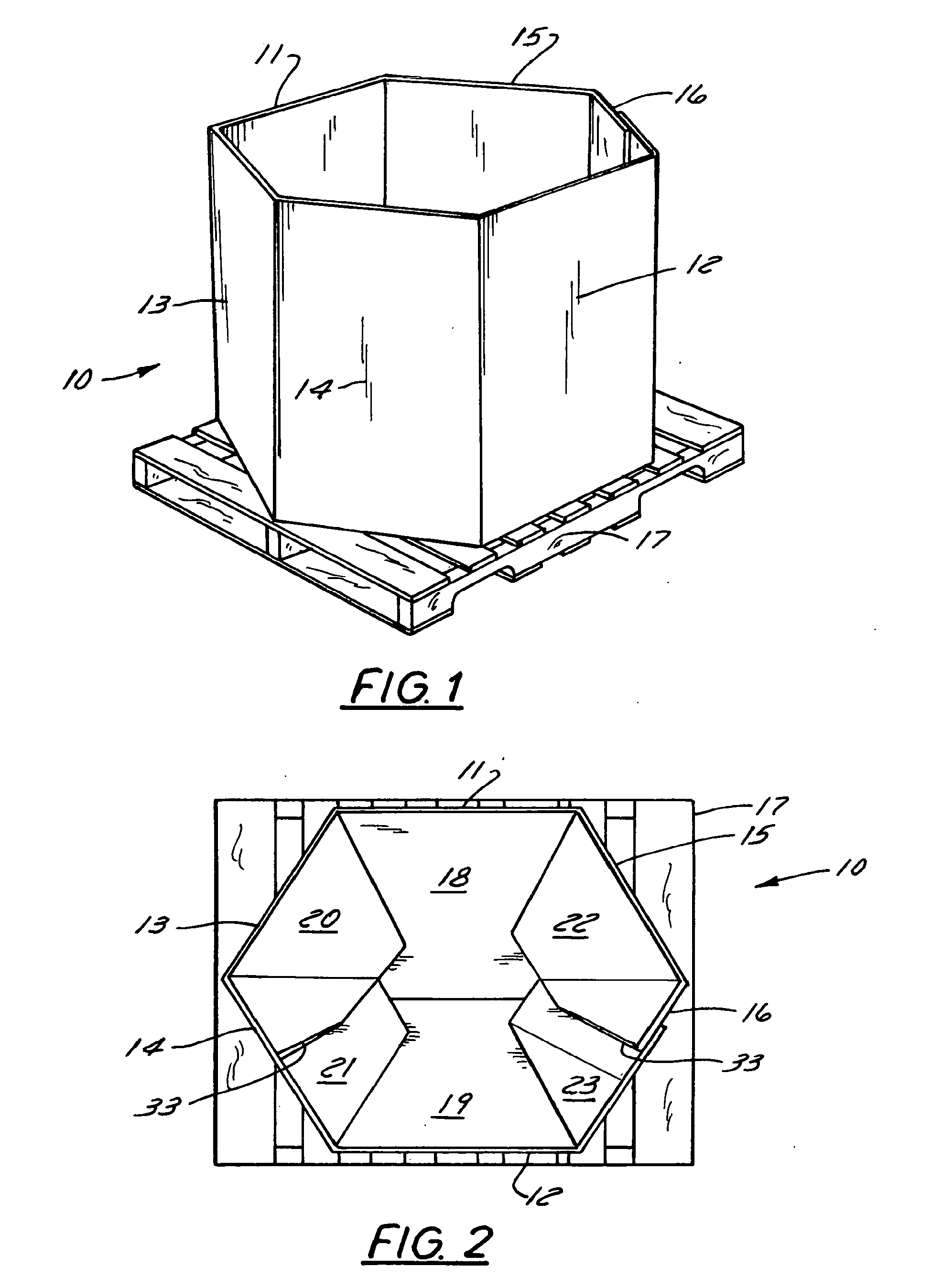

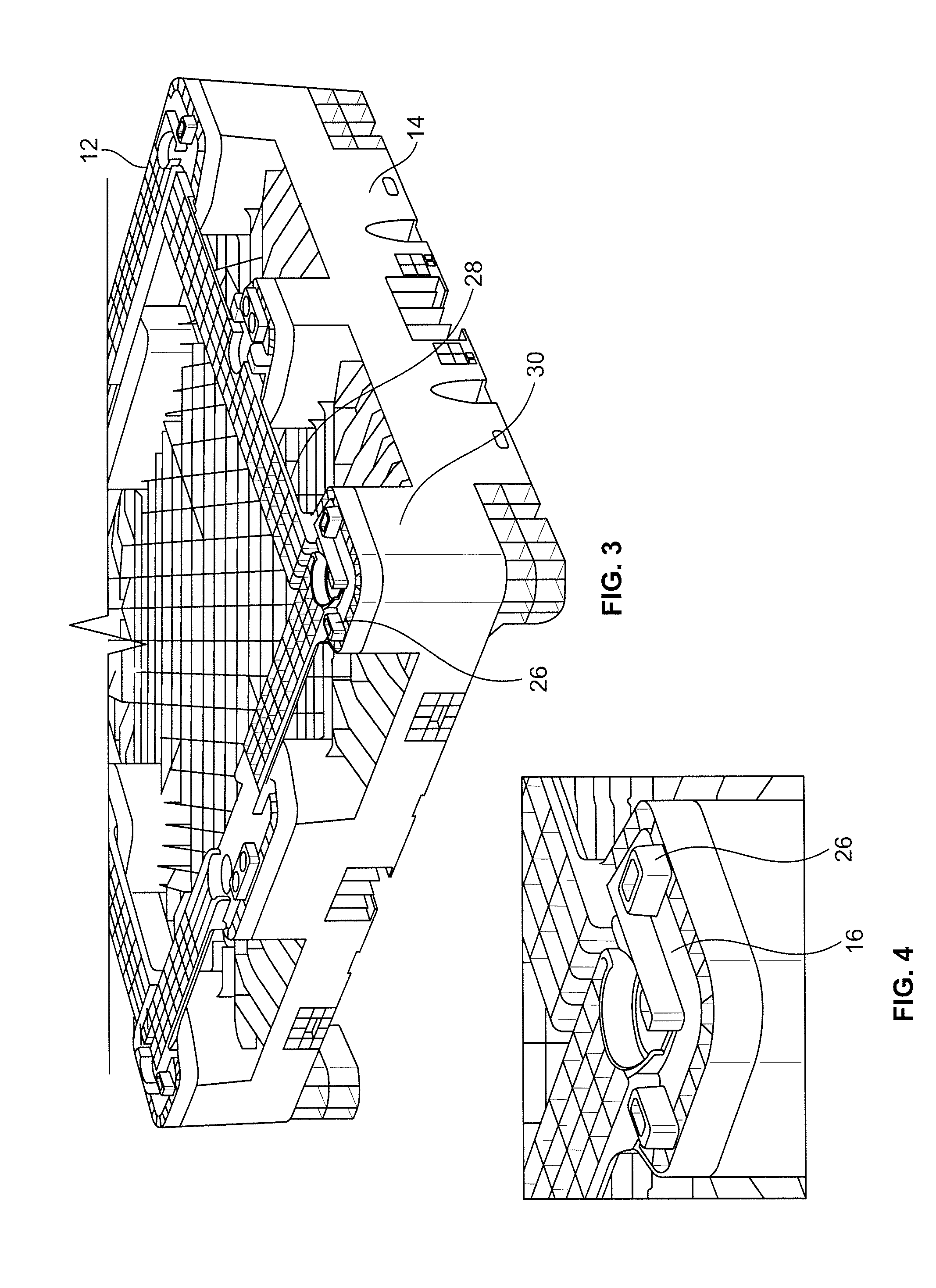

Octagonal bulk bin

An octagonal bulk bin of corrugated paperboard has opposed parallel side walls spaced a predetermined distance apart and opposed parallel end walls spaced a predetermined distance apart. The side and end walls are joined by diagonal corner panels. The diagonal corner panels are made wider than the corner panels in a conventional bin, and the side and end walls are narrower, with the corner panels and the end walls having approximately the same width, while maintaining the predetermined spacing. This configuration reduces the bulge experienced when product is loaded into the bin. In addition to the wider corner panels, or in lieu thereof, scores may be placed in at least one of the side and end panels to define a line along which controlled and predetermined buckling will take place, if buckling occurs.

Owner:INT PAPER CO

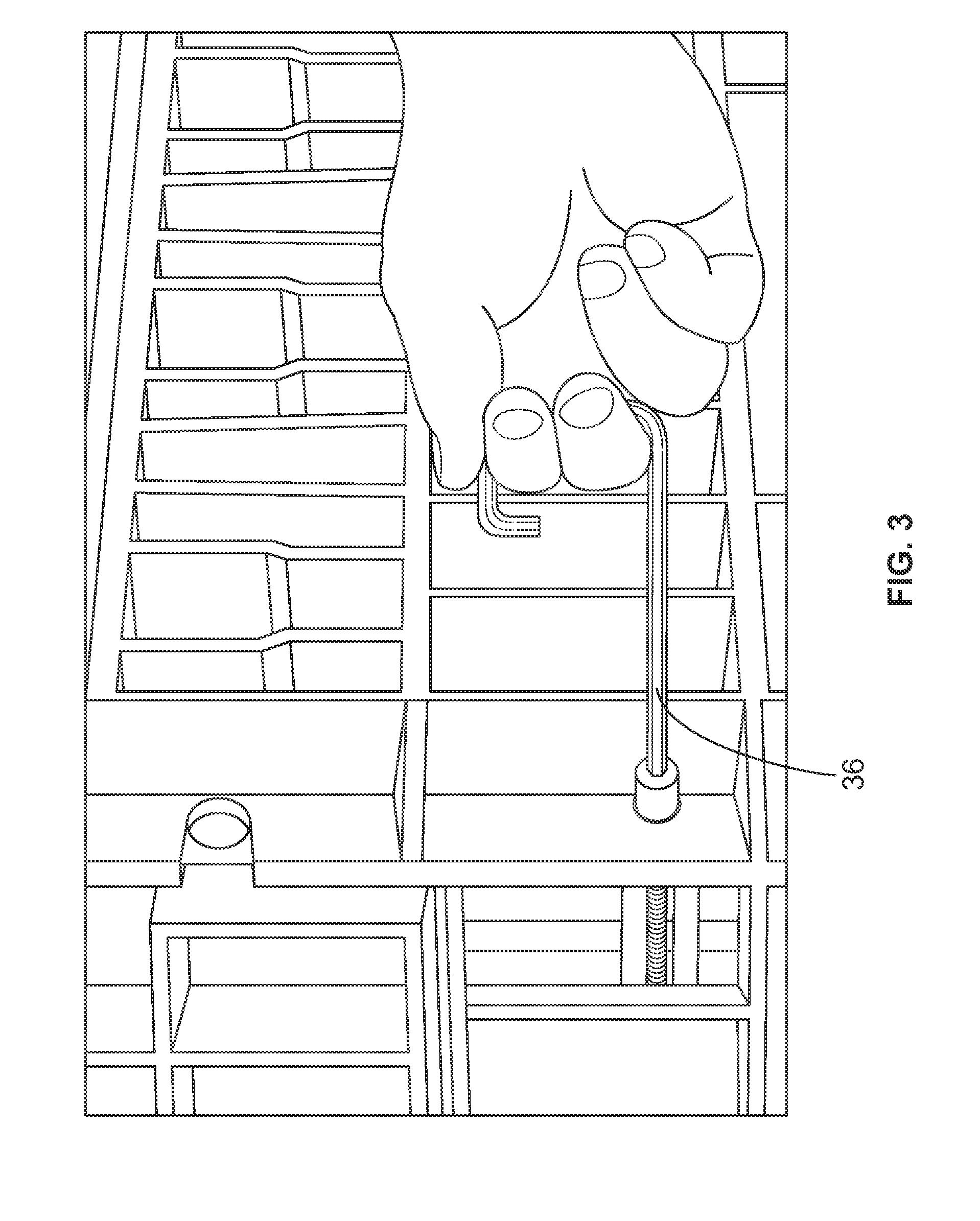

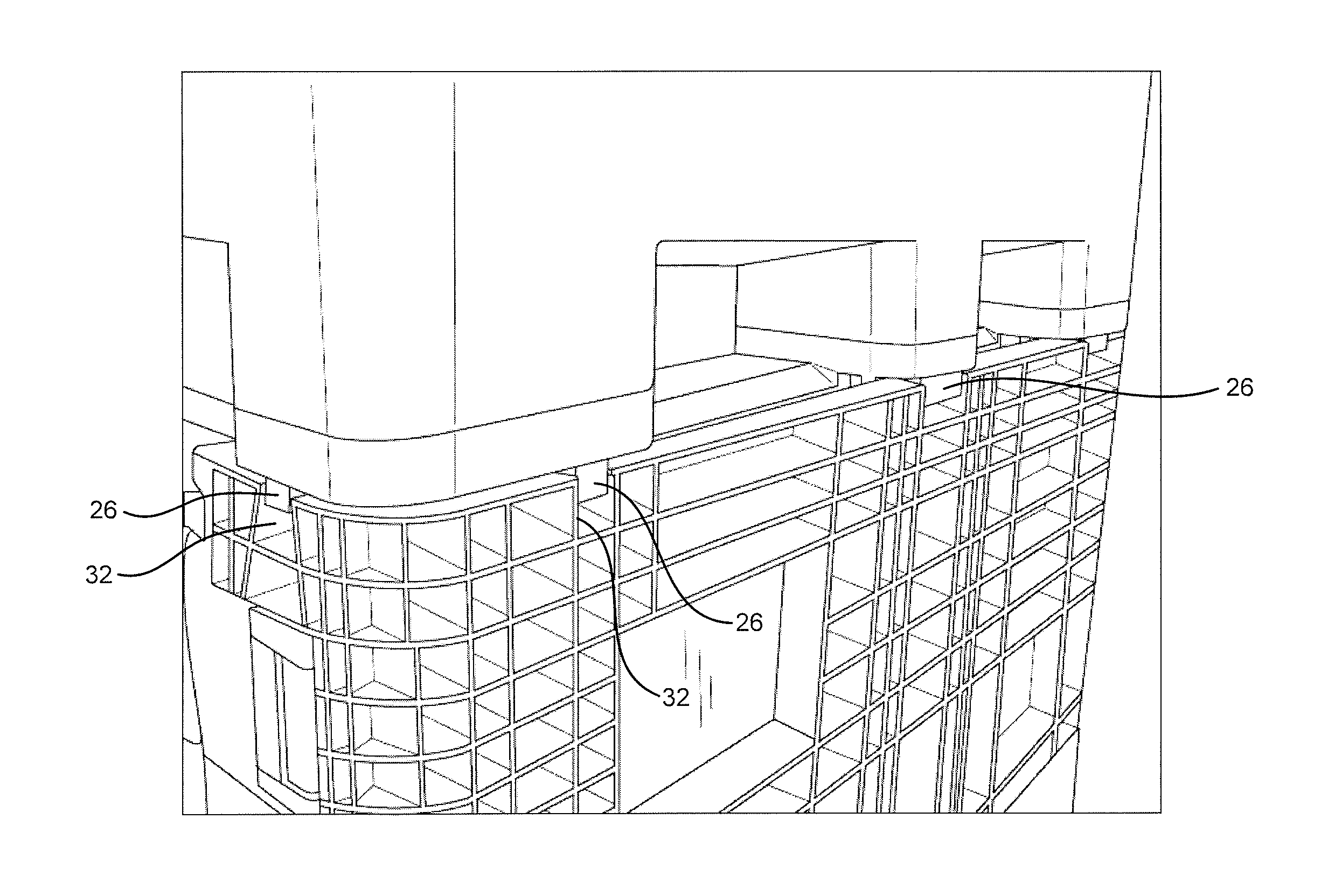

Octagonal bulk bin with self-locking webbed bottom flaps

Owner:INT PAPER CO

Bulk bin shipping containers

ActiveUS8418912B1Reducing degree bulgingMaintain column strengthRigid containersStructural engineeringWall stiffness

The present invention provides a bulk bin having a greater column strength by being resistant to wall bulging. The bulk bin is formed mainly of multiple wall corrugated board with the corrugations in a first wall oriented vertically and the corrugations in a second wall oriented horizontally. The orthogonal orientation of the corrugations results in a greater wall stiffness and less wall bulging, maintaining the wall in linear vertical orientation and retaining maximum column strength.

Owner:PACKAGING & CRATING TECH LLC

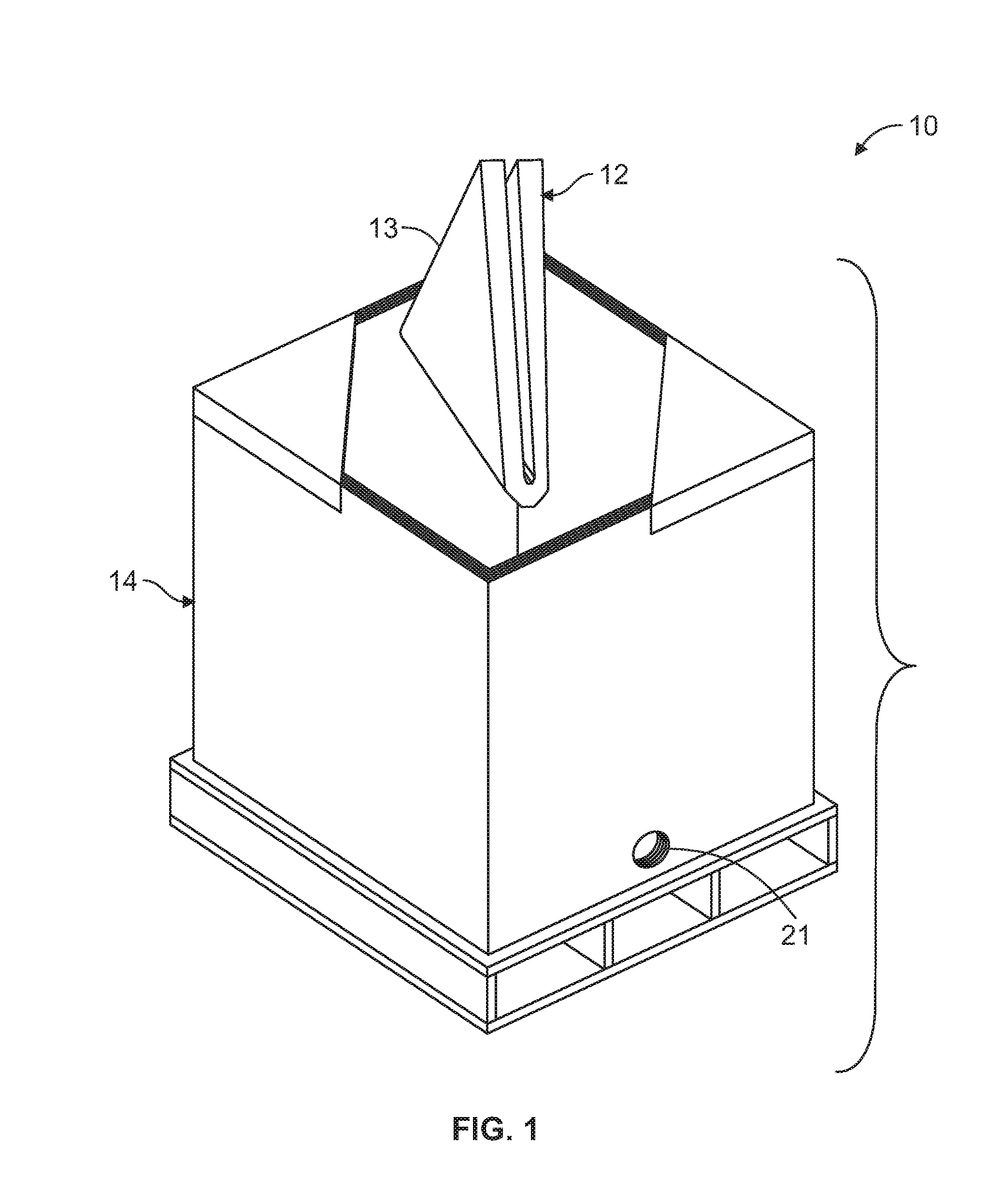

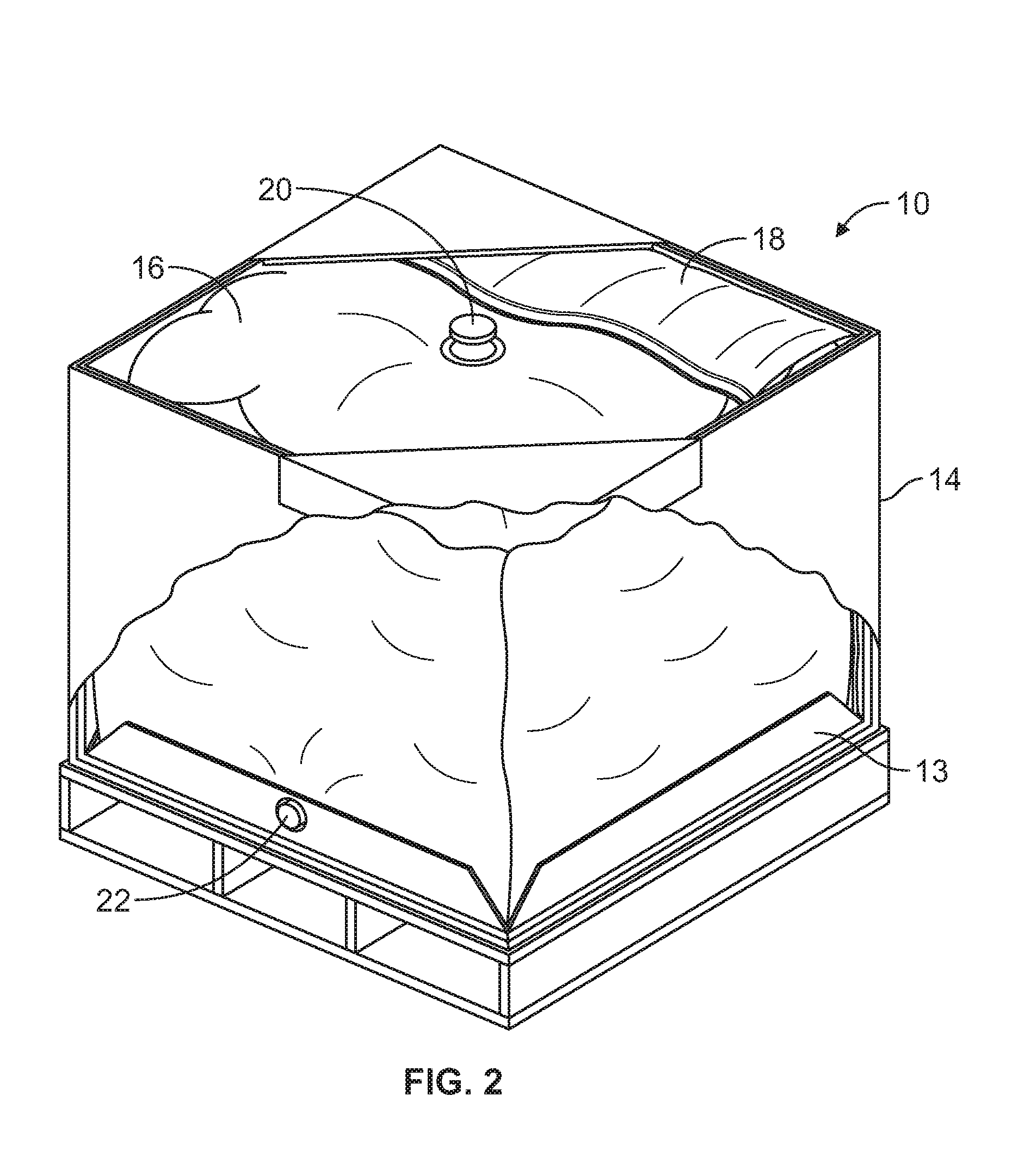

Bulk bin and bag

InactiveUS20130228574A1Avoid enteringAvoid interferenceClosuresBagsEngineeringMechanical engineering

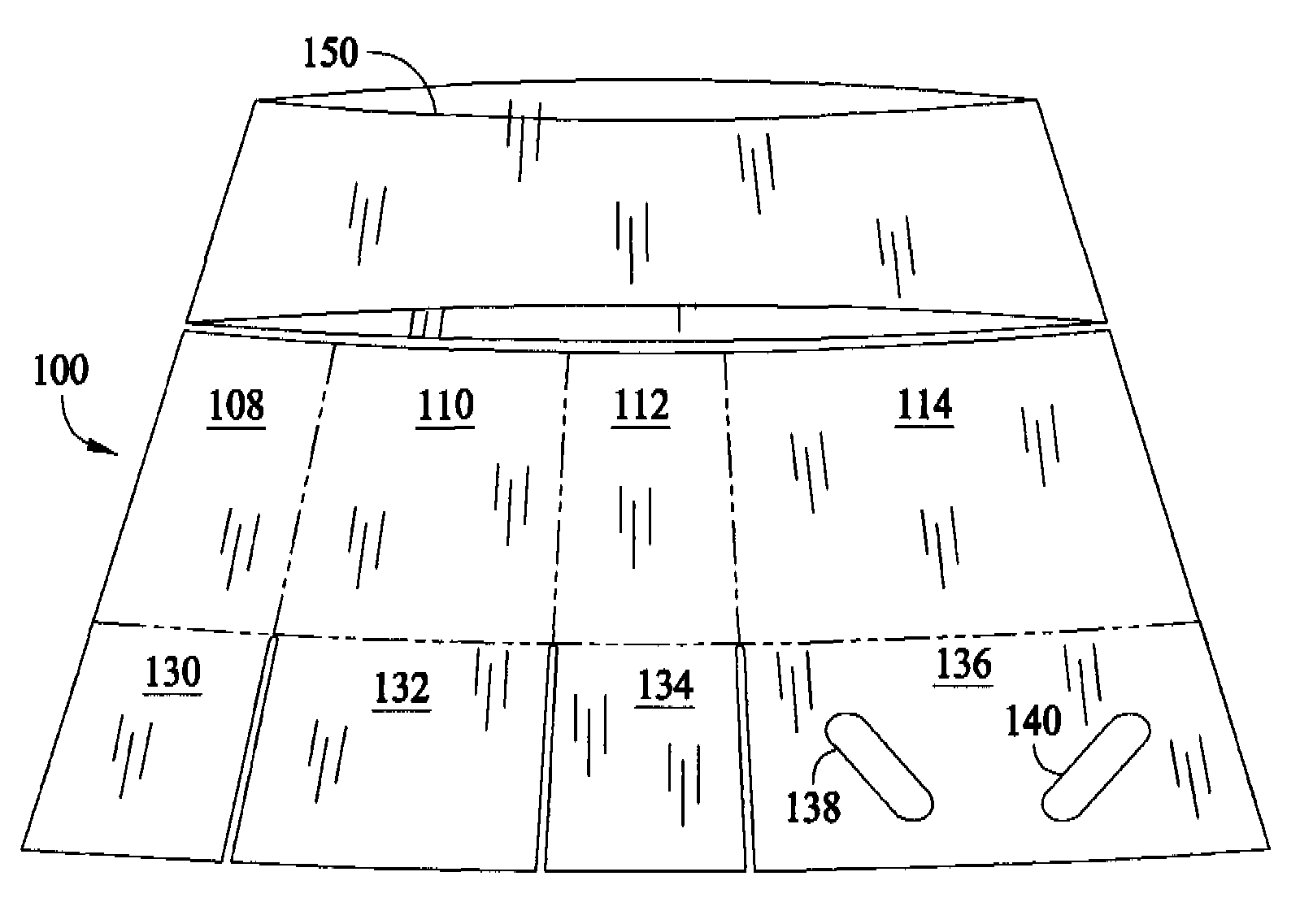

The present invention relates to a bulk bin for use with a liner bag. The bulk bin includes a sub-structure that is configured to receive forktines of lifting machinery for moving the bulk bin and a collapsible upper assembly that can support a bag with an entrance thereof in an upwardly facing orientation for filling. The bulk bin also includes at least one self supporting stiffened lid, and suitably a pair of lids. The lids may be pivoted from a closed position to an open position by orienting the bin into an inclined position in which the lids can open under gravity.

Owner:MATERIALS HANDLING SYST AUSTRALIA

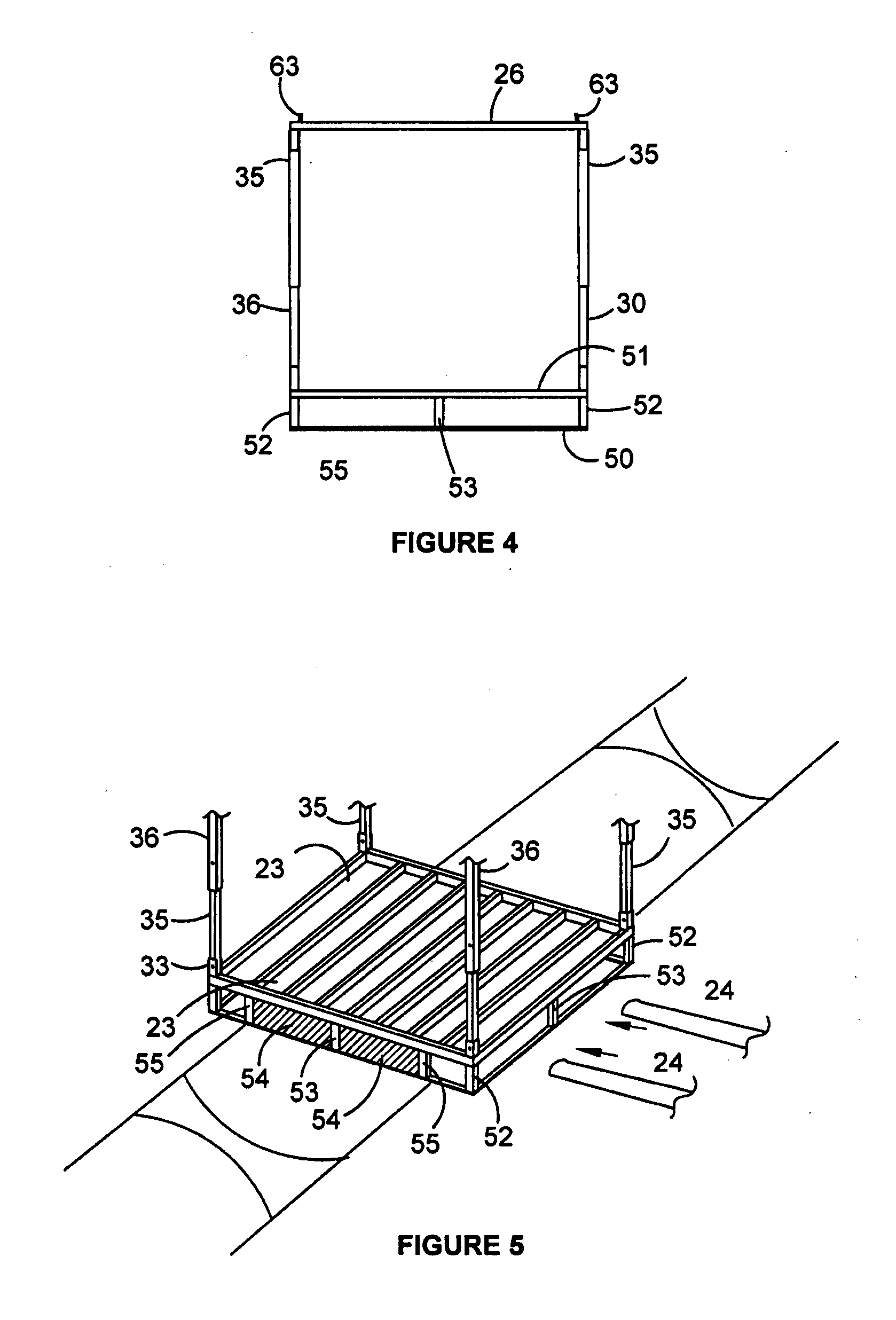

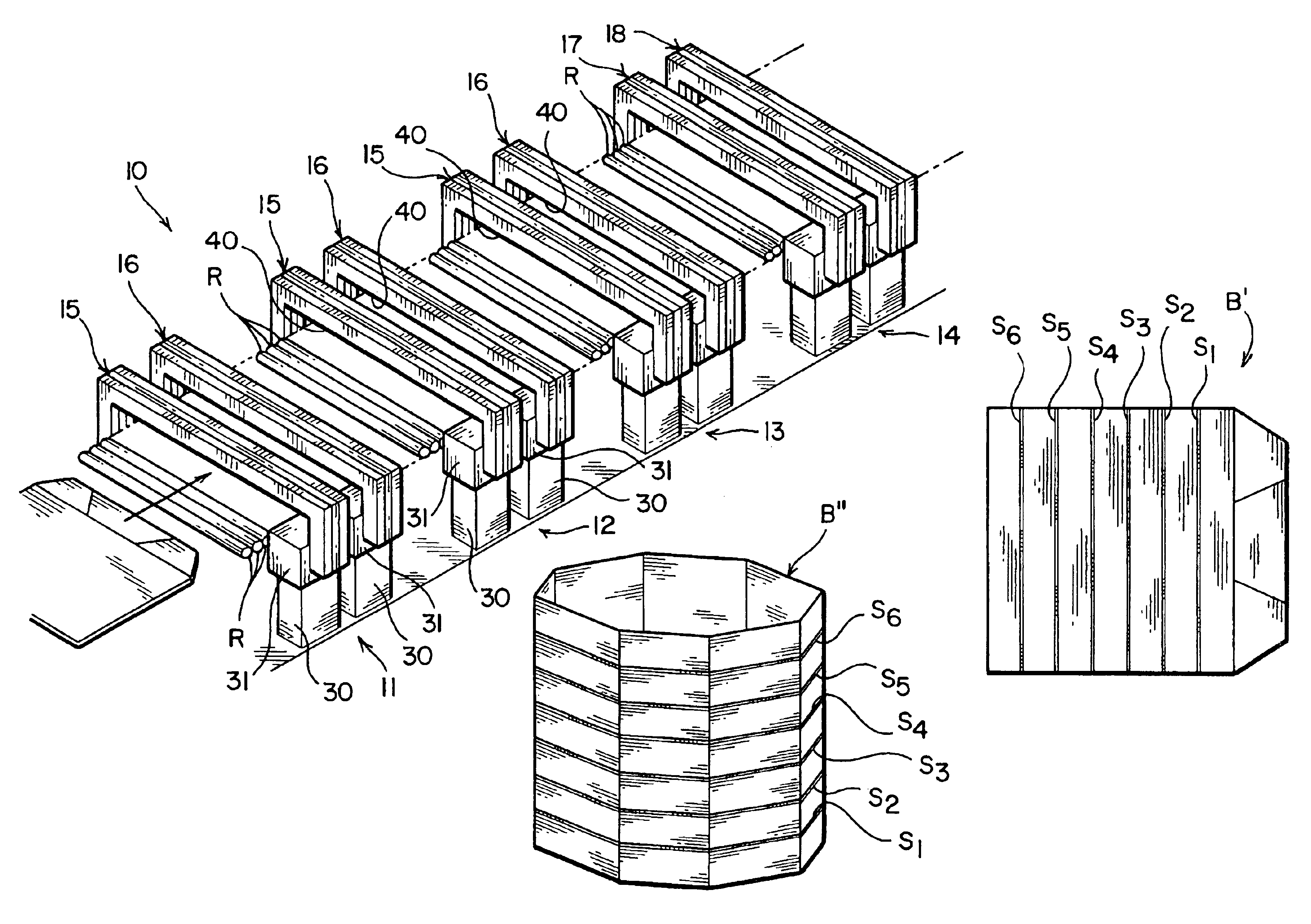

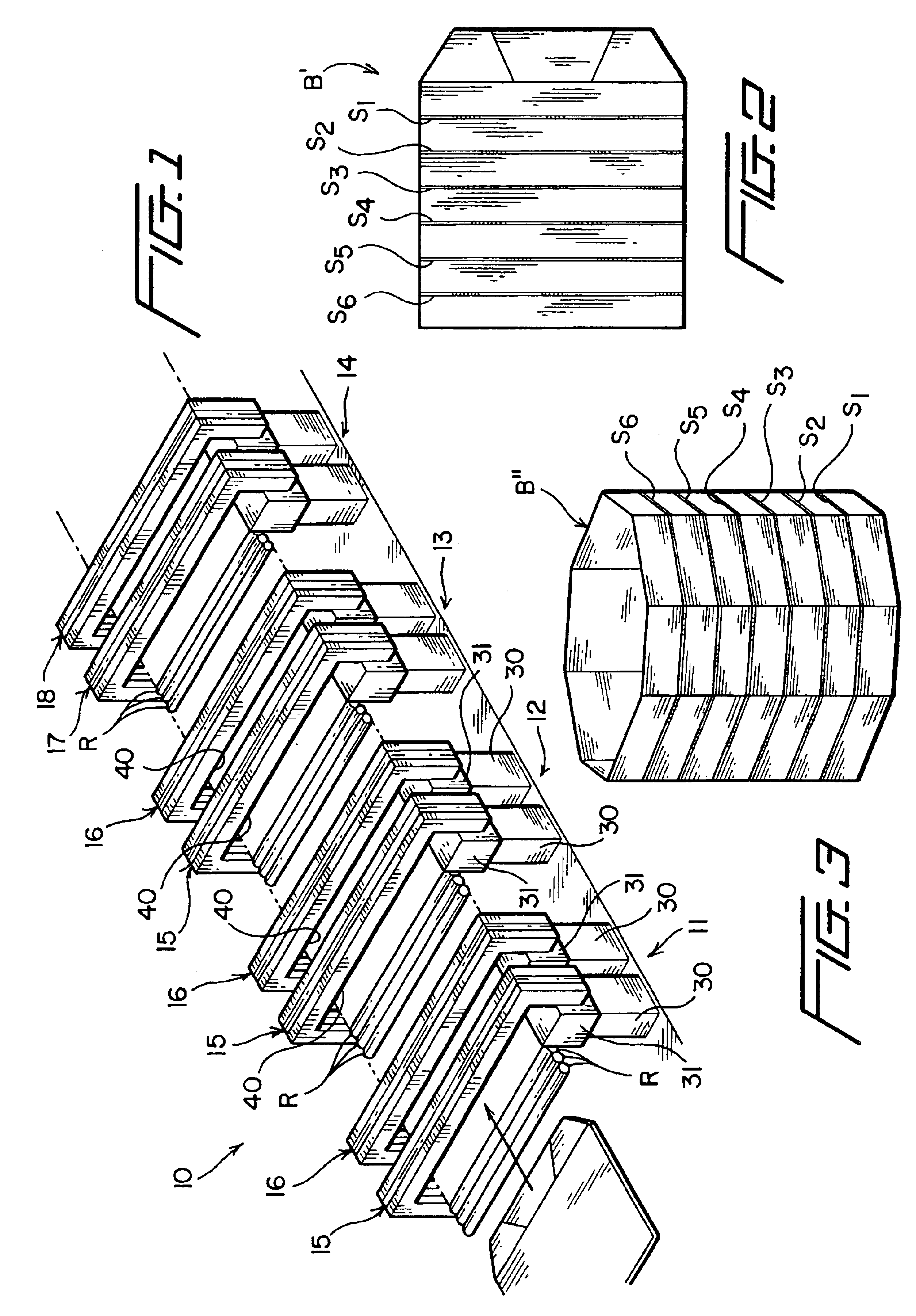

Method and machine for constructing a collapsible bulk bin

A machine for making a reinforced, collapsible bulk bin assembly is provided. The machine includes a body blank feeding device for providing a body blank from a stack of body blanks, an erecting device for partially erecting the body blank, a folding device for partially folding a bottom blank, a bottom insertion device for inserting the partially folded bottom blank into the partially erected body blank, and first fingers for attaching major flaps of the body blank to the bottom blank. The machine also includes second fingers for attaching minor flaps of the body blank to major flaps of the body blank, wherein the erecting device collapses the partially erected body blank after the first fingers attach the major flaps to the bottom blank.

Owner:WESTROCK SHARED SERVICES LLC

Bulk bin with auto-closing bottom

Owner:INT PAPER CO

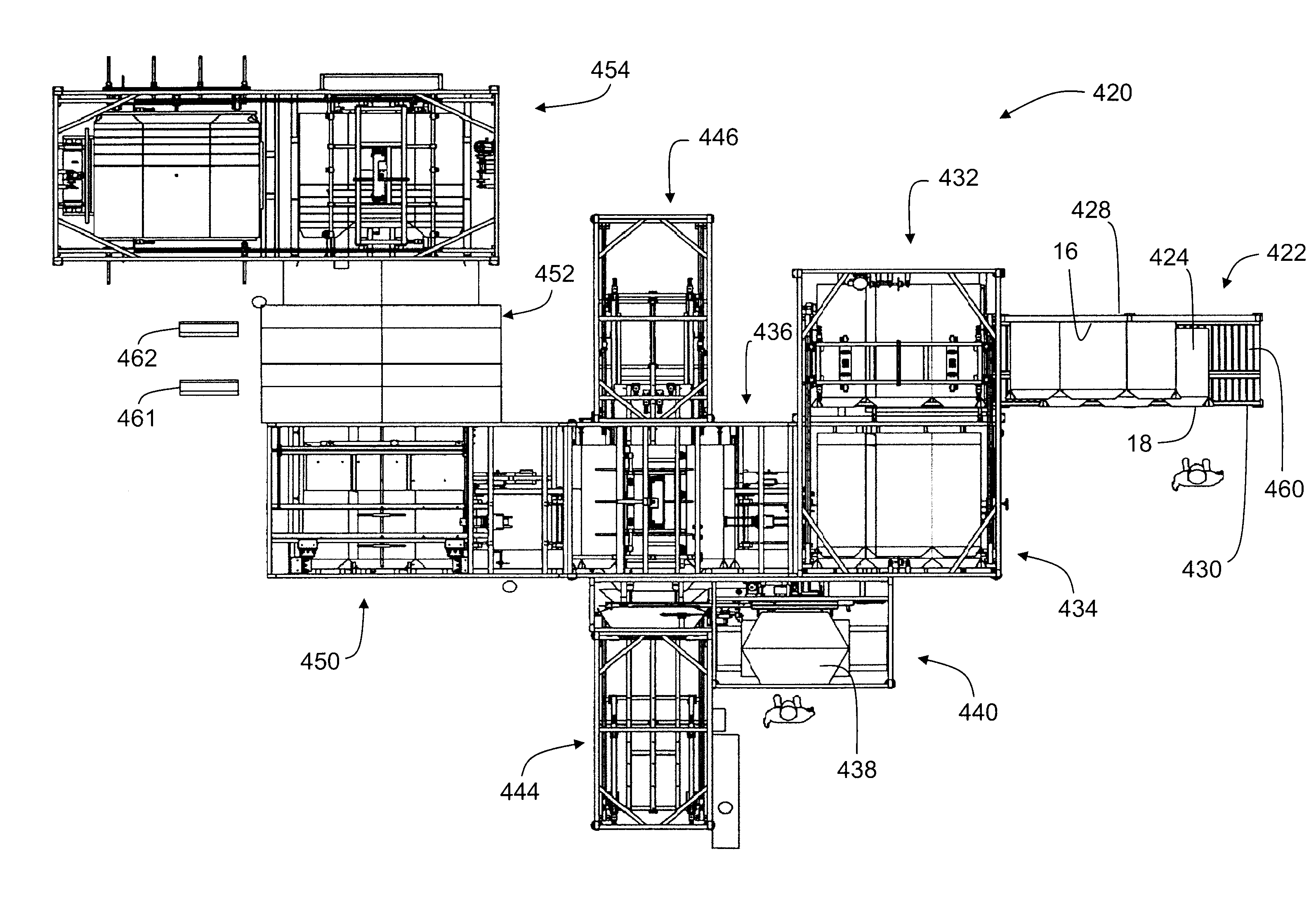

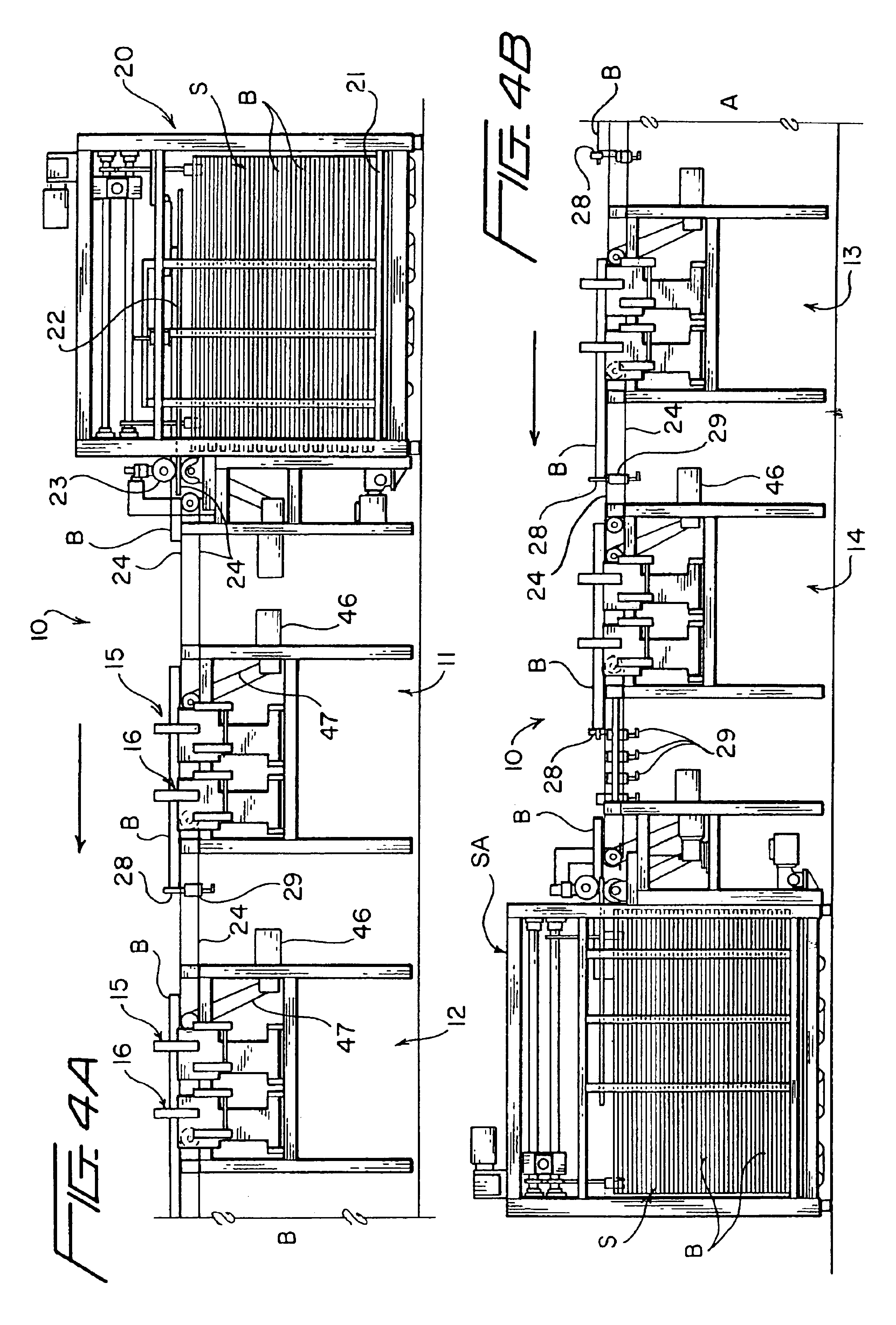

Automated bulk box strapper

A machine and method for applying reinforcing strapping to bulk boxes. The machine includes a plurality of strapping head assemblies arranged in series, with each adapted to apply a strap in encircling relationship to a box at a predetermined location on the box. As the box advances through successive strapping head assemblies, straps are applied in predetermined spaced relationship on the box, until the desired number of straps have been applied. The number, spacing and tension of the straps may be quickly and easily adjusted. In an embodiment of the invention, the strapping head assemblies are arranged in pairs in individual modules. A recovery strapping head assembly is provided just prior to exit from the machine to apply any strapping missed by a preceding strapping head assembly.

Owner:INT PAPER CO

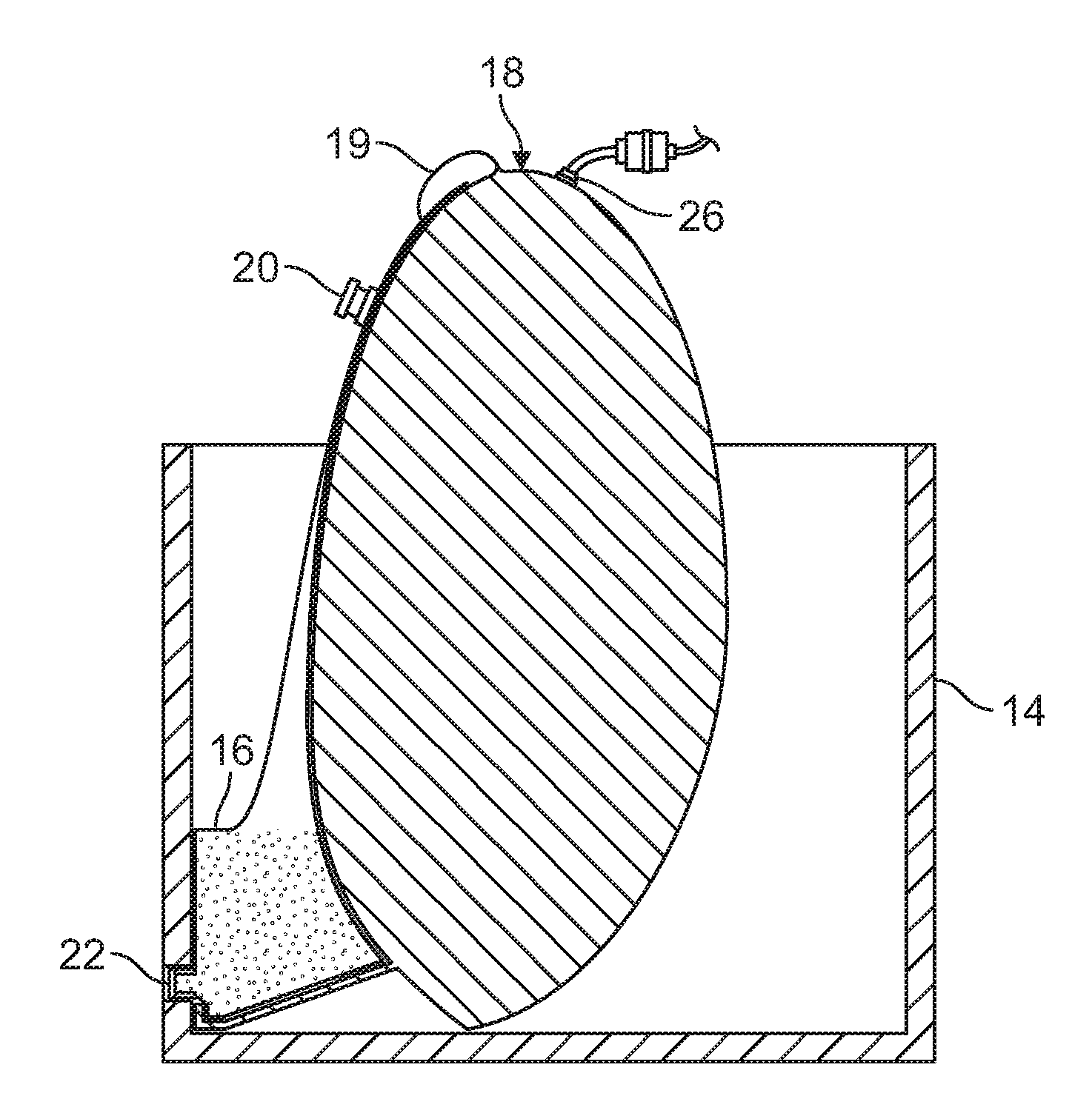

System for complete dispensing of flowable materials from a bulk shipping container

ActiveUS20170008697A1High quality plastic materialGood flexibilityLarge containersLiquid transferring devicesBulk boxEngineering

The present invention is directed to a system for fully dispensing liquid from a bulk shipping container. The system includes a bulk bin and a cassette disposed therein. The cassette includes a cassette board, a liquid bag having inlet and outlet ports and an air inflated bag that is attached to the liquid bag. The air bag includes an air inlet port formed at one end thereof and used for inflating the air bag from a source of pressurized air. The air bag further includes an obstruction region defined by a weld line that is formed on an opposite end from the air inlet port to redirect the pressurized air within the air bag when inflating the air bag reaches a level at which the pressurized air counteract the liquid pressure within the liquid bag so as to urge the liquid toward the outlet port of the liquid bag.

Owner:INT PAPER CO

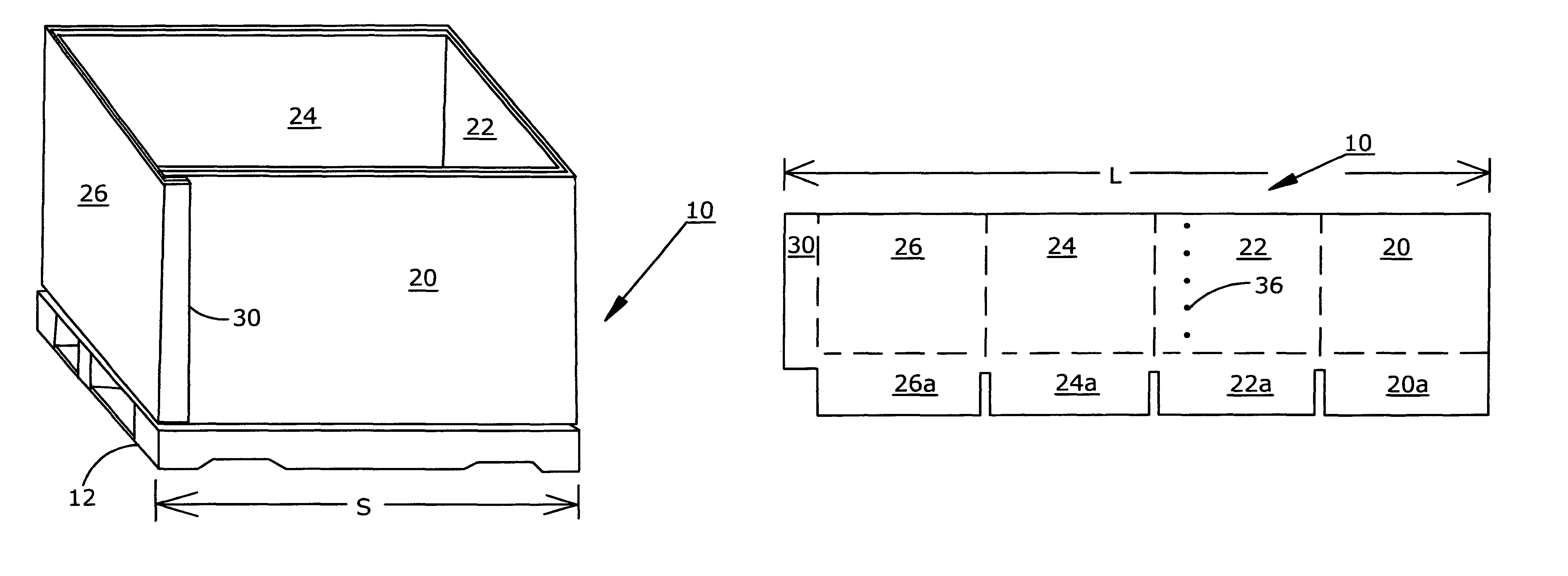

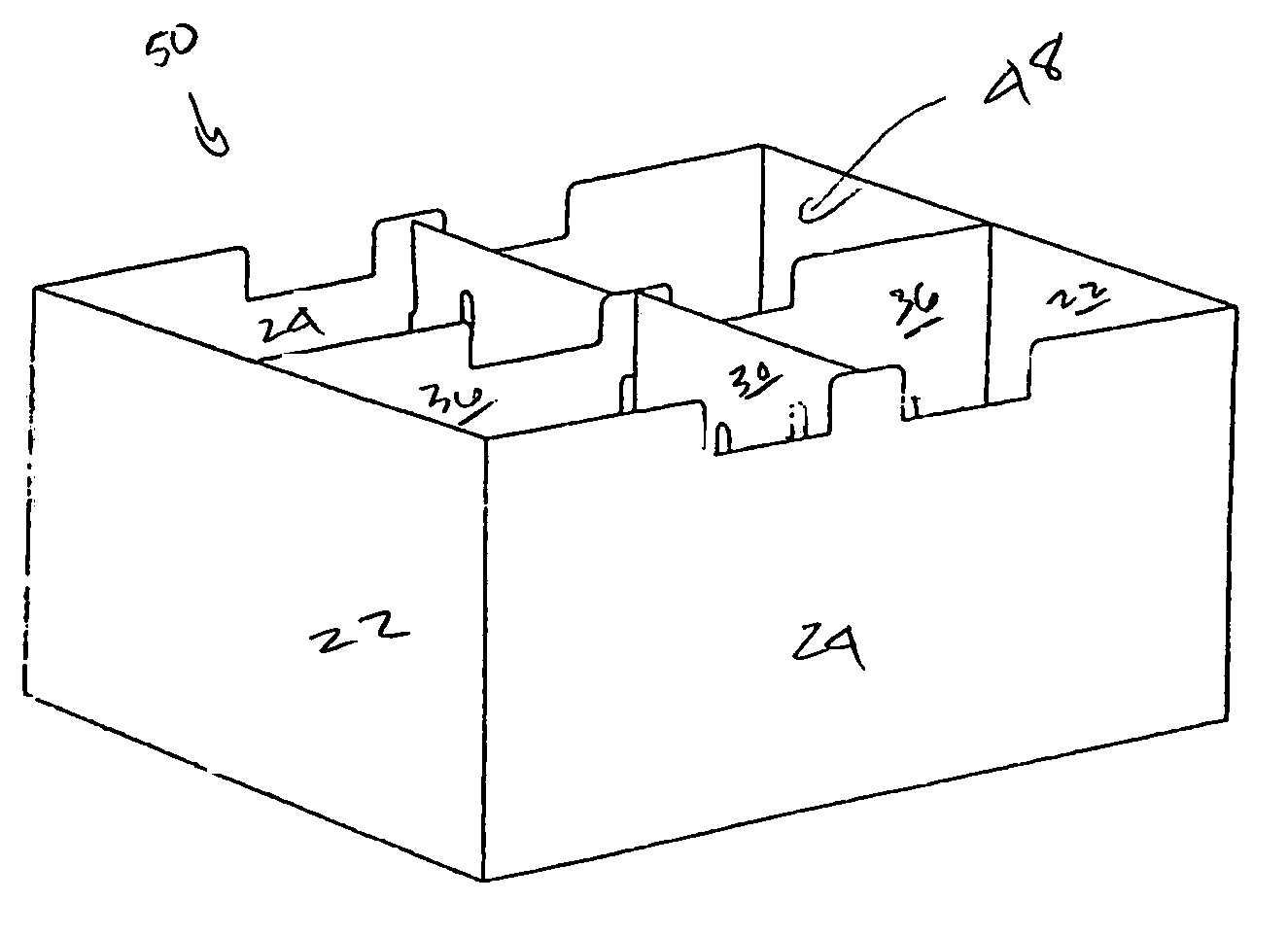

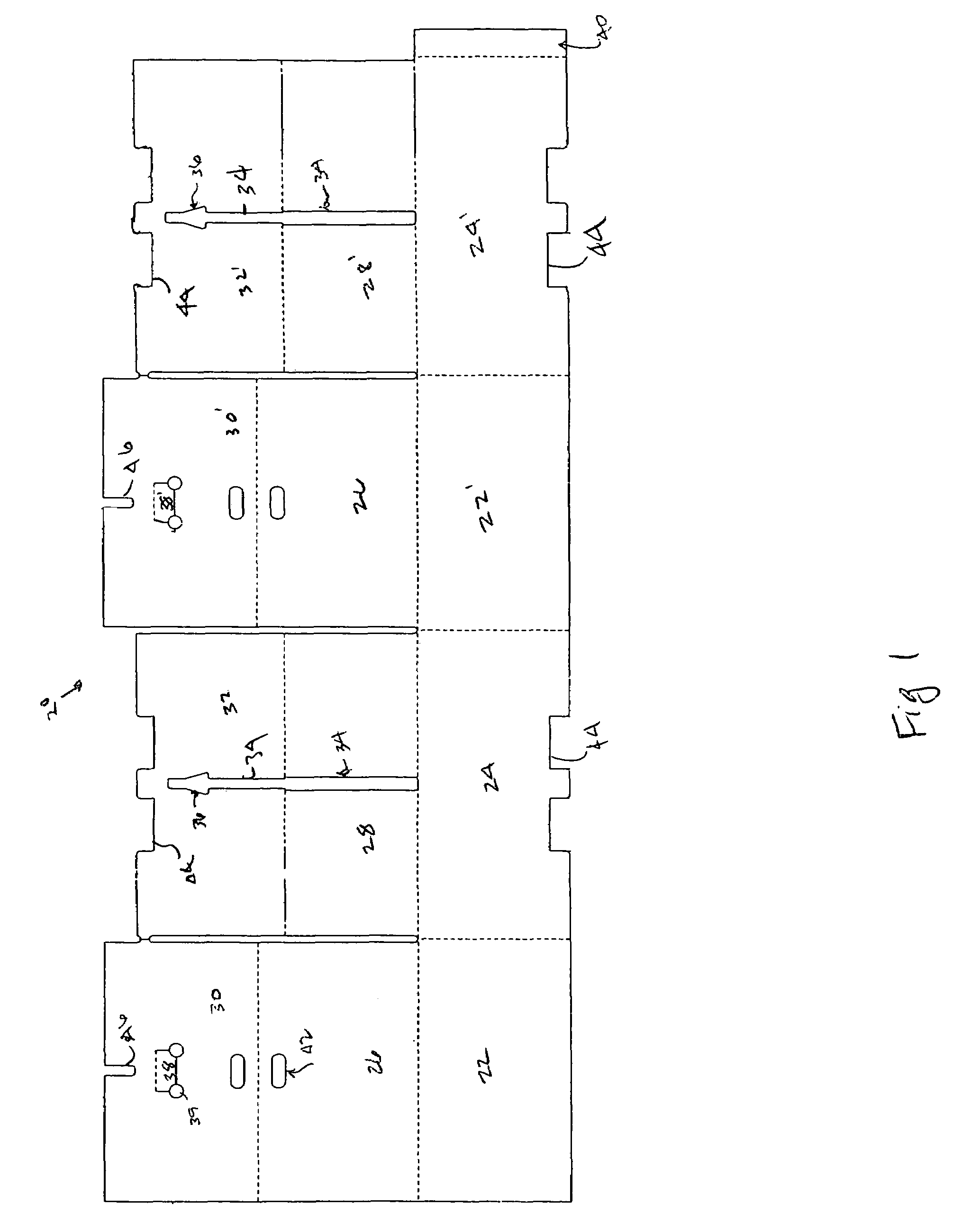

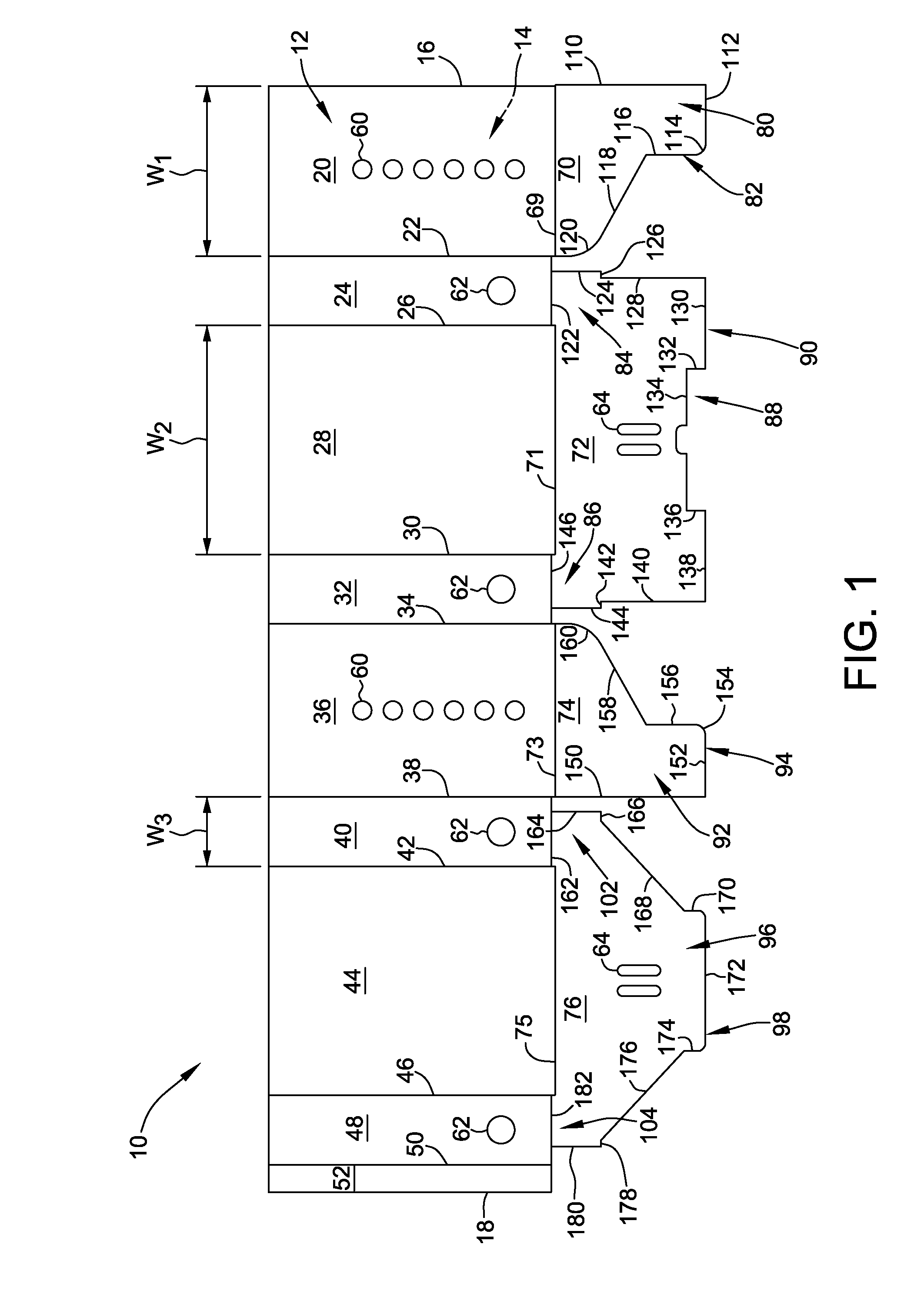

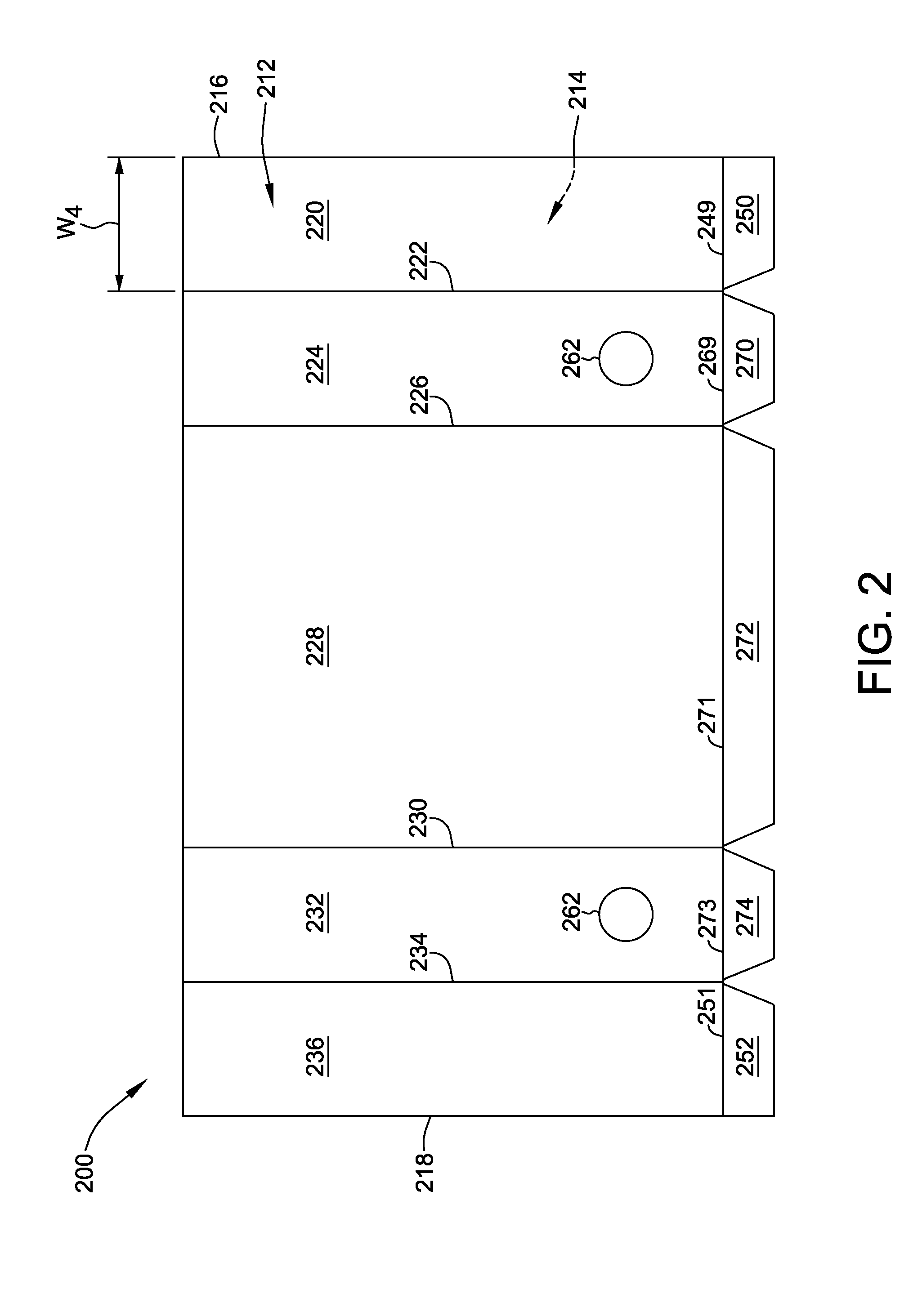

Single piece bulk bin blank and container

The present invention is directed to a divided bulk bin container and blank. In accordance with the present invention, a single sheet of foldable material is cut and scored to define container blank. The blank includes a pair of opposed first side panels and a pair of a opposed second side panels coupled with the first side panels. An outer bottom panel is connected with said first side panel and an inner bottom panel is connected with said second side panel. Also, a first divider panel is connected with said outer bottom panel and a second divider panel is connected with said inner bottom panel. Further, a divider slot is formed in said inner bottom panel and said second divider panel. The nature of the divider slot is such that the width of said divider slot is at least twice the thickness of the first divider panel.

Owner:INT PAPER CO

Bulk Bin Container with Removable Side Wall

Owner:ORBIS CORP

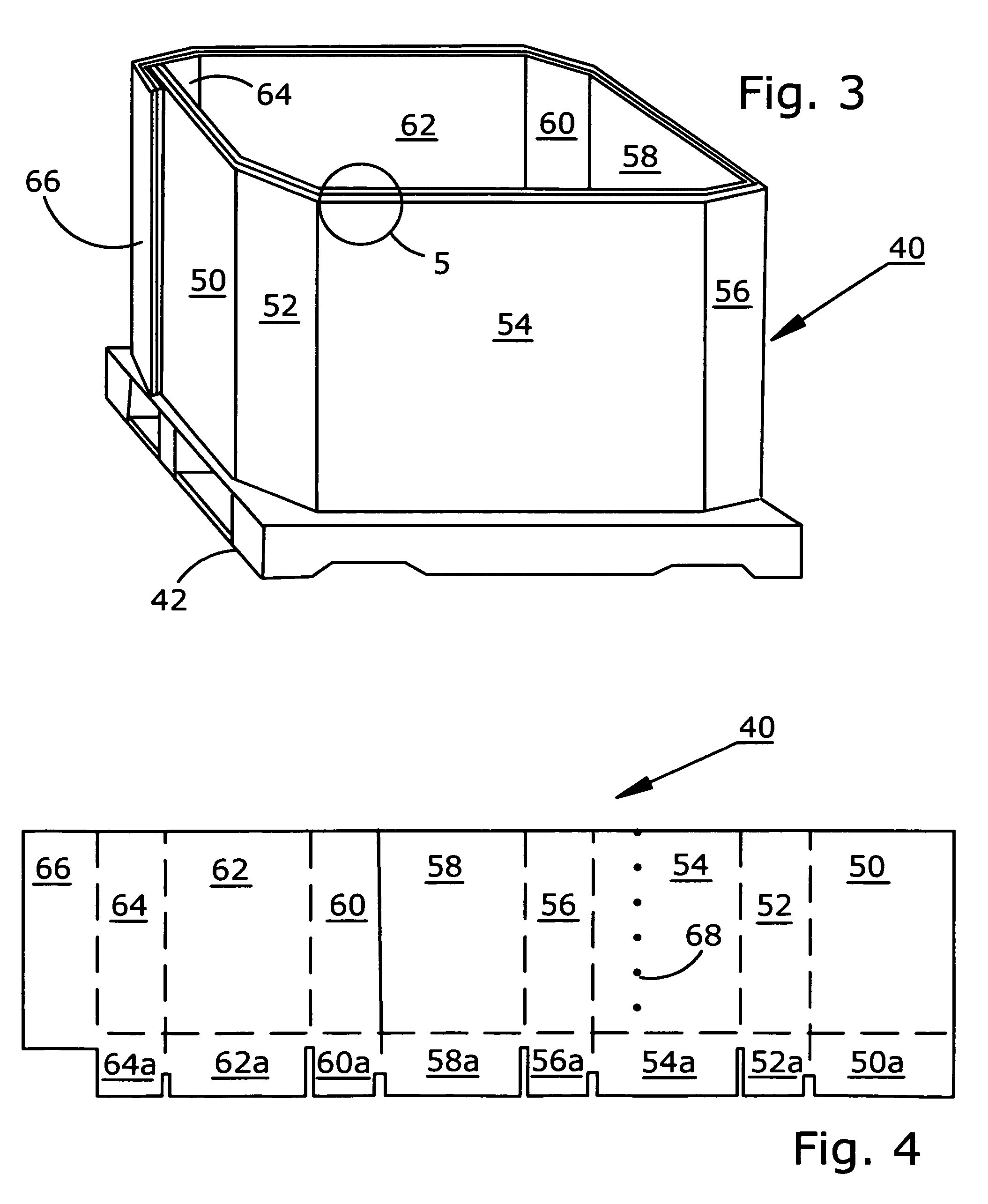

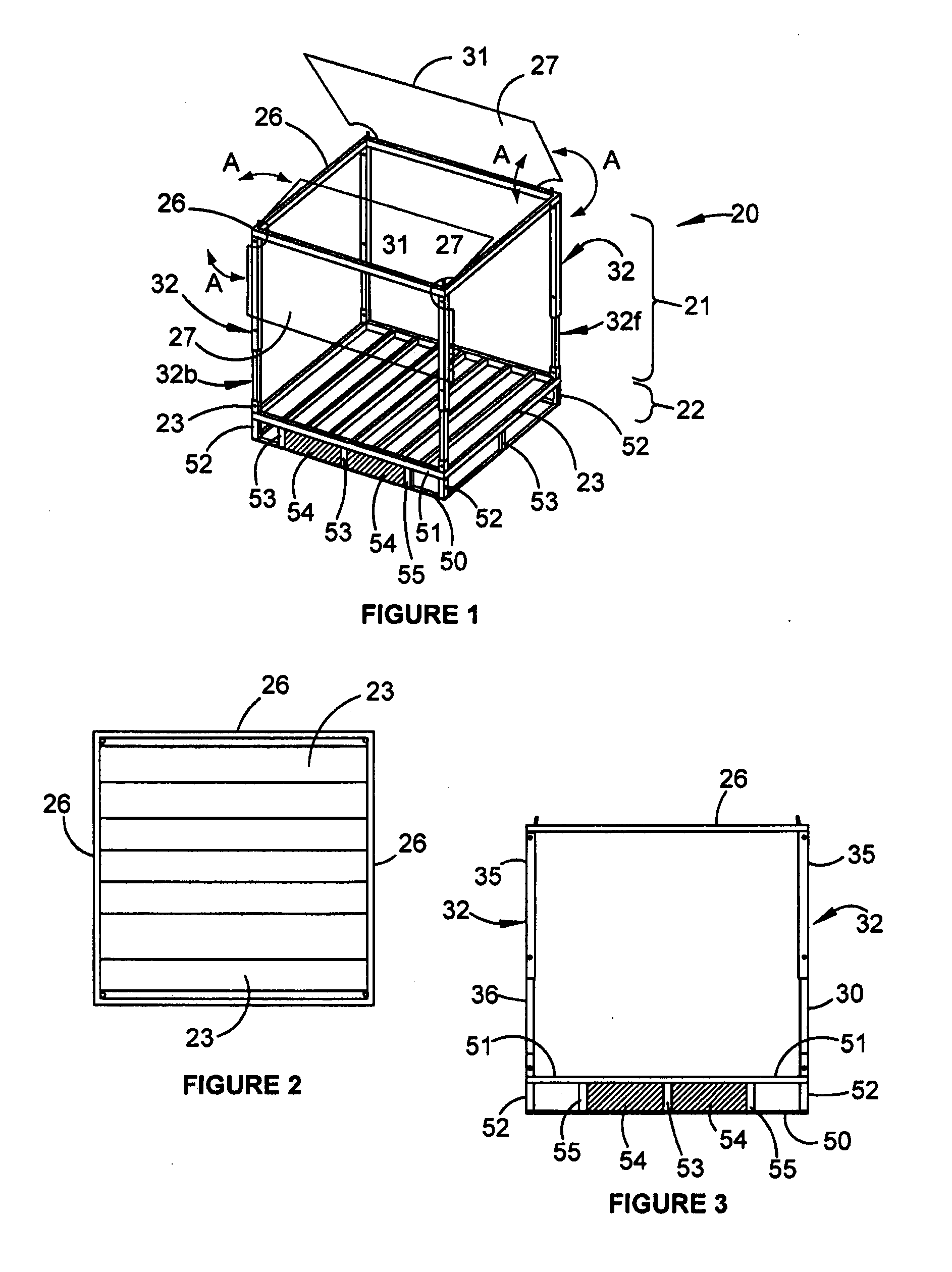

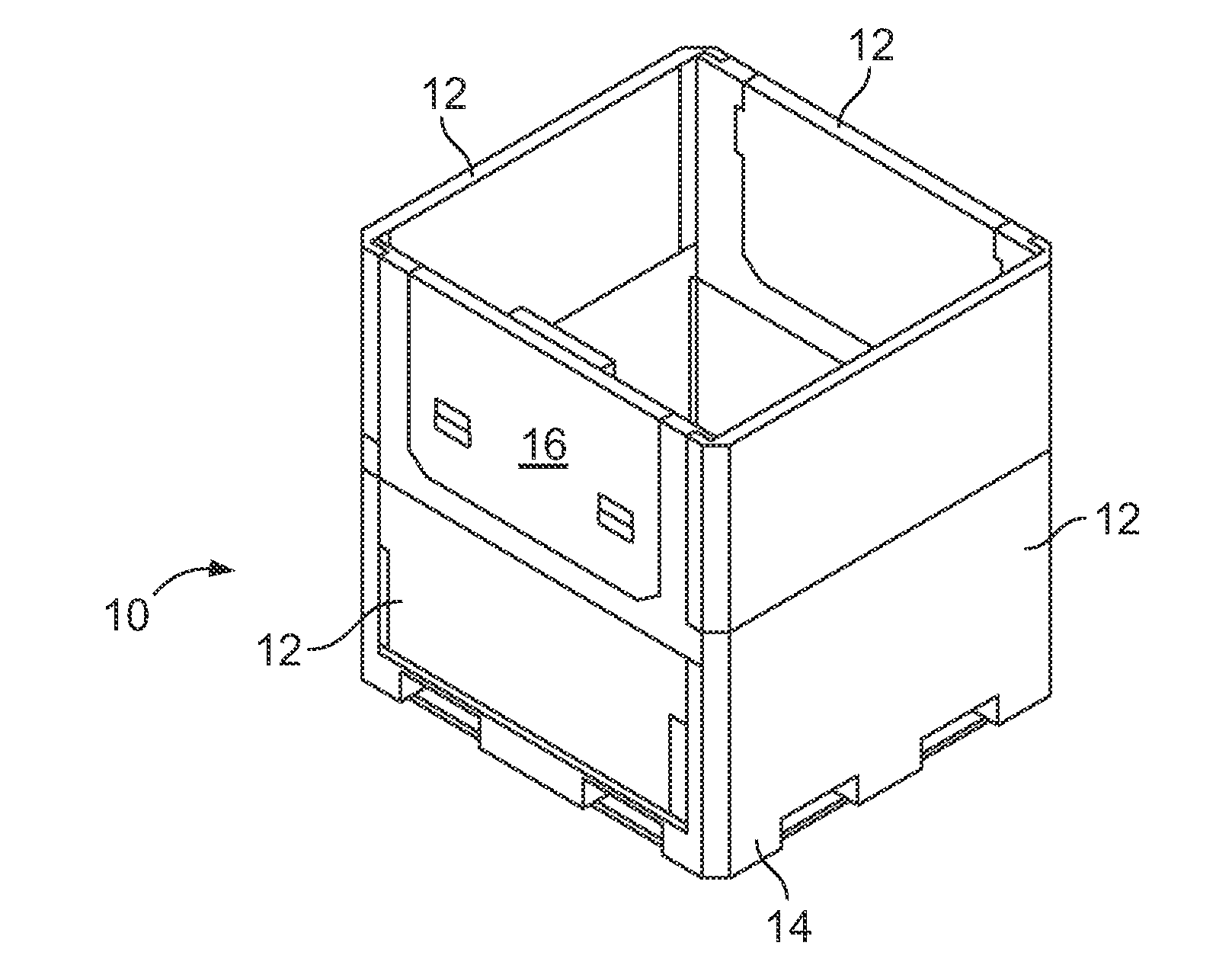

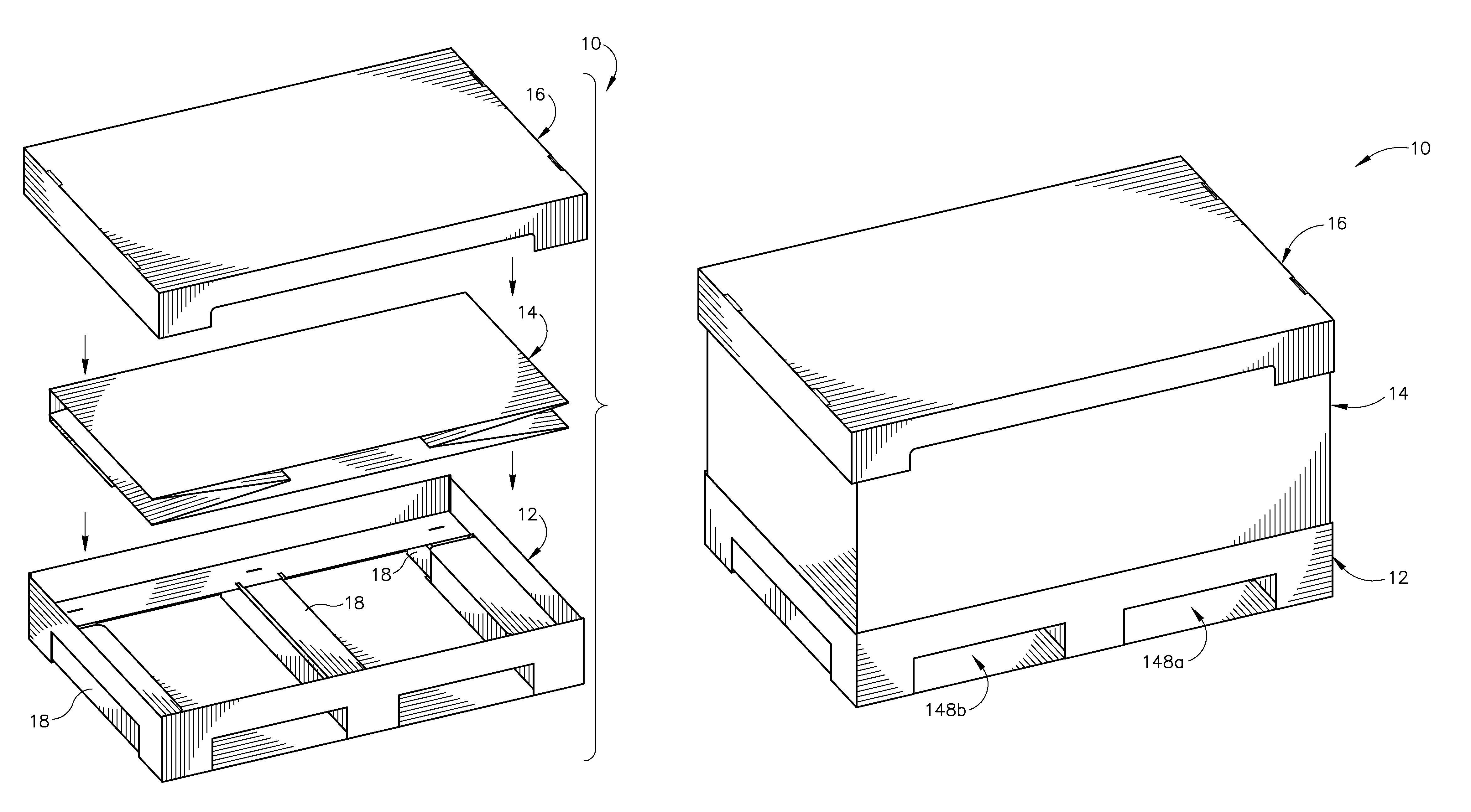

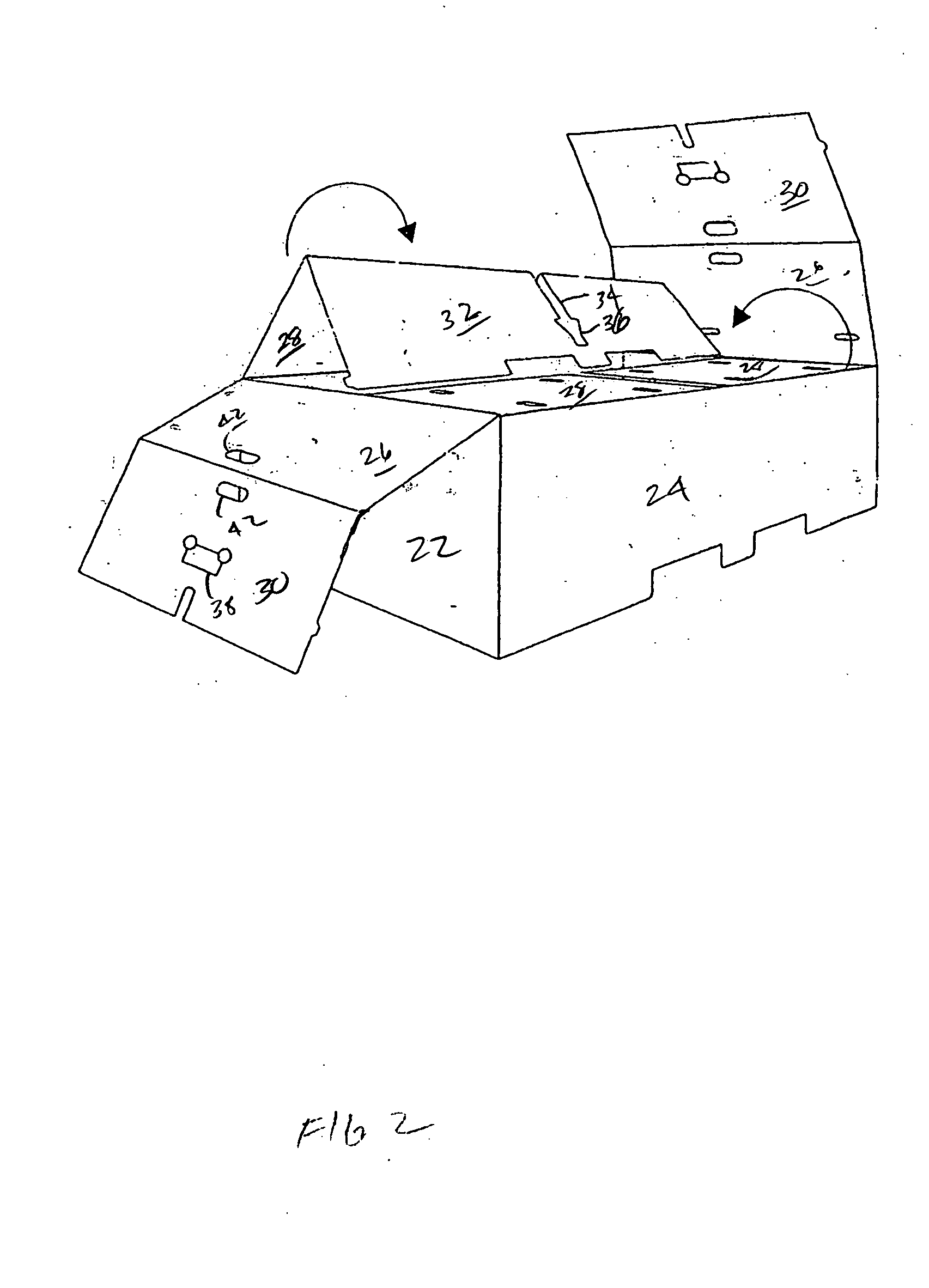

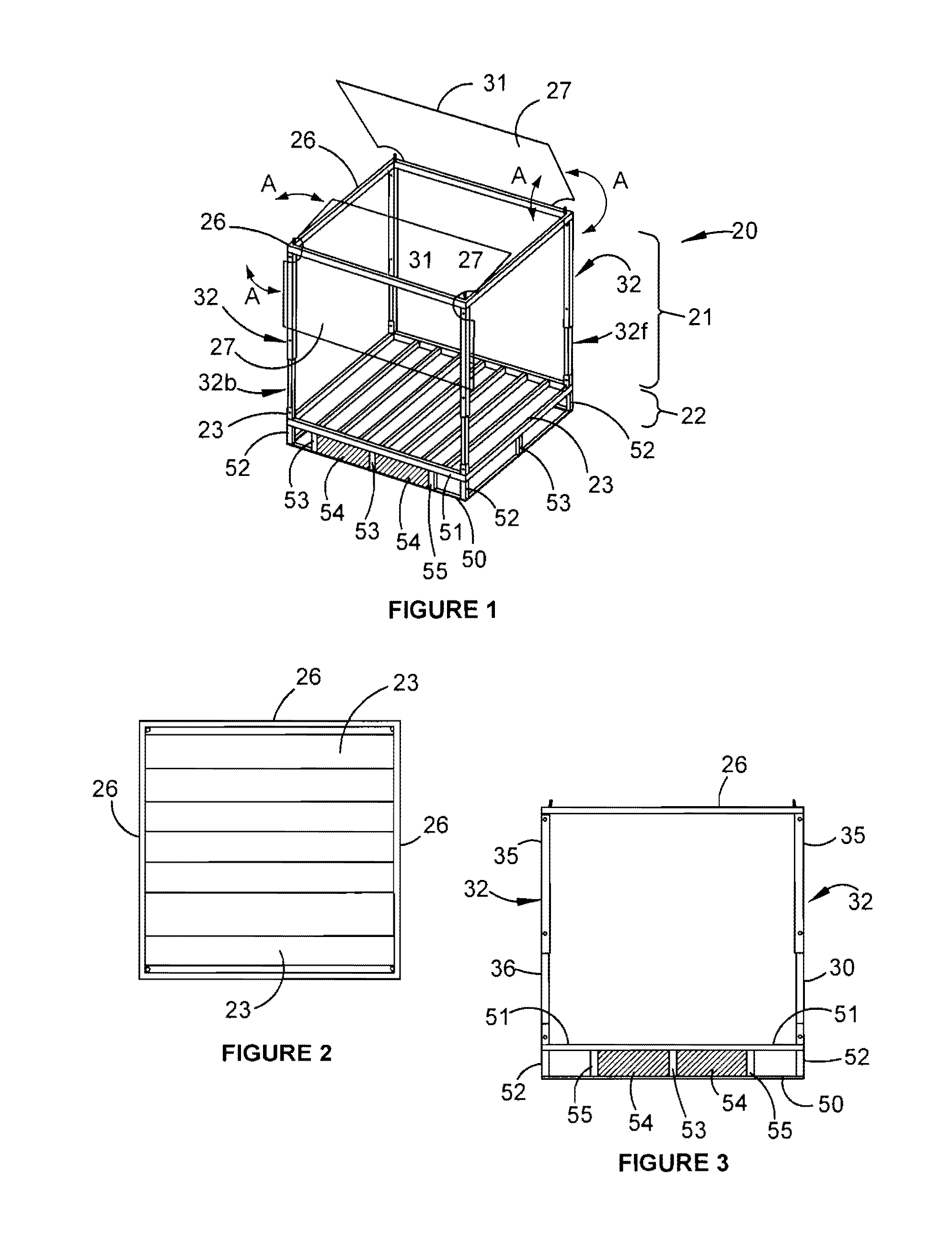

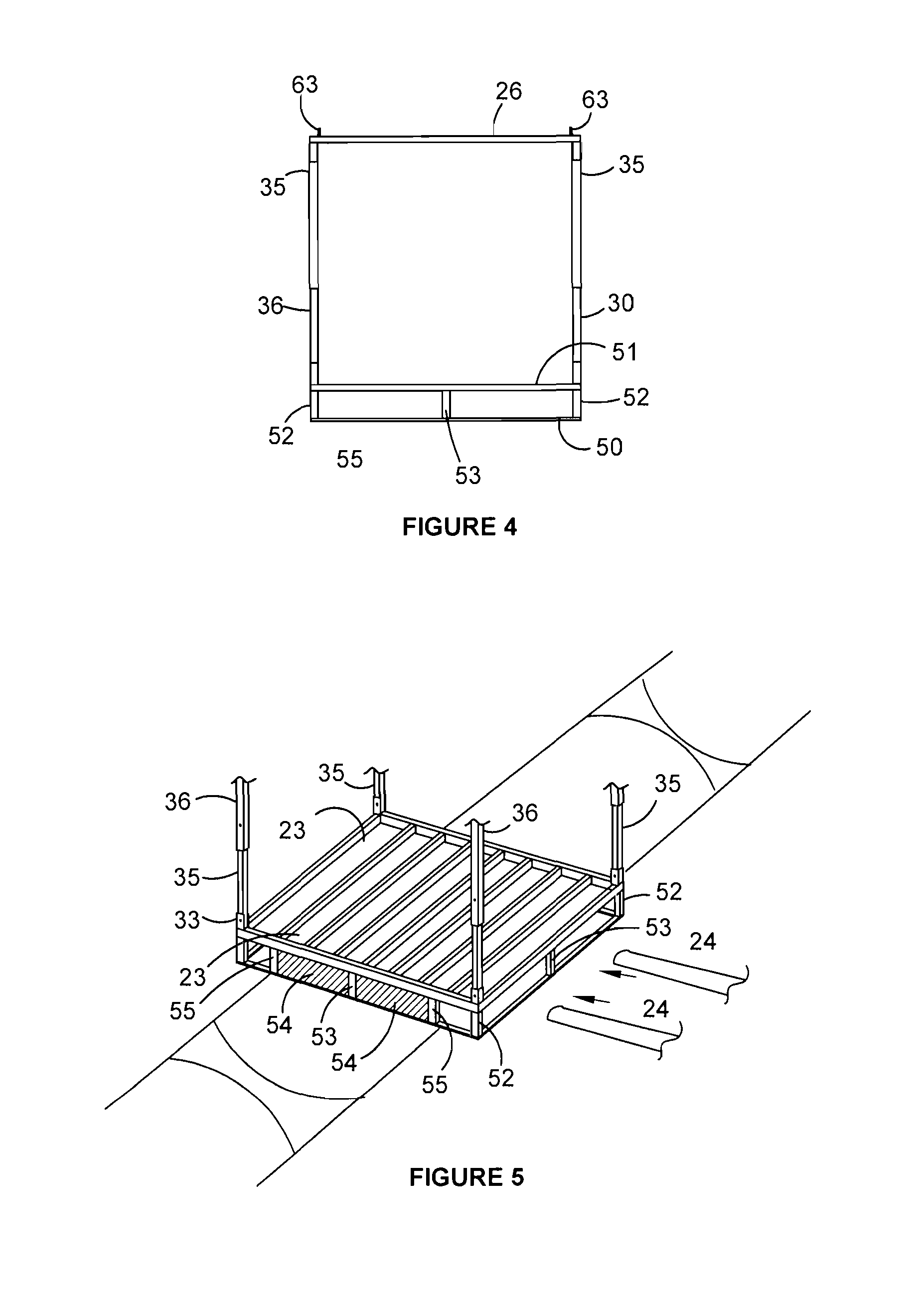

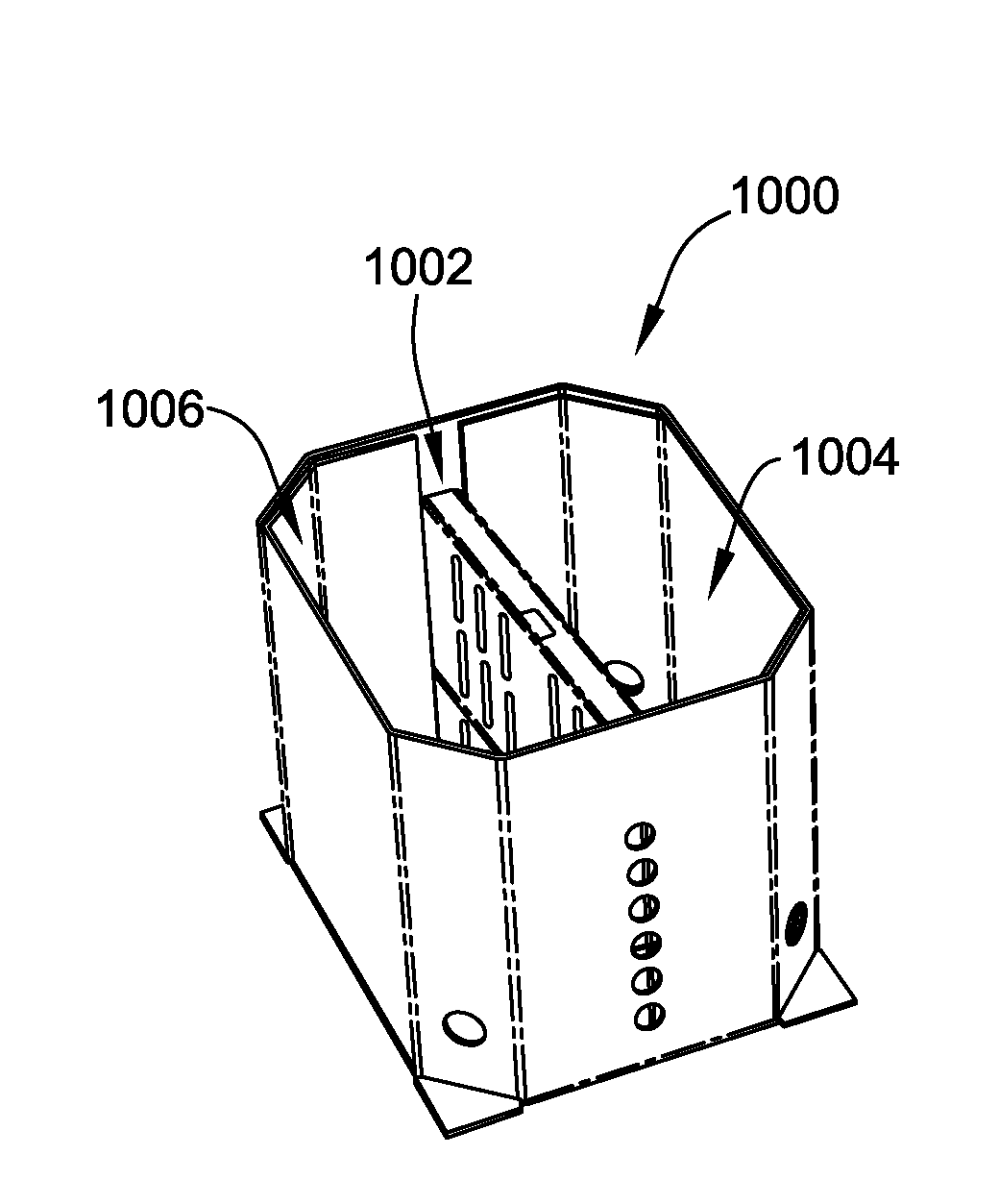

Collapsible bulk bin container

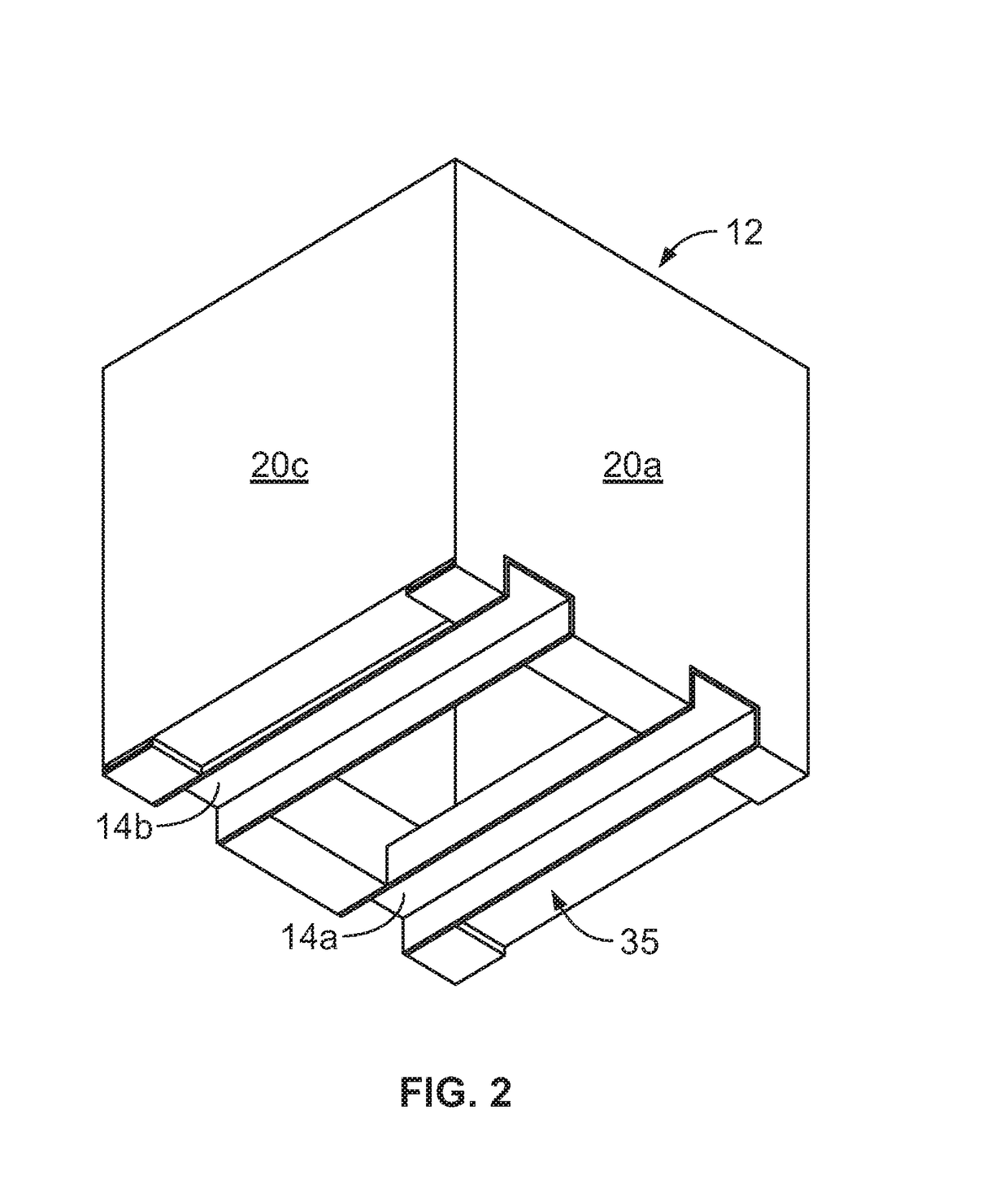

ActiveUS8783461B2The process is convenient and fastEfficient stackingBoxes/cartons making machineryBox making operationsInterior spaceFolded form

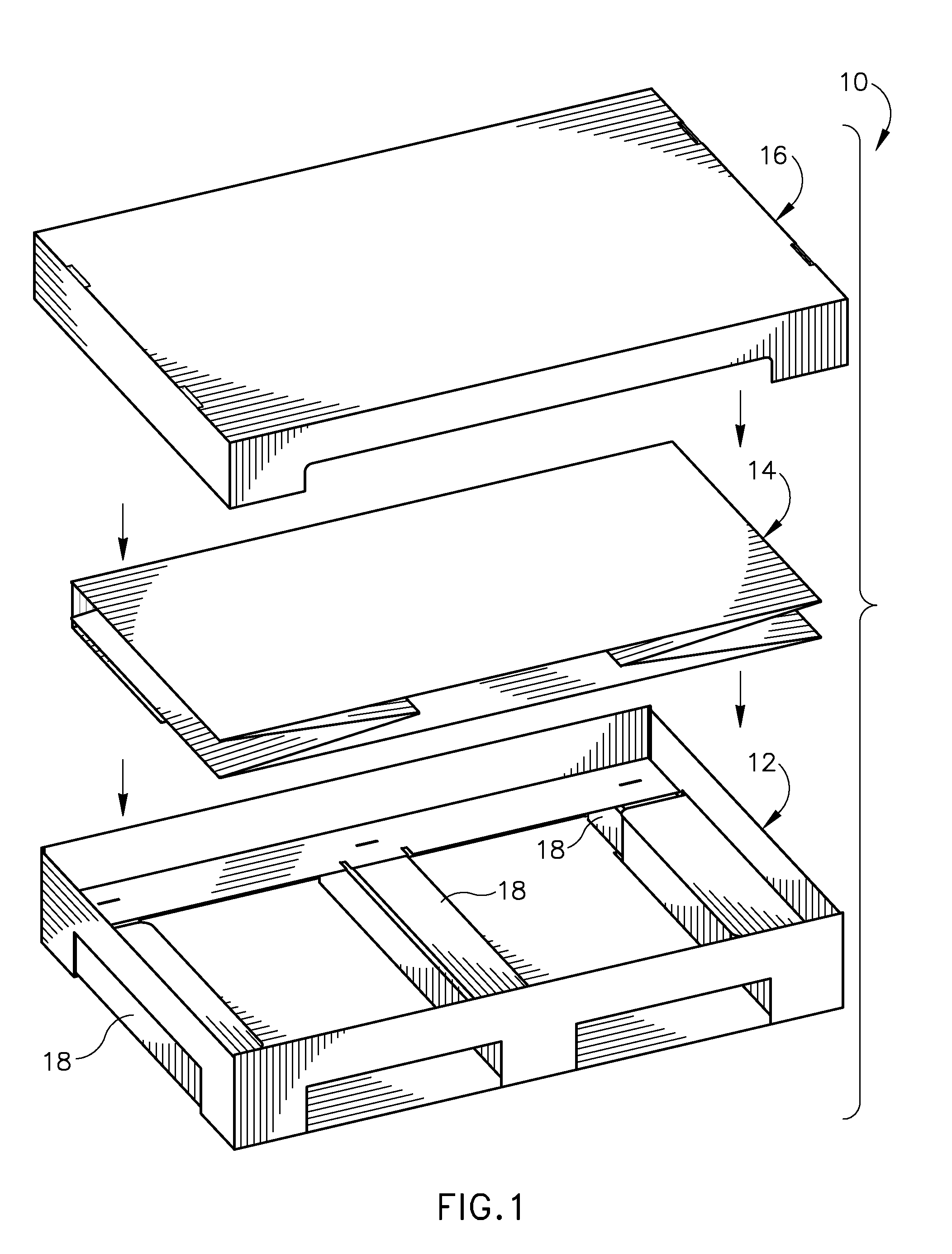

A collapsible shipping container is capable of configured from a collapsed position for storage and transportation to a constructed position for containment of articles therein and back again to the collapsed position after use. The collapsible shipping container comprises a foldable tray having at least two pallet runner sleeves spaced apart from one another and each of which being formed on respective opposed lateral edges of the foldable tray. A plurality of elongated pallet runners each of which having an inner support structure integrally formed thereto. The plurality of elongated pallet runners each of which is adapted to be inserted into each of the respective plurality of pallet runner sleeves. A foldable side wall body is adapted to rest upon the foldable tray to form an interior space to receive a plurality of articles. The foldable side wall body comprises end walls, side walls, and side body flaps to form an enclosed bottom thereof. Each of the end walls includes an articulation fold formed therein so that during the collapsed position, the articulation folds move toward the interior space and during the constructed position, the articulation folds move away from the interior space. A lid is configured to telescopically enclosing the collapsible shipping container.

Owner:VERITIV OPERATING CO

Reinforced bulk bin and methods for making same

A reinforced bulk bin, and methods for making same, wherein a collapsible bulk bin, preferably fabricated from paper, paperboard and / or corrugated paperboard, is provided with a reinforcing plastic sleeve, which is placed on the bin while in its collapsed configuration. When in place, and prior to the bin being deployed, the sleeve is under tension. When the bin is deployed, the sleeve exerts restraining force, distributed over the surfaces of the side walls of the bin. The sleeve may be positioned on the collapsed bin either manually or mechanically.

Owner:WESTROCK SHARED SERVICES LLC

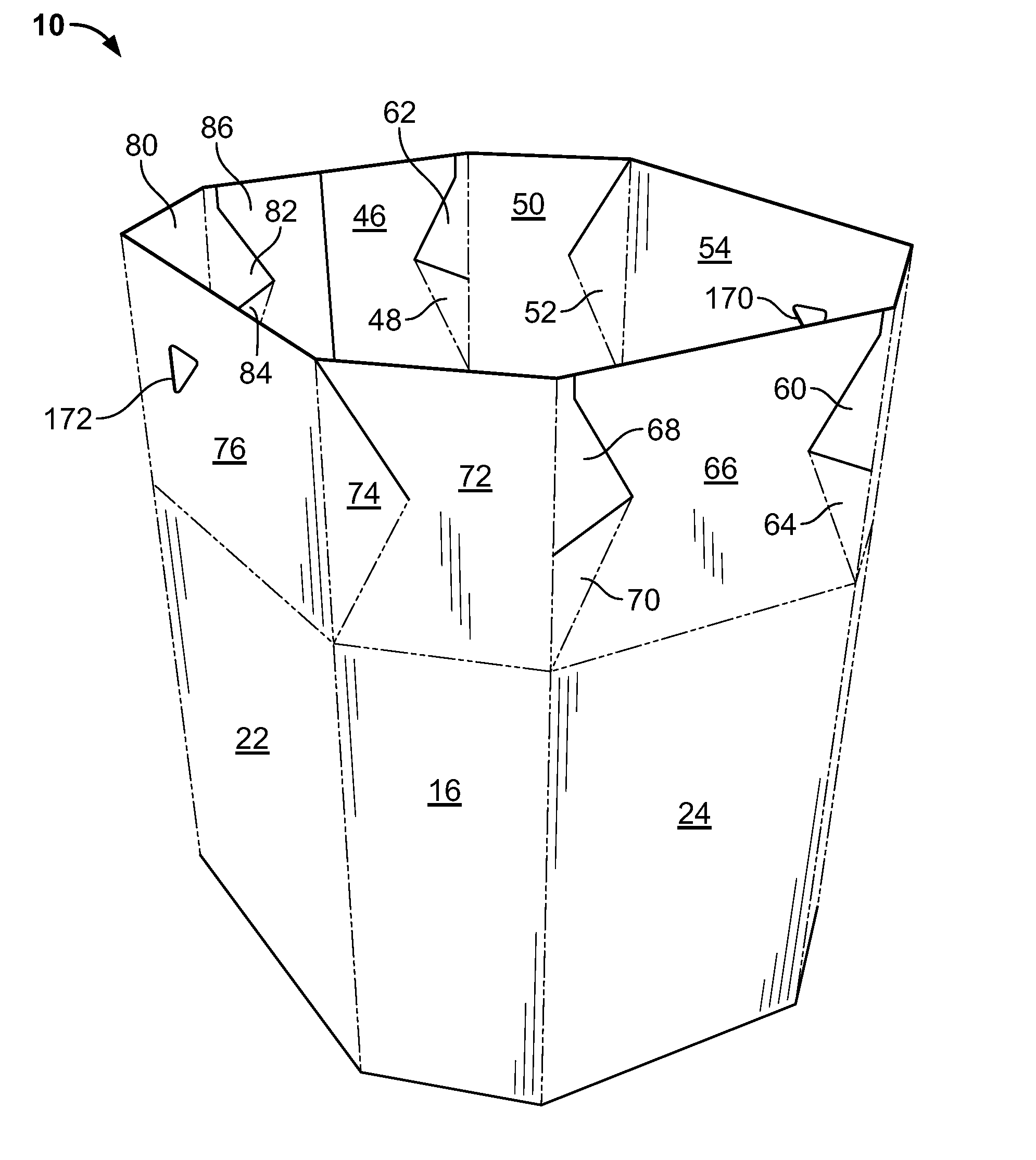

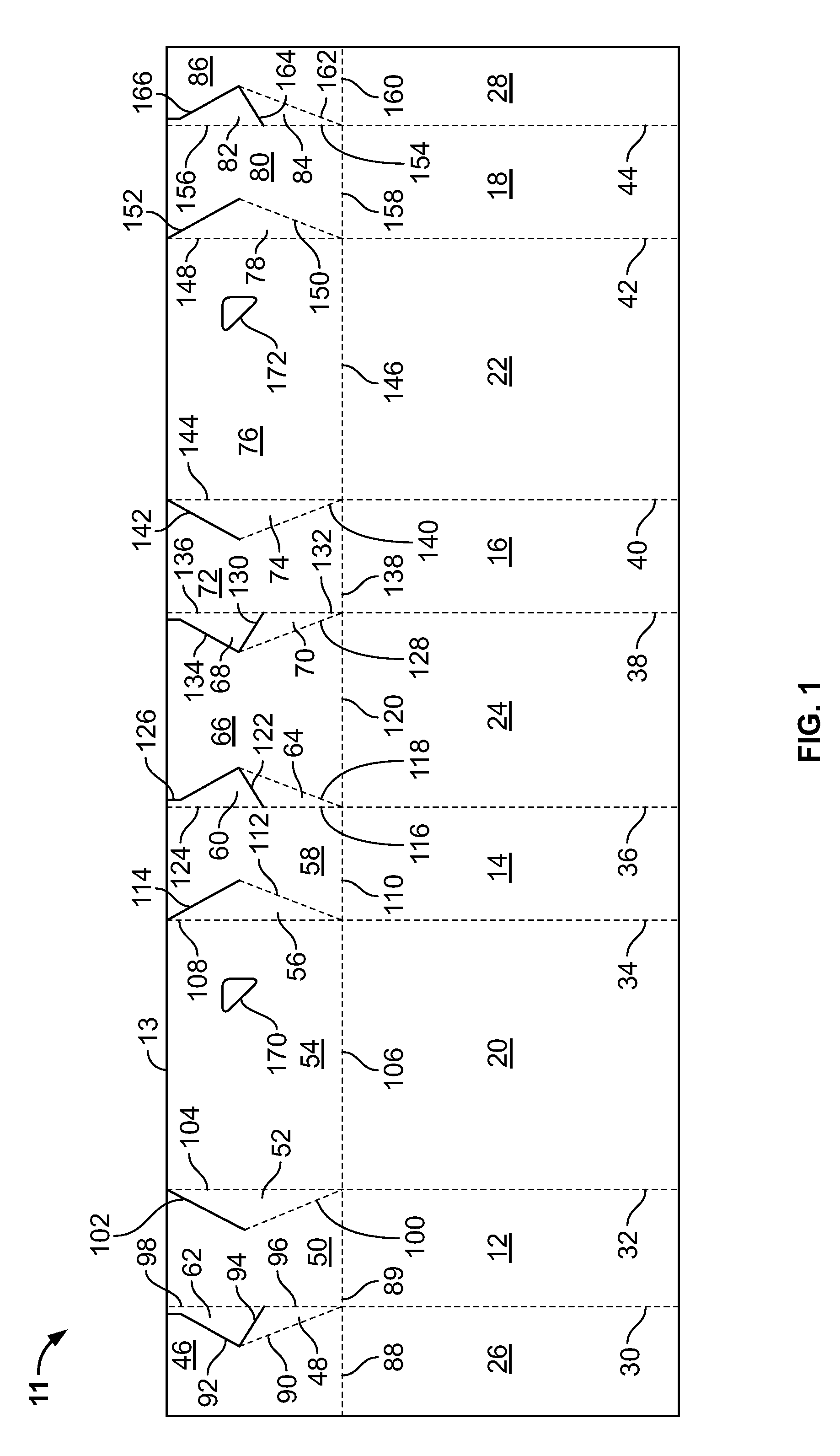

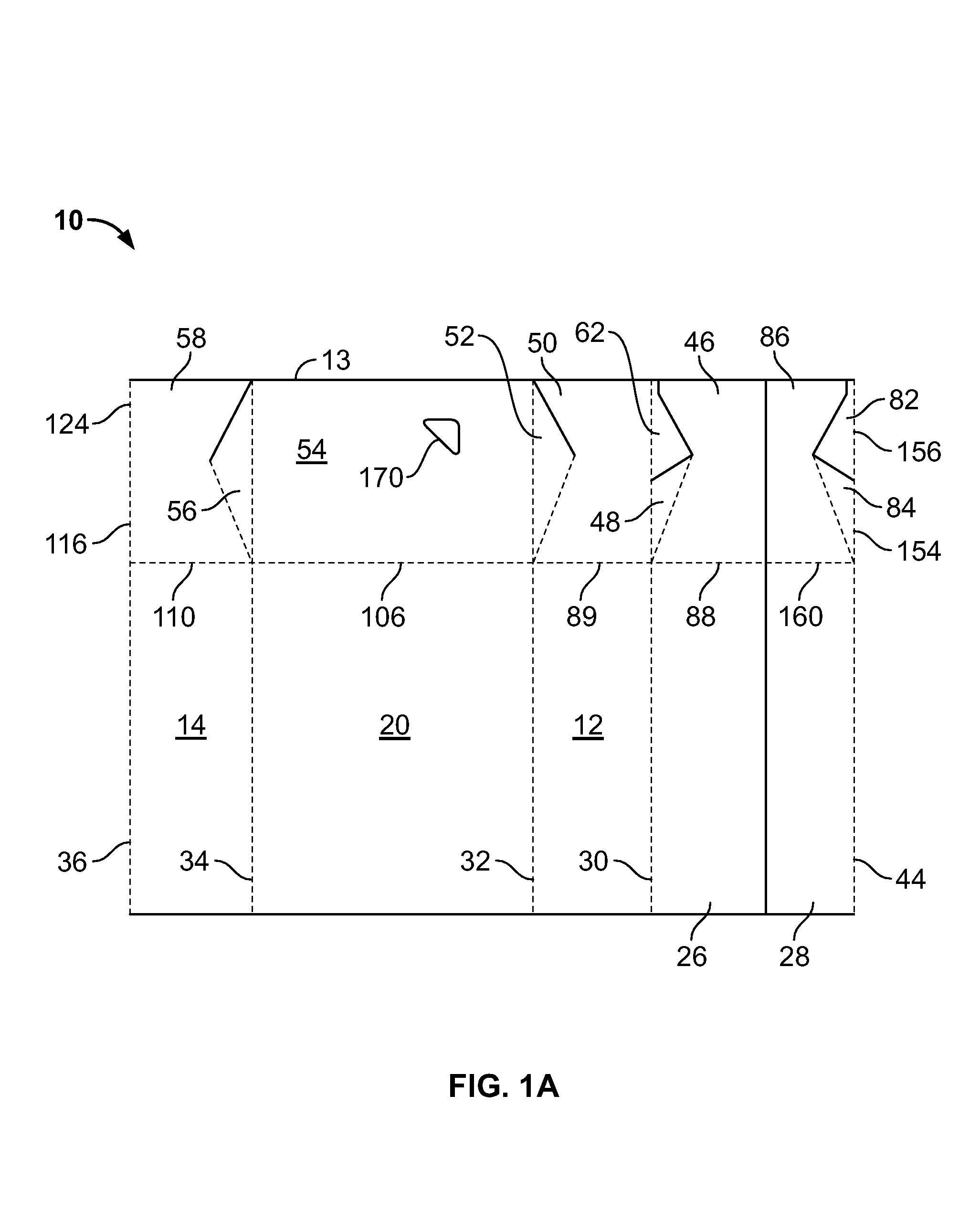

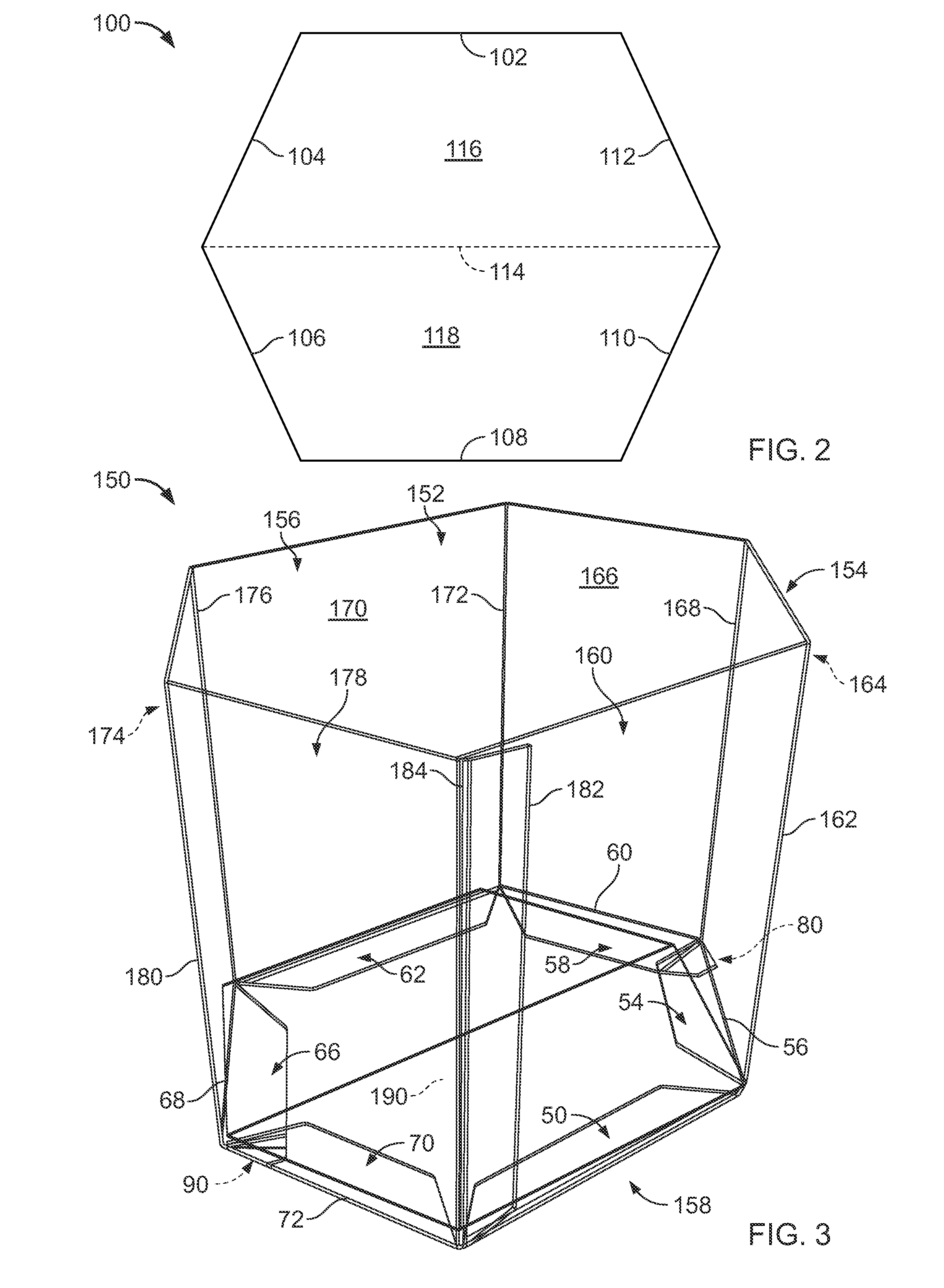

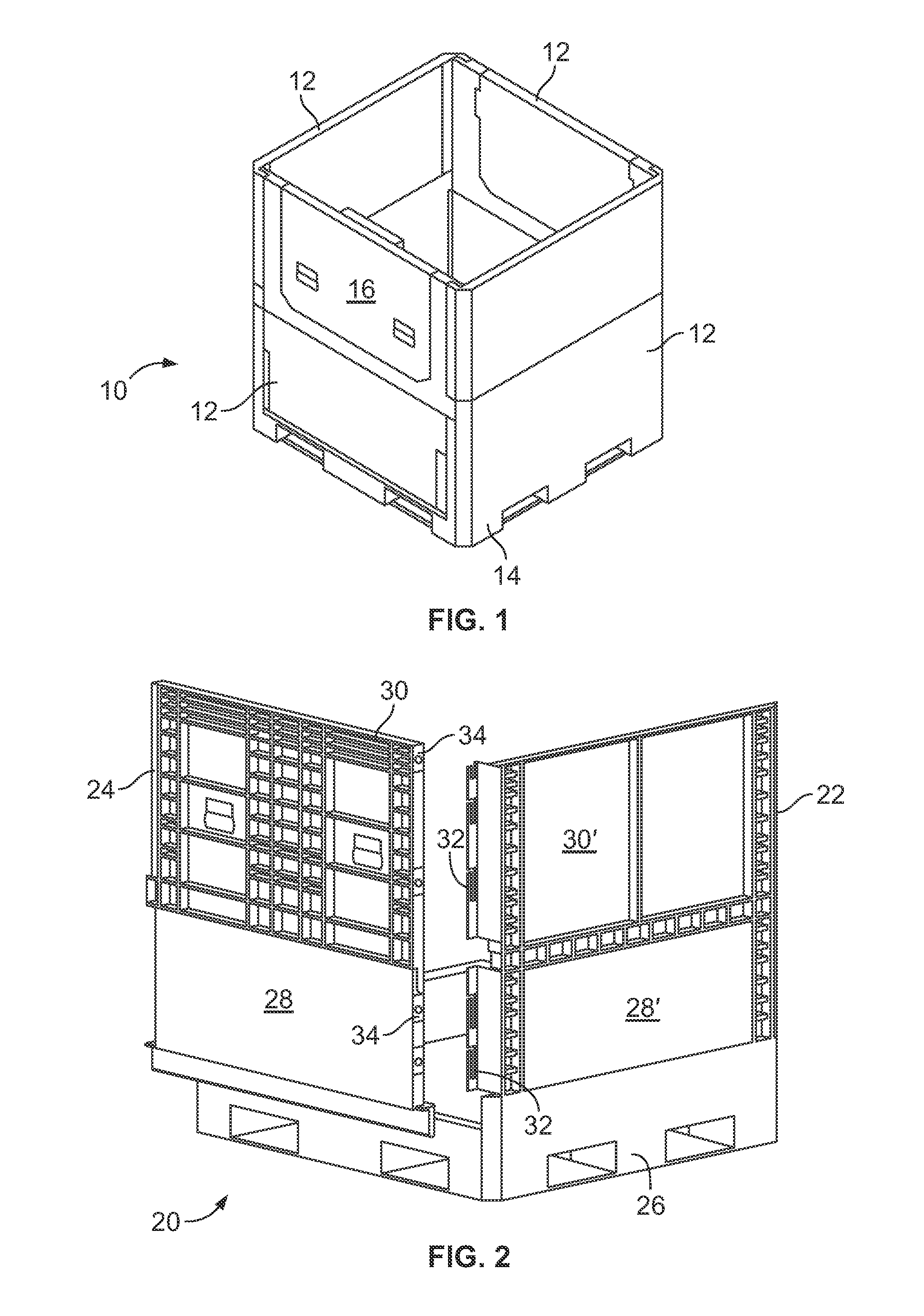

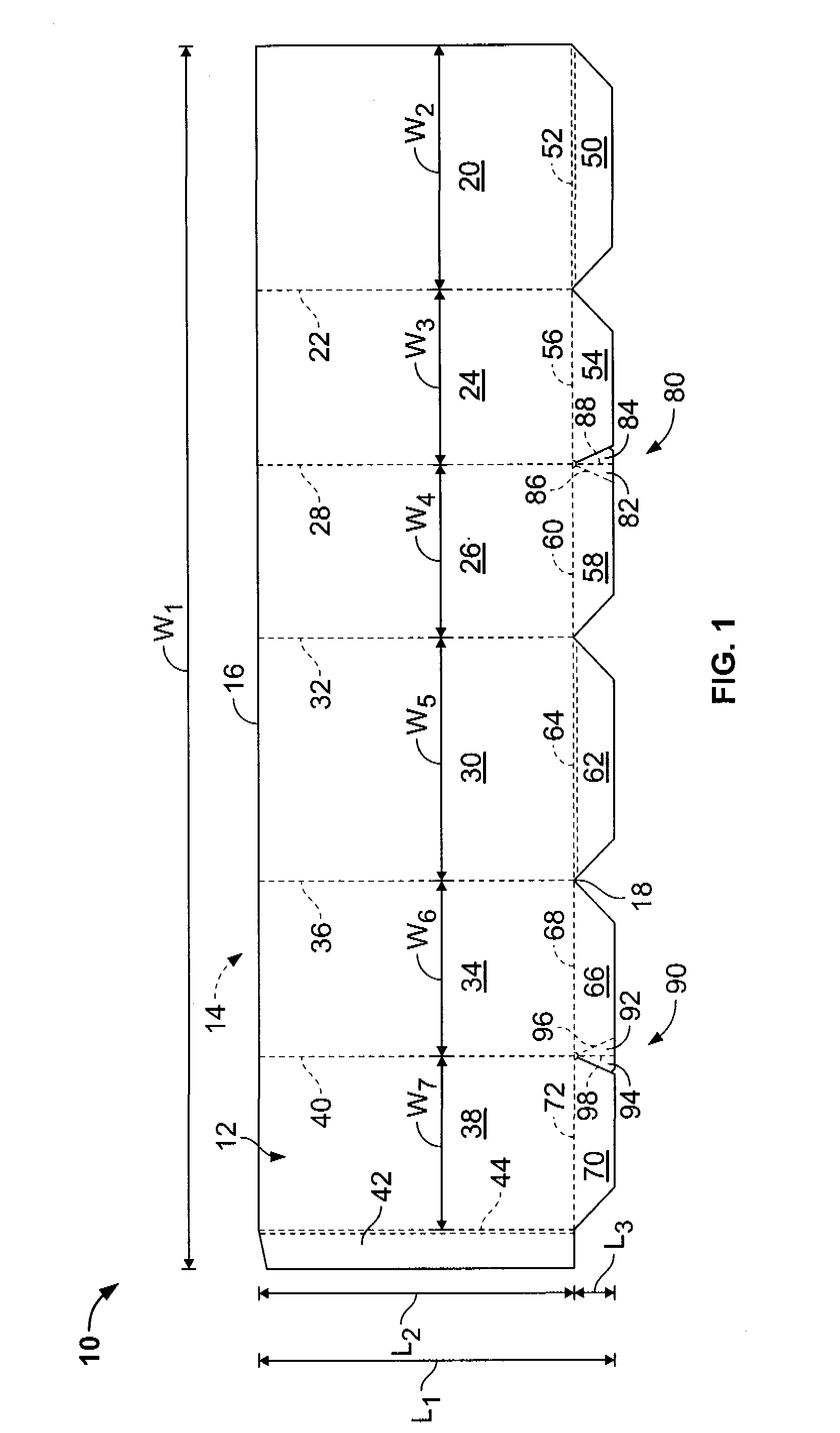

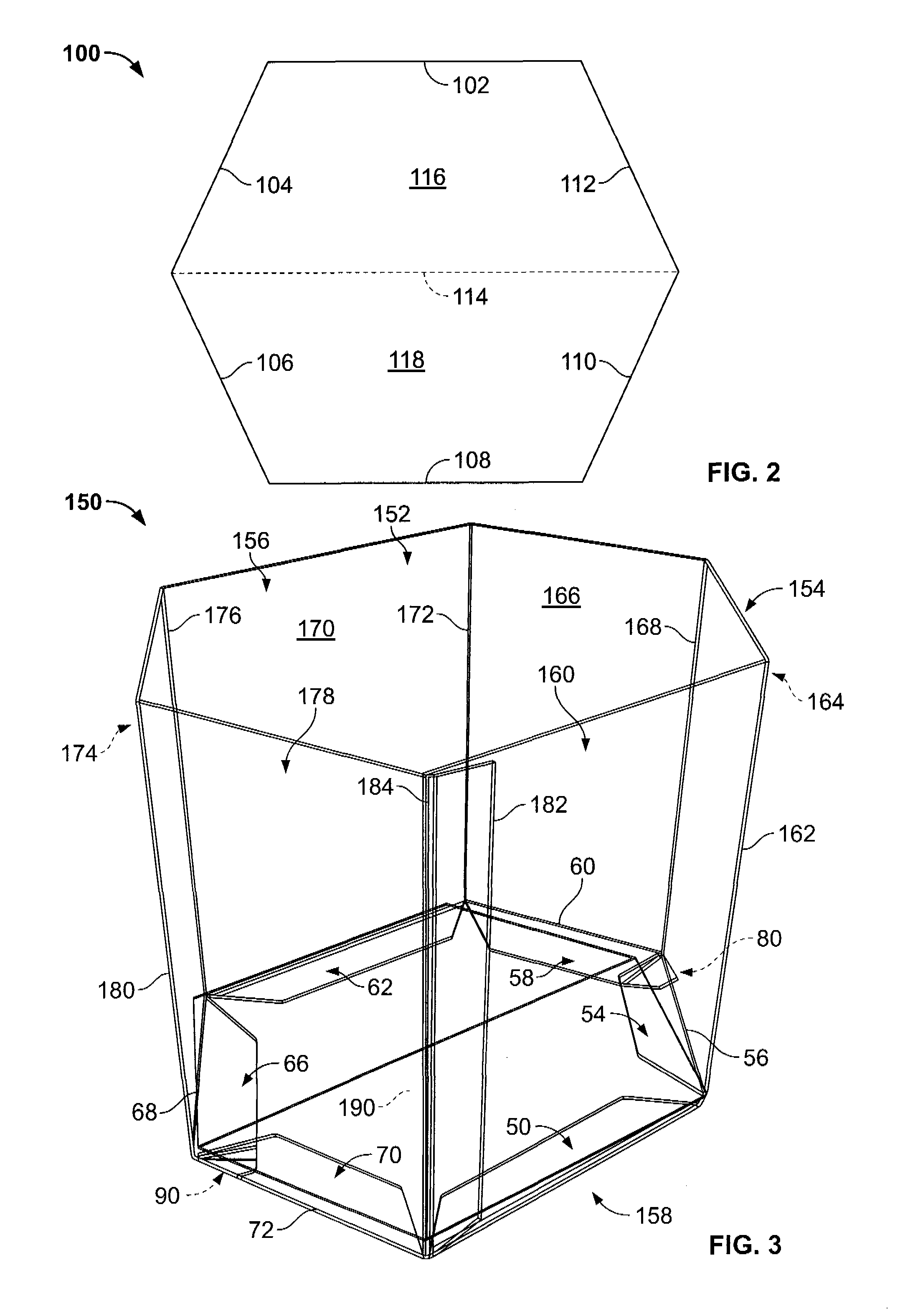

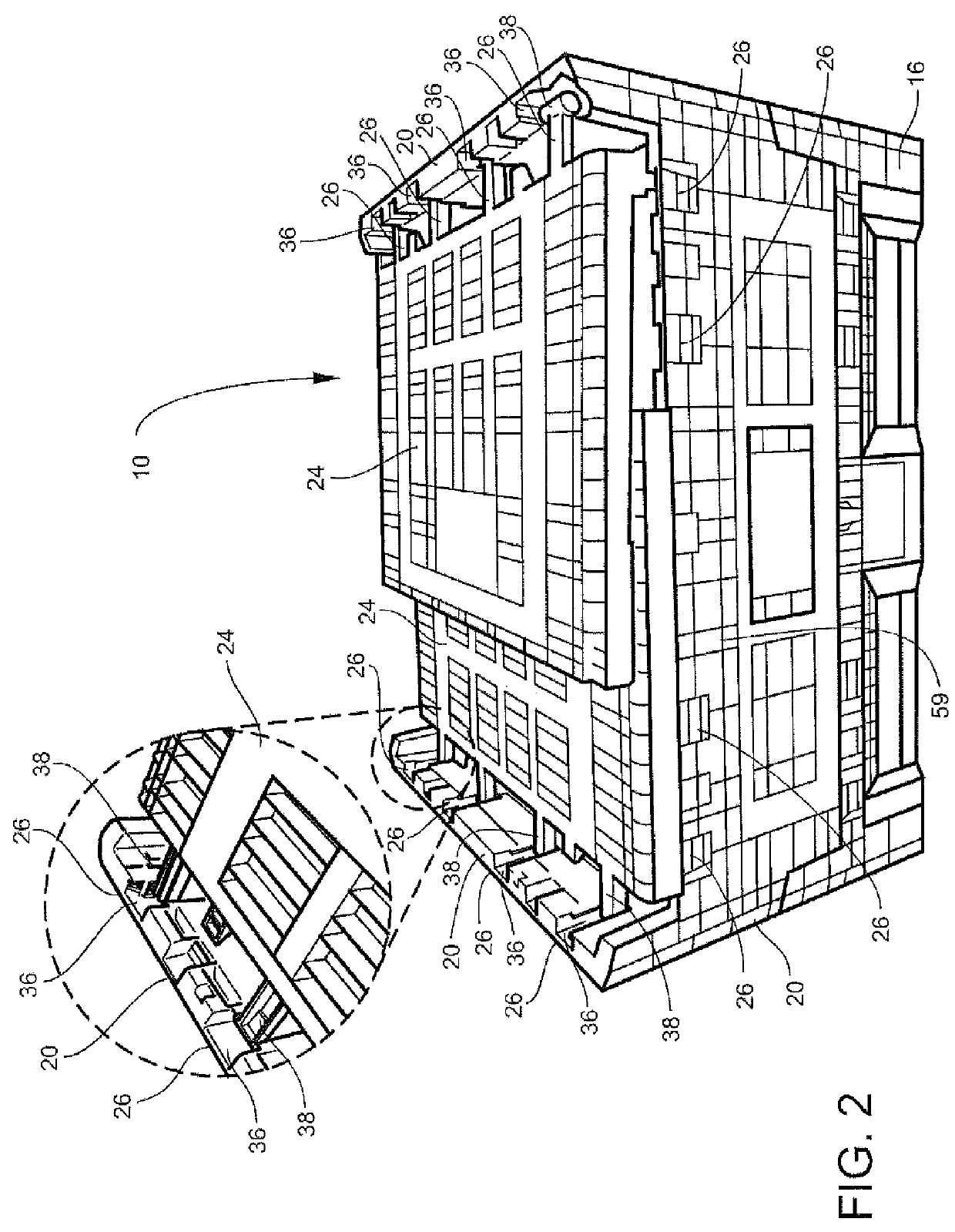

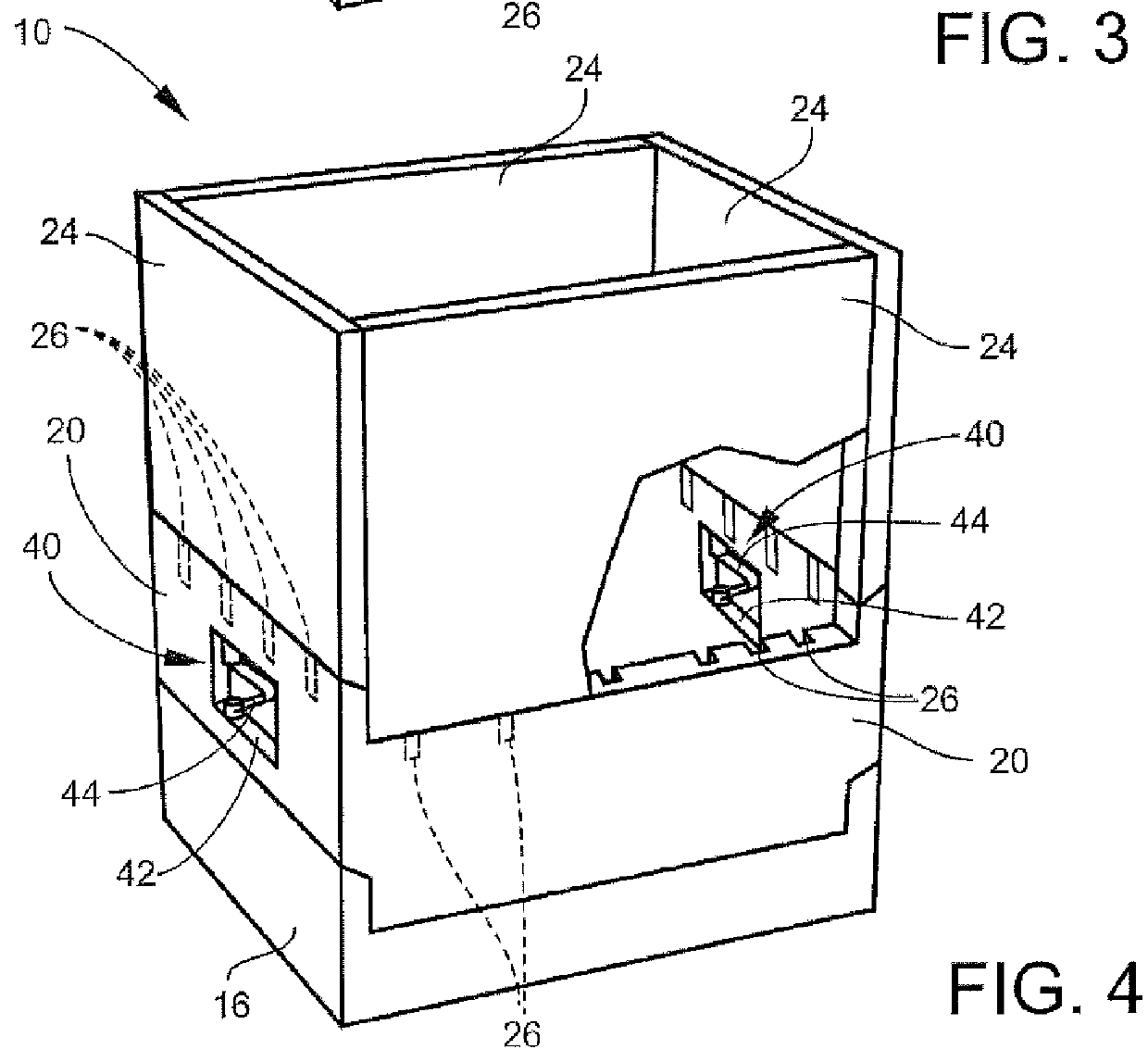

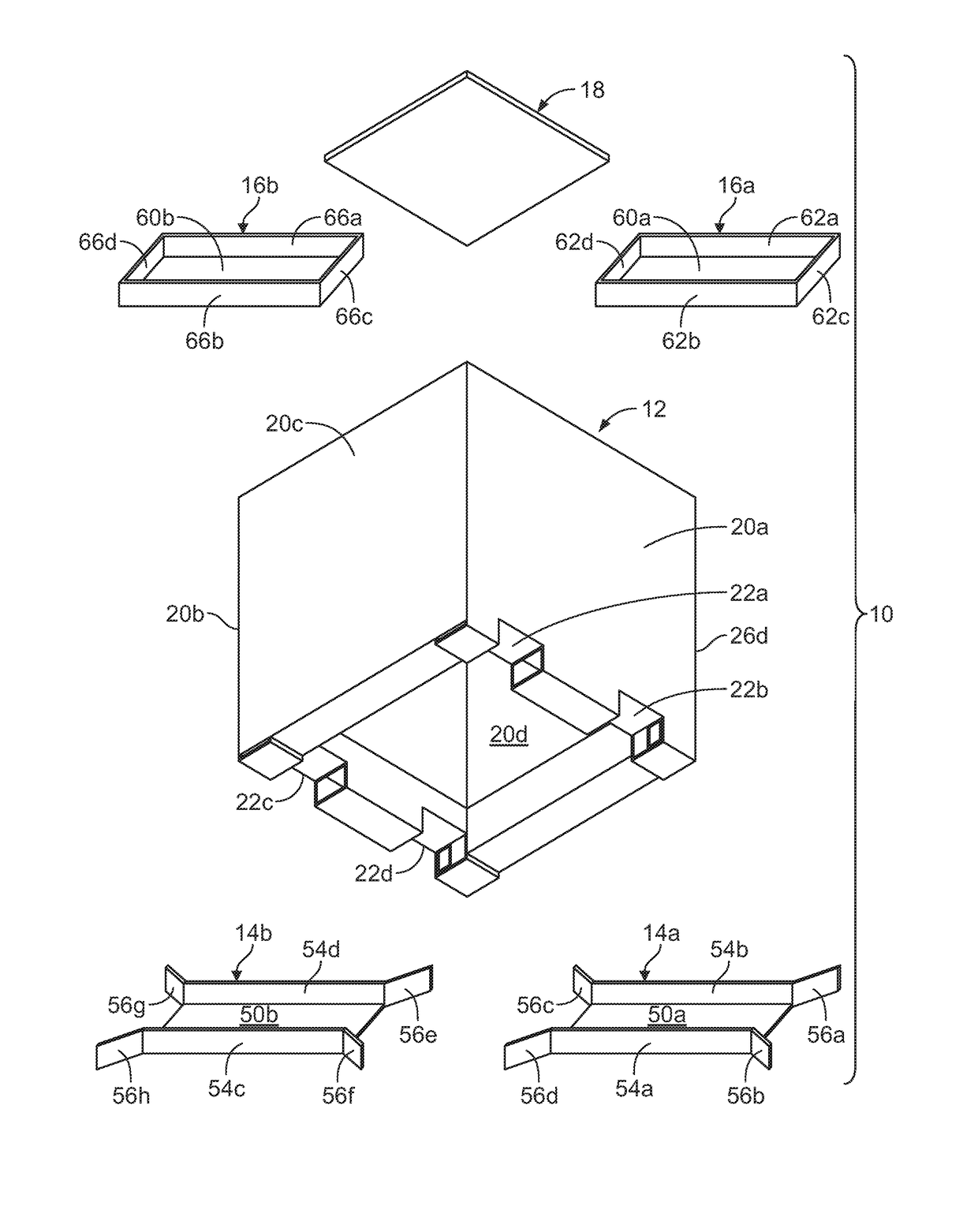

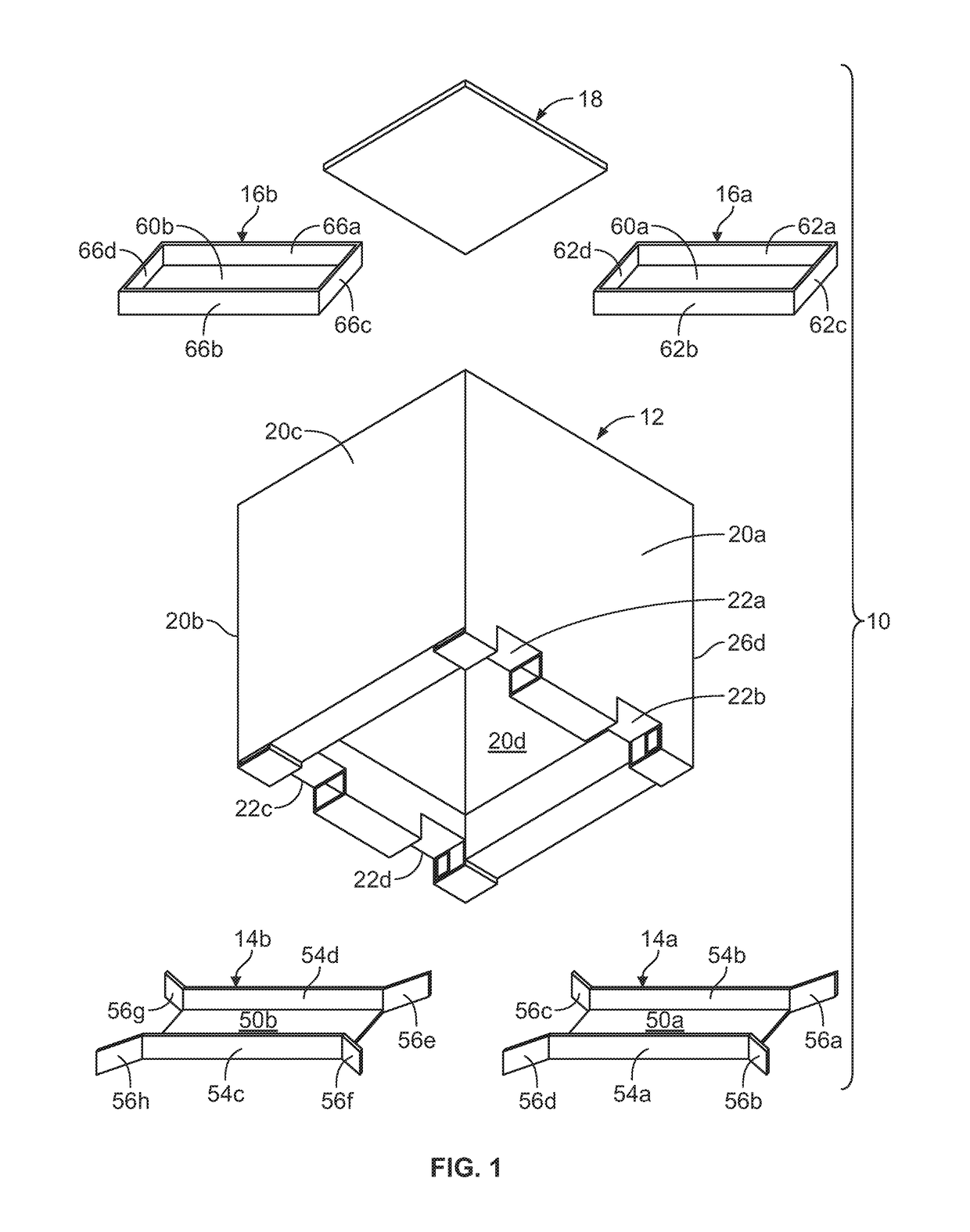

Collapsible bulk bin and methods for constructing the same

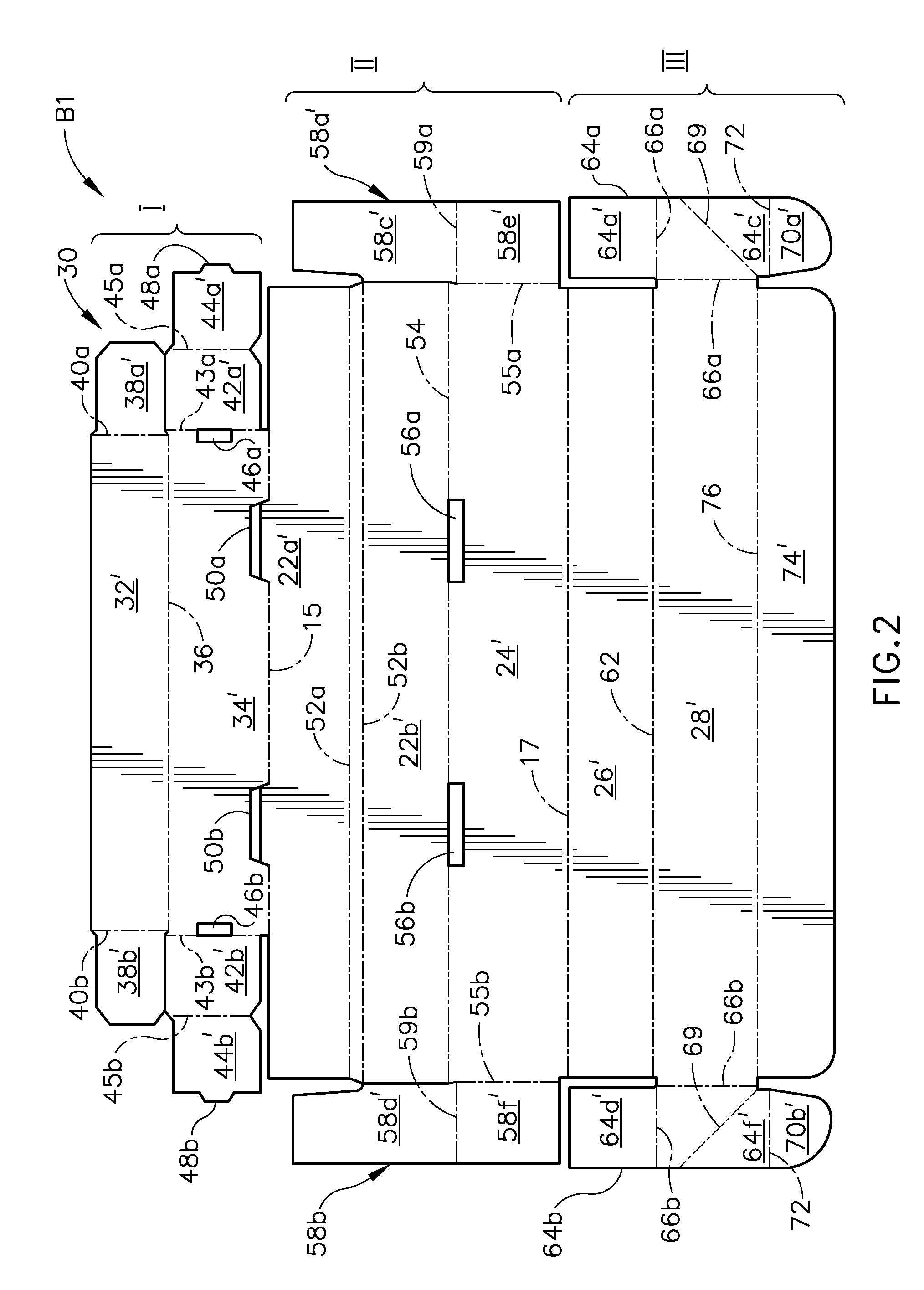

A container configured to be selectively moved between a substantially flat position and a deployed position is provided. The container includes a first blank of sheet material for forming side walls of the container, and a second blank of sheet material for forming a bottom wall of the container. The first blank having an interior surface and an opposing exterior surface, a top edge and a bottom edge. The first blank includes a first side panel, a second side panel, a third side panel, a fourth side panel, a fifth side panel, and a sixth side panel wherein each of the side panels are coupled across a fold line. The first blank also includes end flaps extending from the bottom edge of each of the side panels wherein at least two of the end flaps includes a tab joint. The second blank having a plurality of side edges equal to a number of side panels of the first blank, each side edge having a width substantially equal to a width of the side panels of the first blank. The second blank is foldable and is coupled to at least one end flap of the first blank for forming a bottom wall of the container.

Owner:WESTROCK SHARED SERVICES LLC

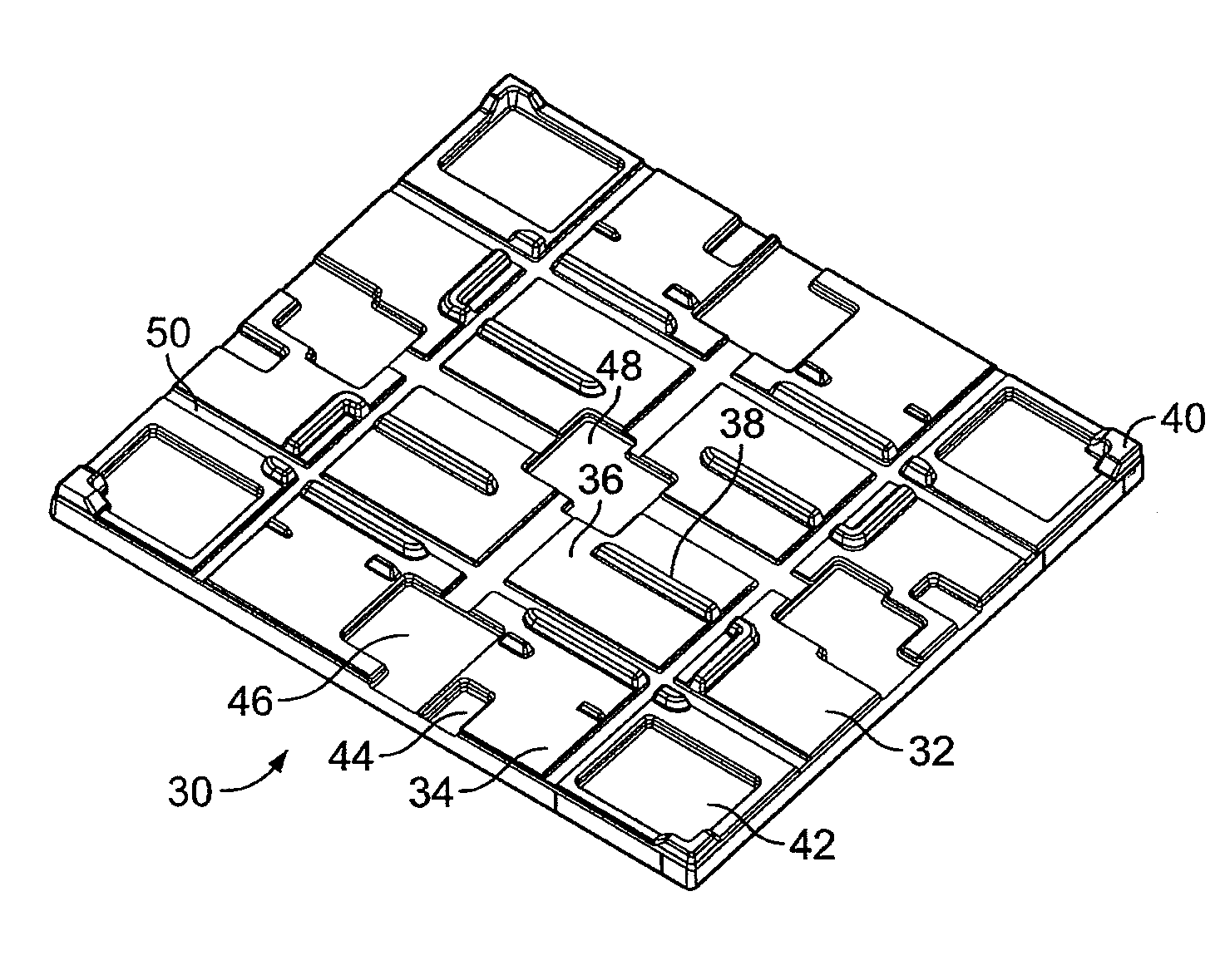

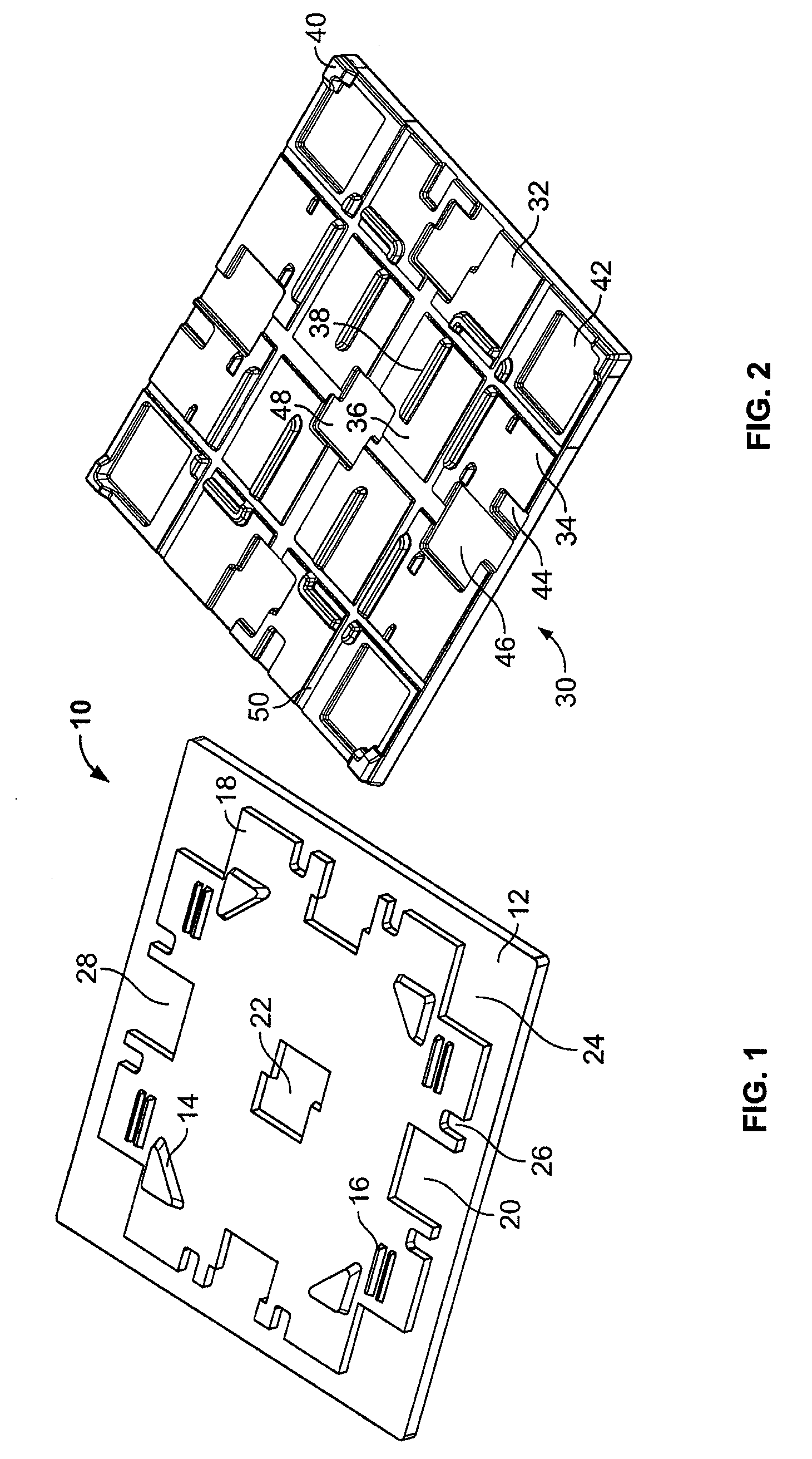

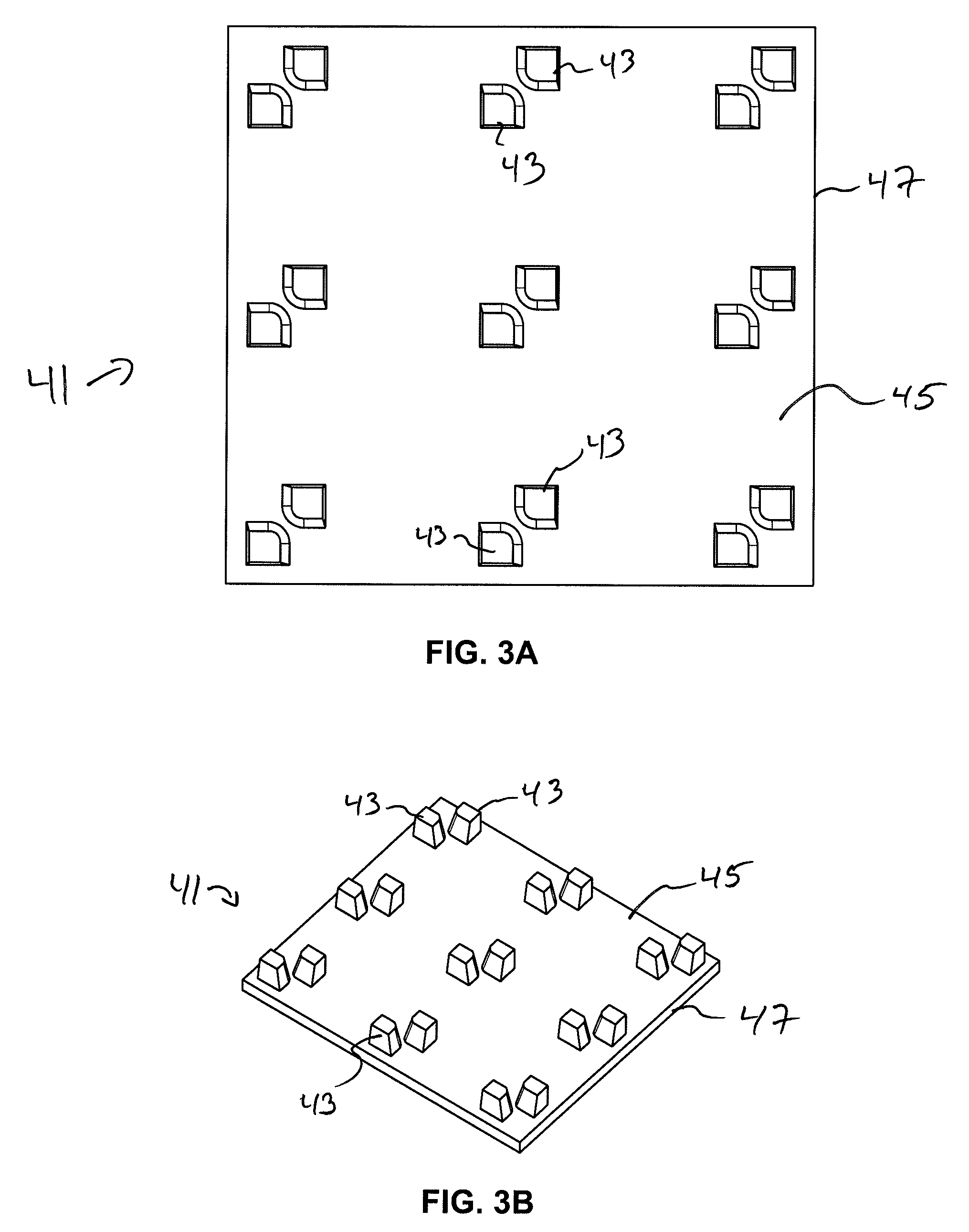

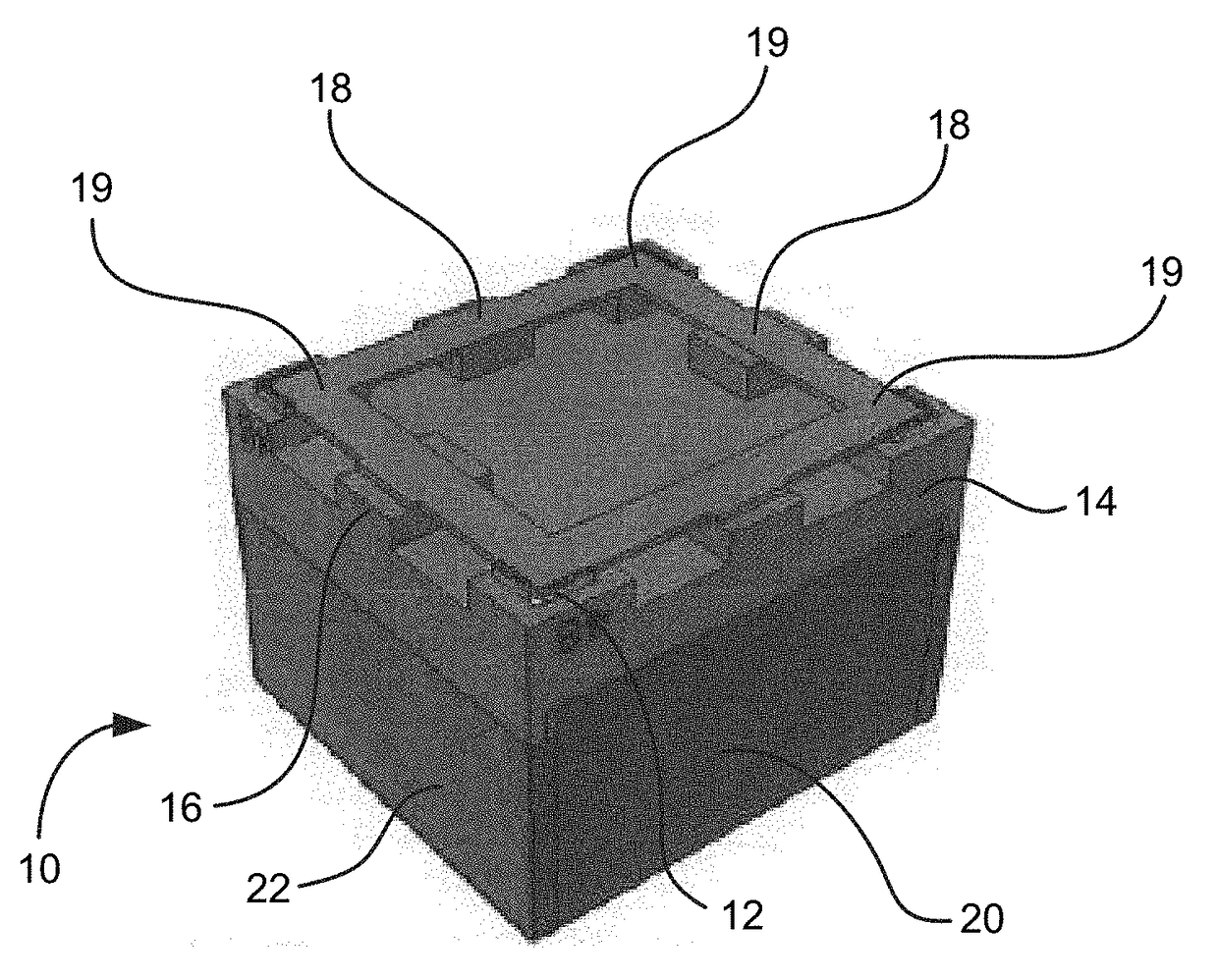

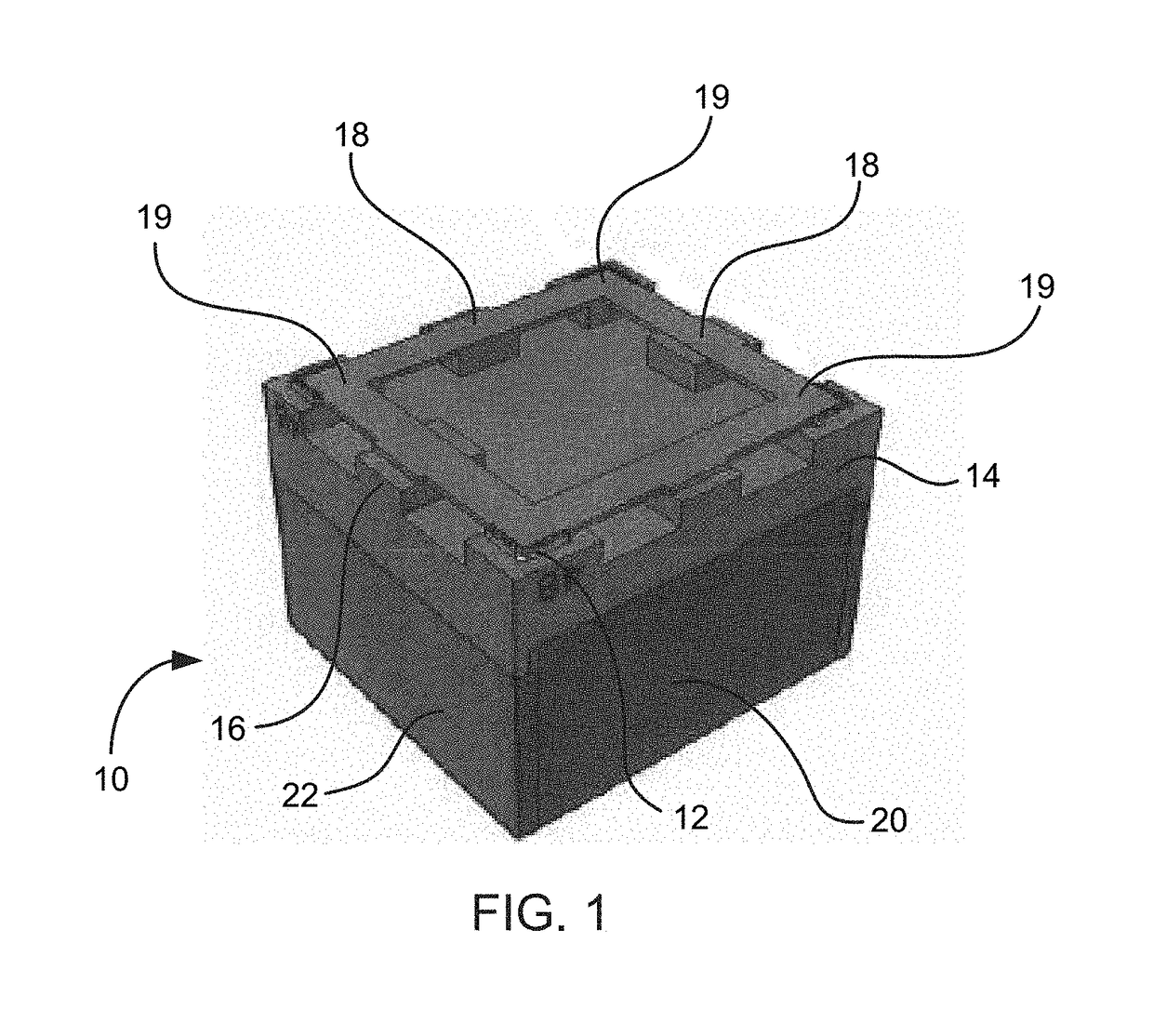

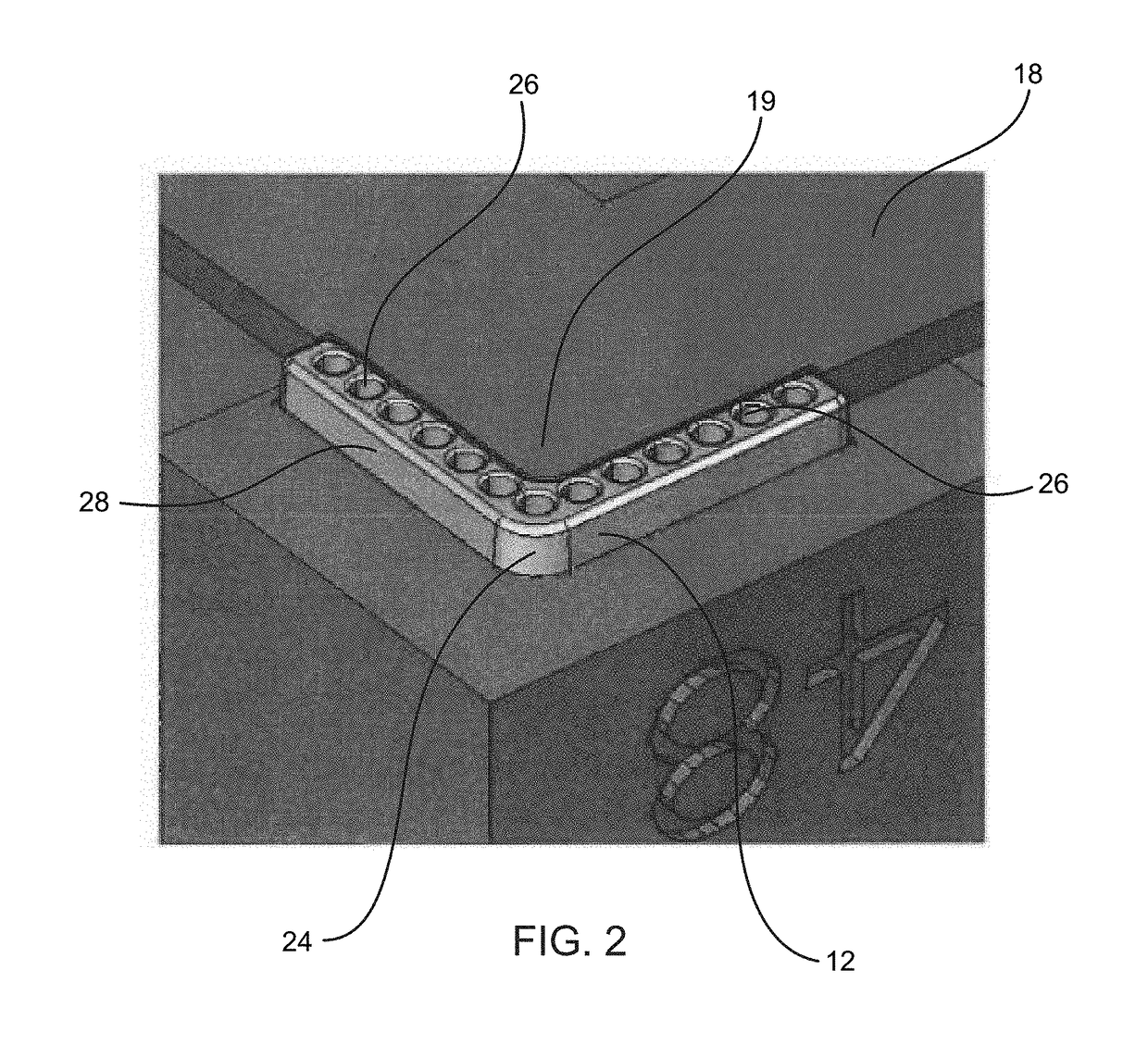

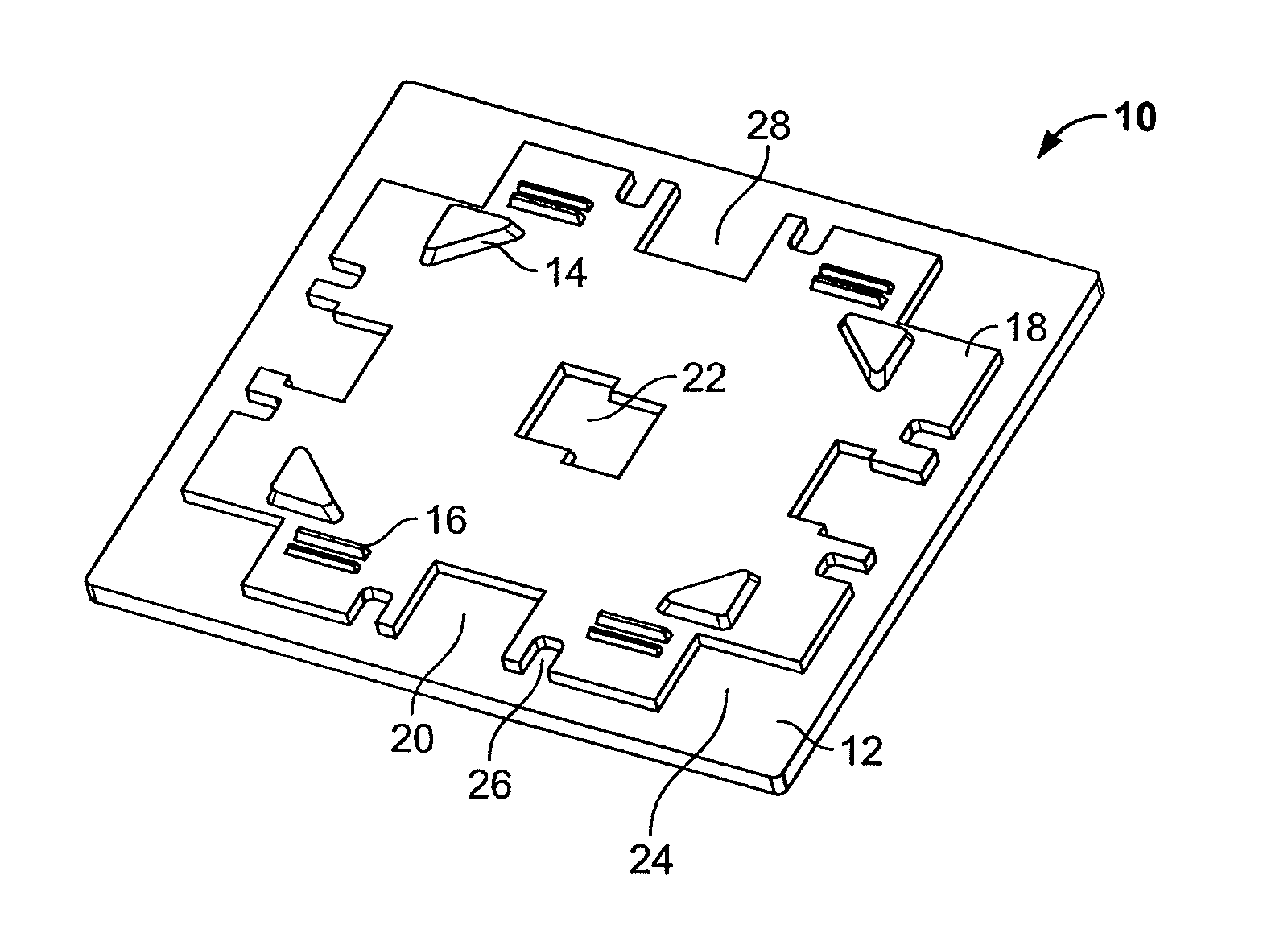

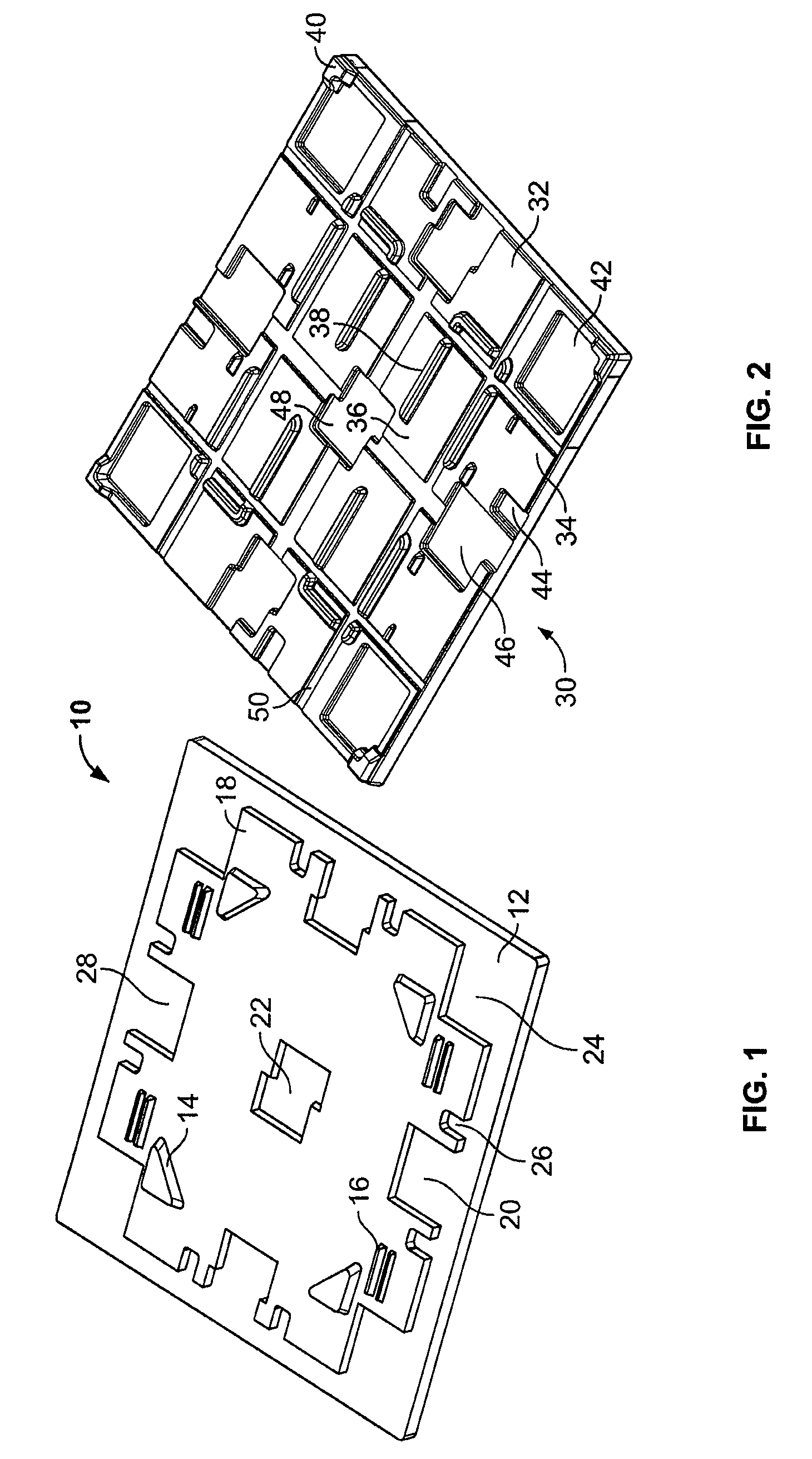

Bulk Bin with Interlocking Elements for Stacking

A bulk bin container having a plurality of first interlocking elements along a bottom portion of the container, and a corresponding plurality of second interlocking elements along a top portion of the container. The interlocking elements help distribute impact forces to a stack of such containers.

Owner:ORBIS CORP

Single piece bulk bin blank and container

InactiveUS20050067475A1Rigid containersInternal fittingsBulk boxElectrical and Electronics engineering

The present invention is directed to a divided bulk bin container and blank. In accordance with the present invention, a single sheet of foldable material is cut and scored to define container blank. The blank includes a pair of opposed first side panels and a pair of a opposed second side panels coupled with the first side panels. An outer bottom panel is connected with said first side panel and an inner bottom panel is connected with said second side panel. Also, a first divider panel is connected with said outer bottom panel and a second divider panel is connected with said inner bottom panel. Further, a divider slot is formed in said inner bottom panel and said second divider panel. The nature of the divider slot is such that the width of said divider slot is at least twice the thickness of the first divider panel.

Owner:INT PAPER CO

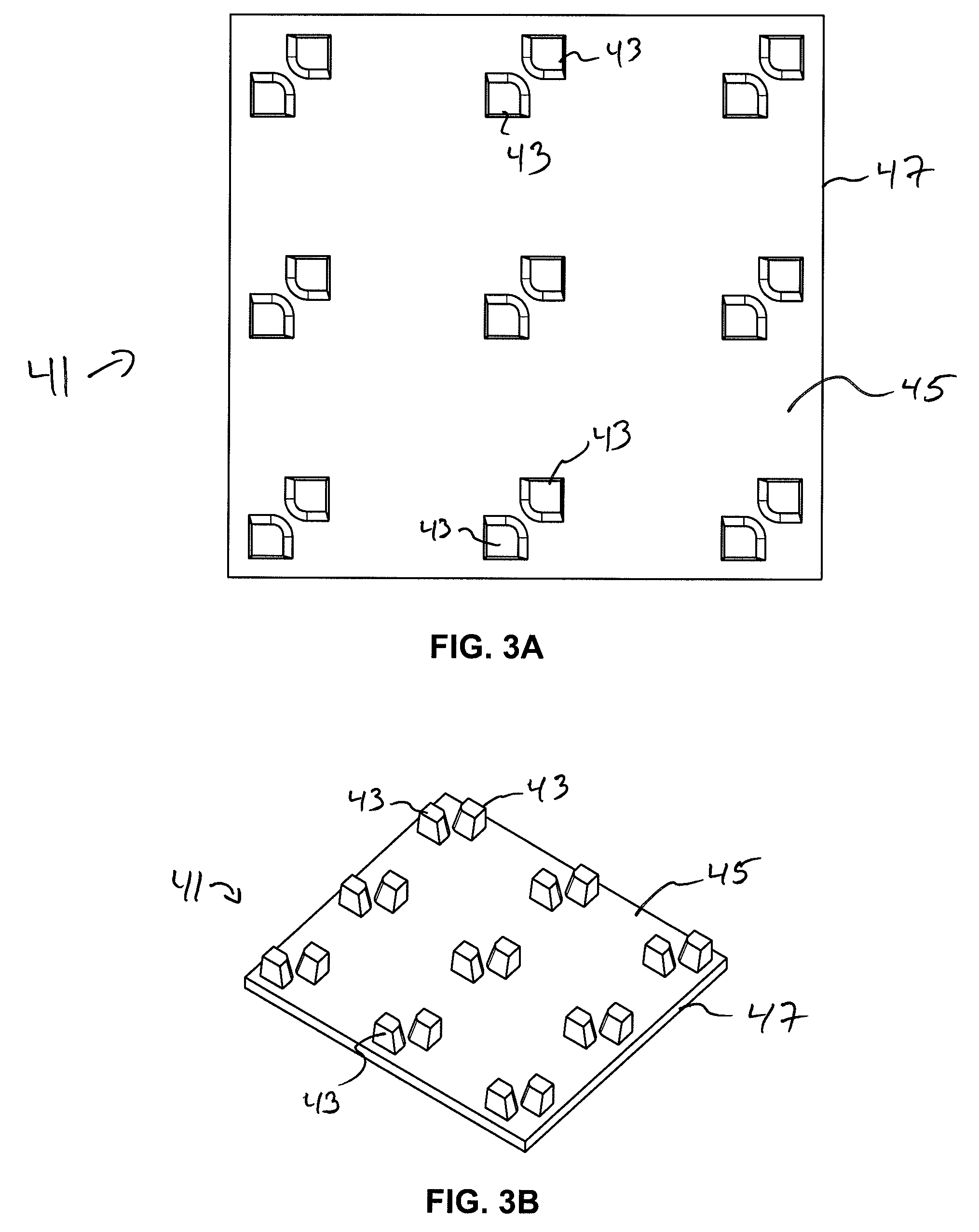

Top cap

ActiveUS20090218244A1Reliable matingReduce weightOther accessoriesContainer/bottle contructionBulk boxPlastic materials

A top cap designed to allow any of a pallet, a bulk bin and a metal rack, each having a different support configuration, or any of a nestable pallet and a bulk bin, to stack securely on an upper surface of the top cap. The top cap including a plurality of raised and / or indented portions on the upper surface configured to mate with a bottom surface of the pallet, bulk bin or metal rack. The top cap also being configured to allow other pallets, bulk bins, or metal racks to stack securely on the upper surface of the top cap. The top cap being formed from a molded plastic material.

Owner:ORBIS CORP

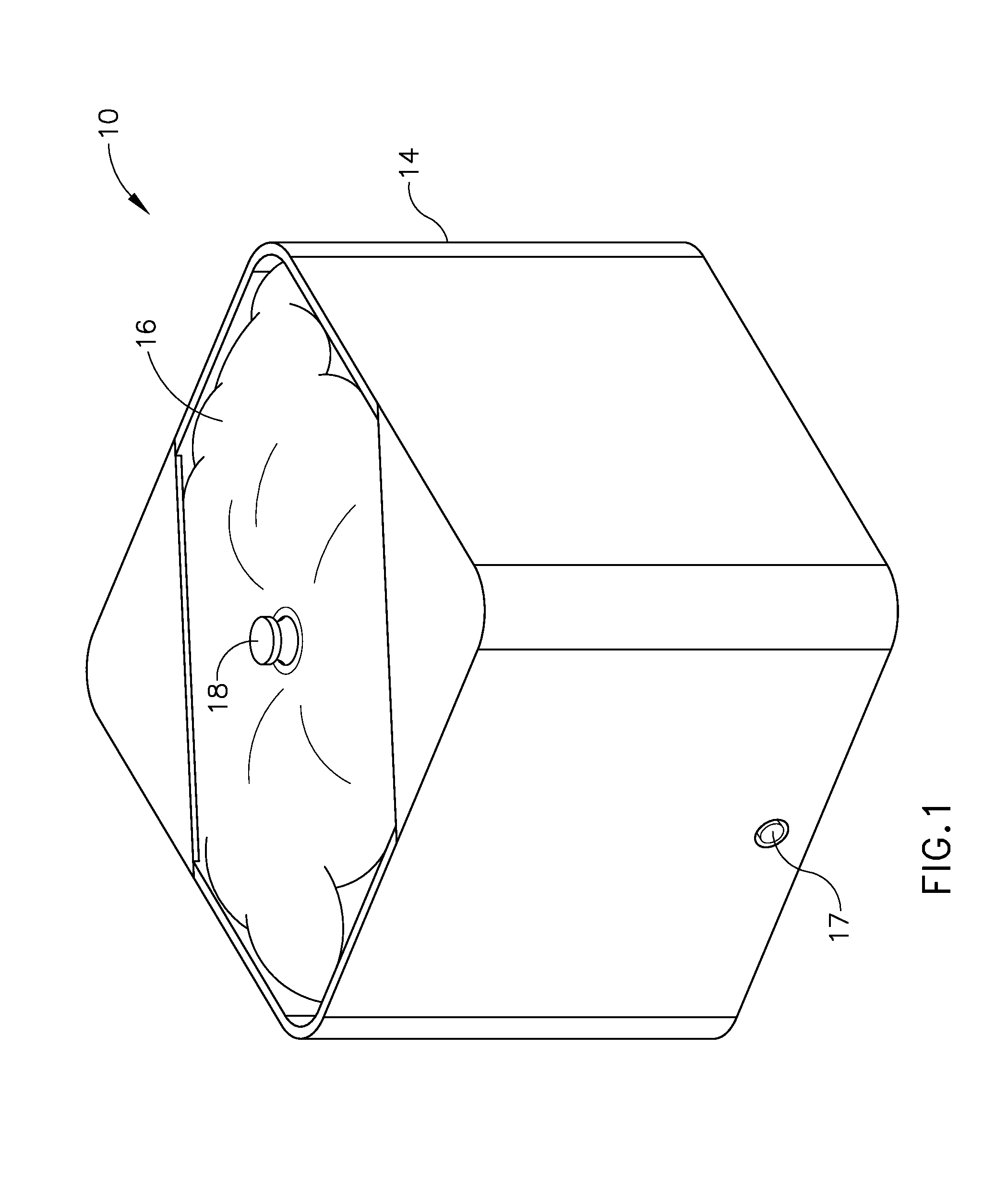

Bulk bin and bag

The present invention relates to a bulk bin for use with a liner bag. The bulk bin includes a sub-structure that is configured to receive forktines of lifting machinery for moving the bulk bin and a collapsible upper assembly that can support a bag with an entrance thereof in an upwardly facing orientation for filling. The bulk bin also includes at least one self supporting stiffened lid, and suitably a pair of lids. The lids may be pivoted from a closed position to an open position by orienting the bin into an inclined position in which the lids can open under gravity.

Owner:MATERIALS HANDLING SYST AUSTRALIA

Bulk bin and bag dispensing apparatus

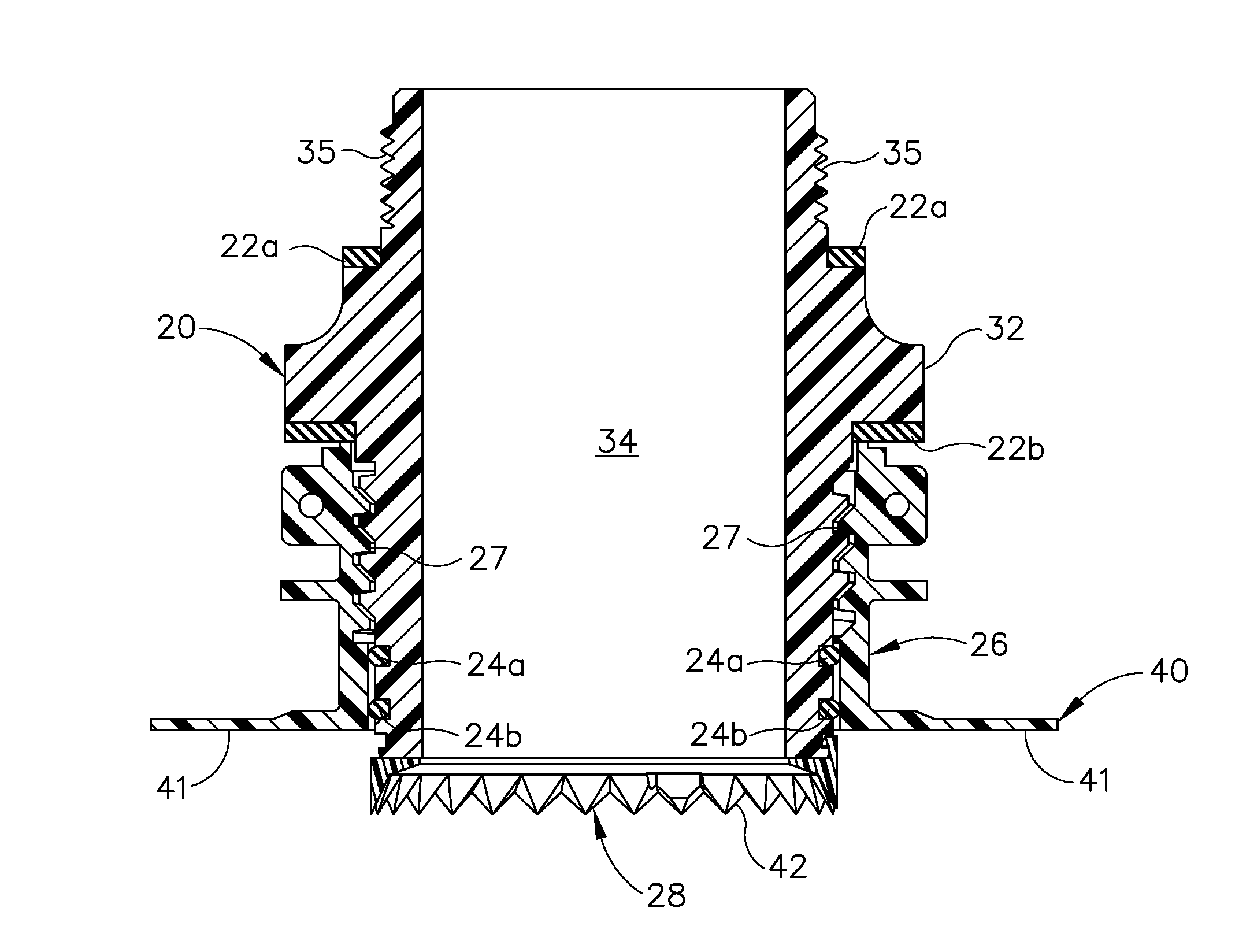

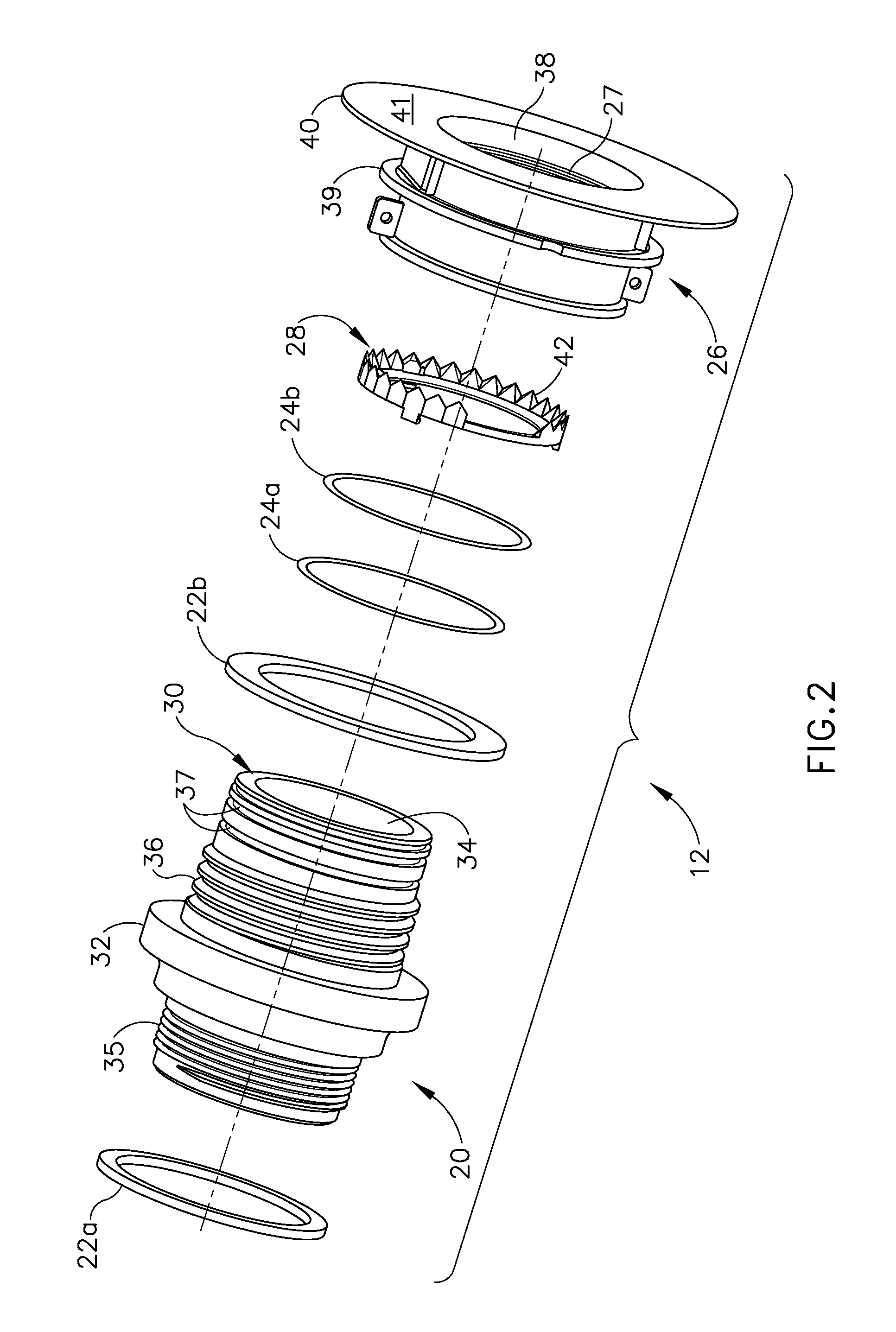

InactiveUS20130292412A1Eliminate leaksExemption stepsLiquid flow controllersLiquid dispensingButtressBulk box

A bulk bin and bag dispensing apparatus comprises a bag fitment having an elongated buttress female thread and a nipple adapted to be joined to the bag fitment. The nipple comprises an elongated body portion having an axial flow passage therethrough and a projection portion extends radially therefrom. The body portion further includes a first end and a second end. The first end is defined by male buttress thread thereto and the second end is defined by NPT thread thereto. The first end includes a ring cutter and at least one sealing means attached thereto so that the nipple strokes threadedly within the elongated buttress female thread causing the ring cutter to puncture a bag membrane to thereby permit liquid to be dispensed through the flow passage.

Owner:INT PAPER CO

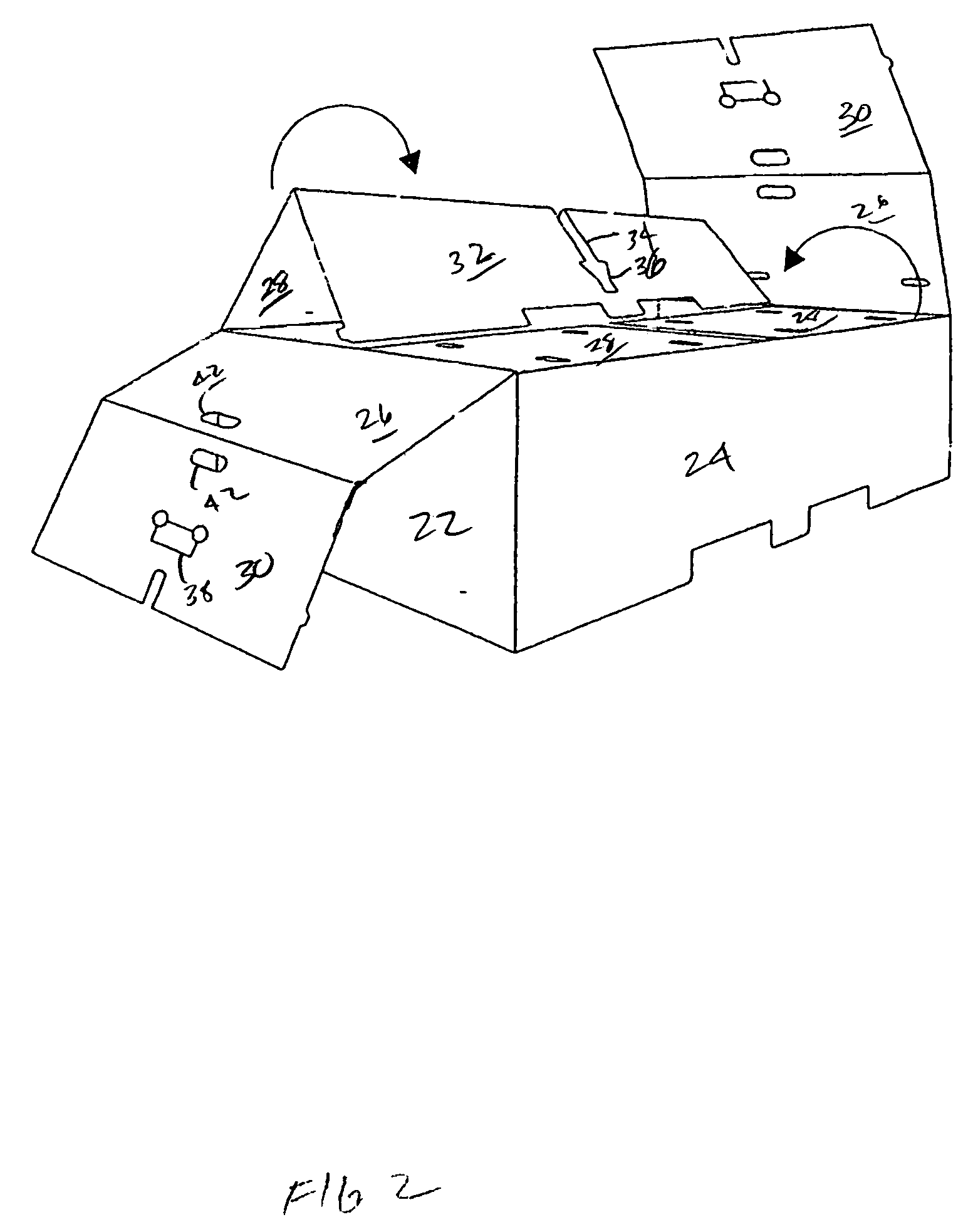

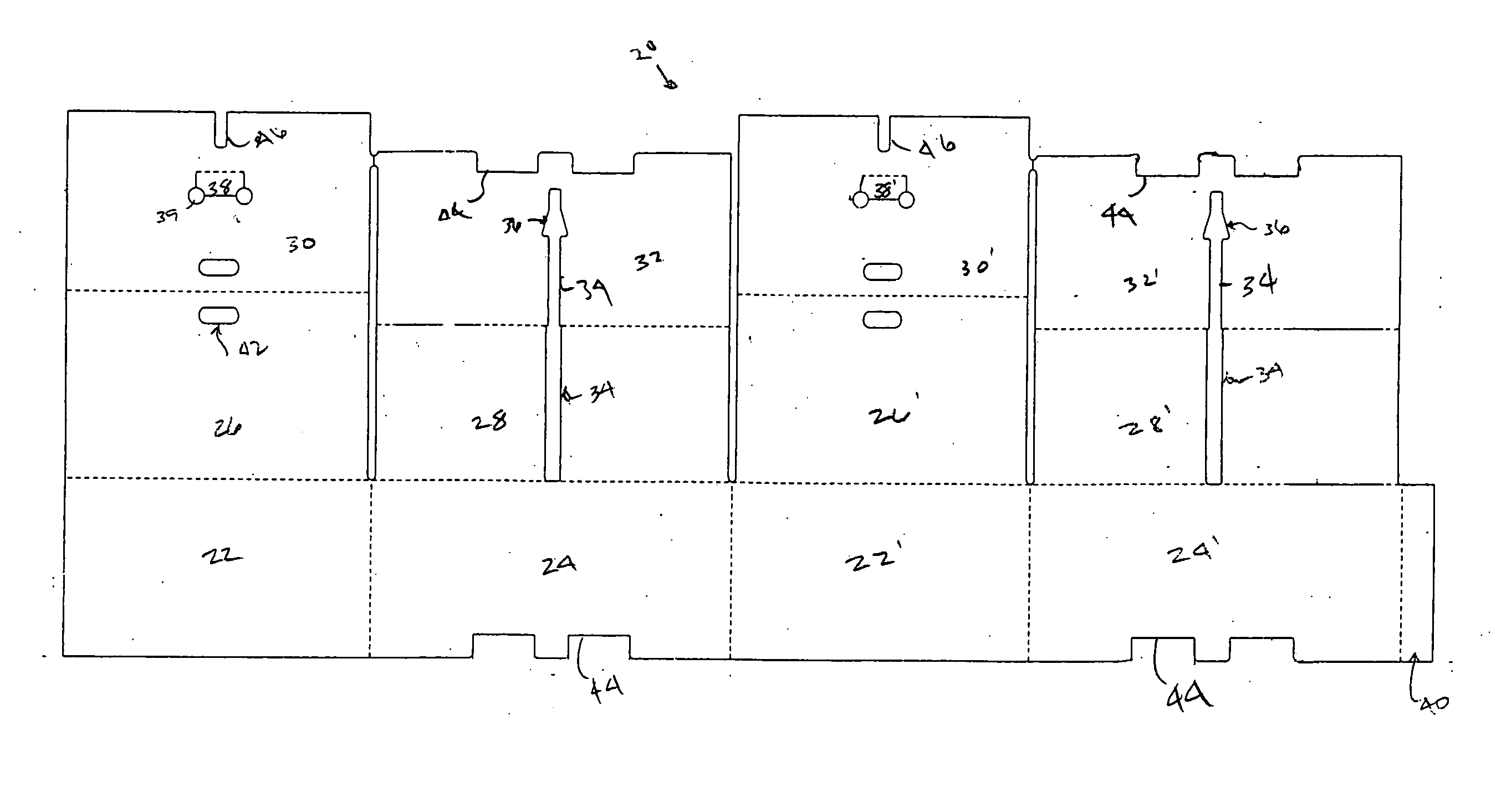

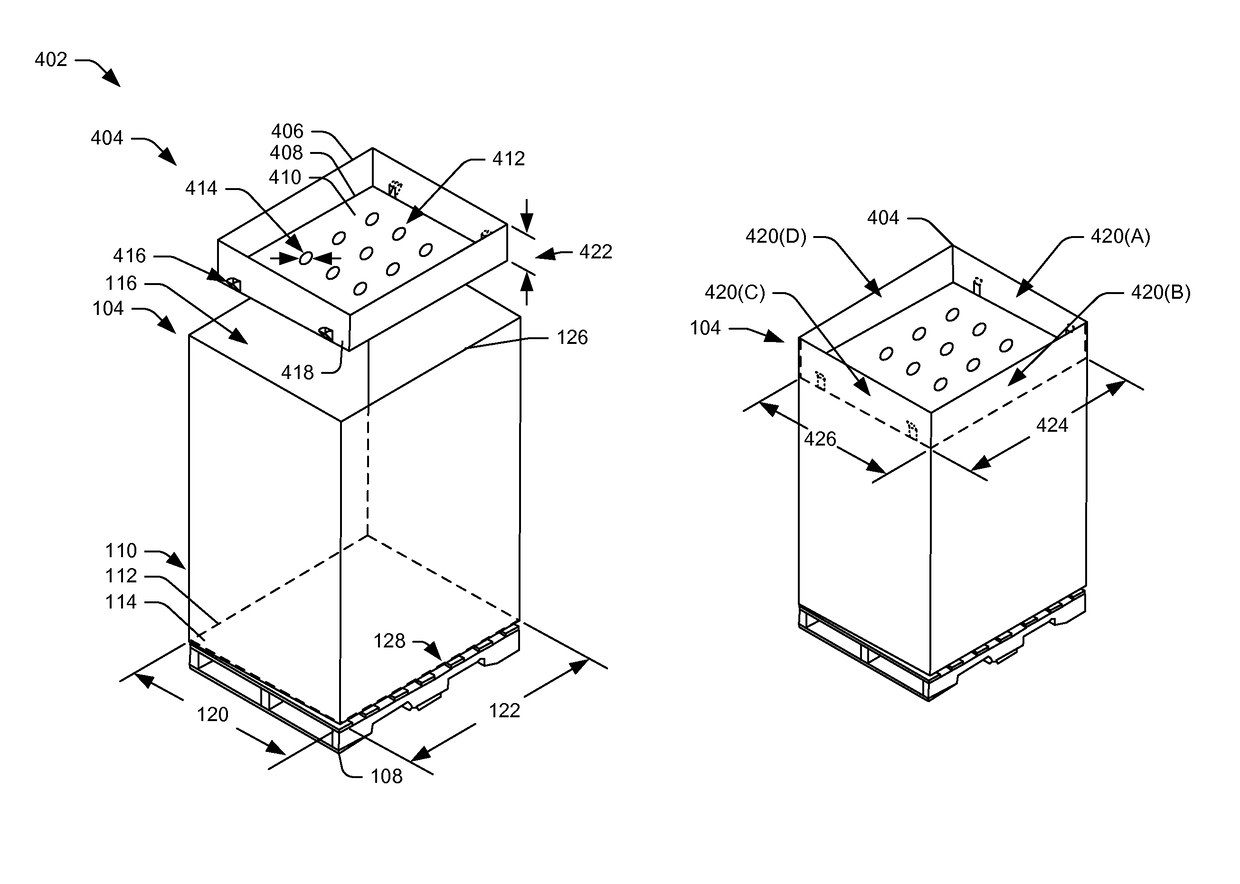

Rotating sidewall stop for supporting folding sidewalls of a height-extended bulk box

A height-extended bulk box that includes a base having four sides, four height-extending walls connected to respective sides of the base and four sidewalls pivotally mounted to respective ones of the height-extending walls and movable between a vertically erected use position and a collapsed configuration wherein the sidewalls are rotated inwardly into the area defined by a quadrilinear base. At least one sidewall stop is positioned on one of the height-extending walls and is movable between a non-use stowed position and a deployed position that extends into the volume of the bulk box and arrests movement of a first of the sidewalls to be moved into a collapsed position past a position substantially parallel to the top deck of the base.

Owner:SCHAEFER SUBCO LLC

Reinforced bulk bin and methods for making same

A reinforced bulk bin, and methods for making same, wherein a collapsible bulk bin, preferably fabricated from paper, paperboard and / or corrugated paperboard, is provided with a reinforcing plastic sleeve, which is placed on the bin while in its collapsed configuration. When in place, and prior to the bin being deployed, the sleeve is under tension. When the bin is deployed, the sleeve exerts restraining force, distributed over the surfaces of the side walls of the bin. The sleeve may be positioned on the collapsed bin either manually or mechanically.

Owner:WESTROCK SHARED SERVICES LLC

Bulk bin assembly with a horizontal ventilation insert and method for forming the same

A bulk bin assembly formed from a plurality of blanks material is provided. The bulk bin assembly includes a container portion including a plurality of side walls, wherein at least one side wall has a ventilation opening defined therein. The bulk bin assembly further includes a ventilation insert including a plurality of side panels and at least one insert opening defined in at least one side panel. The ventilation insert is positioned within a cavity of the container portion such that an air flow channel defined by the plurality of side panels is in air flow communication with the ventilation opening of the container portion to permit ambient air to flow through the ventilation opening and through the insert opening.

Owner:WESTROCK SHARED SERVICES LLC

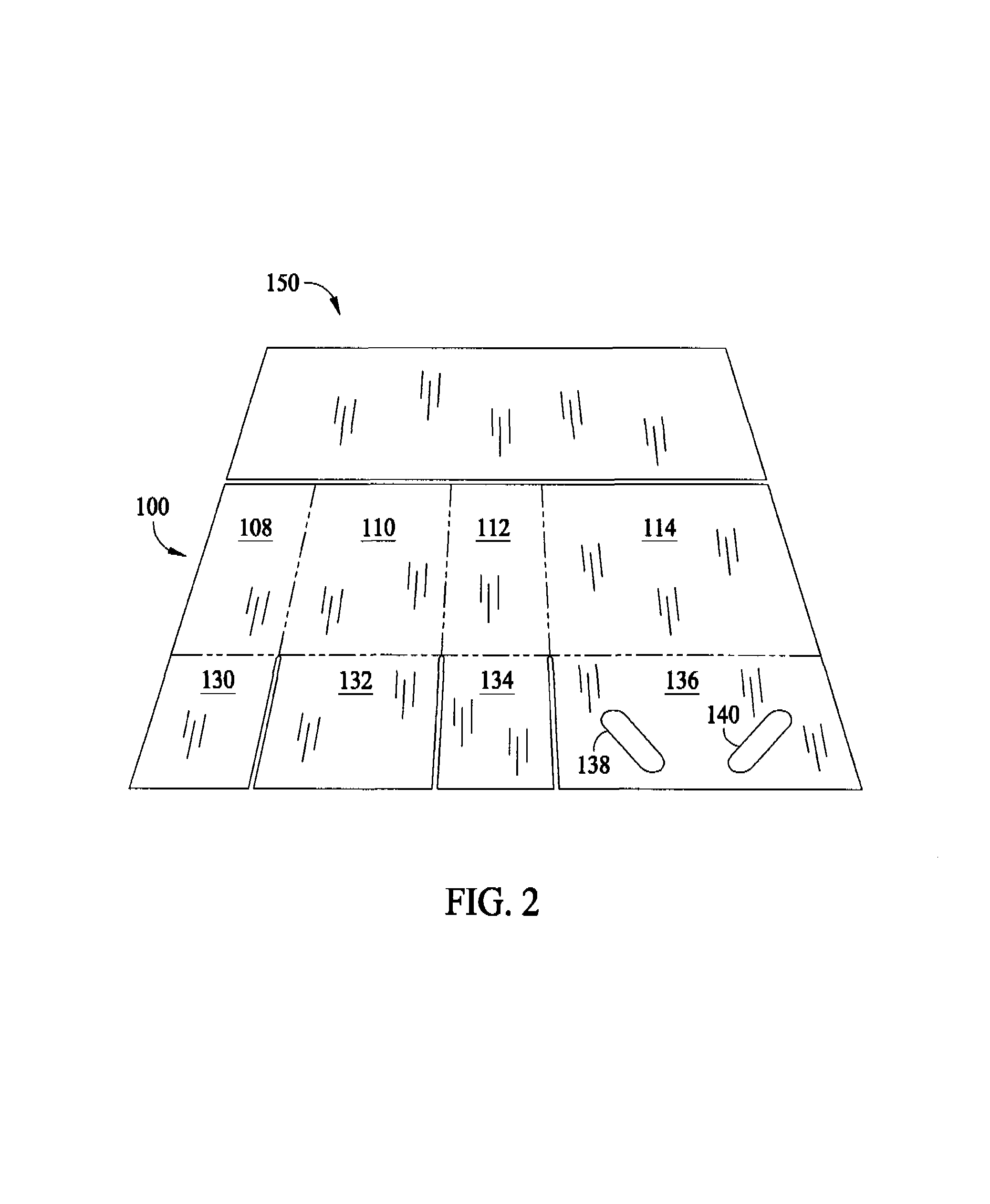

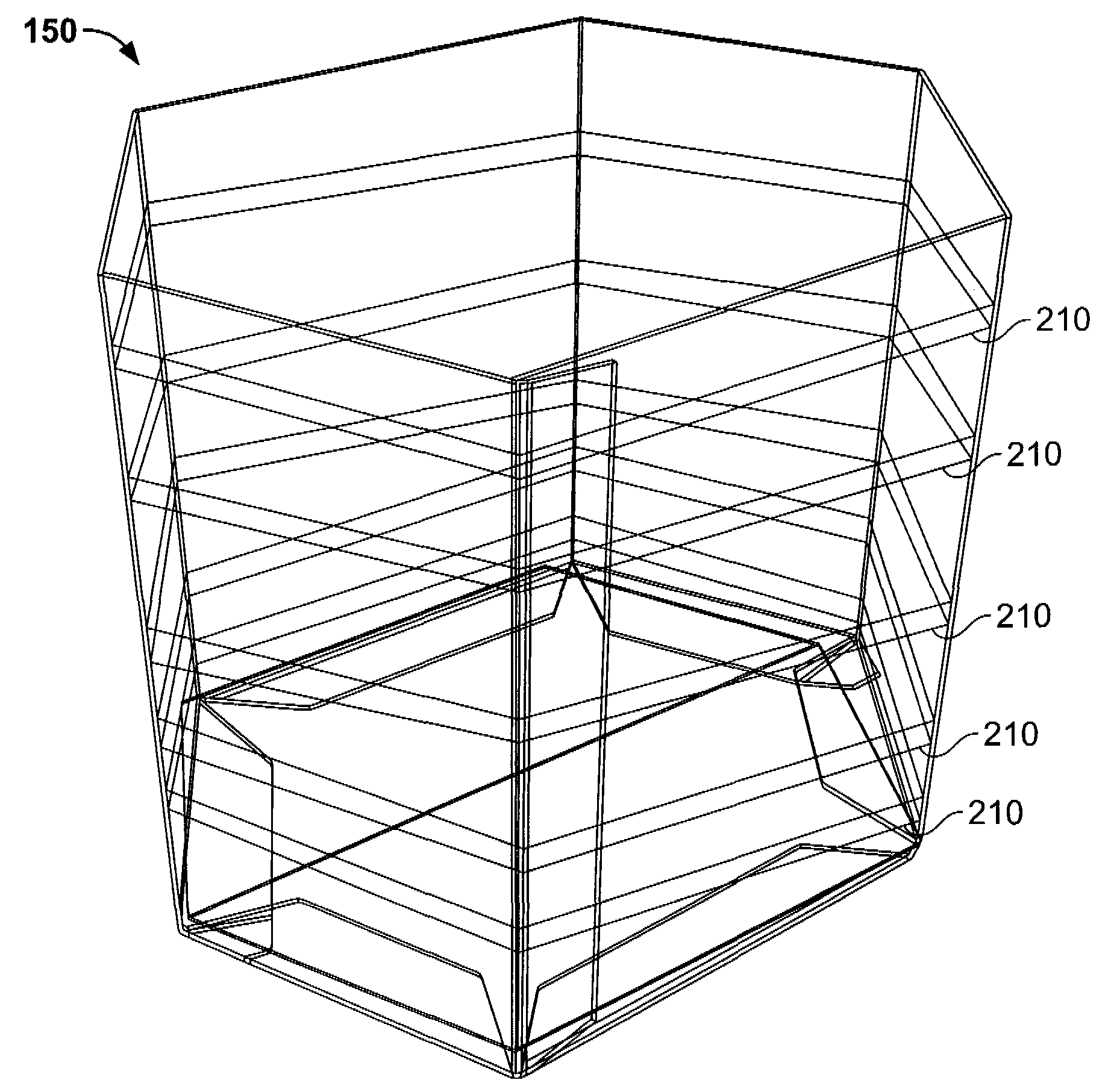

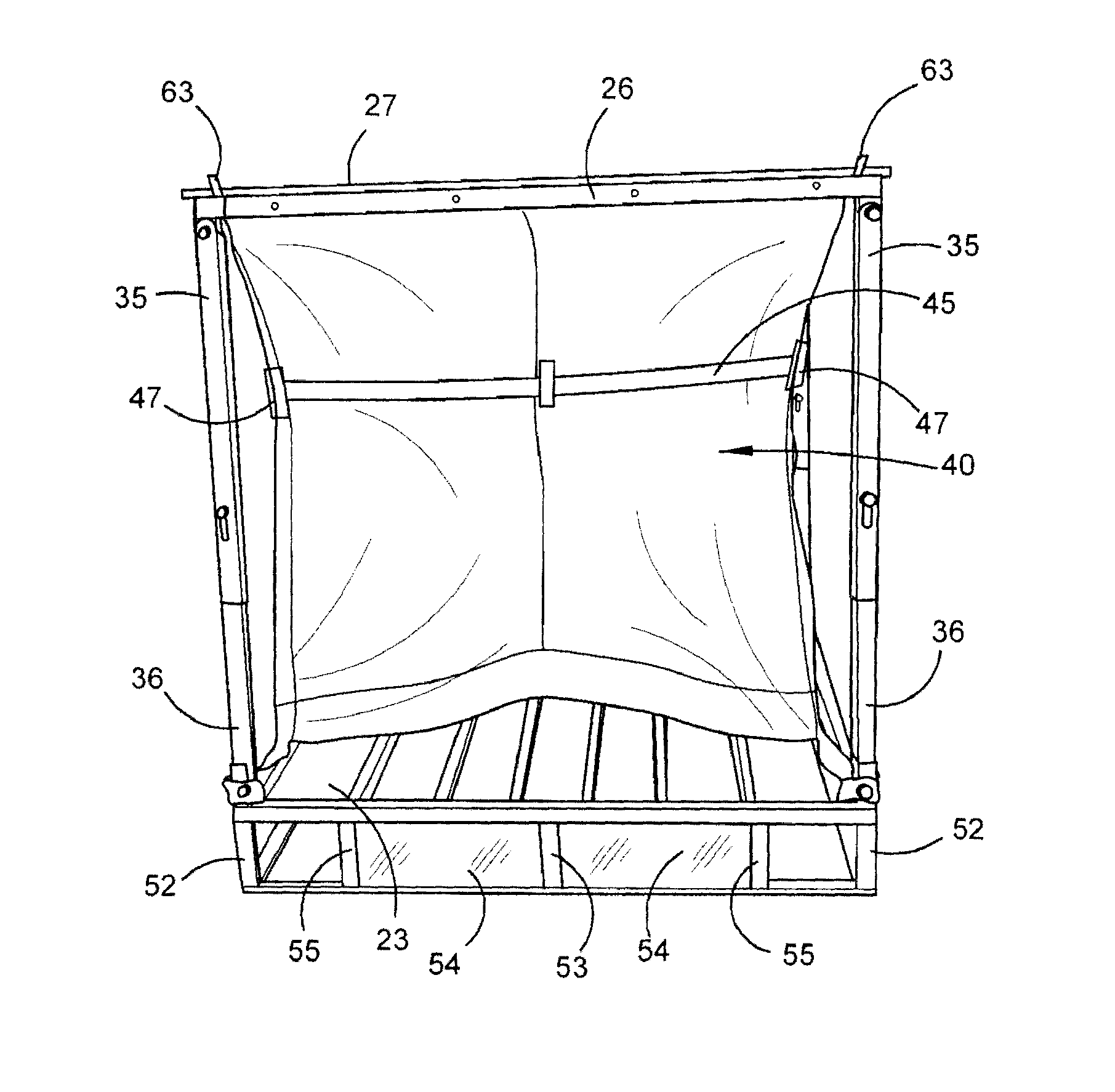

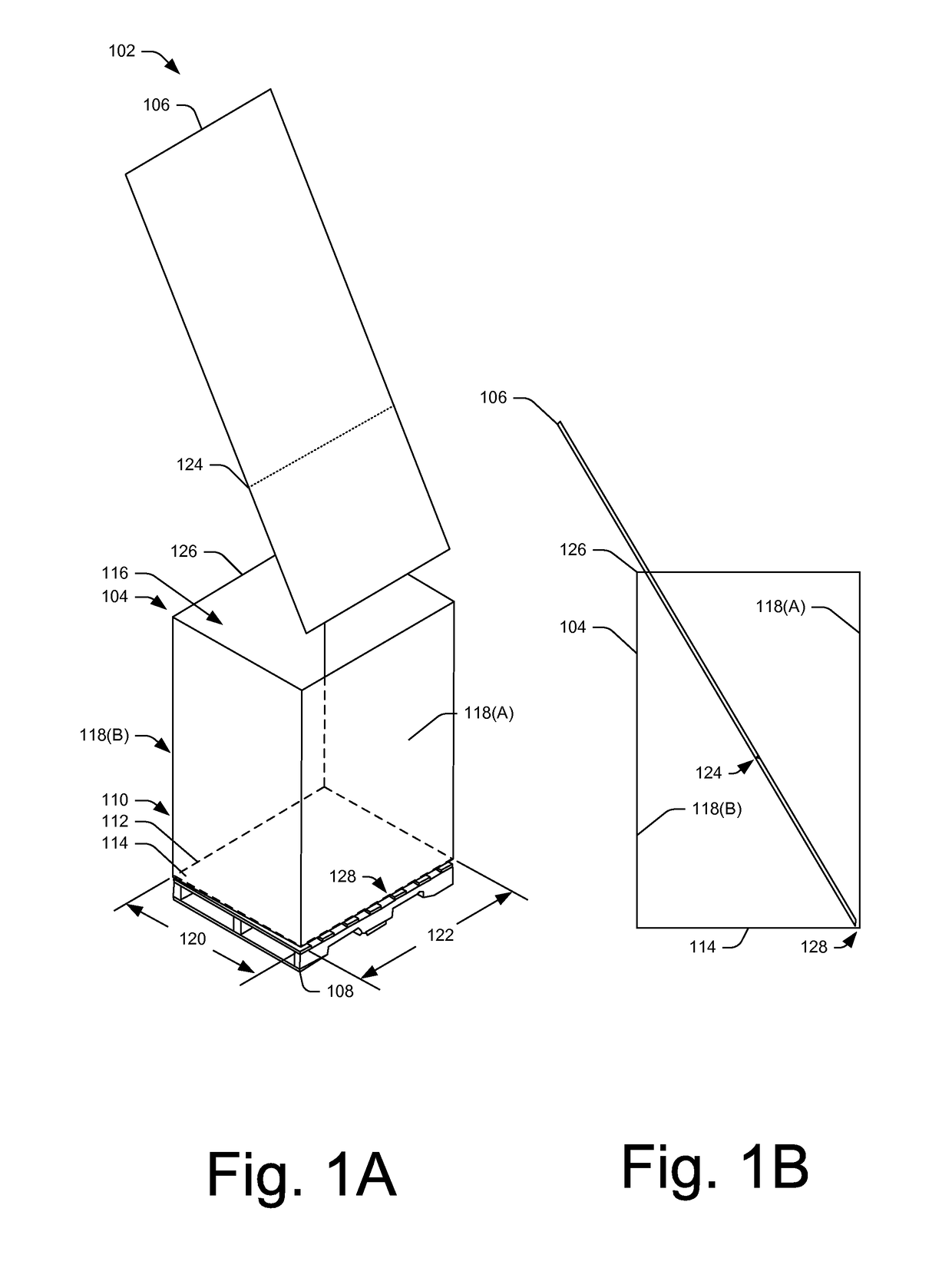

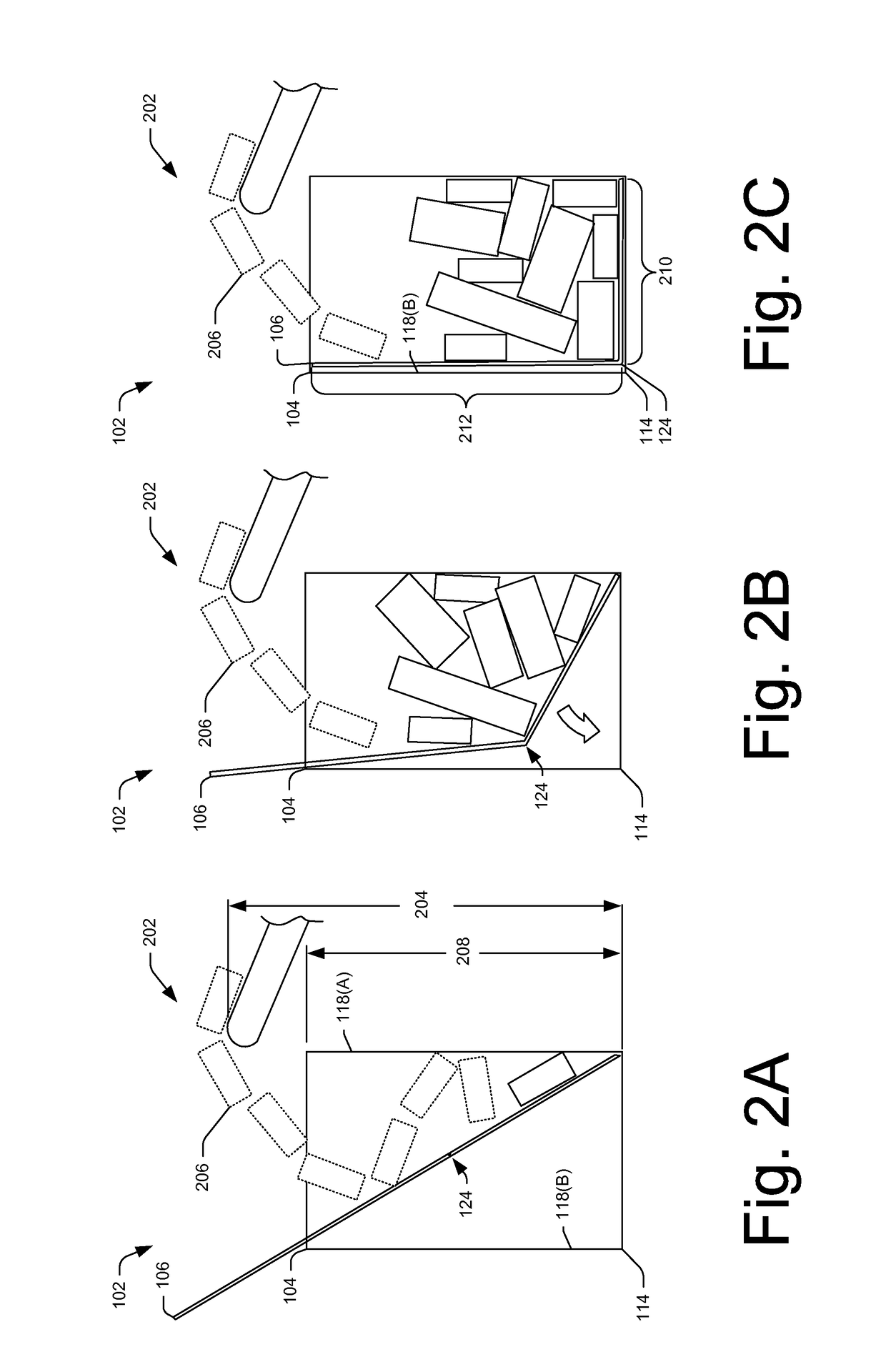

Bulk box dampening systems

A packaging assembly comprises a bulk box having a shock absorber to dampen a kinetic energy of product being dispensed from a conveyor system. The shock absorber may be a rectangular sheet shock absorber disposed diagonally in the bulk box, a shuttle tray shock absorber disposed in an opening of the bulk box, a deflector net disposed in an opening of the bulk box, or a inflatable bag shock absorber disposed in the bulk box, for example.

Owner:AMAZON TECH INC

Pallet-free bulk bin container

A pallet-free bulk bin container comprises an open-ended bulk bin having a frame base at one end. A pair of channel inserts is configured to be engaged with the frame base to form pallet runners. A pair of center-filler supports is configured to enclose one end of the open-ended bulk bin. The bulk bin container may be shipped in a collapsed or knocked-down state and easily assembled into a larger container for use and being disassembled for re-use.

Owner:INT PAPER CO

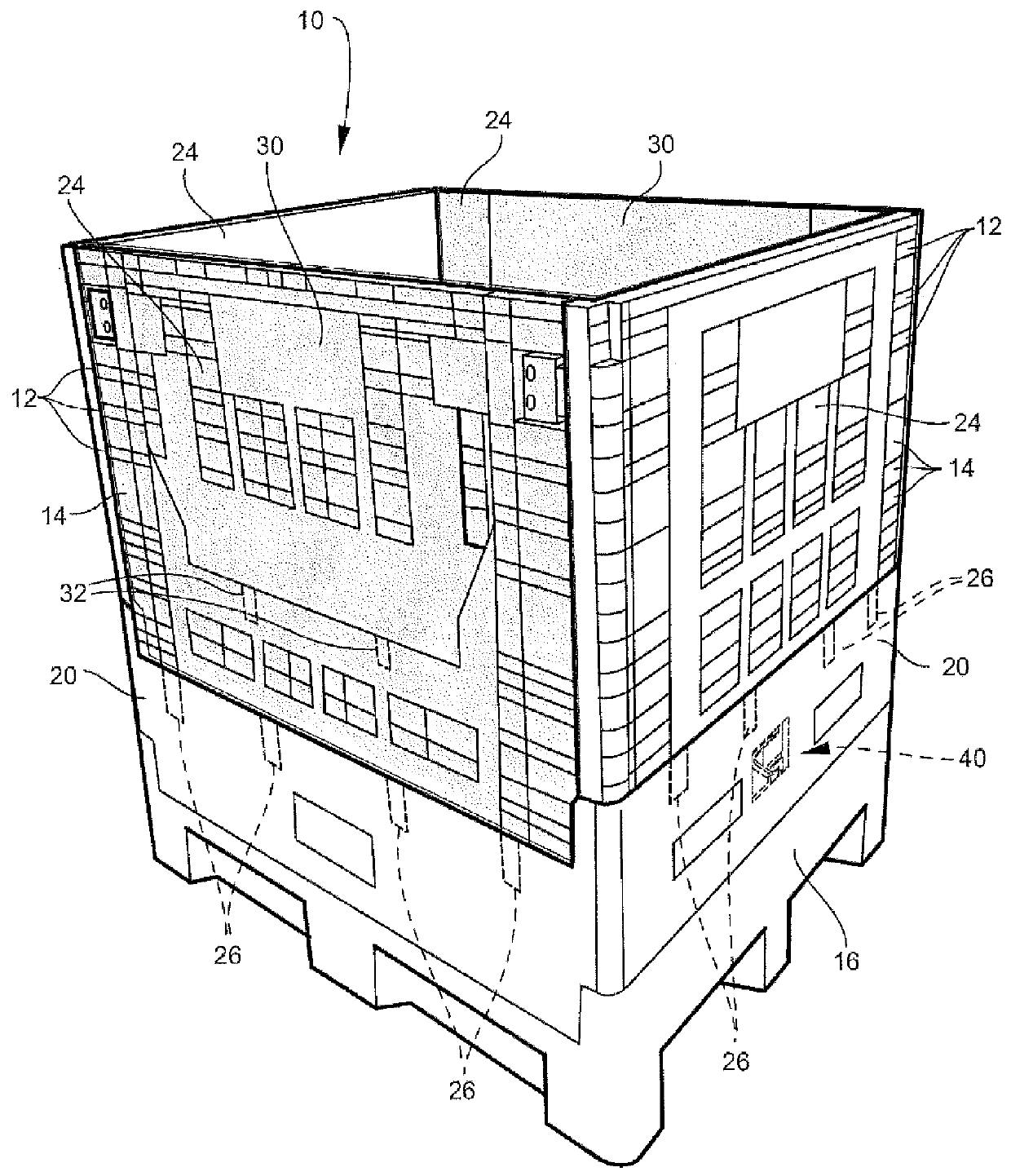

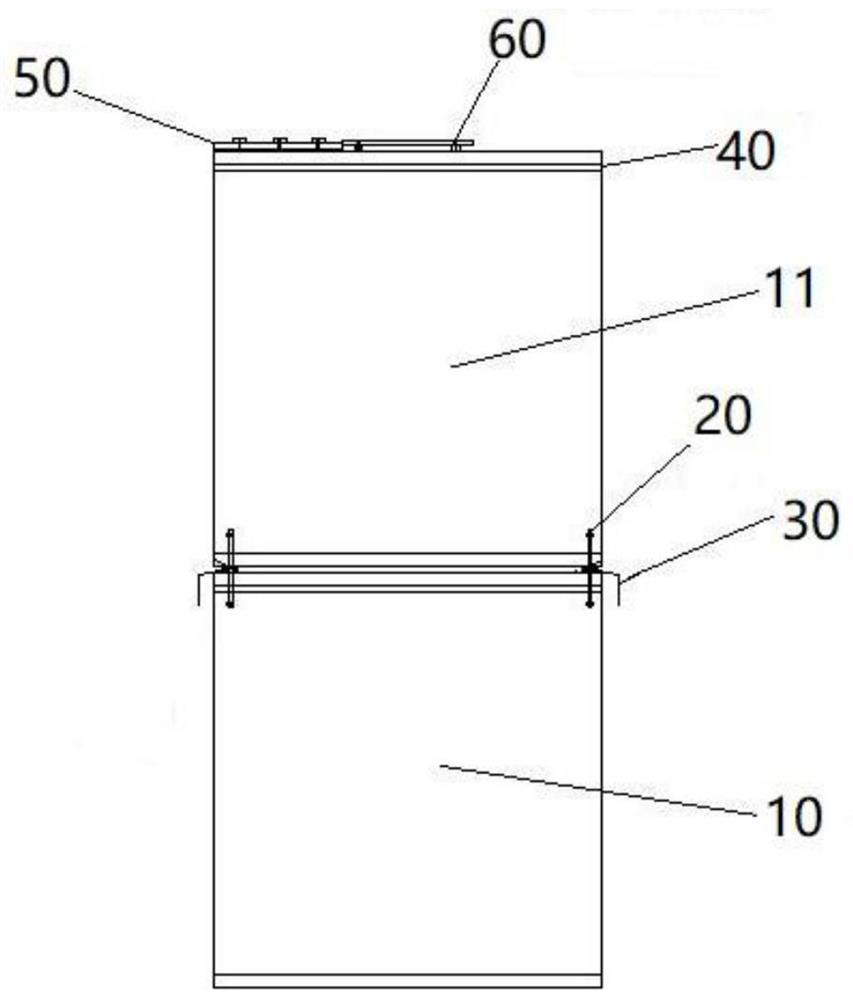

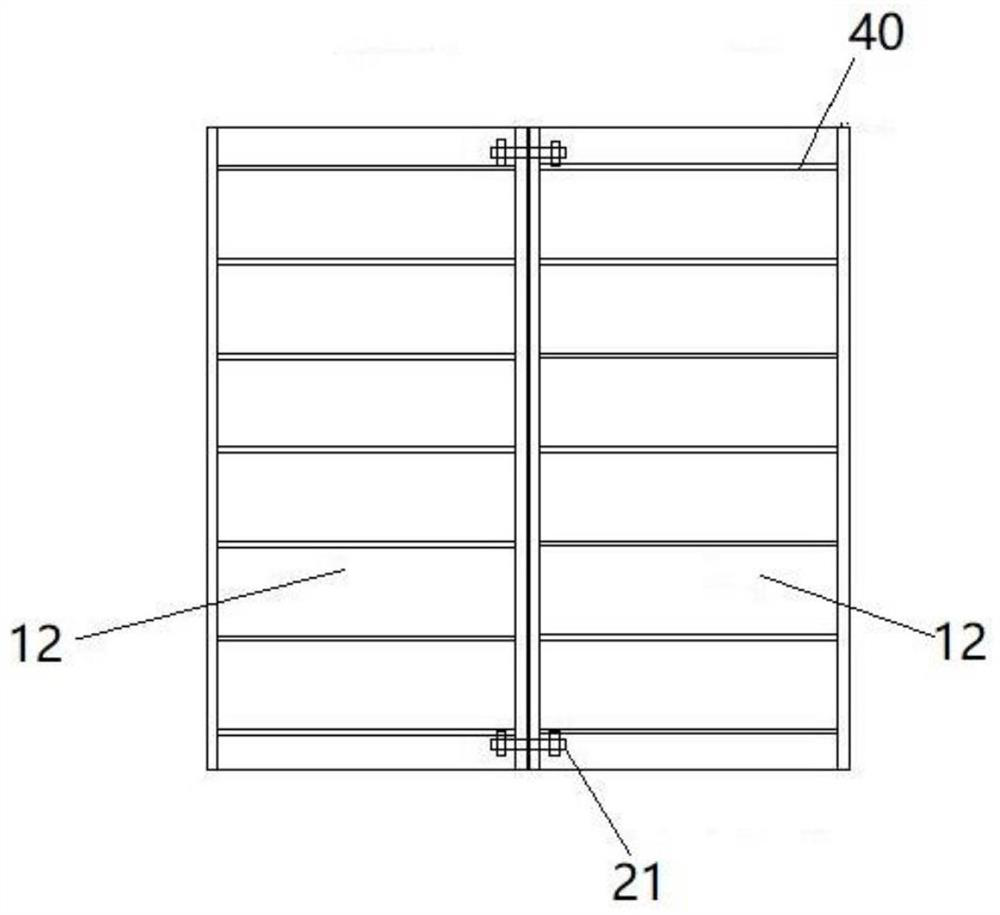

Rapid installation method of combined container house

InactiveCN111636571AReduce the difficulty of positioningImprove installation efficiencyBuilding insulationsBulk boxBox girder

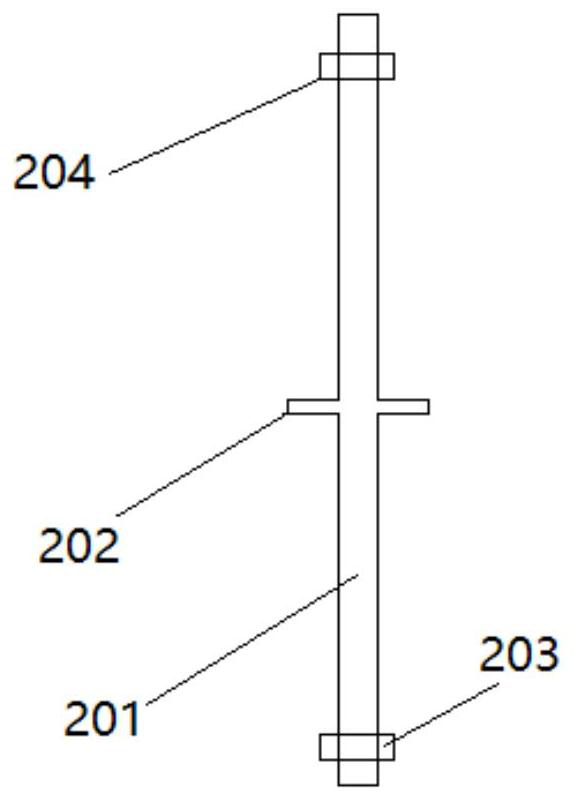

The invention relates to a rapid installation method of a combined container house. The rapid installation method of the combined container house comprises the steps that a first combined container house is hoisted and placed at a setting-out position on the ground according to construction requirements; the upper top plate of the first combined container house is taken as a positioning surface, and positioners are installed at the positions of four corner post reserved holes; four corner post reserved holes on the lower bottom plate of a second combined container house are placed on positioning rods of the four positioners of the first combined container house in one-to-one correspondence; after the second combined container is in place, nuts on the positioners are tightened to connect the upper and lower combined container house into a whole; and after the combined container houses are assembled, a load-bearing device and an aisle device are installed on the top box beams of an uppermost container house. The positioners can be disassembled and assembled at any time, can be adjustable and suitable for the rapid assembly of various bulk boxes, can reduce the positioning difficultyof a box house in the hoisting process, and has high installation efficiency.

Owner:CHINA FIRST METALLURGICAL GROUP +1

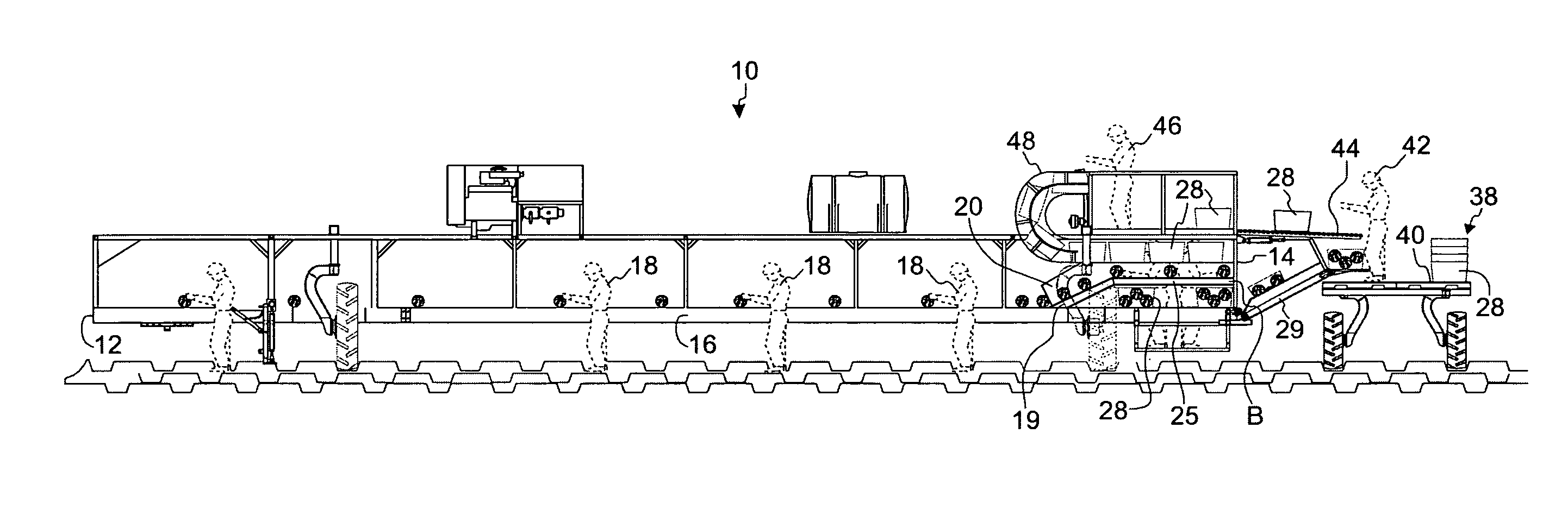

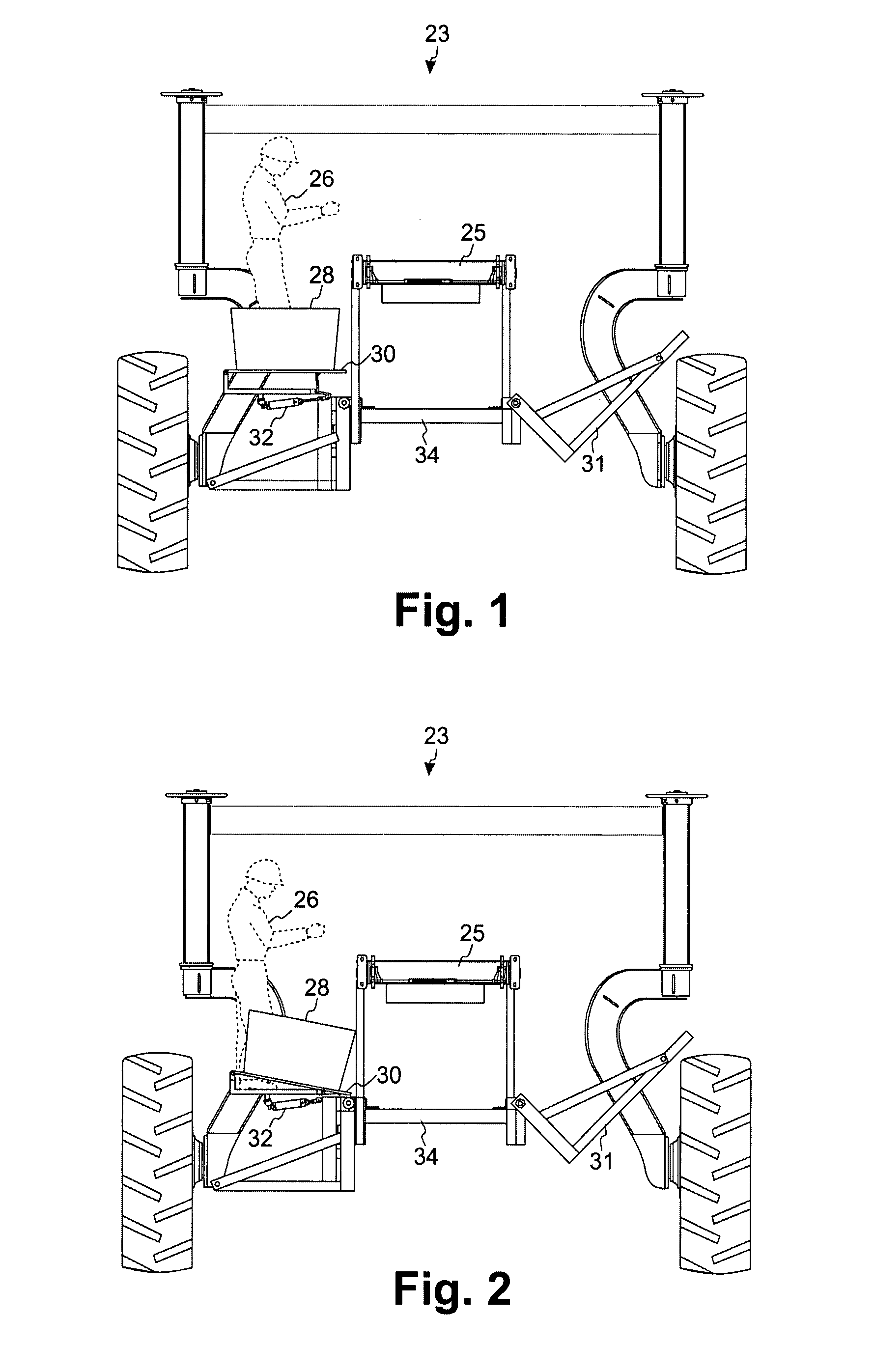

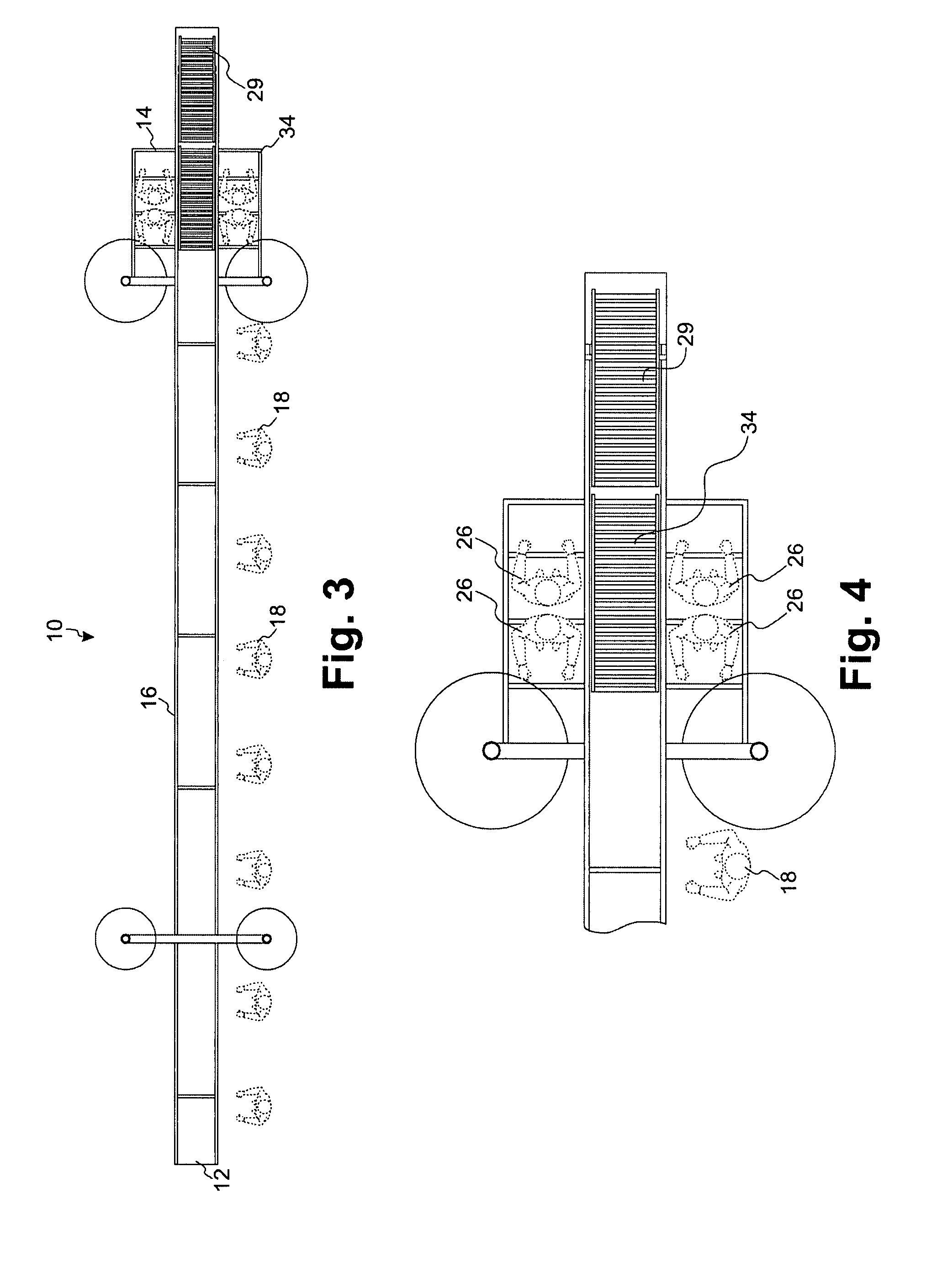

Combination bulk and tote loading harvesting apparatus and method

A harvester capable of alternate configurations for bulk and tote loading. In a tote loading configuration, harvested produce is moved along a main conveyor, elevated to a raised conveyor area, packed into totes, and the packed totes are then moved onto a lower conveyor for further transport. In a bulk loading configuration, the harvested produce is transported along the main conveyor, to a raised conveyor area, and are then lifted using an elevator for placement into a bulk bin.

Owner:RAMSAY HIGHLANDER

Bulk bin with integrated shock absorber

A stackable bulk bin container having shock absorbing elements is provided. The bulk bin container includes a base portion and four collapsible sidewalls. The base includes feet extending downward. The feet are connected by stringers forming four corner portions. Shock absorbing elements are positioned proximate the corner portions in the base of the container. The shock absorbing elements absorb energy from impacts when the container is stacked on like containers.

Owner:ORBIS CORP

Top cap

ActiveUS9296515B2Reduce weightReliable matingOther accessoriesContainer/bottle contructionBulk boxPlastic materials

A top cap designed to allow any of a pallet, a bulk bin and a metal rack, each having a different support configuration, or any of a nestable pallet and a bulk bin, to stack securely on an upper surface of the top cap. The top cap including a plurality of raised and / or indented portions on the upper surface configured to mate with a bottom surface of the pallet, bulk bin or metal rack. The top cap also being configured to allow other pallets, bulk bins, or metal racks to stack securely on the upper surface of the top cap. The top cap being formed from a molded plastic material.

Owner:ORBIS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com