Bulk bin and bag dispensing apparatus

a technology for dispensing equipment and bags, which is applied in the direction of liquid dispensing, liquid flow controllers, packaging, etc., can solve the problems of small amount of product collected or spilled on the floor, difficult to cross-thread coarse threads, and general difficulty in starting soft fine threads, so as to eliminate cross-threading and eliminate leakage , the effect of eliminating leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

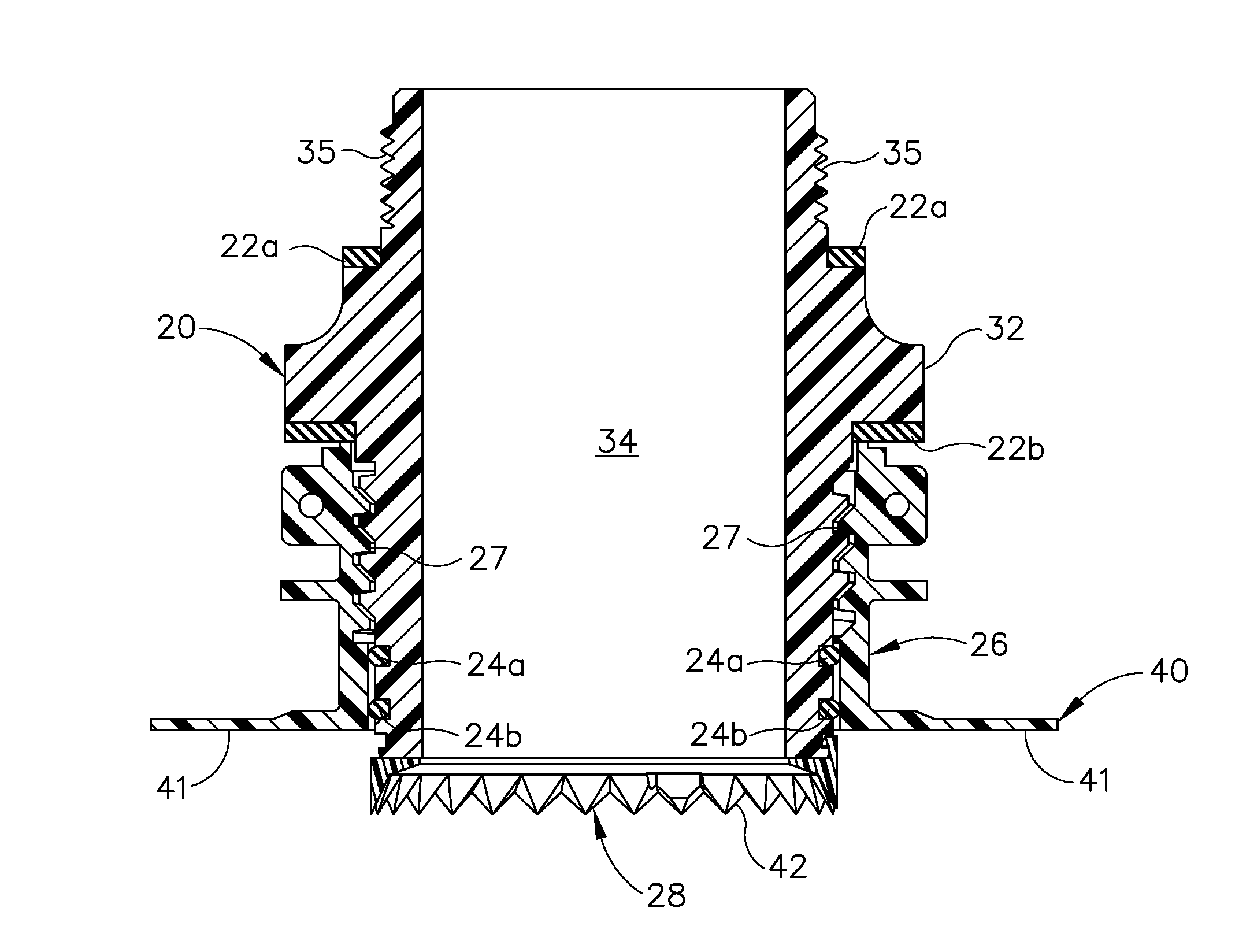

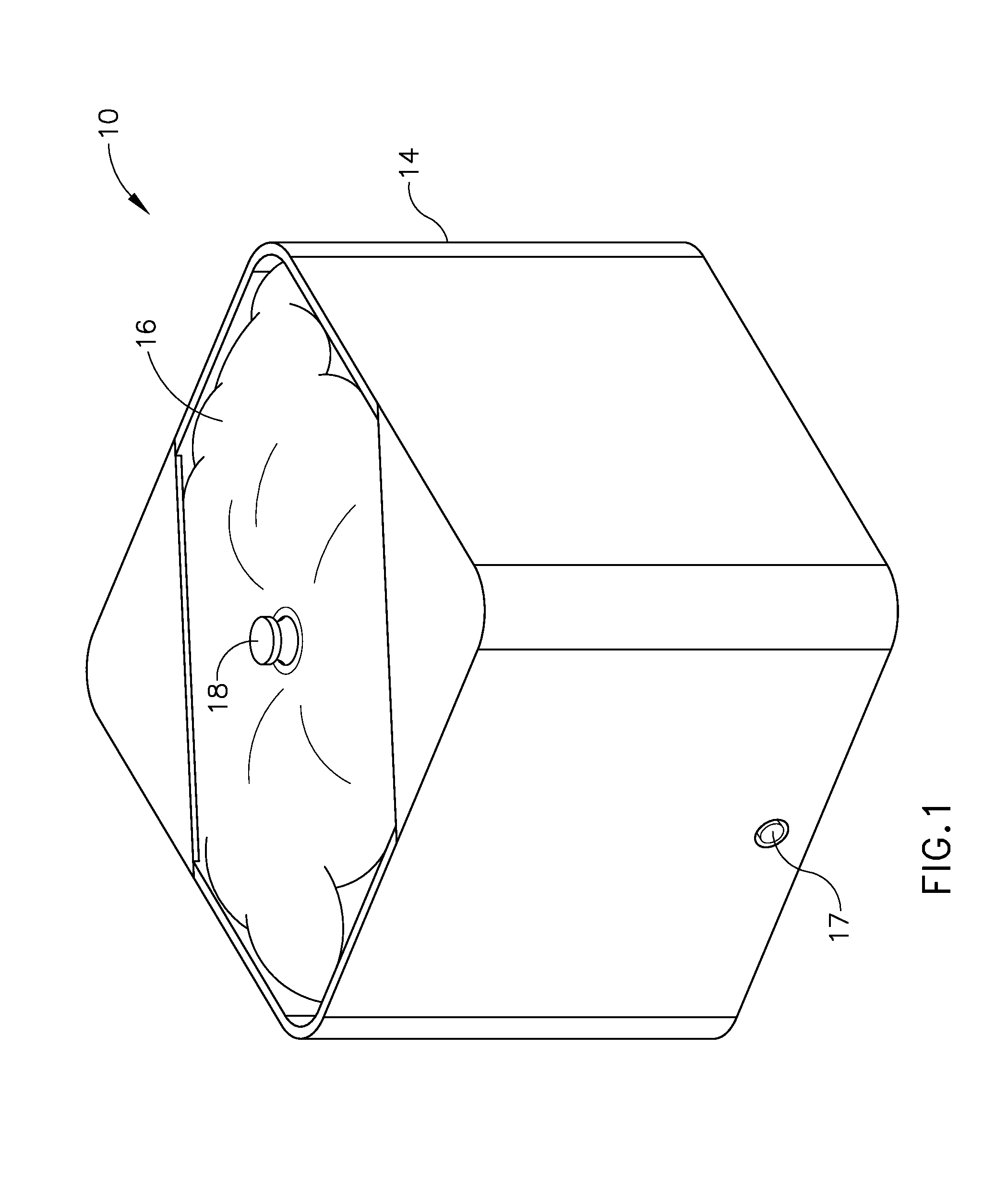

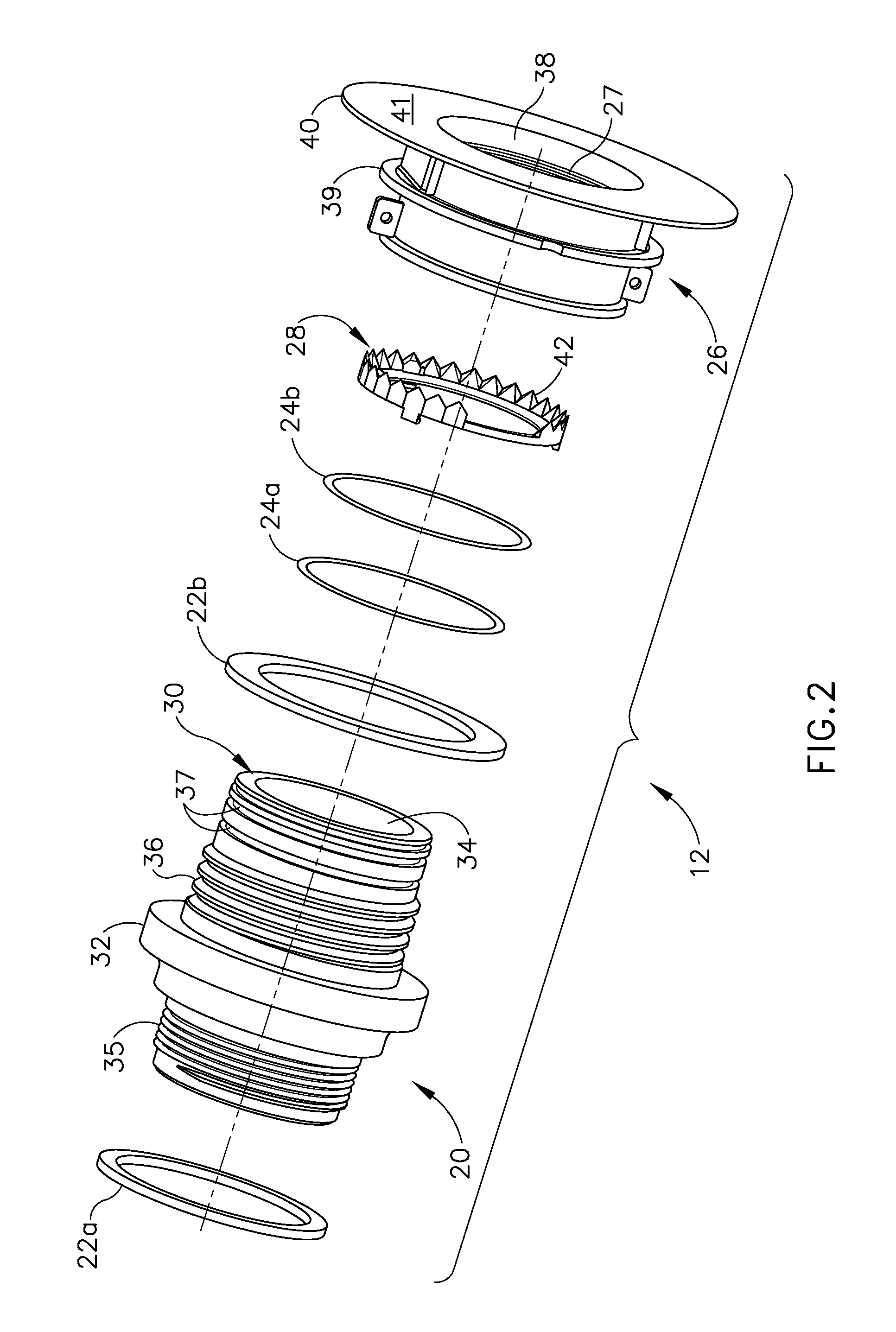

[0017]FIG. 1 is a top perspective view of an intermediate bulk container (IBC) 10 defined by a bag and box combination receiving a dispensing apparatus (not shown in FIG. 1) in accordance to the preferred embodiment of the invention. The bag and box combination is comprised of a rigid bulk bin or box 14 and a plastic bag 16 made of suitable flexible material such as plastic. One particularly suitable container for forming the rigid bulk bin 14 is sold by International Paper Company under the trademark SpaceKraft™. The bulk bin 14 is made from a continuously wound sleeve of linerboard and corrugated medium to create a package that is six to ten layers thick with no seam. This seamless construction has no manufacturing joint which offers extraordinary strength-up to 75,000 pounds of top-to-bottom compression strength without wood or metal components. However, one of ordinary skilled in the art would appreciate that the invention may also be used with other outer rigid bulk bin. The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com