Automatic can opening device

An automatic, can opener technology, applied in packaging, transportation and packaging, unsealing by removing items, etc., can solve the problems of low manual operation efficiency, high labor intensity, and complicated operation, so as to save labor costs and increase production efficiency , the effect of improving the economic efficiency of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

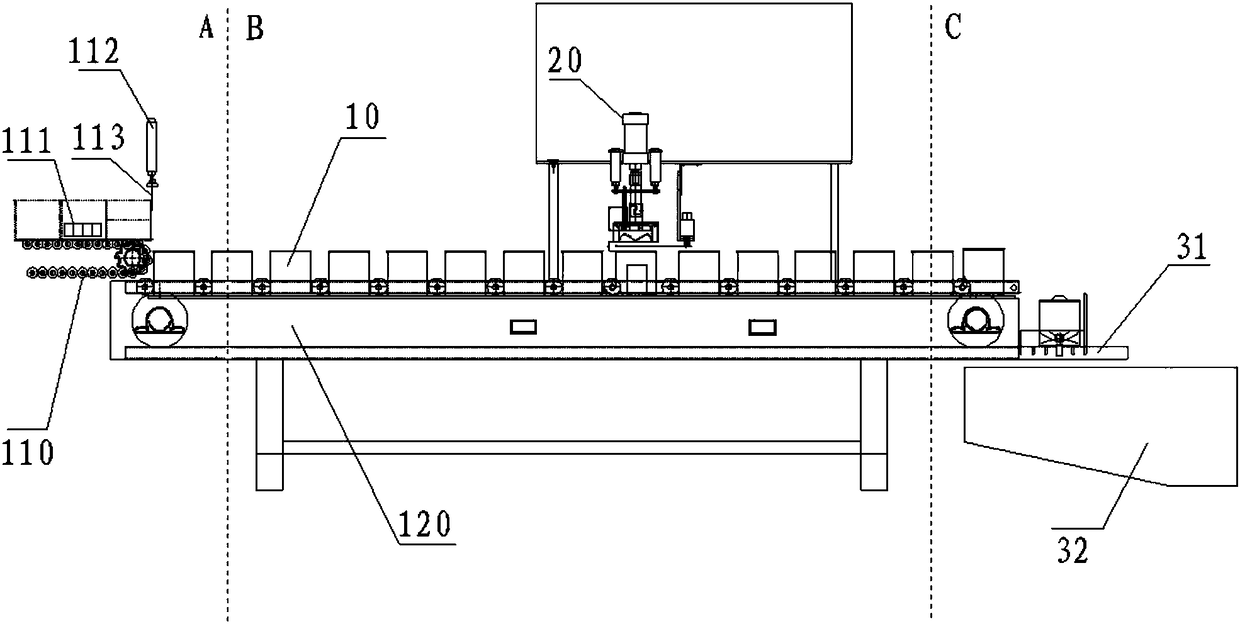

[0032] see Figure 1 to Figure 4 , an automatic can opening device, comprising a transportation module, a can opening module 20 and a collection module, the transportation module passes through the feeding area A, the opening area B and the unloading area C in sequence, and the opening module 20 is arranged on In the can opening area B, the collection module is set in the unloading area C and is located at the end of the transport module,

[0033] The transportation module is used to sequentially transport the cans 10 to the can opening area B for opening the cans, and transport the opened cans to the unloading area C;

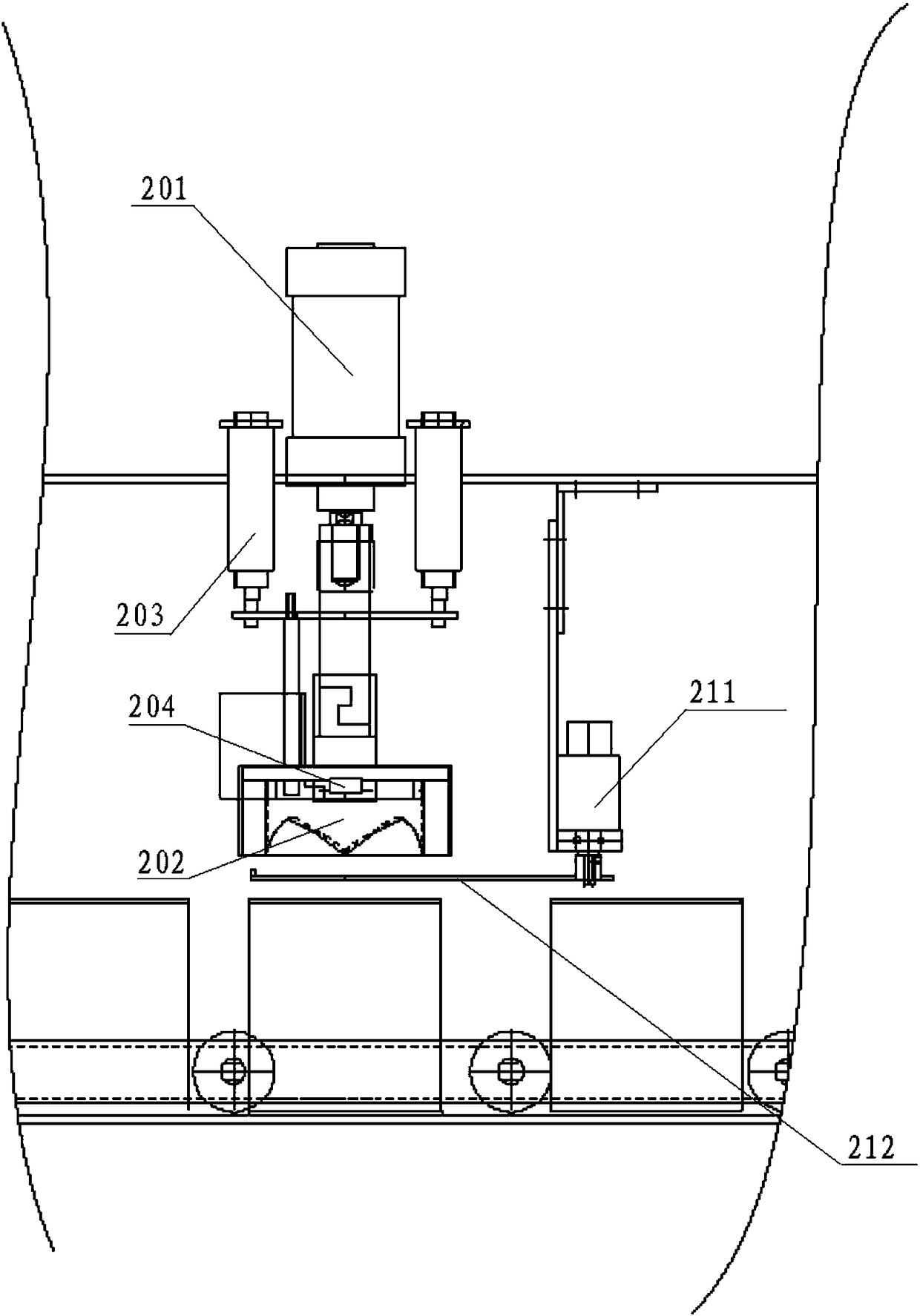

[0034] The can opening module 20 is used to open the can and separate the can from the lid of the can;

[0035] The collection module is used to collect the contents of the can.

[0036] In this embodiment, the automatic can opening device is controlled and coordinated by the PLC control servo system. The transport module arranges the cans in a team and tran...

Embodiment 2

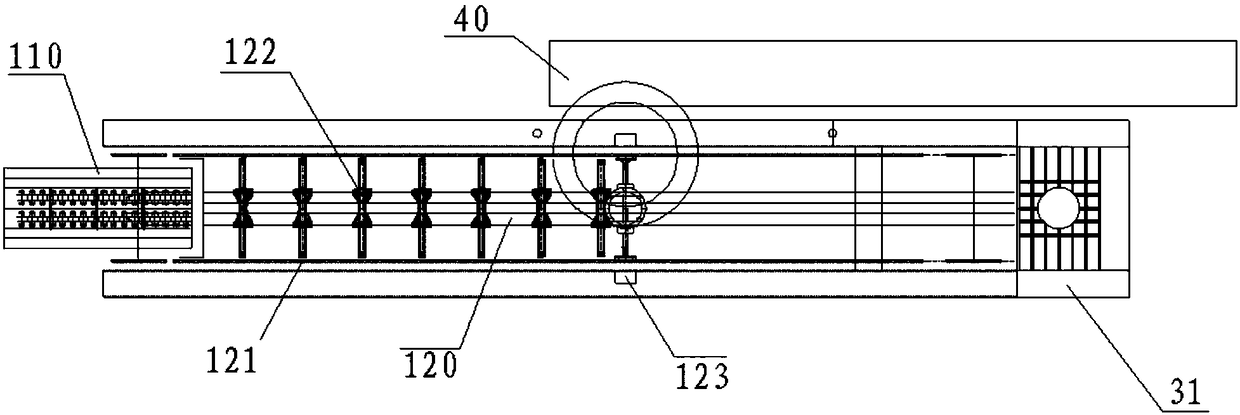

[0040] On the basis of Embodiment 1, the transport module includes an array transport line 110 and a can opening conveyor line, the head end of the can opening conveyor line is arranged below the end of the array transport line 110,

[0041] The entire line of transportation 110 is located in the feeding area A, and includes a fixed can mechanism 111 arranged on one side of the conveyor belt and a can-down mechanism arranged at the end of the conveyor belt. The fixed can mechanism 111 is used to prevent the movement of the next can. The can mechanism is used to control whether the current can enters the can opening conveying line;

[0042] The can opening conveying line includes two can conveying chains 121 and can conveying guide rails 120, the two can conveying chains 121 are arranged around the can conveying guide rails 120 along the length direction of the can conveying guide rails 120, and the can conveying chains 121 include intervals between them. The roller 122 is shap...

Embodiment 3

[0049] On the basis of Embodiment 2, the can opening conveyor line is located at the can opening module 20 and is provided with a can positioning mechanism 123, and the can positioning mechanism 123 is used to fix the cans 10 so that the can opening module 20 can open the cans 10. .

[0050] In this embodiment, the can positioning mechanism is composed of can positioning blocks arranged on both sides of the can opening conveying line and a driver for driving the can positioning blocks to realize tightening or loosening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com