Preparation method for convenient rice noodle

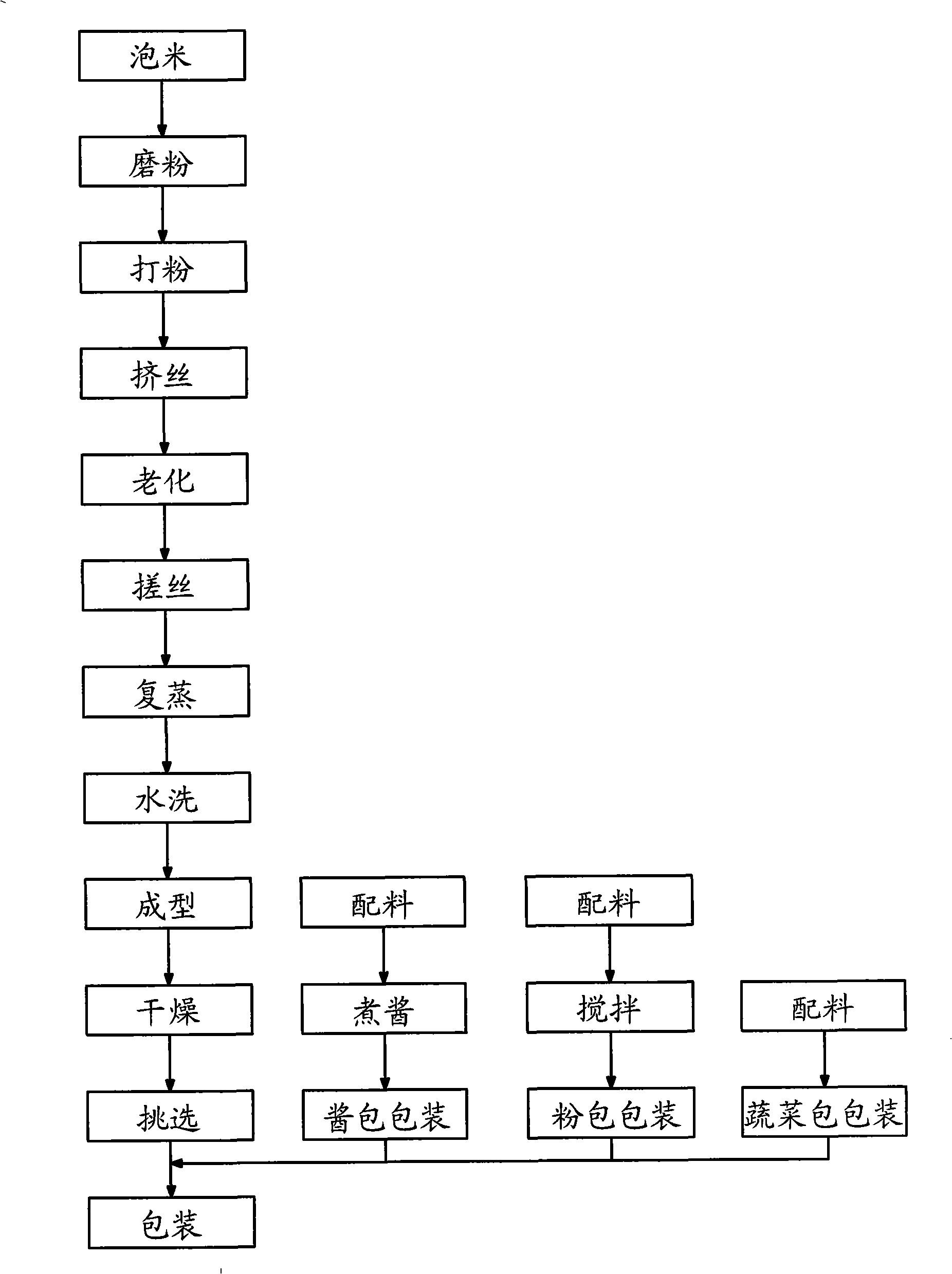

A production method and technology of rice noodle, applied in food preparation, application, food science and other directions, can solve the problems of not adapting to market demand, lack of rice fragrance, easy to stick and form agglomerates, etc., to achieve easy extrusion, smooth organization, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

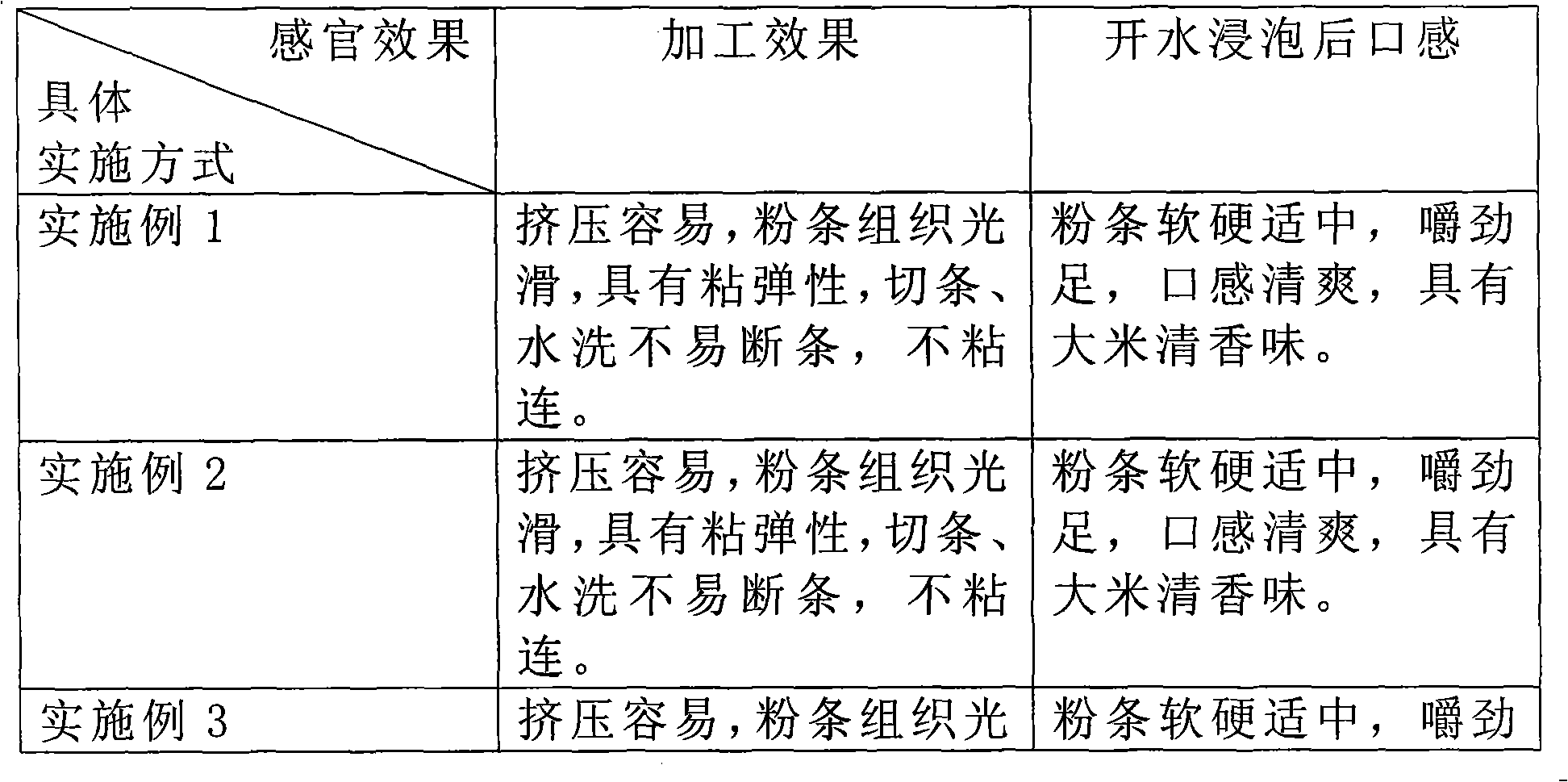

Embodiment 1

[0028] Select the early indica rice and the late indica rice with a weight ratio of 3:1, soak them in drinking water for 2 hours, pass the early indica rice and the late indica rice through a pulverizer (model: QWJ-60A) and a mixer (model: KR5A-40 ) Grinding, grinding to the fineness of rice flour can pass through 80 mesh sieves.

[0029] Add drinking water to the rice noodles ground by a micro pulverizer and a blender and stir well, so that the moisture content of the rice noodles reaches 40% by weight, and then put them into a self-cooked silk extruder (model: JN-A) for extrusion The way of heat generation by machine friction is to extrude silk at a temperature of 90°C. After extrusion, the diameter of vermicelli is 0.6-0.9mm, and the degree of vermicelli maturity is more than 90%.

[0030] The vermicelli is extruded from the wire extruder and fully cooled during the process of falling. After falling to a certain length, it is cut off with scissors, picked up from the middle...

Embodiment 2

[0033] Select the early indica rice and the late indica rice with a weight ratio of 1:1, soak them in drinking water for 3 hours, pass the early indica rice and the late indica rice through a pulverizer (model: QWJ-60A) and a mixer (model: KR5A-40 ) and grind until the fineness of rice flour can pass through a 70-mesh sieve.

[0034] Add drinking water to the rice noodles ground by a micro pulverizer and a blender and stir well, so that the moisture content of the rice noodles reaches 35%, and then put them into a self-cooked silk extruder (model: JN-A) for extrusion The way of heat generation by machine friction is to extrude silk at a temperature of 100°C. After extrusion, the diameter of the vermicelli is 0.5-0.8mm, and the degree of vermicelli maturity is more than 90%.

[0035] The vermicelli is extruded from the wire extruder and fully cooled during the process of falling. After falling to a certain length, it is cut off with scissors, picked up from the middle with a ba...

Embodiment 3

[0038] Select the early indica rice and the late indica rice with a weight ratio of 5:1 and soak them in drinking water for 1 hour. ) to grind until the fineness of rice flour can pass through a 100-mesh sieve.

[0039] Add drinking water to the rice noodles ground by a micro pulverizer and a blender and stir well, so that the moisture content of the rice noodles reaches 45%, and then put them into a self-cooked silk extruder (model: JN-A) for extrusion The way of heat generation by machine friction is to extrude silk at a temperature of 85°C. After extrusion, the diameter of vermicelli is 0.6-0.9mm, and the degree of vermicelli maturity is more than 80%.

[0040] The vermicelli is extruded from the wire extruder and fully cooled during the process of falling. After falling to a certain length, it is cut off with scissors, picked up from the middle with a bamboo stick, and hung on the shelf in the aging room. The aging room is kept sealed, the humidity is controlled at 70% to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com