Metallized membrane capacitance embedding wax

A technology of metallized film and potting wax, which is applied in the direction of capacitors, fixed capacitor shells/packages, chemical instruments and methods, etc., can solve the problems of toughness and plasticity, easy to be brittle, easy to leak, large shrinkage, etc., and achieve heat resistance And the effect of good cold resistance, excellent electrical properties and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

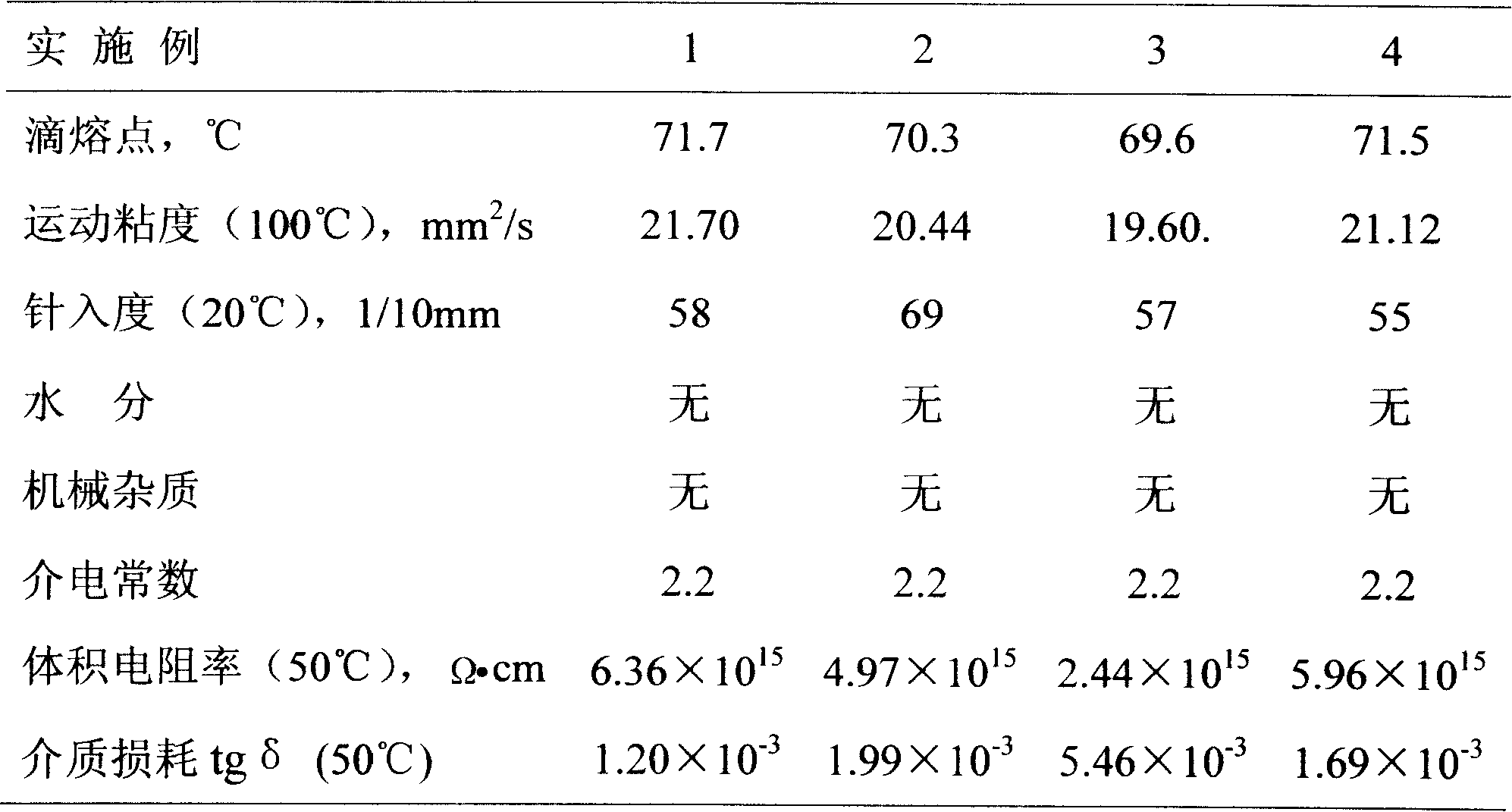

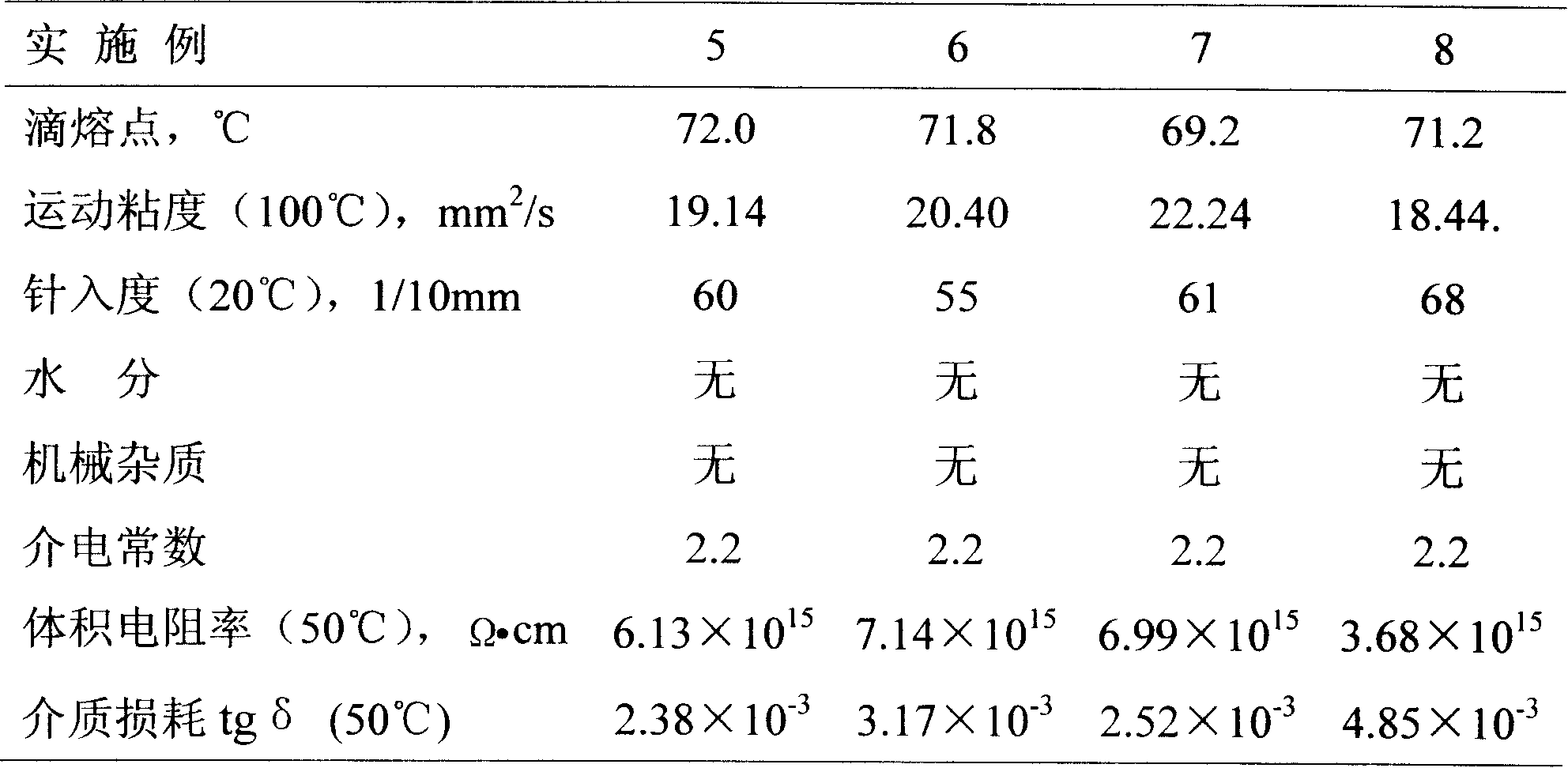

[0029] Embodiment: (below all represent by weight percentage)

[0030] experiment method

[0031] The following test methods are the usual ones for testing waxes used in the electronics industry used in the examples.

[0032] Dropping melting point GB / T8026

[0033] Penetration GB / T4985

[0034] Kinematic viscosity GB / T265

[0035] Moisture GB / T260

[0036] Mechanical impurities GB / T511

[0037] Dielectric constant GB / T5654

[0038] Volume resistivity GB / T5654

[0039] Dielectric loss GB / T5654

Embodiment 1

[0042] 70 # Microcrystalline wax, dropping point 69.4°C (Dushanzi Refinery) 28%

[0043] 75 # Microcrystalline wax, dropping point 76.4°C (Nanchong Oil Refinery) 15%

[0044] Synthetic wax, with an average melting point of 92.4°C (Jinxi Petrochemical Company) 2%

[0045] Polyisobutylene, average molecular weight 1000 (Jinzhou Lubricating Oil Additive Co., Ltd.) 20%

[0046] Medical Vaseline, dropping point 65.5°C (Hebei Lanlian Feitian Petrochemical Co., Ltd.) 35%

Embodiment 2

[0048] 70 # Microcrystalline wax, dropping point 69.4°C (Dushanzi Oil Refinery) 22%

[0049] 75 # Microcrystalline wax, dropping point 76.4°C (Nanchong Oil Refinery) 16%

[0050] Synthetic wax, with an average melting point of 92.4°C (Jinxi Petrochemical Company) 2%

[0051] Polyisobutylene, average molecular weight 1000 (Jinzhou Lubricating Oil Additive Co., Ltd.) 18%

[0052] Medical Vaseline, dropping point 65.5°C (Hebei Lanlian Feitian Petrochemical Co., Ltd.) 42%

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

| Dropping point | aaaaa | aaaaa |

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com