Hall chip forming tool

A Hall chip, forming tooling technology, applied in metal processing, terminal application devices, etc., can solve the problems of damage to the capacitor part and chip part of the Hall chip, slow down the running speed, etc., to ensure displacement accuracy, ensure stability, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

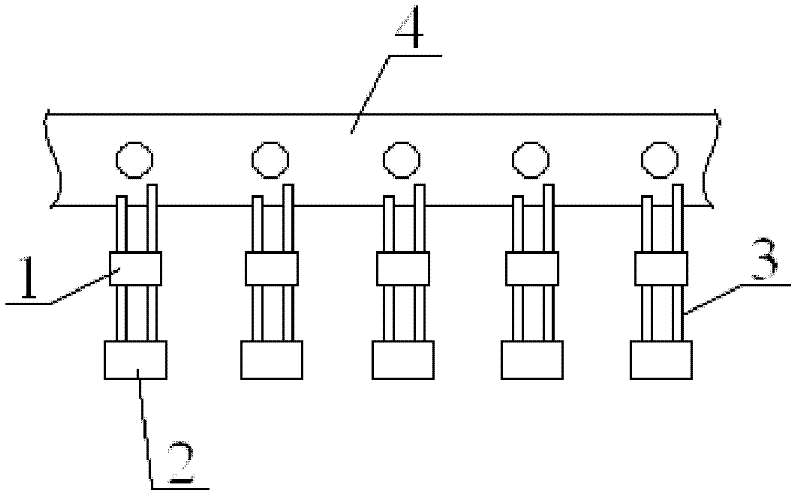

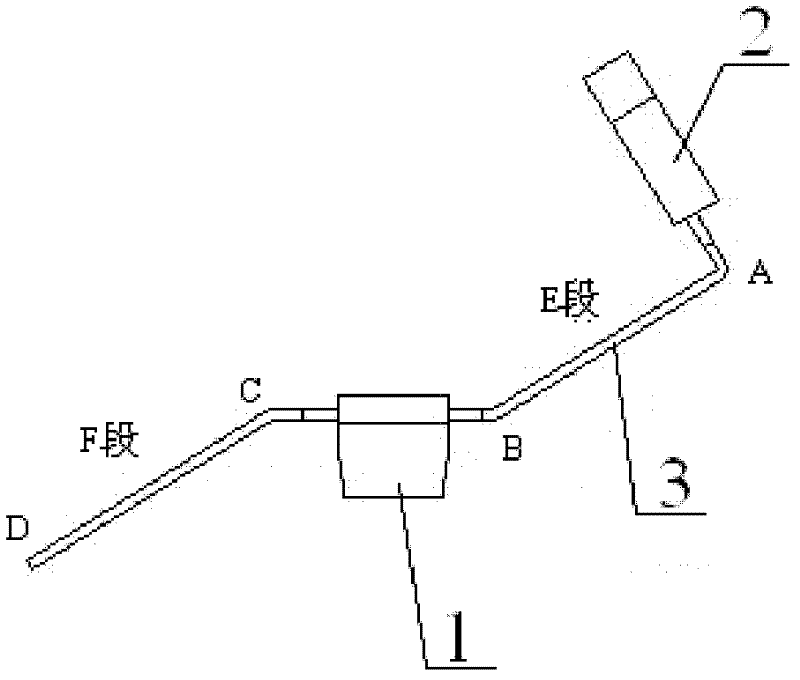

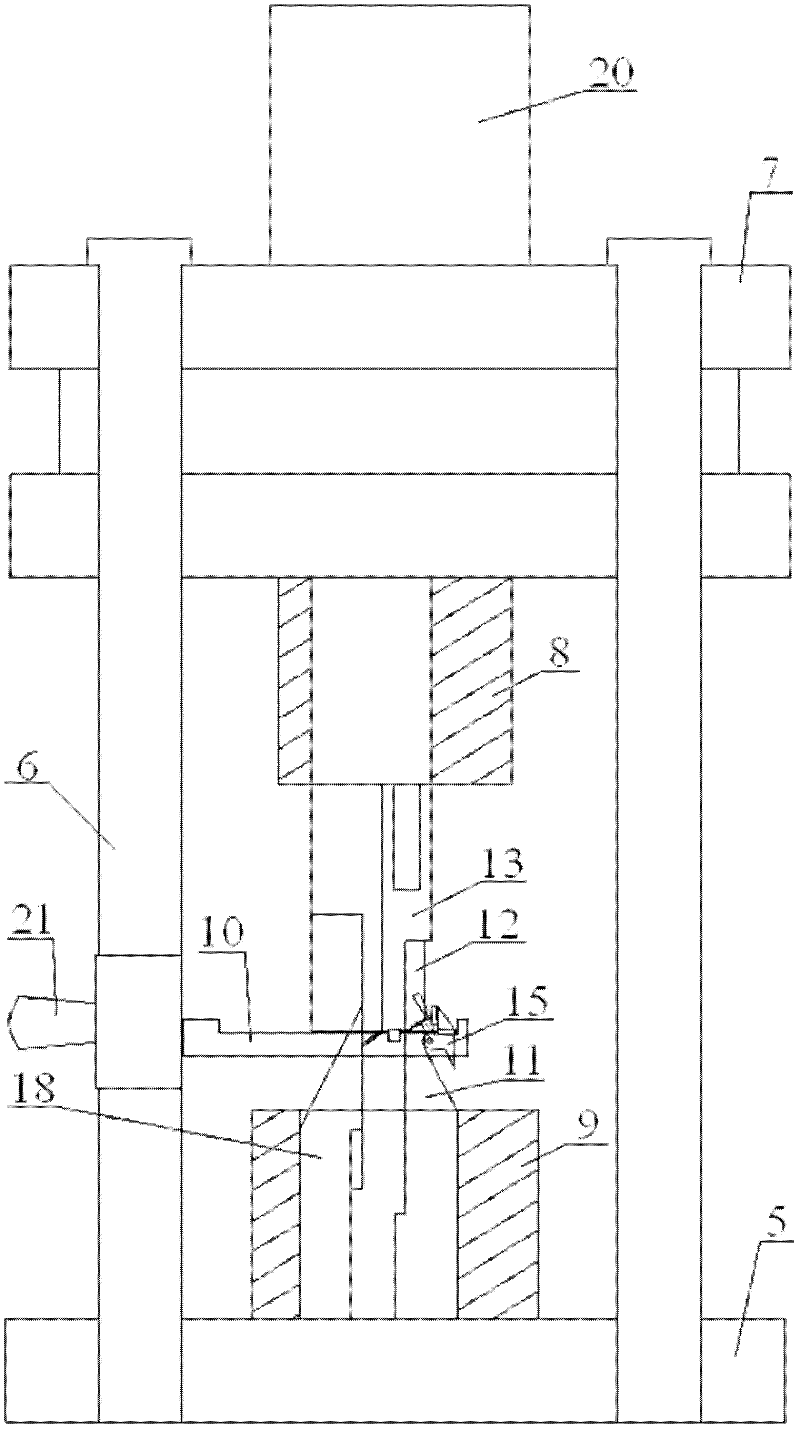

[0028] Referring to the accompanying drawings, referring to the accompanying drawings, a Hall chip forming tooling includes a lower mold base 5, four guide pillars 6 are respectively fixed around the upper surface of the lower mold holder 5, and the four guide pillars 6 are fitted by sliding An upper mold base 7 is installed, and upper and lower fixing blocks 8, 9 are respectively elastically installed above the upper and lower mold bases 7, 5, and feed guide grooves 10 are fixedly installed between the four guide pillars 6, and feed guide grooves The middle part of 10 is provided with an opening, and the lower fixed block 9 is fixedly equipped with a support seat 11, and the support seat 11 extends from the opening in the middle part of the feeding guide groove 10; Upper die pressing block 12,13, upper blade and upper die pressing block 12,13 are positioned at the top of support seat 11, wherein the end of upper blade 12 has wedge-shaped knife edge 14, is positioned at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com