Method for rapidly preparing large-area and uniform black silicon material, and device thereof

A large-area, black silicon technology, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve the problems of poor surface microstructure uniformity, low efficiency, and inability to meet mass production, and achieve high preparation efficiency and uniformity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

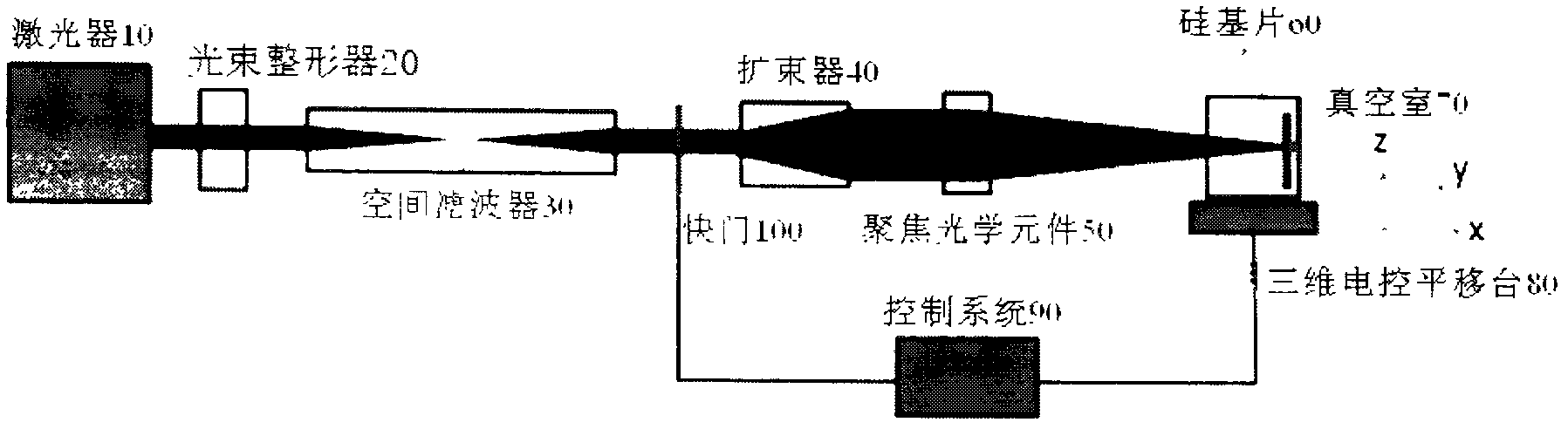

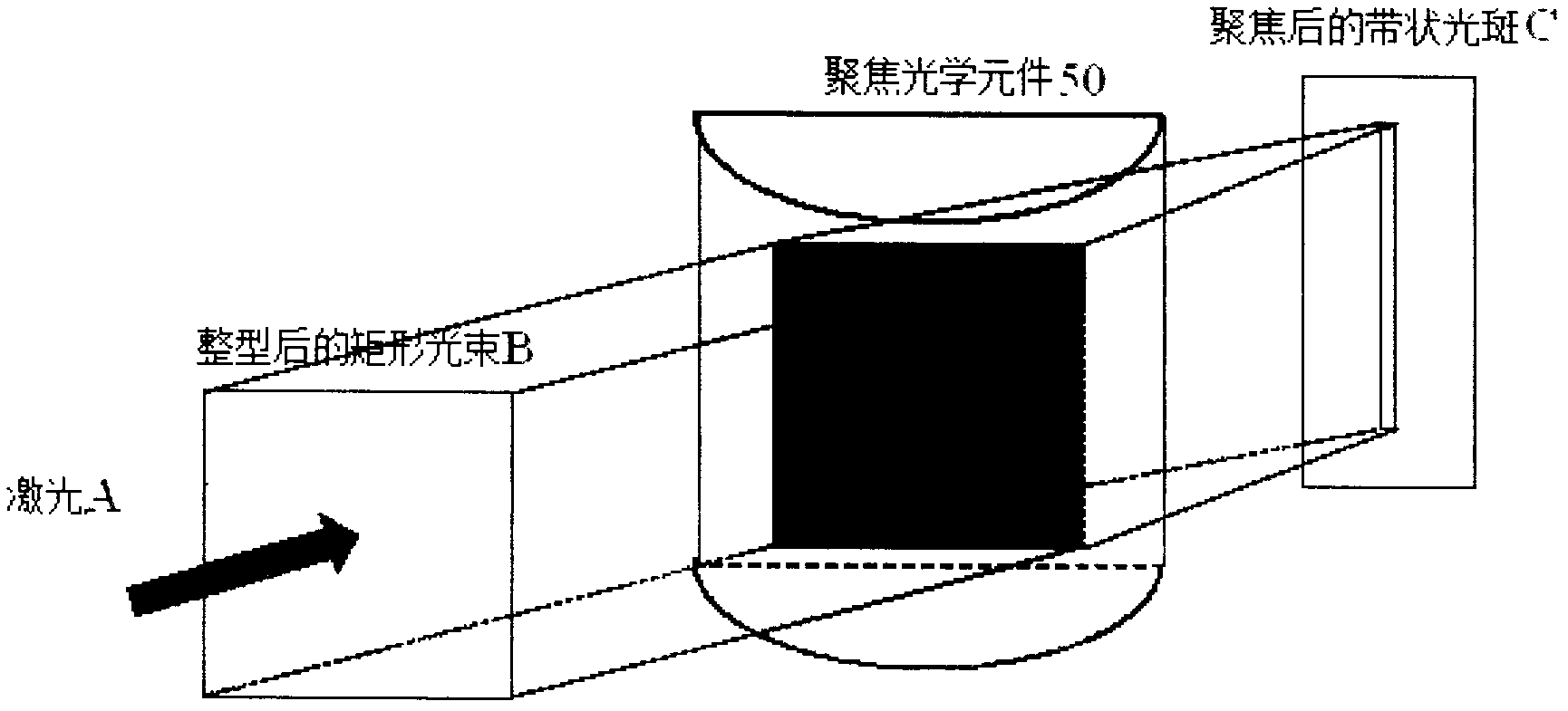

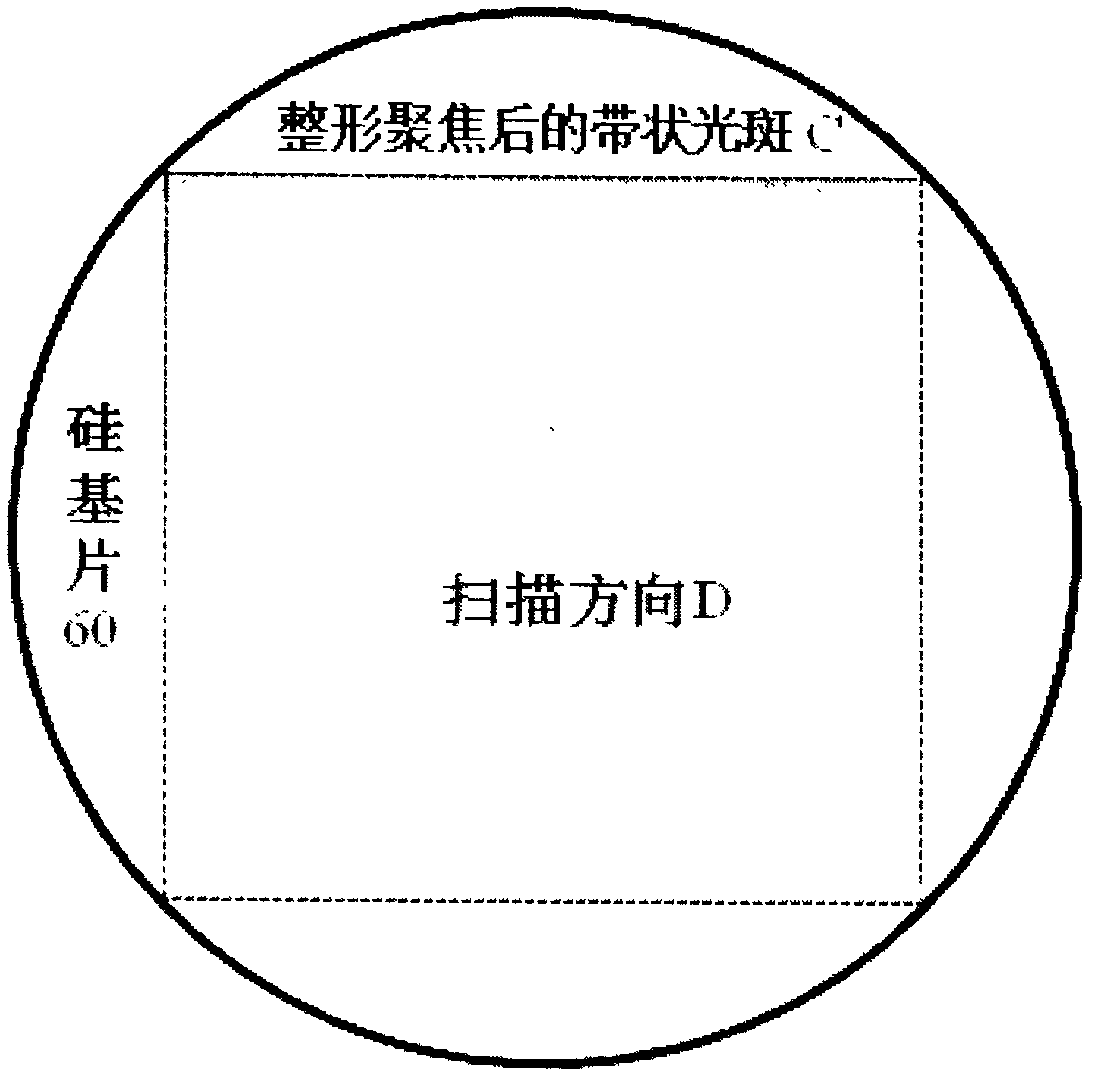

[0029] The invention discloses a method and equipment for rapidly preparing large-area black silicon materials by using pulsed laser raster scanning. figure 1It is a schematic diagram of the equipment structure and laser light path for rapid preparation of black silicon materials. The laser 10 emits a pulsed laser beam with a pulse width ranging from femtoseconds to milliseconds, including femtoseconds, picoseconds, nanoseconds, etc.; the output frequency of the laser 10 ranges from 0.1-100K Hz, and the single pulse energy output by the laser 10 ranges from Joule - 1000 Joule range. Because the beam output by the laser 10 is generally a circular beam, in order to obtain a surface microstructure with uniform physical and chemical prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com