Pulp for lithium ionic cell electrode and manufacturing method thereof

A lithium-ion battery and slurry technology, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of reducing the main component content of slurry, delamination, dry material splashing, etc., and achieve improved storage stability , Conducive to uniform distribution, improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

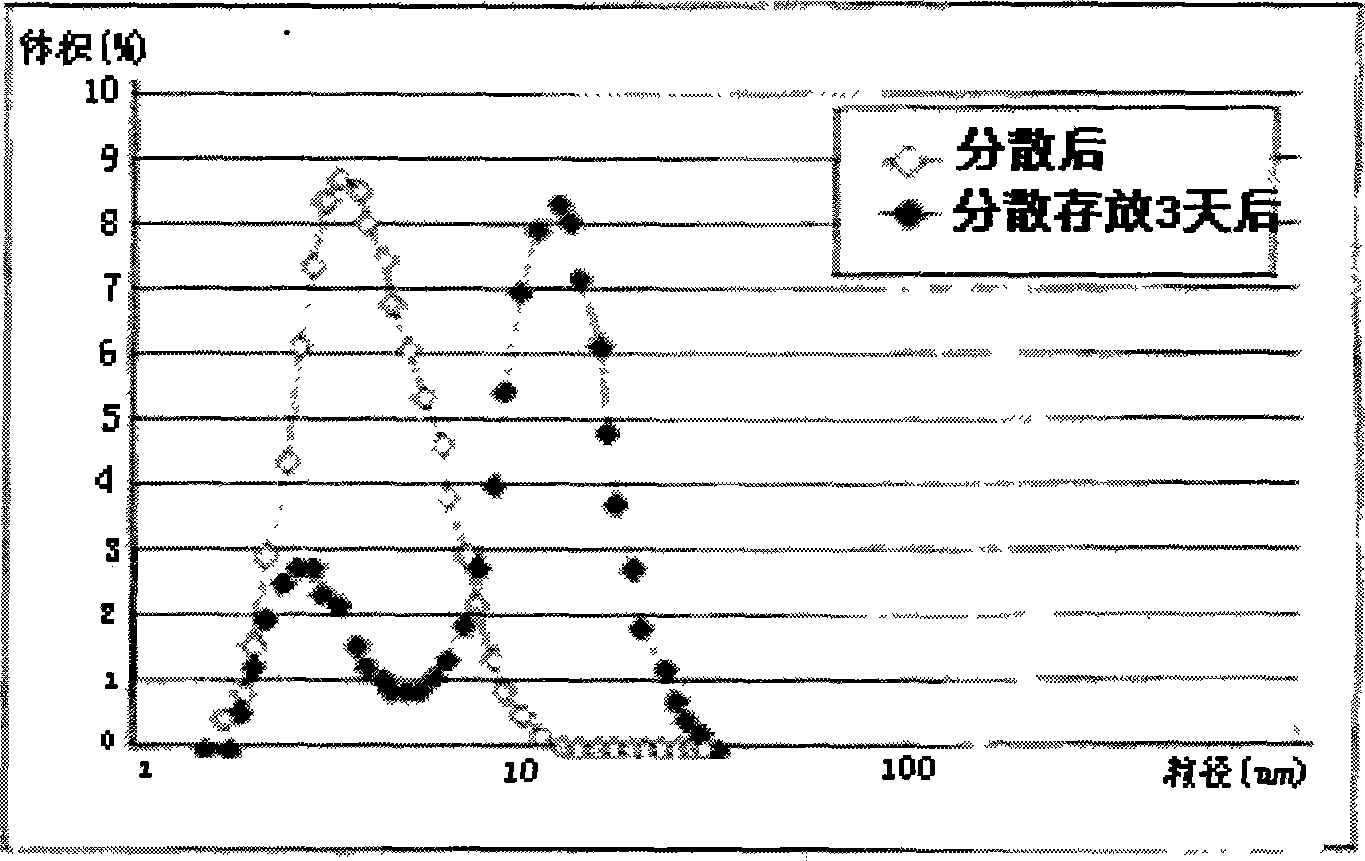

Embodiment 1

[0040] Weigh 0.3Kg polyvinylidene fluoride (PVDF), weigh the solvent N-methylpyrrolidone (NMP) according to the concentration of 8% PVDF glue and add it to the rubber tube, adjust the speed to 2000 rpm and stir for 45 minutes to make polyvinylidene Vinyl fluoride is completely dissolved to form a colloid. Then take by weighing 0.2Kg acetylene black as the conductive agent and add in the rubber tube, stir at a speed of 3000 rpm for 30 minutes to make the conductive glue, then weigh 10Kg lithium cobaltate and the conductive glue prepared in front and 0.6Kg of solvent N- Add methylpyrrolidone into the mixing tank together, stir at a low speed of 200 rpm and a high speed of 2500 rpm for 30 minutes to form a premixed slurry, and continuously input the prepared premixed slurry into a disperser with a slurry pump for dispersion ( The FM-80-50 model disperser produced by Japan T.K.FILMICS company is used, the rotation speed is 10000 rpm, and the dispersion time is set to 60 seconds), ...

Embodiment 2

[0048] Weigh 0.6Kg polyvinylidene fluoride (PVDF) according to the concentration of 10% PVDF glue, weigh the solvent dimethylformamide (DMF) and add it to the rubber tube, adjust the speed to 3000 rpm and stir for 60 minutes to completely dissolve the PVDF Colloid is obtained. Take 0.4Kg acetylene black as conductive agent and add in the plastic tube, stir at a speed of 4000 rpm for 45 minutes to obtain conductive glue, then weigh 10Kg lithium iron phosphate and the aforementioned conductive glue prepared and 6.6Kg Add the solvent dimethylformamide into the mixing tank together, stir at a low speed of 150 rpm and a high speed of 3000 rpm for 30 minutes to form a premixed slurry, and continuously input the prepared premixed slurry into the disperser with a slurry pump Disperse (the FM-80-50 model disperser produced by Japan T.K.FILMICS company is adopted, the rotation speed is 15000 rpm, and the dispersion time is set as 30 seconds), and the dispersed slurry is continuously outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com