Method for preparing Al-Si-Cu-based alloy metallographic sample and displaying tissue thereof

A technology of aluminum-silicon-copper and samples, which is applied in the field of preparing aluminum-silicon-copper alloy metallographic samples and displaying structures, can solve problems such as inability to distinguish grain boundaries, surface flow, and hinder microscopic analysis of samples, and achieve low labor intensity and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

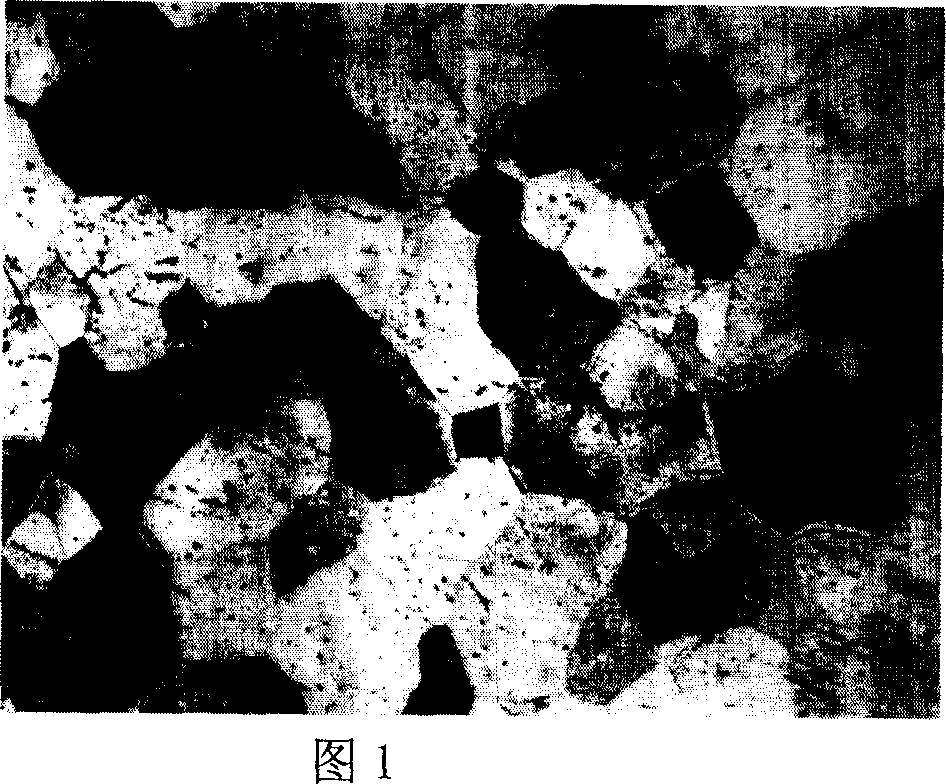

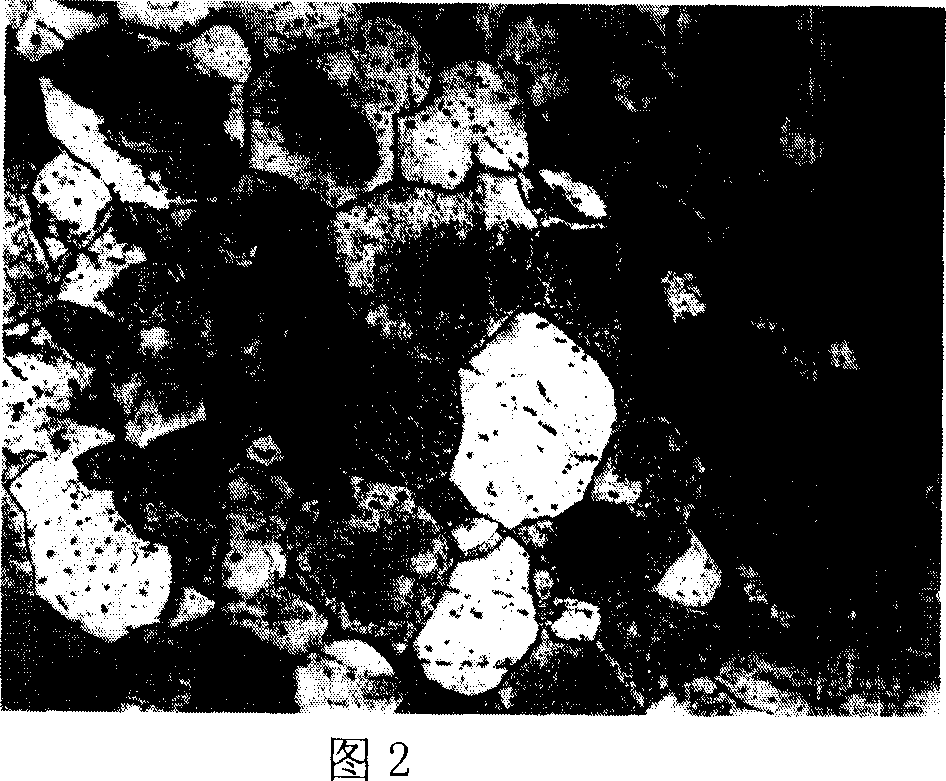

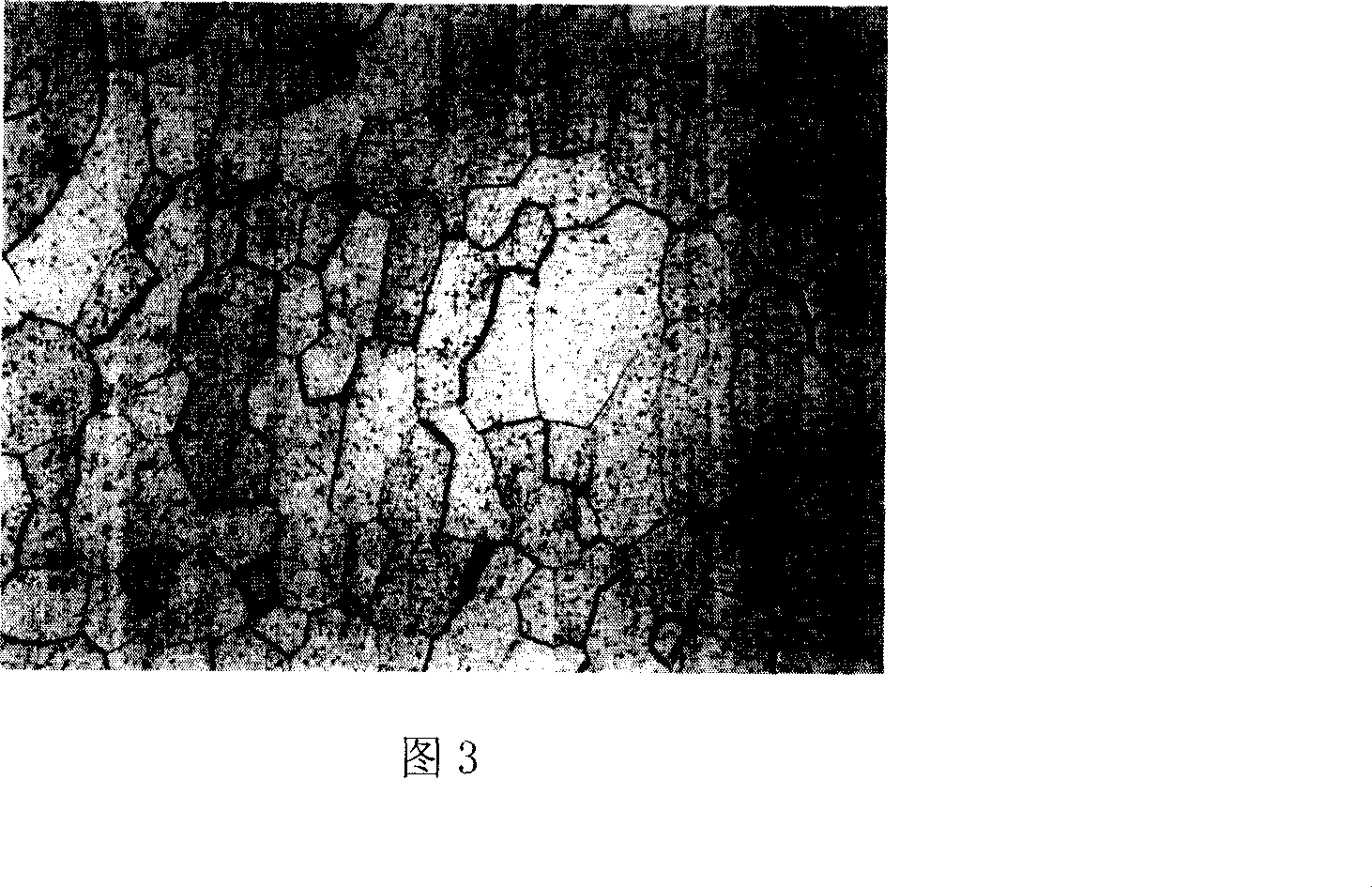

Image

Examples

Embodiment 1

[0033] The samples were prepared through the following steps:

[0034] a. Coarse grinding: take about 1.5cm 2 Polish the sample with water on 400# alumina water sandpaper, then use 1000# alumina water sandpaper to polish it with water, then use 1500# alumina water sandpaper to polish it with water, and then use 2000# silicon carbide water sandpaper to polish it with water Light, turn 90 degrees before changing the sandpaper each time, until the scratches from the previous process are worn away, and the new scratches are in the same direction. Before changing the sandpaper, the sample should be cleaned with water to remove sand particles.

[0035] b. Electropolishing: Polish the roughly ground sample with an electropolishing machine. The polishing parameters are voltage 25V, time 20s, and polishing 3 times. Rinse and cool with water after each polishing.

[0036] c. Flannel polishing: use 1μm diamond abrasive paste to polish on silk cloth, polish in one direction, use light pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com