Low dielectric, wave-transparent porous ceramic material and preparation process thereof

A porous ceramic, low dielectric technology, applied in ceramic products, circuits, electrical components, etc., can solve the problems of unsatisfactory electrical properties of traditional ceramic materials, and achieve a scientific and reasonable preparation method, easy to implement, and excellent dielectric properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

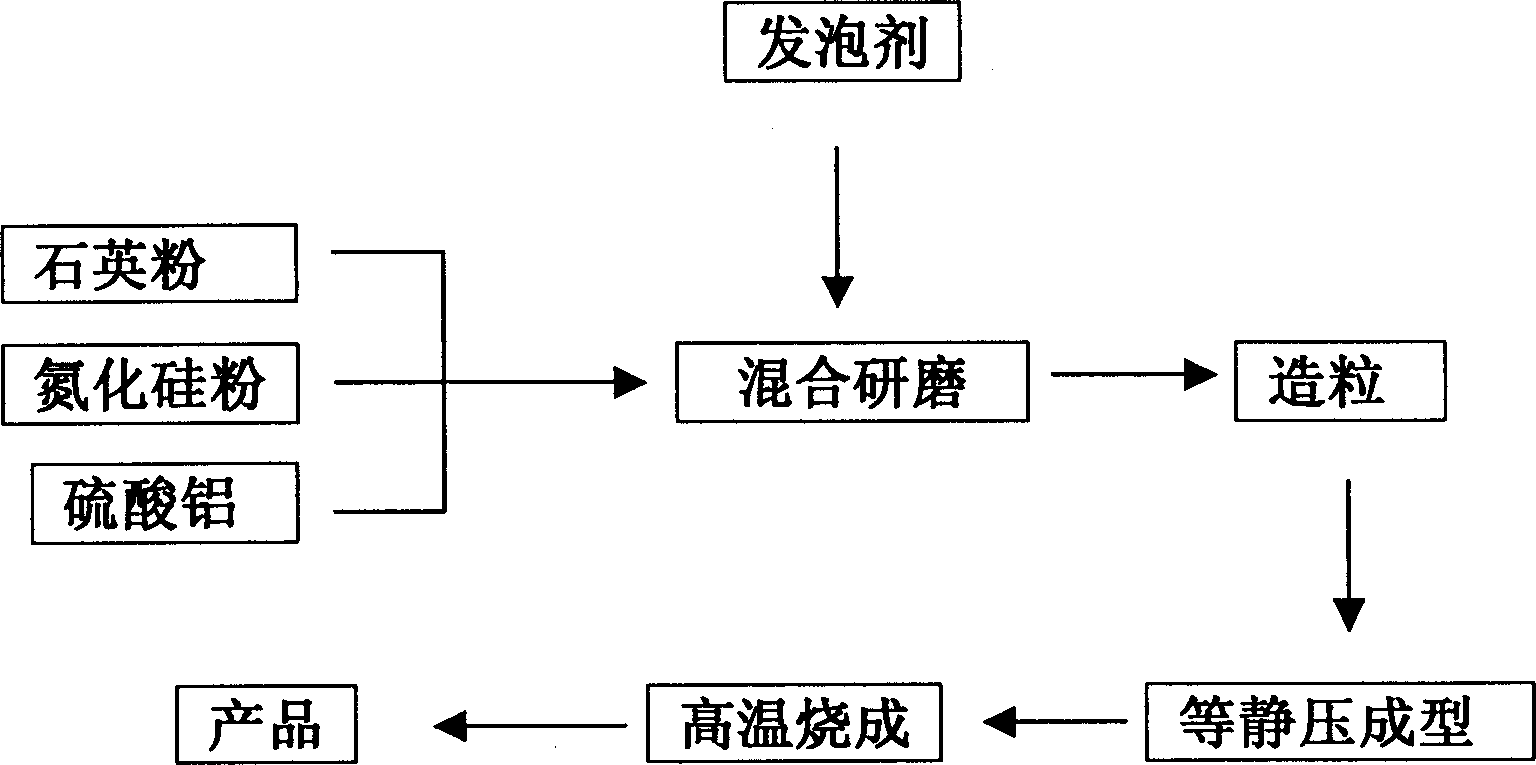

[0025] The preparation method of the low dielectric and wave-transparent porous ceramic material of the present invention is as follows:

[0026] Weigh 100 grams of quartz powder passed through a 1000 mesh sieve, with a silicon dioxide weight content of 99.99%, 90 grams of water-soluble solid aluminum phosphate powder produced by Xinxiang Fengfan Industrial Company, 9 grams of 0.45-5 micron silicon nitride powder, and α-phase nitrogen The weight content of SiO is 95%, and the ingredients are mixed with absolute ethanol by ball milling, and a foaming agent of 3% by weight of the ingredients is added for granulation, and the particle size is controlled to be 70-80 microns, wherein the foaming agent is an aqueous solution of silicon phosphate. The ratio of phosphorus to silicon is controlled to be 1:1, and the concentration is 50% by weight. The granulated particles are formed by cold isostatic pressing at a pressure of 100 MPa, and then fired at a high temperature of 930-980° C....

Embodiment 2

[0030] The preparation method of the low dielectric and wave-transparent porous ceramic material of the present invention is as follows:

[0031] Weigh 80 grams of quartz powder with a particle size of 2-10um, the weight content of silicon dioxide is 99.98%, 90 grams of aluminum phosphate powder, 12 grams of 0.5-3 micron silicon nitride powder, and the weight content of α-phase silicon nitride is 94%. , using absolute ethanol to mix the ingredients evenly by ball milling, adding a foaming agent with a weight of 5% of the ingredients to granulate, and the particle size is controlled to be 60 to 70 microns, wherein the foaming agent is an aqueous solution of silicon phosphate, and the ratio of phosphorus to silicon is controlled to be 1: 1. The concentration is 45% by weight. The granulated particles are formed by cold isostatic pressing at a pressure of 95MPa, and then fired at a high temperature of 900-960°C for 50 minutes to obtain the low-dielectric and wave-transparent poro...

Embodiment 3

[0033] The preparation method of the low dielectric and wave-transparent porous ceramic material of the present invention is as follows:

[0034] Weigh 110 grams of quartz powder with a particle size of 5-15um, the weight content of silicon dioxide is 99.99%, 85 grams of aluminum phosphate powder, 14 grams of 0.6-4 micron silicon nitride powder, and the weight content of α-phase silicon nitride is 93%. , using ball milling to mix the ingredients evenly with absolute ethanol, adding a foaming agent with a weight of 8% of the ingredients to granulate, and the particle size is controlled to be 70 to 80 microns, wherein the foaming agent is an aqueous solution of silicon phosphate, and the ratio of phosphorus to silicon is controlled to be 1: 1. The concentration is 55% by weight. The granulated particles are formed by cold isostatic pressing at a pressure of 120 MPa, and then fired at a high temperature of 1000-1060° C. for 40 minutes to obtain the low-dielectric and wave-transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com