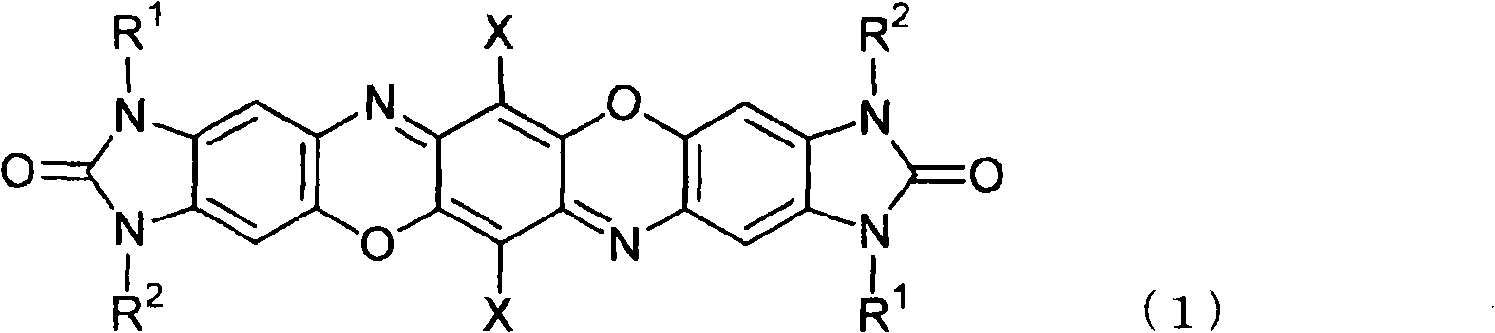

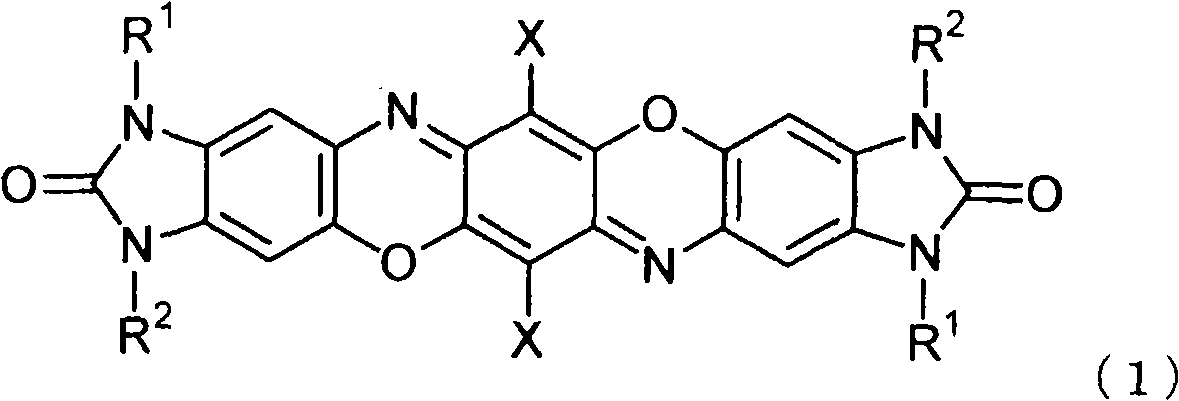

Lightproof composition and color filter

A composition and light-shielding technology, which is applied in the field of light-shielding composition and color filter, and can solve the problems that have not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Manufacture of opacifying compositions

[0057] Take 60.0 parts of Pigment Blue 80 ("Hostaperm Blue R5RVP2548" manufactured by Clariant, coloring material), 20.0 parts of cationic polymer dispersant (manufactured by Ajinomoto Fine Technology, "Ajisper PB821"), and propylene glycol monomethyl ether ethyl 320.0 parts of acid ester (solvent) were blended, and dispersion processing was performed for 3 hours with a paint mixer to prepare a dispersion liquid. Here, as the medium of the paint mixer, 0.4mmΦ zirconia beads are used at a filling ratio of 20%. Next, 11.9 parts of propylene glycol monomethyl ether acetate solution ("V-259ME" manufactured by Nippon Steel Chemical Co., Ltd.) of 56.5% by weight of an alkali-developing photosensitive resin having a bisphenol fluorene type epoxy diacrylate structure, two 6.8 parts of pentaerythritol hexaacrylate (photosensitive resin), 1-(9-ethyl-6-(2-methylbenzoyl)-9H-carbazol-3-yl)ethanone-1-O-acetyl oxime (photopolymerization initi...

Embodiment 2~4

[0062] The coloring material used in Example 1 was changed as shown in Table 1, and the others were the same as in Example 1 to manufacture a light-shielding composition for color filters and a model color filter. Then, the obtained cured film was measured in the same manner as in Example 1 for optical density, image forming ability, and volume resistivity. As a result, high-quality model color filters excellent in light-shielding properties and insulating properties were obtained in all of them. The results are shown in Table 1. Also, for example, for the coloring material used in Example 2, "PB80 / PY139=70 / 30" shown in Table 1 means that the coloring material contains 70% by weight of PB80 and 30% by weight of PY139, Same for other meanings.

[0063] Table 1

[0064] in solids

coloring material

Amount (weight%)

Types and formulations of coloring materials

Amount

(% by weight in coloring material)

Spend

...

Embodiment 5

[0078] Take 35.0 parts of Pigment Blue 80 ("Hostaperm Blue R5RVP2548" manufactured by Clarionto, coloring material), 15.0 parts of Pigment Yellow 139 (manufactured by BASF, "Paliotol Yellow D 1819", coloring material), cationic polymer dispersant (manufactured by Ajinomoto Fine Technology Co., Ltd., "Ajisper-PB821") 16.7 parts and 266.7 parts of propylene glycol monomethyl ether acetate (solvent) were mixed, and the dispersion processing was carried out in the same manner as in Example 1 to prepare a dispersion liquid. Next, 22.4 parts of propylene glycol monomethyl ether acetate solution ("V-259ME" manufactured by Nippon Steel Chemical Co., Ltd.) of 56.5% by weight of an alkali-developing photosensitive resin having a bisphenol fluorene type epoxy diacrylate structure, two 12.6 parts of pentaerythritol hexaacrylate (photosensitive resin), 2.5 parts of bisphenol fluorene type epoxy resin ("ESF-300" manufactured by Nippon Steel Chemical Co., Ltd.), 1-(9-ethyl-6-(2-methyl benzoy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com