Preparation method of hydroxy-polyacrylate aqueous dispersion and waterborne paint containing hydroxy-polyacrylate aqueous dispersion

A hydroxy polyacrylate and acrylic monomer technology, applied in the field of polyacrylate, can solve the problems of difficult to meet the needs of automotive coatings, poor appearance of two-component coating films, short storage period of polymer emulsions, etc., and achieve excellent physical properties. and chemical properties, excellent appearance, improved water resistance and alkali and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

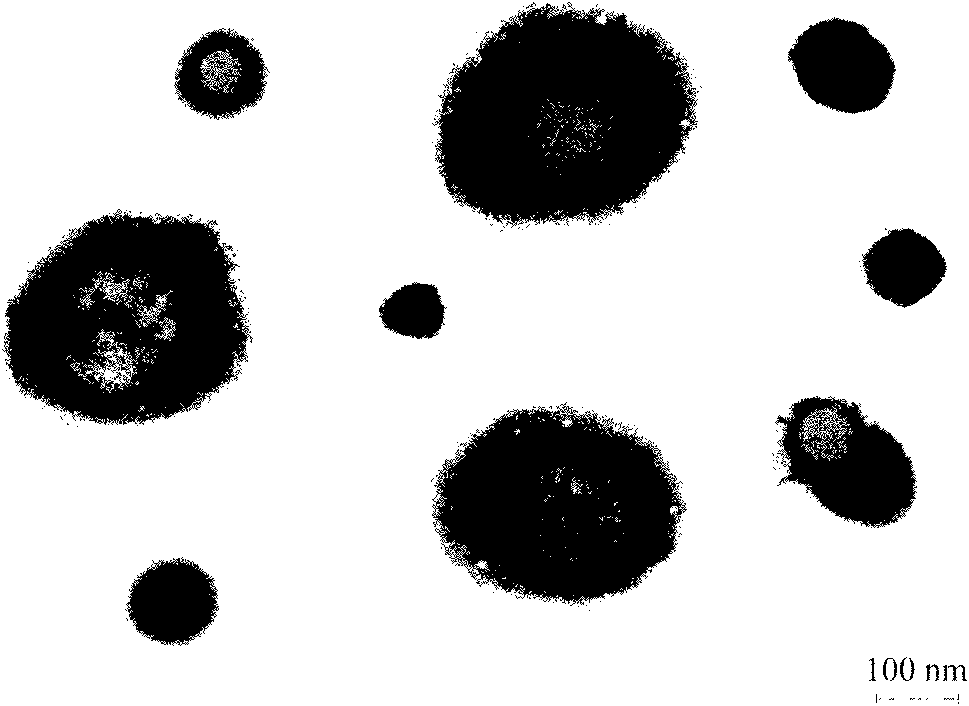

Image

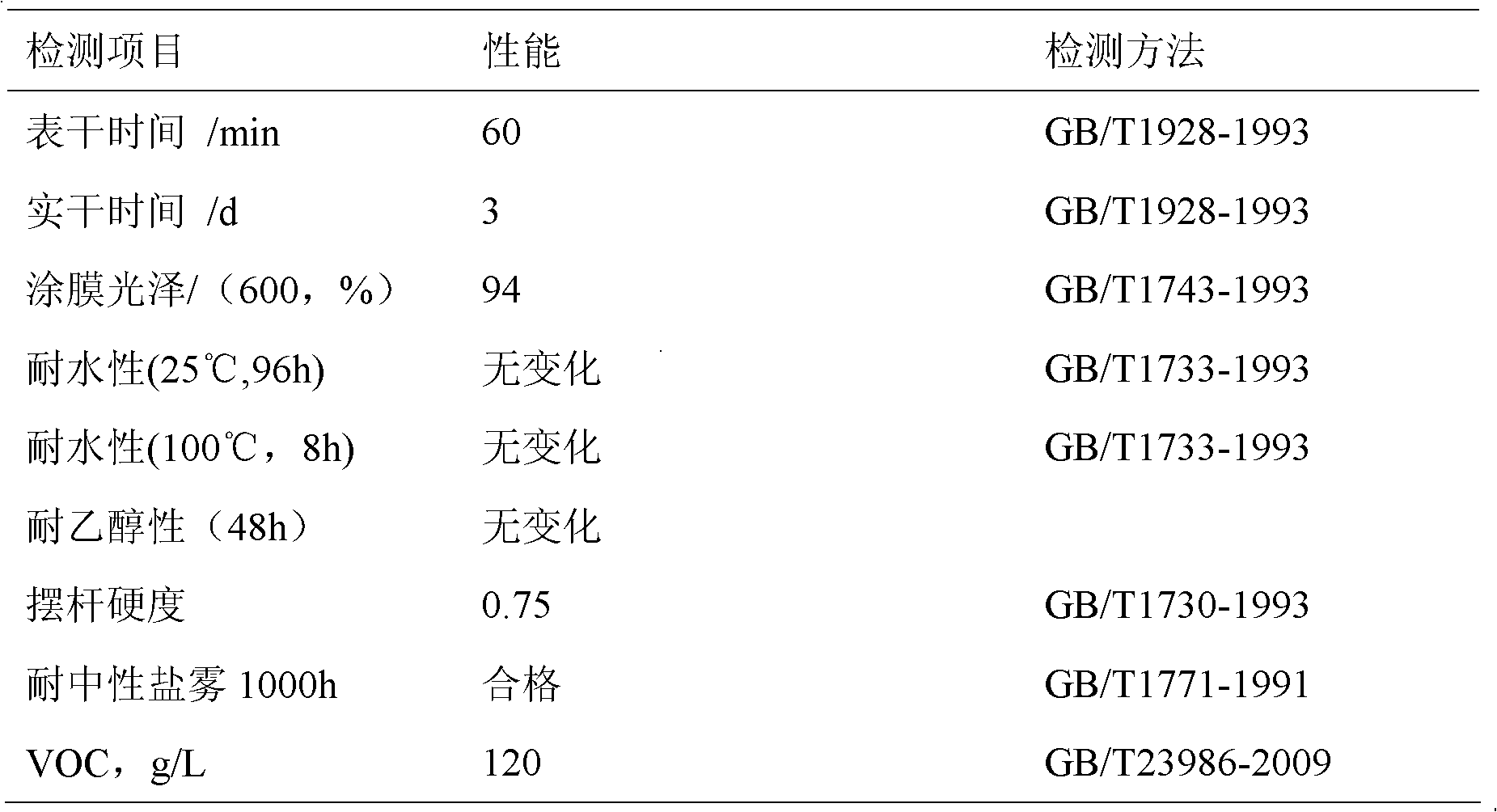

Examples

Embodiment 1

[0050] (1) Preparation of hydroxypolyacrylate containing carboxylate

[0051] (a) Raw material composition

[0052] Acrylic monomer A: 20g methyl methacrylate; 5g butyl acrylate; 18.5g hydroxyethyl methacrylate; 5g methacrylic acid;

[0053] Initiator: 1.5g azobisisobutyronitrile;

[0054] Dodecylmercaptan: 0.24g;

[0055] Organic solvent: 50g acetone;

[0056] (b) process steps

[0057] In the reaction kettle, add 15g of acetone and dodecyl mercaptan, under the protection of nitrogen, raise the temperature to 70°C, add the mixed solution of acrylic acid monomer, initiator and remaining acetone dropwise within 2.5h, keep it warm for 1h, and cool down to 45°C °C, adjust the pH of the system to 7.0 with ammonia water to obtain carboxylate-containing hydroxyl polyacrylate.

[0058] (2) Preparation of hydroxypolyacrylate without carboxylate

[0059] (a) Raw material composition

[0060] Acrylic monomer B: 5g methyl methacrylate; 5g ethyl acrylate; 15g butyl methacrylate; 20...

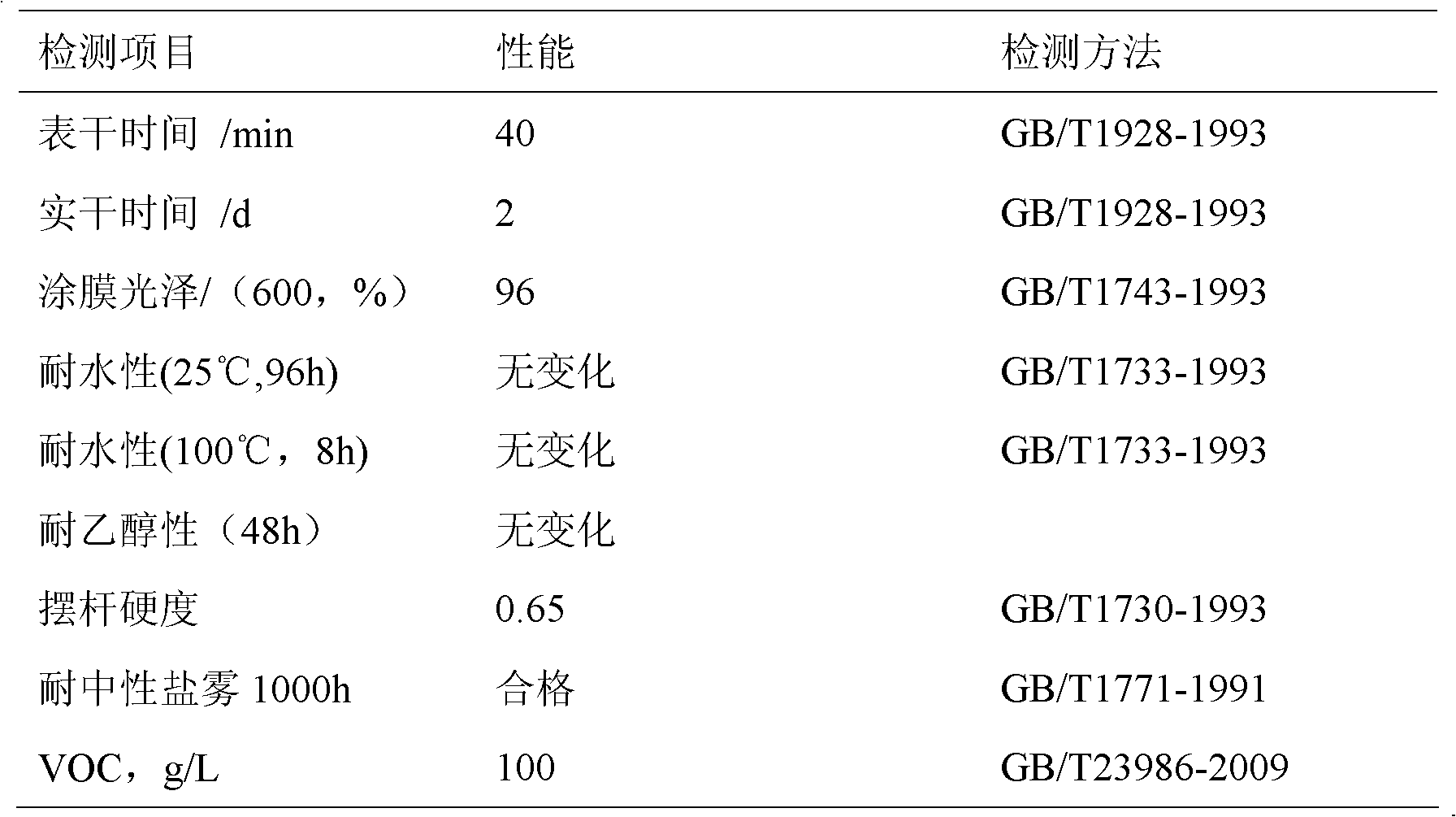

Embodiment 2

[0088] (1) Preparation of hydroxypolyacrylate containing carboxylate

[0089] (a) Raw material composition

[0090] Acrylic monomer A: 10g methyl methacrylate; 20g styrene; 10g butyl acrylate; 5g hydroxypropyl acrylate; 3g methacrylic acid;

[0091] Initiator: 1.5g benzoyl peroxide;

[0092] Dodecylmercaptan: 0.24g;

[0093] Organic solvent: 50.5g isopropanol

[0094] (b) process steps

[0095] In the reaction kettle, add 20.5g of isopropanol and dodecyl mercaptan, under the protection of nitrogen, raise the temperature to 70°C, add the mixed solution of acrylic acid monomer, initiator and remaining isopropanol dropwise within 2.5h, and keep it warm for 1h , the temperature was lowered to 45° C., and the pH of the system was adjusted to 7.5 with triethanolamine to obtain carboxylate-containing hydroxyl polyacrylate.

[0096] (2) Preparation of hydroxypolyacrylate without carboxylate

[0097] (a) Raw material composition

[0098] Acrylic monomer B: 10g methyl methacrylat...

Embodiment 3

[0127] (1) Preparation of hydroxypolyacrylate containing carboxylate

[0128] (a) Raw material composition

[0129] Acrylic monomer A: 1g methyl methacrylate; 24g butyl acrylate; 15g hydroxyethyl methacrylate; 5g methacrylic acid;

[0130] Initiator: 1.2g p-tert-butyl benzoyl peroxide;

[0131] Dodecylmercaptan: 0.225g;

[0132] Organic solvent: 53.5g butanone

[0133] (b) process steps

[0134] In the reaction kettle, add 23.5g organic solvent and dodecyl mercaptan, under the protection of nitrogen, raise the temperature to 60°C, add the mixed solution of acrylic acid monomer, initiator and remaining organic solvent dropwise within 2.5h, keep it warm for 1h, The temperature was lowered to 40° C., and the pH of the system was adjusted to 7.5 with triethanolamine to obtain carboxylate-containing hydroxyl polyacrylate.

[0135] (2) Preparation of hydroxypolyacrylate without carboxylate

[0136] (a) Raw material composition

[0137] Acrylic monomer B: 1g methyl methacrylat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Coating hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com