Building Panel

a technology of building panels and metal oxides, applied in the field of building panels, can solve the problems of expensive and time-consuming installation of prior art siding products, inability to meet the needs of construction workers, and the need to cut the building panel by hand,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

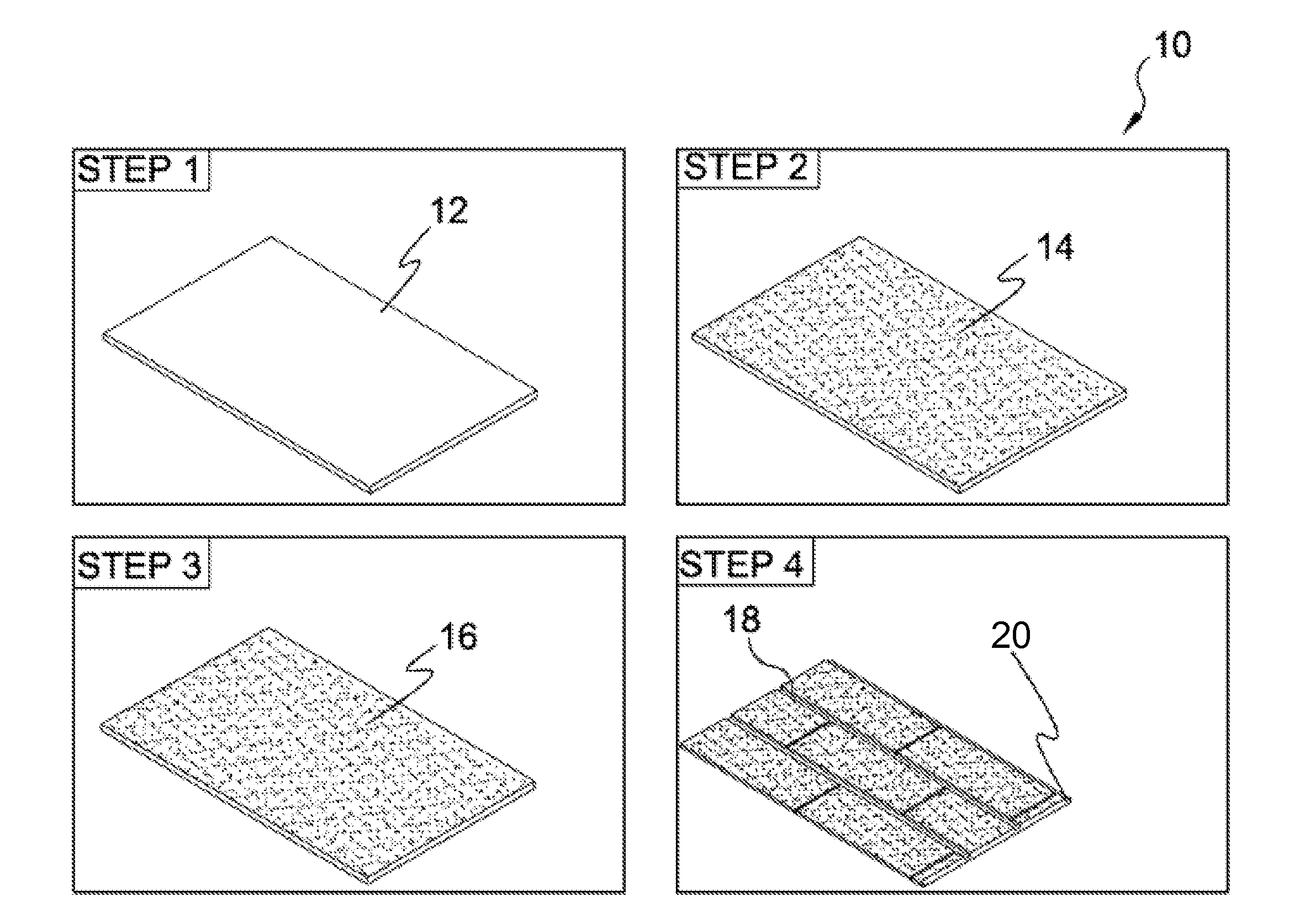

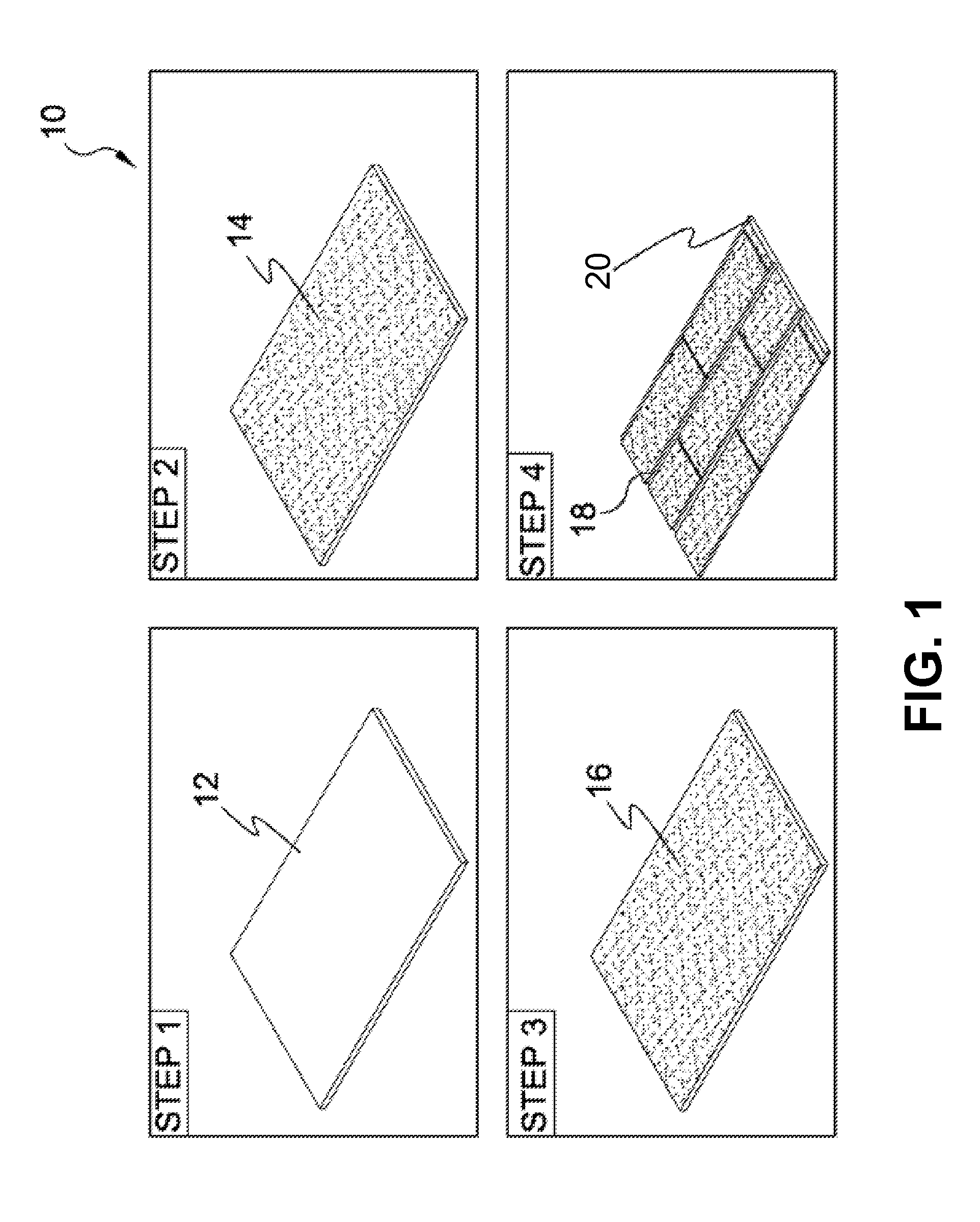

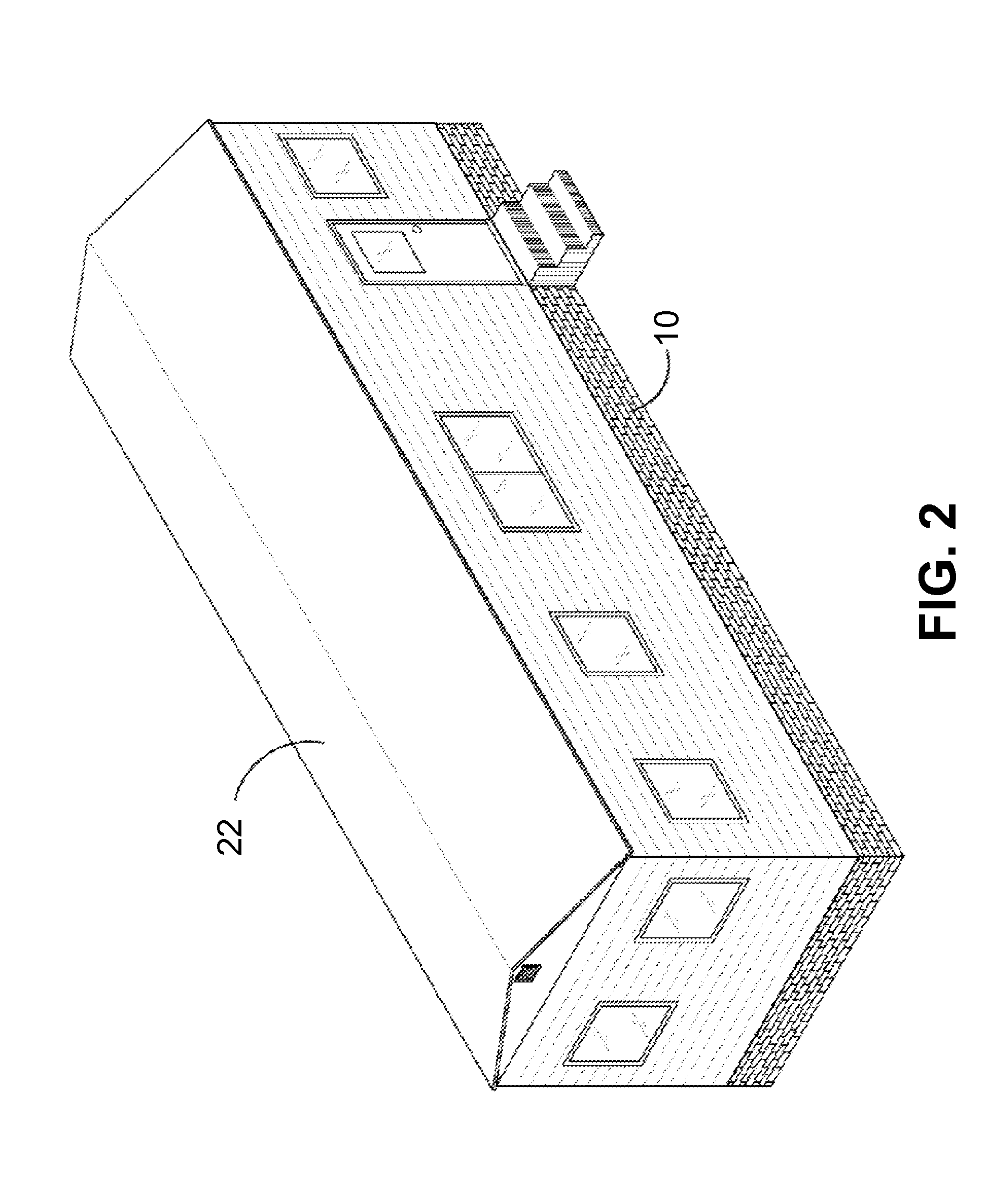

[0035]With reference to FIGS. 1-22, the preferred embodiments of the present invention may be described. The building panel 10 is made of a building board 12 that is tooled and treated to look like brick or rock. The building panel 10 can be used for siding, skirting, hearth wall panels and fireplace surrounds. The building board 12 is preferably magnesium oxide (MgO) board. MgO board is a strong, structural, non-combustible, water resistant, mold resistant, termite resistant, and impact resistant building material. MgO board will not burn, rot or deteriorate. The MgO board has substantial and important benefits over use of the fiber cement board, including being less abrasive and thus capable of being machine cut in the tooling process. The building board 12 is preferably 0.5 inches thick but it will vary in height, length and width depending on the application. For the example, in preferred embodiments, the building panels are 10.75 inches×67.625 inches, 21.5 inches×43.625 inches,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com