Self-thickening pure acrylic latex used in art paints, and preparation method thereof

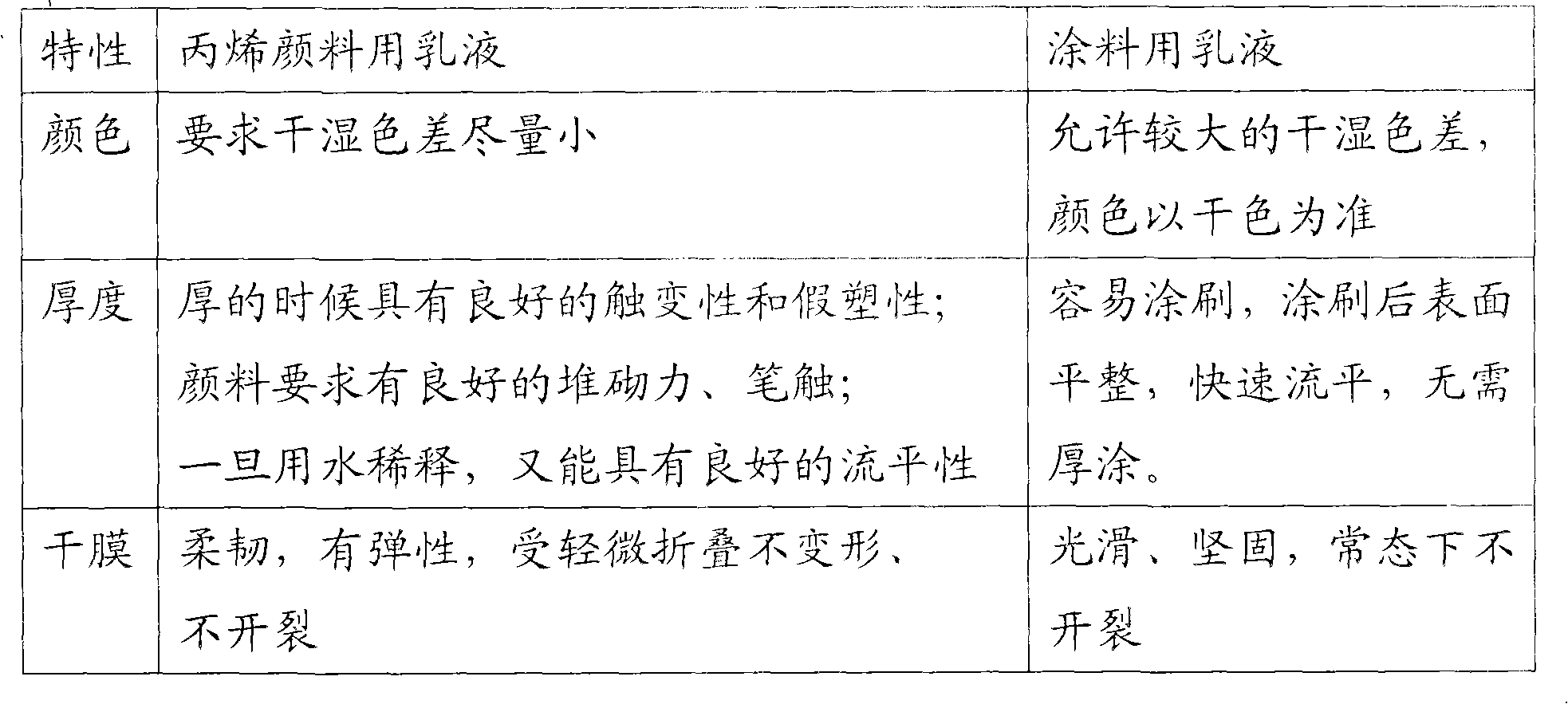

A technology of pure acrylic latex and pigments, which is applied in art paints, dyeing methods, coatings, etc., can solve the problems of emulsion stability and other performance requirements, and can not meet the special requirements of art paints, etc., to achieve superior thixotropy, good Adhesive force, effect of narrow size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The present invention will be described in detail below in conjunction with the examples and related diagrams. However, the invention is not limited to the specific examples given.

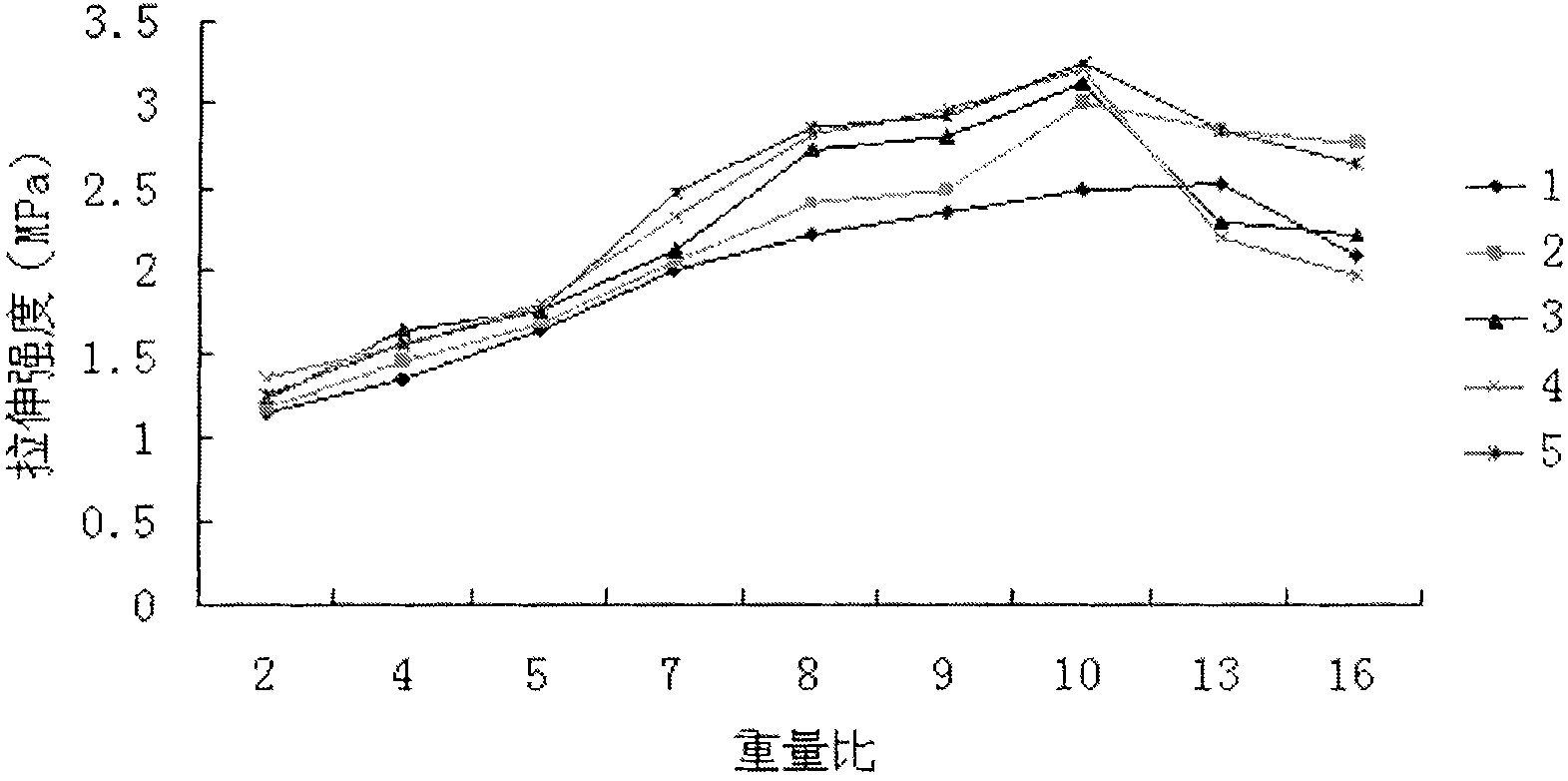

[0037] Each component was weighed according to the parts by weight of each component given in Examples 1-5 in Table 1. Mix the polymerized monomer in advance, suck it into the metering drop device, that is, the mixed monomer A liquid, dissolve the initiator in water and pour it into another liquid drop device, that is, the initiator drop liquid B liquid, and the water-soluble crosslinking liquid The agent is dissolved in water and poured into another dripping device, which is the cross-linking agent dripping liquid C, and the emulsifier is heated and dissolved in water, which is the emulsifier aqueous phase liquid D, which takes one-third of the total amount of the mixed monomer A liquid One, one-third of the total amount of the initiator dripping liquid B, one-third of the total amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com