Bi-component polyurethane coating with low infrared emissivity and preparation method thereof

A two-component polyurethane, low-infrared emission technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of physical and mechanical properties that are difficult to meet the requirements, high infrared emission rate, low infrared emission rate, etc., to achieve infrared Good stealth performance, excellent comprehensive performance, good physical and mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

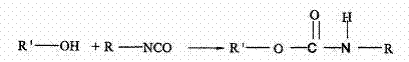

Method used

Image

Examples

Embodiment 1

[0029] A two-component polyurethane coating with low infrared emissivity is prepared from the following materials in parts by weight:

[0030] Hydroxy acrylic resin 91.7

[0031] Melamine formaldehyde resin 8.3

[0032] Flake flake aluminum powder 5

[0033] Titanium dioxide 16.7

[0034] Acrylic Paint Thinner 75

[0035] Leveling agent 1.55

[0036] Defoamer 1.55

[0037] HDI biuret curing agent 33.3.

[0038] During preparation: mix the hydroxy acrylic resin and melamine formaldehyde resin in the above weight parts evenly, then add diluent, leveling agent, defoamer and titanium dioxide, and mix evenly; then add floating flake aluminum powder, stir evenly; finally Add HDI biuret curing agent and mix evenly to prepare the coating.

[0039] After that, spray the prepared paint on a clean tinplate sheet with a spray gun, and after the coating is surface-dry (6 hours), place it in an oven for 12 hours at 60-70°C to obtain a coating.

[0040] The properties of the coating ...

Embodiment 2

[0043] A two-component polyurethane coating with low infrared emissivity is prepared from the following materials in parts by weight:

[0044] Hydroxy acrylic resin 91.7

[0045] Melamine formaldehyde resin 8.3

[0046] Flake flake aluminum powder 5

[0047] Titanium dioxide 15.7

[0048] Acrylic Paint Thinner 75

[0049] Leveling agent 1.55

[0050] Defoamer 1.55

[0051] HDI biuret curing agent 33.3.

[0052] When preparing, mix the hydroxyacrylic resin and melamine formaldehyde resin in the above weight parts evenly, then add acrylic paint thinner, leveling agent, defoamer and titanium dioxide, and mix evenly; then add floating flake aluminum powder, and stir evenly ; Finally, add HDI biuret curing agent and mix evenly to obtain the coating.

[0053] Afterwards, the prepared paint is sprayed on a clean tinplate sheet with a spray gun. After the surface of the coating is dry (6 hours), then place it in an oven at 60-70°C for 12 hours to obtain a coating.

[0054] Th...

Embodiment 3

[0057] A two-component polyurethane coating with low infrared emissivity is prepared from the following materials in parts by weight:

[0058] Hydroxy acrylic resin 91.7

[0059] Melamine formaldehyde resin 8.3

[0060] Flake flake aluminum powder 15

[0061] Titanium dioxide 13.7

[0062] Acrylic Paint Thinner 75

[0063] Leveling agent 1.55

[0064] Defoamer 1.55

[0065] HDI biuret curing agent 33.3.

[0066] When preparing, mix the above-mentioned hydroxy acrylic resin and melamine formaldehyde resin in the above weight parts evenly, then add acrylic paint thinner, leveling agent, defoamer and titanium dioxide, and mix evenly; then add floating flake aluminum powder , and stir evenly; finally add HDI biuret curing agent, mix evenly, and the coating is prepared.

[0067] Afterwards, the prepared paint is sprayed on a clean tinplate sheet with a spray gun. After the surface of the coating is dry (6 hours), then place it in an oven at 60-70°C for 12 hours to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com