Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Hard film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone imitation paint and production method

InactiveCN107699123AHighlight substantive featuresSignificant progressAntifouling/underwater paintsPaints with biocidesGlass fiberWeather resistance

The invention discloses stone imitation paint and a production method. The stone imitation paint comprises raw materials, namely polyurethane, a glass fiber, an acrylic resin liquid, an elastic resinliquid, white quartz sand, natural colorful sand, water, a composite coupling agent, a leveling agent, a defoaming agent and an anti-settling agent. The stone imitation paint disclosed by the invention is diverse in color, sufficient in attractiveness and good in imitation property, and a constructed surface has the third-dimensional property and the multi-color decoration attractiveness, and haswaterproof anti-cracking properties, water and alkali resistance, weather resistance, water scrubbing resistance, anti-fouling properties, alga resistance and chemical resistance. In addition, the stone imitation paint is good in stone texture, good in waterproof and cracking resistance, relatively long in weather-resistant service life, vivid in color, relatively good in anti-fouling property, relatively simple and convenient to construct, relatively applicable to heat-preservation base materials, low in manufacturing cost, rich in color and specification, simple and easy to construct and excellent in anti-cracking waterproof property.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Bi-component polyurethane coating with low infrared emissivity and preparation method thereof

ActiveCN102732145AImprove performanceLow emissivityPolyurea/polyurethane coatingsEmissivityMelamine formaldehyde

The invention discloses a bi-component polyurethane coating with low infrared emissivity and a preparation method thereof, relating to coatings with low infrared emissivity. The bi-component polyurethane coating with low infrared emissivity is prepared from the following raw materials by weight: 91.7 of hydroxy acrylic resin, 8.3 of terpolycyantoamino-formaldehyde resin, 5 to 15 of floatable flake aluminum powder, 13.7 to 16.7 of titanium dioxide, 75 of acrylic paint thinner, 1.55 of a levelling agent, 1.55 of an antifoaming agent and 33.3 of an HDI biuret curing agent. The bi-component polyurethane coating prepared in the invention has a good color, good flowing performance and good infrared stealth performance; usage amount of metal powder in the coating is substantially reduced; and the coating has excellent comprehensive properties and is a low-infrared-emissivity coating satisfying practical needs.

Owner:ZHONGBEI UNIV

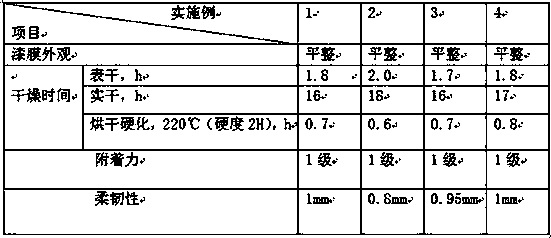

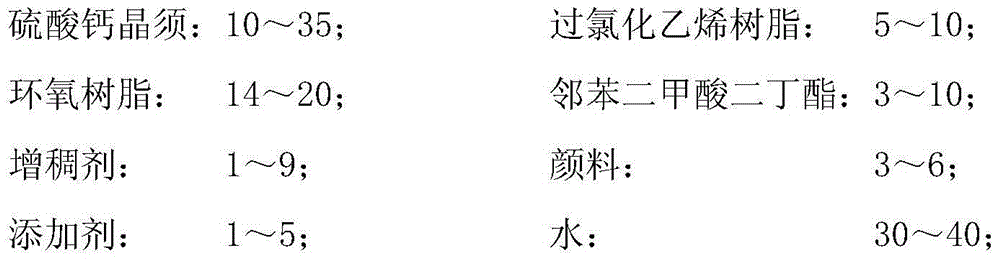

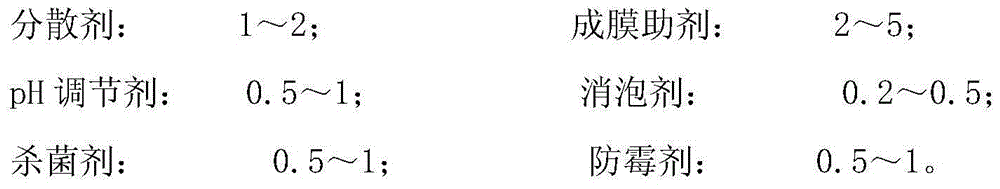

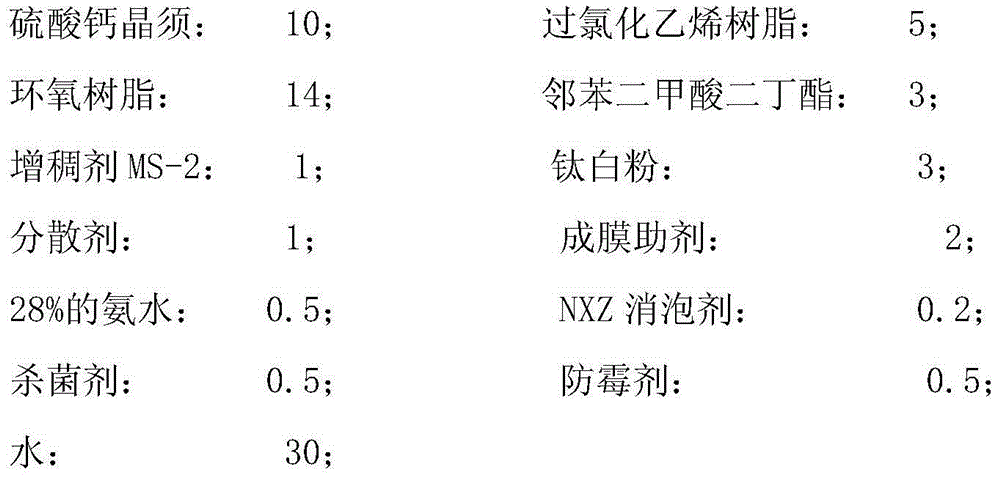

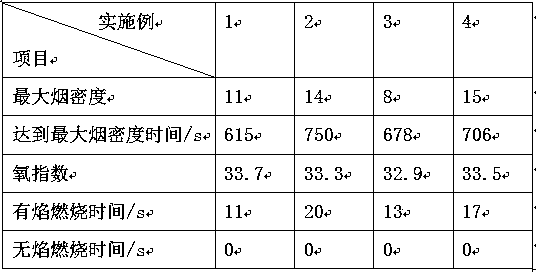

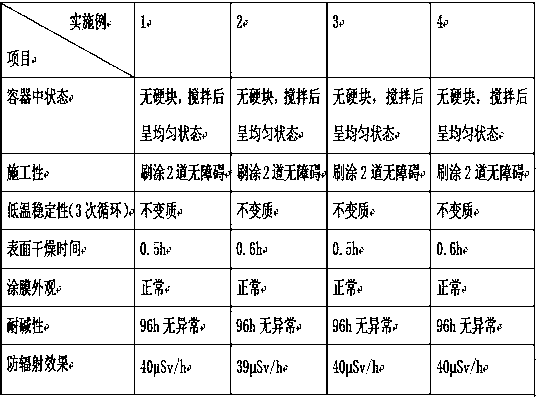

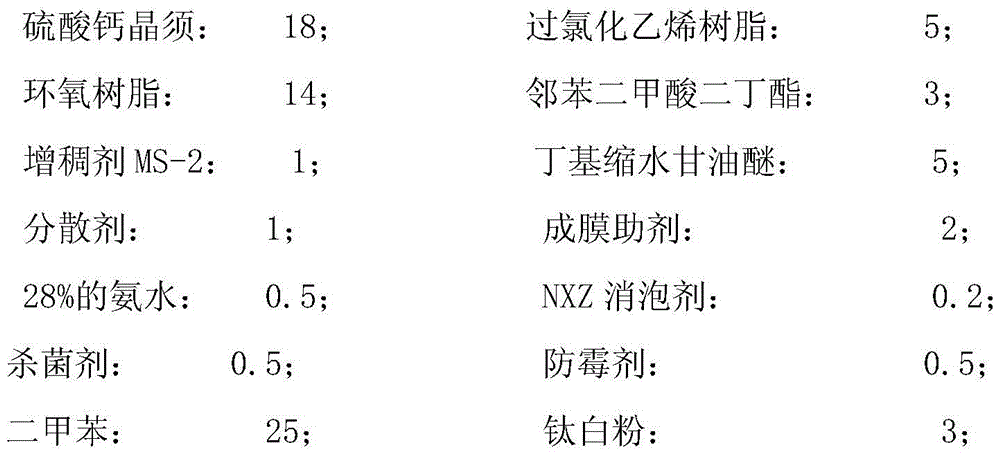

Water-based waterproof coating added with calcium sulfate whiskers and preparation method of coating

InactiveCN104559679AImprove fire performanceGood anti-cracking effectFireproof paintsAntifouling/underwater paintsWater basedEnvironmental resistance

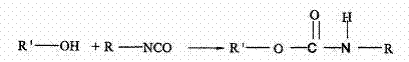

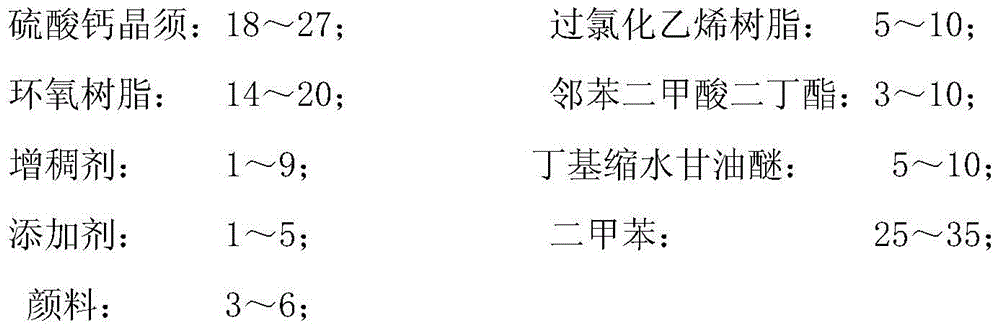

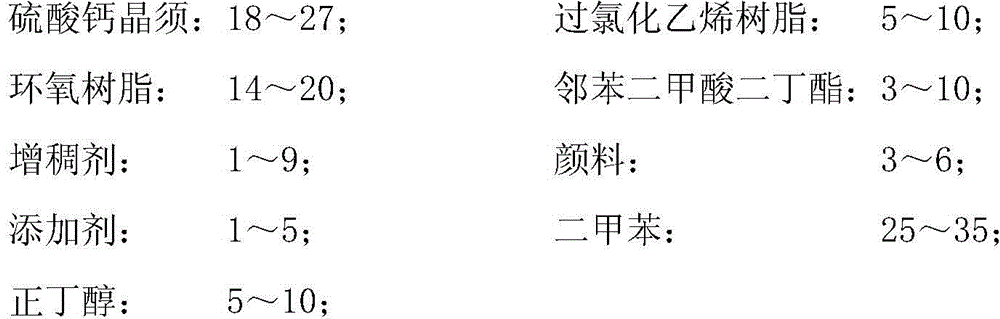

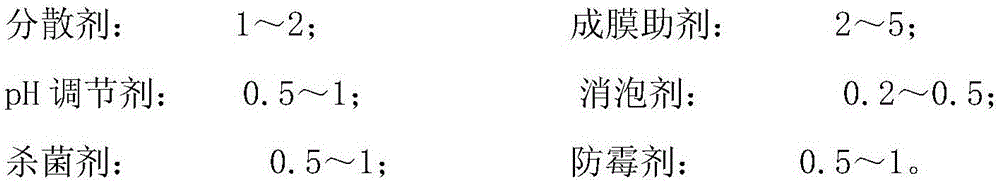

The invention discloses a water-based waterproof coating added with calcium sulfate whiskers and a preparation method of the coating. The water-based waterproof coating is prepared from the following raw materials in parts by weight: 10-35 parts of calcium sulfate whiskers, 5-10 parts of vinyl perchloride resin, 14-20 parts of epoxy resin, 3-10 parts of dibutyl phthalate, 1-9 parts of a thickener, 3-6 parts of pigments, 1-5 parts of additives and 30-40 parts of water. The preparation method comprises the following steps: weighing; modifying; and mixing. The water-based waterproof coating added with calcium sulfate whiskers disclosed by the invention has excellent fireproof effect and anti-cracking property, low in cost of raw materials and non-toxic and environment-friendly. The method for preparing the coating is simple to operate, convenient to produce, low in requirement on equipment and suitable for industrial large-scaled production.

Owner:SICHUAN MINGXIN JIAJIE NEW MATERIAL

Flame-retardant building coating and production method

InactiveCN107793914AHighlight substantive featuresSignificant progressFireproof paintsAntifouling/underwater paintsPorosityFire resistance

The invention discloses a flame-retardant building coating and a production method. The flame-retardant building coating is prepared from the following raw materials: polyurethane, an emulsion, glassfiber, water, a composite coupling agent, a flame retardant, pigment, an antifoaming agent, a wetting agent and a leveling agent. The flame-retardant building coating disclosed by the invention can improve such performance of a film as surface performance, mechanical and optical performance, corrosion resistance, dirt clearing performance and flame retardance, enhances the water repellency, dustadsorption preventing performance and self-repairing function of the coating, and further improves the film in density, toughness, weather resistance, permeation resistance, fire resistance, expansionproperty and the like; moreover, the flame-retardant building coating prolongs the fire-resistant time, reduces the porosity of the film, prevents bacteria from adhering to the film, and clears pollutants on the film surface so as to purify the environment.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Radiation-resistant paint and production method thereof

InactiveCN107793915ANo pollution in the processHard filmCellulose coatingsPolyurea/polyurethane coatingsFiberEnvironmental resistance

The invention discloses radiation-resistant paint and a production method thereof. The radiation-resistant paint is prepared from raw materials including polyurethane, emulsion, sisal fiber, water, composite coupling agents, antiradiation materials, leveling agents and antifoaming agents. The radiation-resistant paint adsorbs volatile organic compounds and formaldehyde in the air; the radiation isprevented; the air is purified. Excellent hardness, finish degree, waterproof performance and crack resistant performance are realized; the stability and the hardness are high; the mechanical property of the paint is enhanced; the used raw materials are nontoxic and harmless; no adverse influence is caused on human bodies and environment; the adhesive force and the antifriction performance of thepaint are improved; the density and the strength of the paint are improved; the occurrence of chalking, map cracking and peeling after paint construction is prevented. The environment is protected; no pollution exists; the cost is low; the use range is wide. The smearing is convenient; the drying speed is high; the construction efficiency can be improved; the appearance is flat and glossy.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Sound absorption coating and production method thereof

InactiveCN107815239AExtend your lifeQuiet indoor environmentAnti-corrosive paintsPolyurea/polyurethane coatingsPerliteEmulsion

The invention discloses a sound absorption coating and a production method thereof. The sound absorption coating is prepared from the following raw materials: polyurethane, emulsion, slag wool fiber,water, a composite coupling agent, diatom ooze, expanded perlite, a levelling agent and a defoamer. The sound absorption coating has good sound absorption property; the coating is free of joints, highin decoration performance, excellent in hardness, finish degree, water resistance and cracking resistance, excellent in stability, and high in hardness; the mechanical property of the coating is enhanced; the usage performance of the coating is more excellent; the adhesion and the friction resistance of the coating are improved; the density and the strength of the coating are increased; the condition that the coating is pulverized, cracked and stripped after being constructed is avoided; the coating is non-toxic and harmless, is free of adverse effects on the human body and the environment, is applicable to reverberation control spaces such as theaters, lecture rooms, conference rooms, swimming pools and gymnasiums, is also applicable to sound improvement environments such as restaurants,dining rooms, offices, airport waiting halls, station waiting rooms, ship waiting rooms, shopping malls and exhibition halls, and can be used as a decorative sound absorption material applied to houses, villas, hotels, guesthouses and entertainment venues.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Inner wall coating and production method

InactiveCN107699125AHighlight substantive featuresSignificant progressFireproof paintsCellulose coatingsCrack resistanceOxygen ions

The invention discloses an inner wall coating and a production method. The inner wall coating comprises raw materials, namely polyurethane, an emulsion, silk powder, a hemp fiber, a composite couplingagent, sepiolite, water, titanium dioxide, white carbon black, a leveling agent and a defoaming agent. The inner wall coating disclosed by the invention is capable of adsorbing formaldehyde and volatile organic compounds in the air, preventing radiation, preventing inflaming and purifying the air. The inner wall coating is excellent in hardness, smoothness, water resistance and cracking resistance, good in stability and high in hardness, the mechanical properties of the coating are improved, human bodies and the environment are prevented from adverse influence as the raw materials are non-toxic and harmless, formaldehyde is eliminated, the air is purified, the humidity is adjusted, negative oxygen ions are released, fire and inflaming are retarded, a wall surface can be cleaned by self, the adhesion property and the friction resistance of the coating are improved, the density and the strength of the coating are improved, and the coating is prevented from powdering, cracking or peelingafter being used. The inner wall coating is environmental-friendly and pollution-free, low in cost and wide in application range, the inner wall coating is convenient to use, rapid in drying speed, high in construction efficiency and smooth and glory in appearance.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Amino-epoxy-alkyd baking varnish

InactiveCN104559703AHard filmGood wear resistanceEpoxy resin coatingsPolyester coatingsChemistryCorrosion

The invention discloses an amino-epoxy-alkyd baking varnish which comprises the following components in parts by weight: 280-320 parts of epoxy resin, 400-460 parts of butylated melamine-formaldehyde resin, 600-680 parts of moderate castor oil alkyd resin, 8-12 parts of a silicone oil solution, 320-360 parts of cyclohexanone and 220-280 parts of dimethylbenzene. Therefore, the amino-epoxy-alkyd baking varnish has the advantages of hard coating, good corrosion resistance and strong adhesive force.

Owner:王新民

Ultraviolet-proof coating and production method

InactiveCN107779079AHighlight substantive featuresSignificant progressPolyurea/polyurethane coatingsRadiation-absorbing paintsEnvironmental resistanceCrack resistance

The invention discloses ultraviolet-proof coating and a production method. The ultraviolet-proof coating is produced from the following raw materials: polyurethane, emulsion, barium sulfate, sisal fibers, aluminum powder, water, a complex coupling agent, nano titanium dioxide, a thickening agent, a defoaming agent, a wetting agent and a leveling agent. The ultraviolet-proof coating disclosed by the invention has excellent hardness, smooth finish, waterproofness and crack resistance, stability is good and hardness is high, ultraviolet-proof property of the coating is enhanced, mechanical properties of the coating are enhanced, the adopted raw materials are non-toxic and harmless, no bad influence is caused to human body and environment, adhesion and rubbing resistance of the coating are improved, density and strength of the coating are improved, and pulverization, fracturing and peeling after coating application are prevented. The ultraviolet-proof coating disclosed by the invention isenvironment-friendly, pollution-free, low in cost, wide in application range, easy to smear and high in drying speed, construction efficiency can be increased, and appearance is smooth and glossy.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

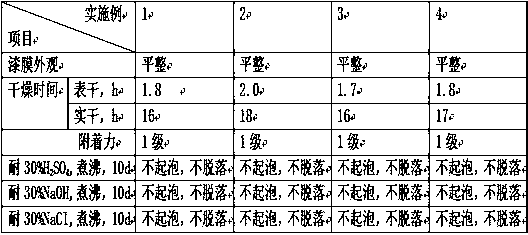

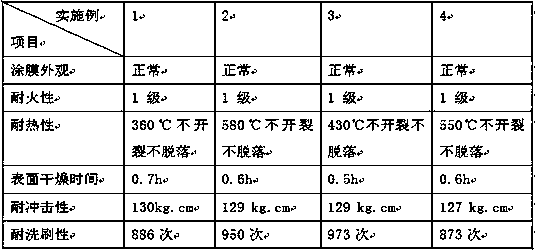

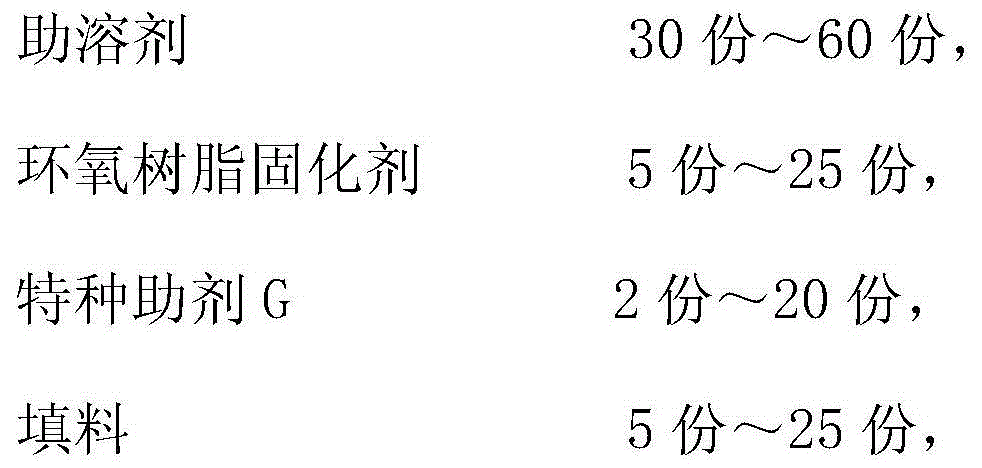

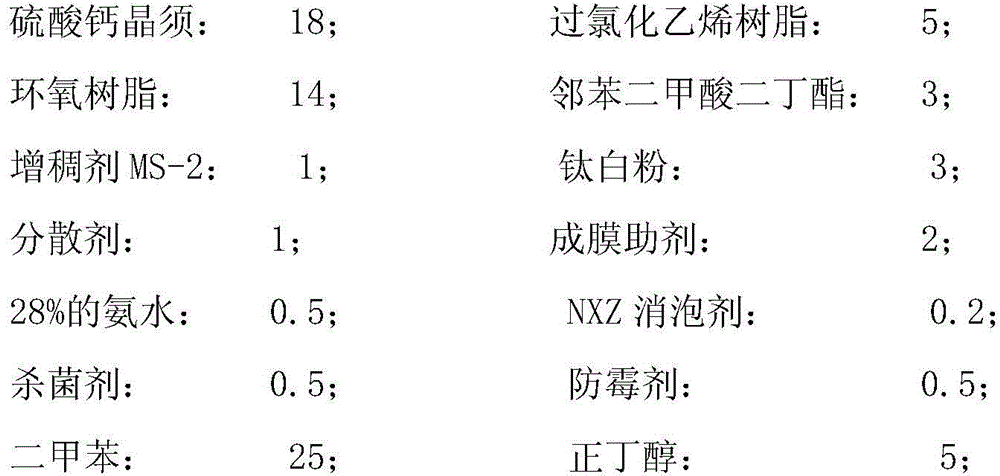

Universal interfacial binding agent

ActiveCN104479605AHard filmOil-freeNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a universal interfacial binding agent which comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 30-50 parts of a cosolvent, 5-25 parts of en epoxy resin curing agent, 2-20 parts of a special auxiliary and 5-25 parts of filler; the component B is water soluble epoxy resin, and the weight ratio of the components A and B is (0.5-5):1. The universal interfacial binding agent provided by the invention has relatively low viscosity under room temperature, the necessary flowing property of the universal interfacial binding agent being used is guaranteed, the operable time is relatively long, and the construction pressure is greatly alleviated. The universal interfacial binding agent provided by the invention has the characteristics of being hard in coating, free of oil separation, short in drying time, green, environment-friendly and pollution-free and convenient to construct. Experiments verify that the viscosity of the universal interfacial binding agent provided by the invention at 20 DEG C is about 200cp and a good application performance for construction within 180 minutes after being mixed can be maintained.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Wooden sound-absorbing board coating and production method thereof

InactiveCN107815233AGood sound absorptionStrong decorationPolyurea/polyurethane coatingsEpoxy resin coatingsEmulsionPerlite

The invention discloses a wooden sound-absorbing board coating and a production method thereof. The wooden sound-absorbing board coating is prepared from polyurethane, epoxy resin, emulsion, glass fibers, a composite coupling agent, water, expanded perlite, 3-iodo-2-propynyl-butyl-carbamate, a flame retardant, a thickening agent, an anti-wear agent, a leveling agent and a defoaming agent. The rawmaterials adopted by the wooden sound-absorbing board coating are non-toxic and harmless as well as free from adverse effects on a human body and the environment; the coating film is hard in a coatingfilm and fine and smooth in hand feeling, has the characteristics of water resistenceresistance, alkali resistance and good adhesion force, and is scrubbing-resistant; after being scrubbed for a plurality of times, no trace is left. The wooden sound-absorbing board coating is environmentally- friendly, free from pollution, low in cost and wide in application scope. The wooden sound-absorbing board coating is convenient to apply, is rapid in drying speed so as to increase the construction efficiency, and is smooth and glossy in appearance.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

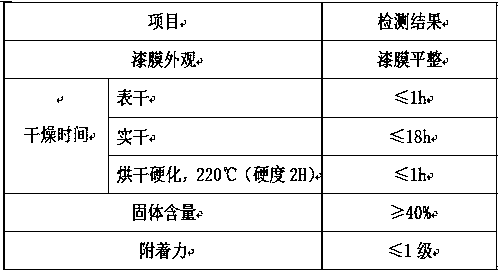

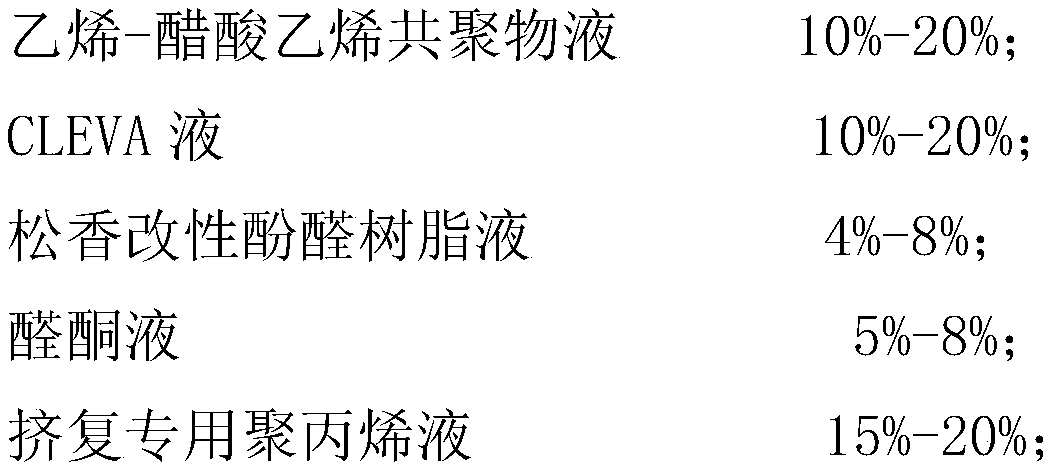

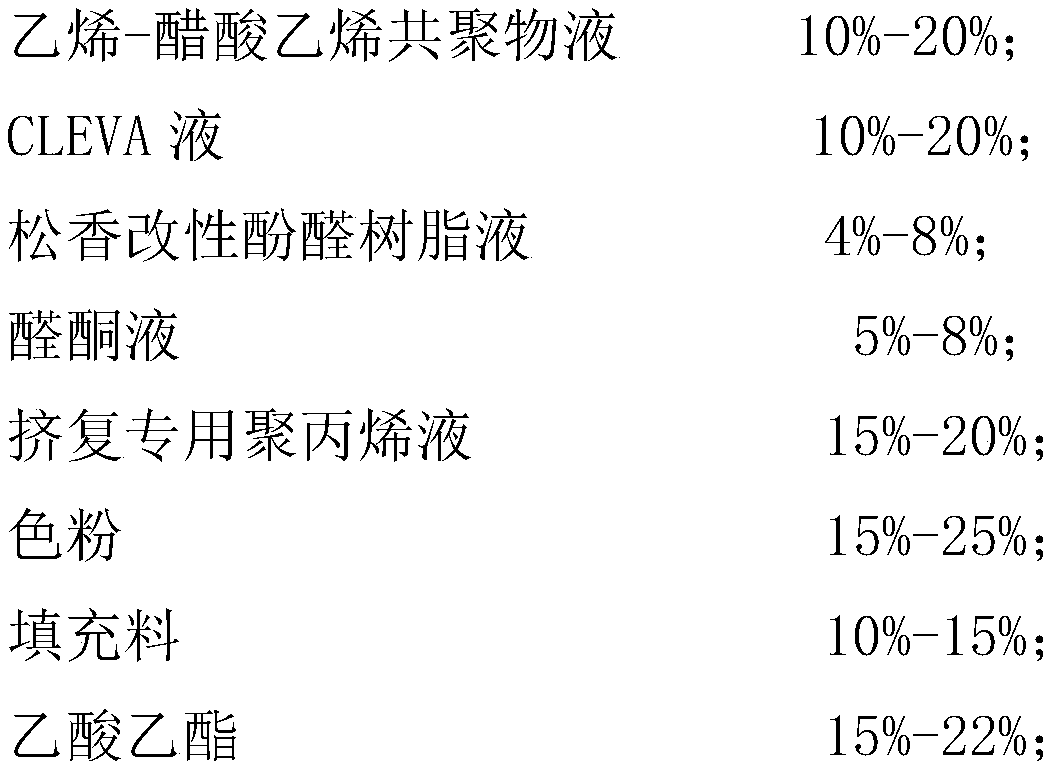

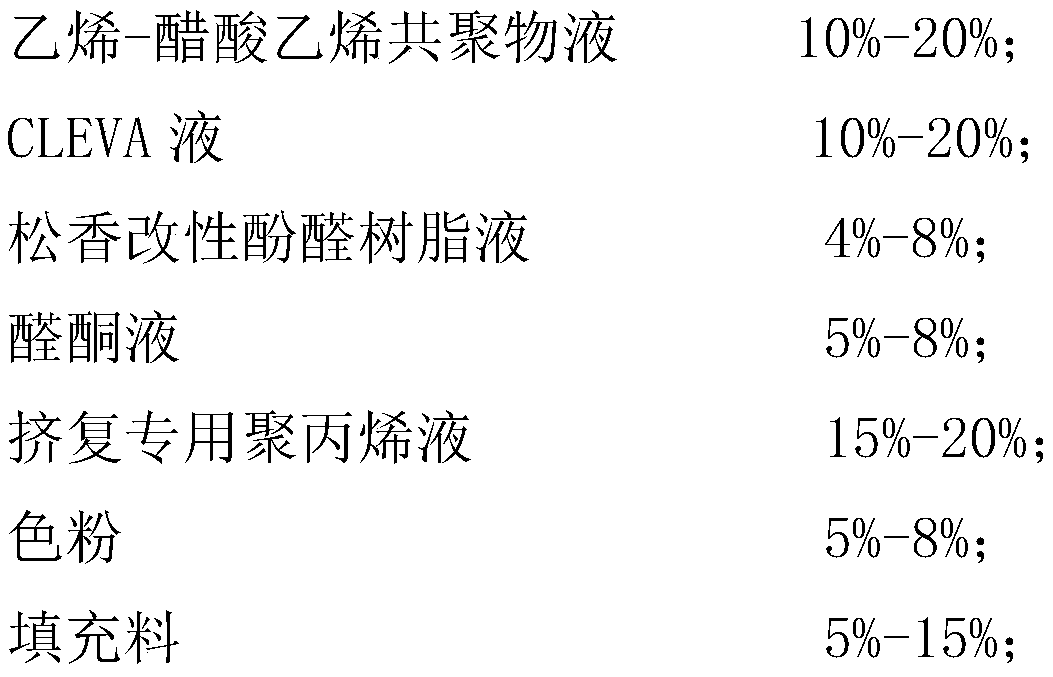

PE//composite PE novel gravure plastic composite ink and preparation method thereof

The invention discloses a PE / / composite PE gravure plastic composite ink and a preparation method thereof. The composite ink comprises the following raw materials in percent by weight: an ethylene-vinyl acetate copolymer liquid; a CLEVA liquid; a rosin modified phenolic resin liquid; an aldehyde ketone liquid; a special polypropylene liquid for extrusion compounding; a color powder; a filler; andethyl acetate. The preparation process is simple, the printed pattern by the prepared product is flat, smooth and fine, the printing effect is good, the adhesion fastness is strong, the composite inkis non-combustible and non-explosive, the printing effect is kept lasting, the surface of the ink film is smooth and wrinkle-free, the printing is clear, the ink does not fall off during the use process, and the drying speed is fast, so that the composite ink can be suitable for using in the printing ink fields, and the product performance is improved.

Owner:重庆宏图新材料科技有限公司

Rustproof anti-crush coating for steel and iron and preparation method of rustproof anti-crush coating

The invention discloses a rustproof anti-crush coating for steel and iron and a preparation method of the rustproof anti-crush coating. The preparation method comprises the following steps: weighing spindle oil, mercury sulfate, benzotriazole, paraffin, diphenylamine, ethyecellulose, vaseline, polybutadiene polyalcohol, petroleum sodium sulfonate ketone, polyether polyisocyanate and dimethylbenzene, stirring the raw materials and then grinding the stirred raw materials, wherein the coating is used for steel and iron surface protection, the coating is smooth in appearance, the viscosity is 60-100 s, surface drying time is 1-5 h, and hard drying time is 20-24 h; the covering force is 200-240 g / cm<3>, and the coating has high adhesive force for metals and is hard in coating film; the coating is high in dampproof and rustproof capacities and water resistance, the shock resistance is 70-90 cm, the salt water resistance is 14-18 d under the condition of soaking in water of 30 DEG C, and the coating is free of bubbling or dropping; the flexibility is 2-4 mm, and the crushing and dropping resistance is high.

Owner:WUXI EPIC TECH

Building coating containing inorganic montmorillonite and production method

InactiveCN107815235AHighlight substantive featuresSignificant progressFireproof paintsPolyurea/polyurethane coatingsEmulsionDefoaming Agents

The invention discloses a building coating containing inorganic montmorillonite and a production method. The building coating containing the inorganic montmorillonite is prepared from the following raw materials: polyurethane, an emulsion, linen fiber, the inorganic montmorillonite, diatom ooze, water, a composite coupling agent, a preservative, a flatting agent and a defoaming agent. The buildingcoating provided by the invention is favorable in coalescence, air permeable in film, not easy to blister, particularly suitable for internal and external plastering, good in permeability and stain resistance, better in hardness, gloss, water resistance and chemical corrosion resistance, and not easy to peel or fall off.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

Glass paint based on lac resin, preparation and use thereof

The invention relates to a coating. A glass paint based on lac resin is a single-component paint, and a main film-forming substance is the lac resin or a composition of the lac resin and crosslinked resin which are mixed according to the weight ratio of not less than 1:1. The glass paint adopts the natural lac resin as the film-forming substance, improves the comprehensive utilization rate of renewable resources, and is an environment-friendly product. The glass paint can adopt ethanol as a solvent, so as to greatly reduce environmental pollution during construction and use. The glass paint has simple technique and simple and convenient operation due to adoption of single-component construction. When the glass paint is painted on the glass surface, the glass paint can be cured into a film after being roasted for 3 to 5 minutes at a temperature of between 130 and 150, and the generated paint film has strong adhesion, good water resistance, strong corrosion resistance and good flexibility and is hard.

Owner:江苏柏鹤涂料有限公司 +1

Anti-yellowing terrace coating and construction method thereof

ActiveCN104109476ADelay yellowing timeSmooth coatingRosin coatingsPolyurea/polyurethane coatingsSodium polyacrylateRosin

The invention discloses an anti-yellowing terrace coating and a construction method thereof. The anti-yellowing terrace coating is prepared from the following raw materials in parts by weight: 50-60 parts of polyurethane, 60-70 parts of rosin water, 15-25 parts of butyl acetate, 15-20 parts of propylene glycol 1-monomethyl ether 2-acetate, 8-15 parts of sodium polyacrylate, 5-10 parts of sodium dehydroacetate, 5-8 parts of xylene, 5-10 parts of tributyl tin chloride, 3-5 parts of benzophenone and 1-3 parts of nipalgin; the construction method of the anti-yellowing terrace coating sequentially comprises the following steps: polishing with abrasive paper, dedusting, puttying, rubbing down a wall surface, roll-painting a thin layer of anti-yellowing terrace coating, airing, roll-painting a second layer of anti-yellowing terrace coating, carrying out roll-painting finishing and naturally airing. The anti-yellowing terrace coating is excellent in anti-yellowing property and is still purely white after being painted for multiple years.

Owner:DRAGON FISH PAINT

Liquid wallpaper coating and production method thereof

InactiveCN107815236ANo pollution in the processHard filmCellulose coatingsAnti-corrosive paintsPreservativeSisal fiber

The invention discloses a liquid wallpaper coating and a production method thereof. The liquid wallpaper coating is prepared from the following raw materials: polyurethane, an emulsion, silk powder, sisal fiber, a compound coupling agent, water, pearl powder, a preservative, a thickener and a defoamer. According to the liquid wallpaper coating disclosed by the invention, the raw materials are non-toxic and harmless; the coating is free of adverse effects on the human body and the environment; the coating film is hard and is fine and smooth in hand feeling; the coating has the characteristics of excellent water resistance, alkali resistance and adhesion, scrubbing resistance, is free of traces after being repeatedly scrubbed, environmentally friendly and pollution-free, low in cost, wide inapplication range, convenient to smear and rapid in drying speed and flat and glossy in appearance, and is capable of improving construction efficiency; the various decoration requirements of consumers are met; the liquid wallpaper coating becomes a fashionable decoration element of the modern space.

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

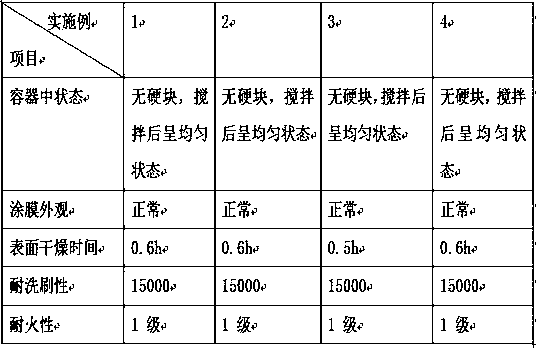

A kind of oil-based waterproof coating with added calcium sulfate whiskers and preparation method thereof

InactiveCN104530918BImprove waterproof performanceLarge specific surface areaAnti-corrosive paintsEpoxy resin coatingsGlycidyl ethersSulfate

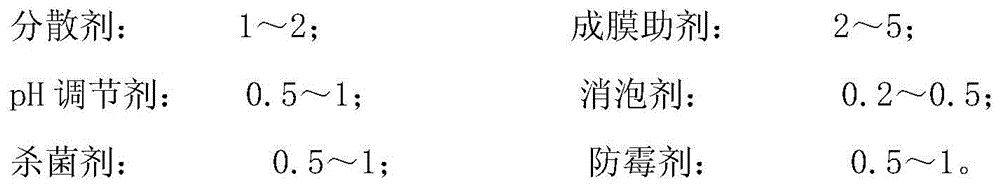

The invention discloses an oily waterproof coating added with calcium sulfate whiskers and a preparation method thereof. The oily waterproof coating is composed of the following raw materials in parts by weight: calcium sulfate whiskers: 18-27; perchlorinated vinyl resin: 5-10 ; Epoxy resin: 14~20; Dibutyl phthalate: 3~10; Thickener: 1~9; Butyl glycidyl ether: 5~10; Additive: 1~5; Xylene: 25~ 35; Pigment: 3-6. The preparation method includes weighing, modifying and mixing. The coating film of the oily waterproof paint added with calcium sulfate whiskers in the present invention is hard, strong in adhesion, excellent in water resistance and corrosion resistance, and low in raw material cost; the method for preparing the coating is simple in operation, convenient in production, and has low requirements on equipment, and is suitable for use in Industrialized mass production.

Owner:SICHUAN MINGXIN JIAJIE NEW MATERIAL

Waterborne polyester composite printing ink

The invention discloses waterborne polyester composite printing ink. The waterborne polyester composite printing ink is prepared from the following components in parts by mass: 80-100 parts of polyethylene terephthalate, 25-30 parts of polyethylene glycol, 2-5 parts of dibutyltin dilaurate, 3-4 parts of ethylene glycol, 4-5 parts of xylene, 5-7 parts of diethylene glycol, 6-8 parts of fatty alcohol polyoxyethylene ether, 3-5 parts of alcohol ethoxylate, 5-6 parts isocaprylic acid, 4-5 parts tetrabutyltin, 5-6 parts of dibutyltin maleate, 4-5 parts of diethylene glycol, 5-8 parts of anhydrous citric acid, 4-5 parts of itaconic acid, 4-5 parts of dimethyl carbonate, 40-50 parts of deionized water, 40-50 parts of acrylic resin, 8-10 parts of methanesiliconic acid sodium salt, 60-65 parts of vinyl acetate-ethylene copolymer emulsion, 8-10 water-soluble varnish and 6-8 parts of pigments. The waterborne polyester composite printing ink has no chlorine, no ketone, no benzene and other harmfulsubstances, and does not cause harm to the human body and the environment when used.

Owner:陈添就

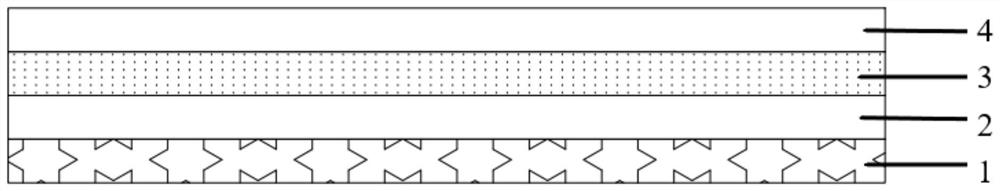

Erasable ink printing paper as well as preparation method and application thereof

PendingCN111778776APrevent penetrationEasy to eraseNon-fibrous pulp additionSpecial paperTear resistanceWear resistance

The invention provides erasable ink printing paper as well as a preparation method and application thereof. The erasable ink printing paper comprises a surface sheet paper layer, a PVP isolation layer, an ink layer and a film coating layer which are sequentially stacked. Based on the erasable ink printing paper, elimination can be achieved by lightly wiping ink with a small amount of water, and the paper has excellent wear resistance, scratch resistance, tear resistance and water resistance.

Owner:MYS GRP CO LTD

A kind of oil-based fireproof coating added calcium sulfate whisker and preparation method thereof

InactiveCN104710906BWith fire performanceReduce manufacturing costFireproof paintsEpoxy resin coatingsEpoxyPeroxide

The invention discloses an oil-based fireproof coating added with calcium sulfate whiskers and a preparation method thereof. The oil-based fireproof coating consists of the following raw materials in parts by weight: calcium sulfate whiskers: 18-27; perchlorinated vinyl resin: 5-10 ; Epoxy resin: 14~20; Dibutyl phthalate: 3~10; Thickener: 1~9; Pigment: 3~6; Additive: 1~5; Xylene: 25~35; Alcohol: 5-10. The preparation method includes weighing, modifying and mixing. The oil-based fireproof coating added with calcium sulfate whiskers has good stability, weather resistance, excellent fireproof effect and low raw material cost; the method for preparing the coating is simple in operation, convenient in production and low in requirements for equipment, and is suitable for industrialization Mass production.

Owner:SICHUAN MINGXIN JIAJIE NEW MATERIAL

Anti-yellowing floor paint and its construction method

ActiveCN104109476BDelay yellowing timeCoated evenlyRosin coatingsPolyurea/polyurethane coatingsChemistryTributyltin chloride

The invention discloses an anti-yellowing terrace coating and a construction method thereof. The anti-yellowing terrace coating is prepared from the following raw materials in parts by weight: 50-60 parts of polyurethane, 60-70 parts of rosin water, 15-25 parts of butyl acetate, 15-20 parts of propylene glycol 1-monomethyl ether 2-acetate, 8-15 parts of sodium polyacrylate, 5-10 parts of sodium dehydroacetate, 5-8 parts of xylene, 5-10 parts of tributyl tin chloride, 3-5 parts of benzophenone and 1-3 parts of nipalgin; the construction method of the anti-yellowing terrace coating sequentially comprises the following steps: polishing with abrasive paper, dedusting, puttying, rubbing down a wall surface, roll-painting a thin layer of anti-yellowing terrace coating, airing, roll-painting a second layer of anti-yellowing terrace coating, carrying out roll-painting finishing and naturally airing. The anti-yellowing terrace coating is excellent in anti-yellowing property and is still purely white after being painted for multiple years.

Owner:DRAGON FISH PAINT

A universal interface adhesive

ActiveCN104479605BHard filmOil-freeNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyDrying time

The invention relates to a universal interfacial binding agent which comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 30-50 parts of a cosolvent, 5-25 parts of en epoxy resin curing agent, 2-20 parts of a special auxiliary and 5-25 parts of filler; the component B is water soluble epoxy resin, and the weight ratio of the components A and B is (0.5-5):1. The universal interfacial binding agent provided by the invention has relatively low viscosity under room temperature, the necessary flowing property of the universal interfacial binding agent being used is guaranteed, the operable time is relatively long, and the construction pressure is greatly alleviated. The universal interfacial binding agent provided by the invention has the characteristics of being hard in coating, free of oil separation, short in drying time, green, environment-friendly and pollution-free and convenient to construct. Experiments verify that the viscosity of the universal interfacial binding agent provided by the invention at 20 DEG C is about 200cp and a good application performance for construction within 180 minutes after being mixed can be maintained.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Basic lead chromate silicate antirust coating used for steel, and preparation method thereof

InactiveCN106010243AStrong adhesionThe appearance of the coating film is smoothAnti-corrosive paintsBituminous coatingsLead ChromateLanolin

The invention discloses a basic lead chromate silicate antirust coating used for steel, and a preparation method thereof. The preparation method comprises the following steps: weighing basic lead chromate silicate, potter's clay, calcium carbonate. Butanol, coal-tar asphalt, lanolin, castor oil, nitrocellulose lacquer thinner, acetone, dibutyl phthalate and perchlorovinyl resin. The preparation method comprises the following steps: stirring above raw materials, and grinding the stirred raw materials to obtain the coating. A film formed by the coating has flat and bright appearance, the viscosity is 70-110s, the surface drying time is 2-6h, and the hard drying time is 24-28h; the covering power is 220-260g / cm<3>, the film has good adhesion to metal, and the film is hard; the film has good moisture, rust and water resistance, the impact resistance is 60-80cnm, and the film has no foaming or shedding phenomenon after being immersed in 30DEG C water for 10-14d; and the flexibility is 1-3mm, and the film has good resistance to heat and humidity.

Owner:WUXI EPIC TECH

Art type powder coating and preparation method thereof

InactiveCN112961524AImprove spraying effectSoft colorArtist's paintsPowdery paintsEpoxyPolymer science

The invention relates to an art type powder coating, which is prepared from the following components in parts by weight: 60-80 parts of polyester resin, 20-30 parts of epoxy resin, 30-40 parts of filler, 1-3 parts of a flatting agent, 2-5 parts of an accelerant, 1-3 parts of an incompatible polymer, 0.5-1.5 parts of a vertical grain agent, 0.3-0.5 parts of polyethylene wax and 0.2-0.5 parts of carbon black. The coating is good in spraying performance, soft in color and luster and flexible, hard and durable in coating film.

Owner:常州森月创意设计有限公司

Water-soluble antirust coating for steel and preparation method of coating

InactiveCN105968892AStrong adhesionImprove moisture resistanceAnti-corrosive paintsMetallic material coating processesHexamethylenetetramineAlkylphenol

The invention discloses water-soluble antirust coating for steel and a preparation method of the coating. The method includes the steps of weighing pure water, boric acid, ammonium hydroxide, sodium hydroxide, hexamethylenetetramine, polyoxyethylenealkylphenol ether, iron oxide red, methyl isobutyl ketone, methyl ethyl ketone, titanium dioxide and mica, and stirring and grinding the raw materials to obtain the coating. The coating is used for protecting steel surfaces, a film is smooth in appearance and has brush marks, the solid content is 46-50%, surface drying consumes 5-25 min, and hard drying consumes 0.2-2.5 h; the covering force is 55-75 g / m<2>, good adhesion force is achieved for metal, adhesion force is 3.5-5.5 MPa, and the film is hard; damp-proof performance, antirust performance and water resistance are good, impact strength is 50-70 N / cm, the salt water resistance is 10-14 d when the coating is soaked in water at 30 DEG C, bubbling and disengaging are avoided, and flexibility is 1-3 mm.

Owner:WUXI EPIC TECH

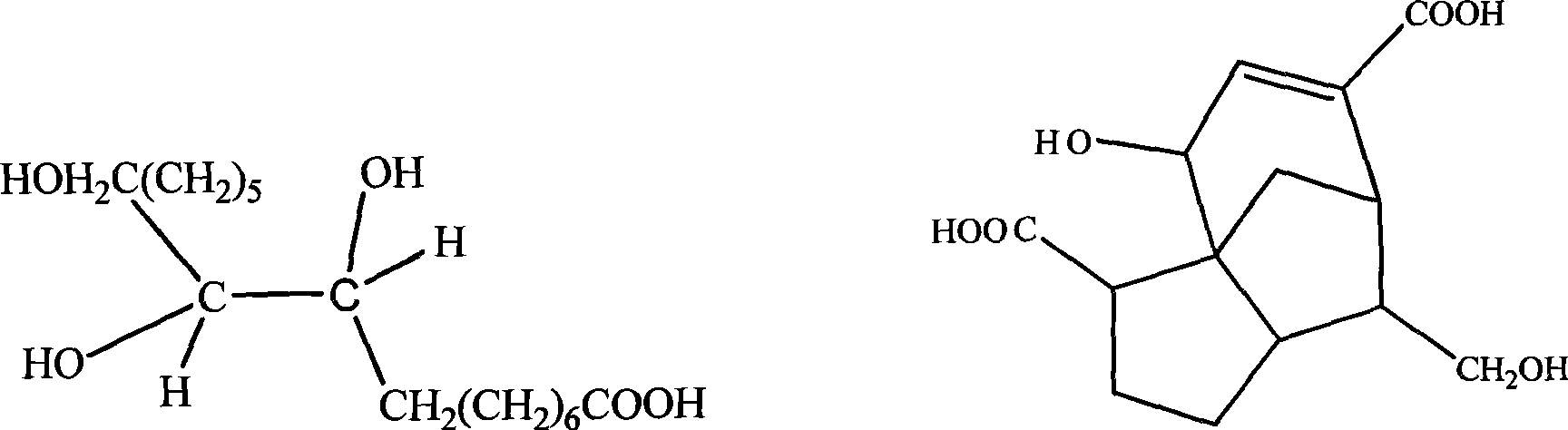

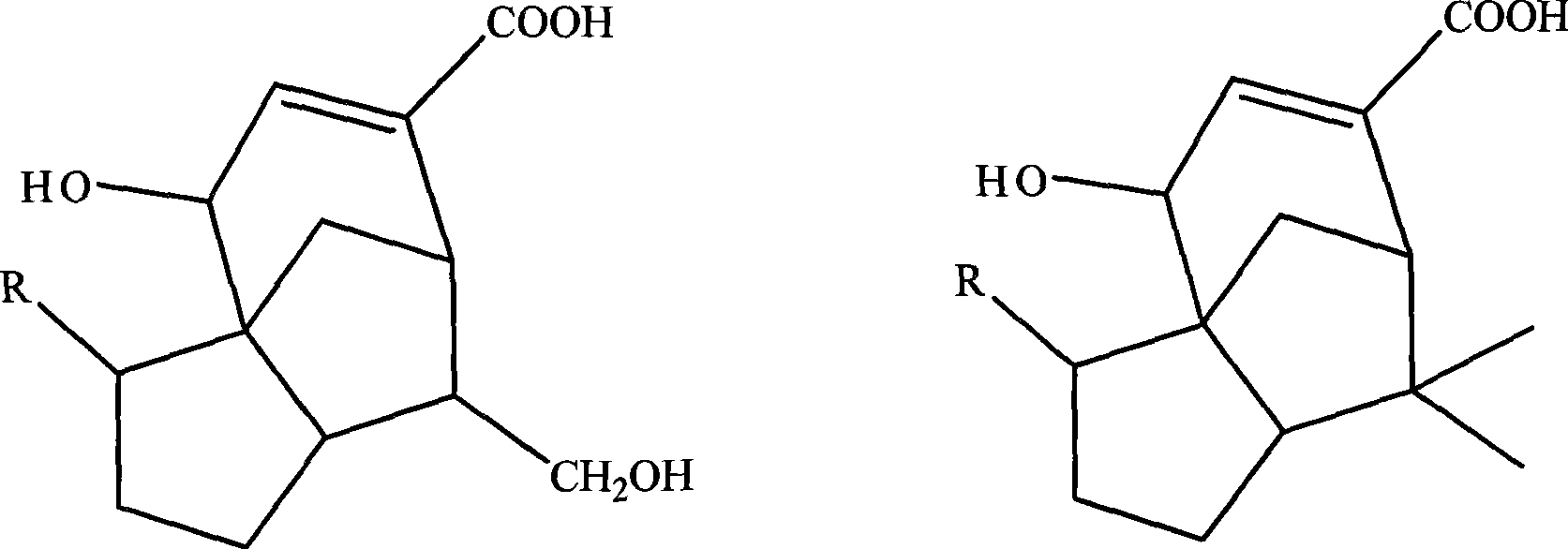

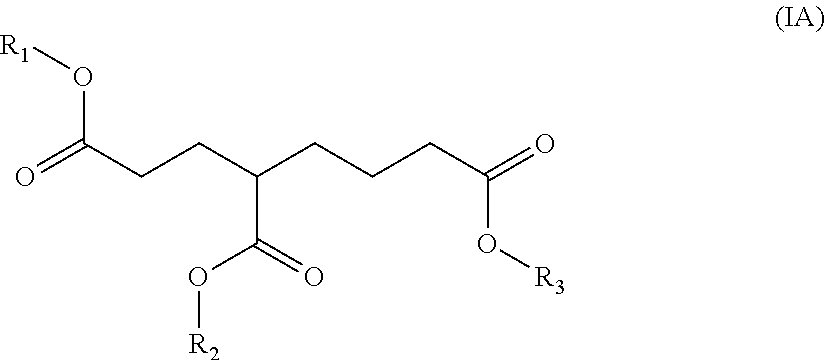

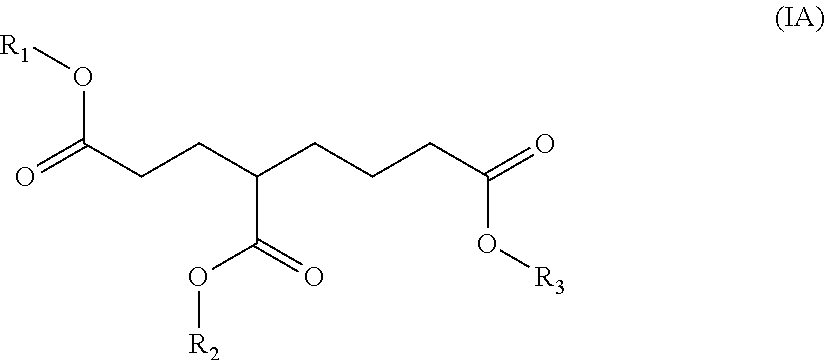

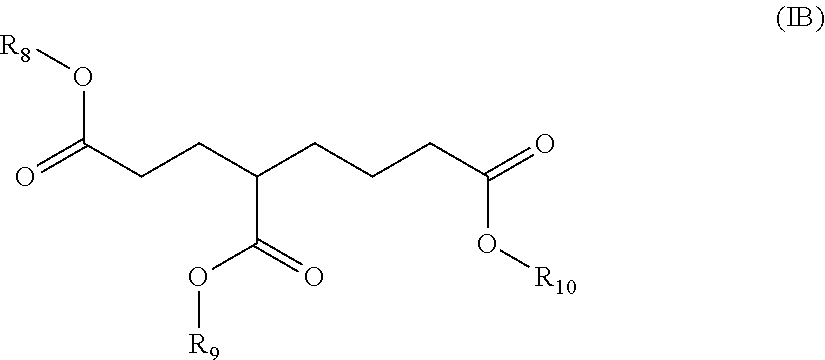

Tri-carboxylic compounds as low-voc coalescing agents and plasticizing agents

ActiveUS20200339826A1Stay flexibleLong-term flexibilityEmulsion paintsCombinatorial chemistryCarboxylic acid

A tri-carboxylic compound of Formula (IA) optionally in combination with a compound of Formula (IIA) behaves as a low-VOC, low odor coalescing agent, while a tri-carboxylic compound of Formula (IA) in combination with a compound of Formula (IIB), or alternatively, a tri-carboxylic compound of Formula (IB) in combination with a compound of Formula (IIA) exhibits dual coalescing and plasticizing properties. A tri-carboxylic compound of Formula (IB) optionally in combination with a compound of Formula (IIB) behaves as low-VOC, low odor plasticizing agent.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

Preparation method of environment-friendly anti-rust oil for horizontal centrifugal pump

The invention discloses a preparation method of environment-friendly anti-rust oil for a horizontal centrifugal pump. The environment-friendly anti-rust oil comprises the following raw materials in parts by weight: 13-16 parts of aqueous anionic acrylate resin emulsion, 5-8 parts of carboxymethyl cellulose sodium, 13-16 parts of dibutyl phthalate, 3-7 parts of nano calcium carbonate, 3-7 parts offerric oxide, 18-20 parts of sodium dihydrogen phosphate, 8-13 parts of polyepoxysuccinic acid, 10-13 parts of an anti-rust additive, 5-7 parts of titanium dioxide, 3-4 parts of an antifoaming agent and the balance of deionized water. Compared with the traditional technology, the method is simple in treatment process and low in cost, the anti-rust additive comprises a dispersing agent, an antifoaming agent, a flatting agent, mercaptoproxy trimethoxysilane and dodecyl succinic acid diethanolamide, and the mercaptoproxy trimethoxysilane and dodecyl succinic acid diethanolamide improve the anti-rust effect of the environment-friendly anti-rust oil. The environment-friendly anti-rust oil is water paint and is environmentally friendly to use.

Owner:安徽环科泵阀有限公司

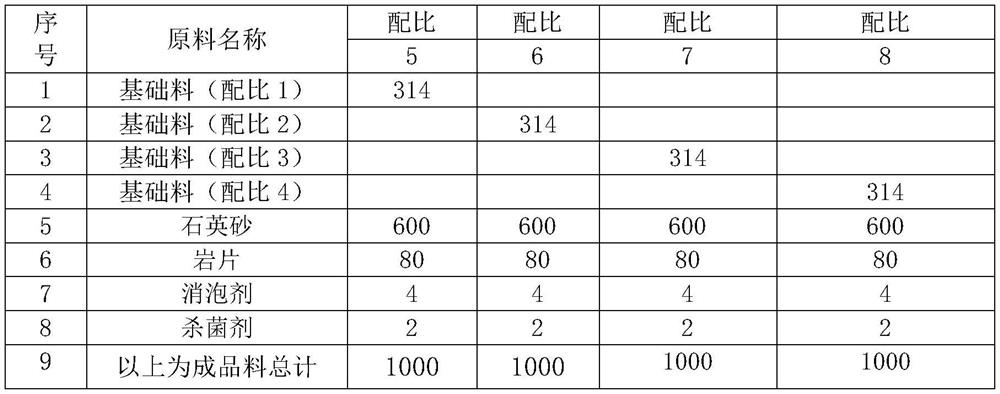

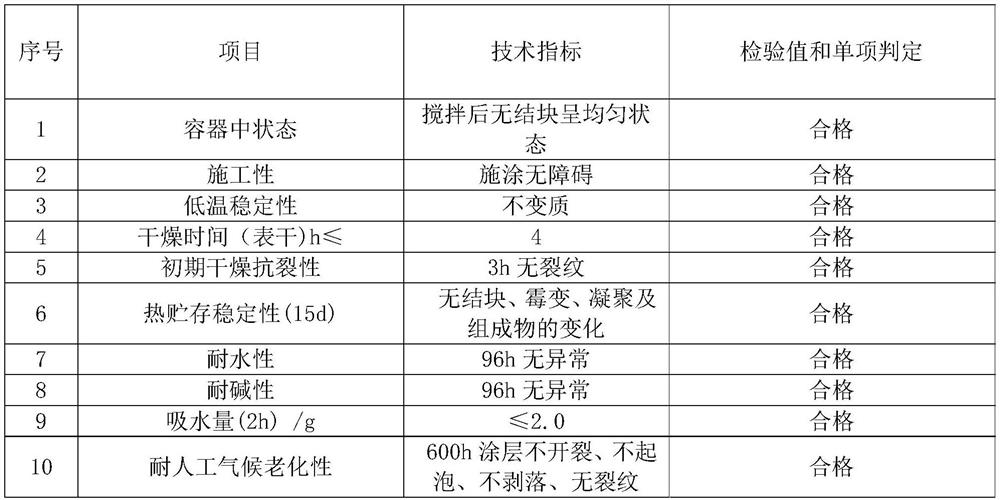

Anti-whitening outer wall real stone paint and preparation method thereof

PendingCN114806235AGood water whitening resistanceImprove water whitening resistanceCoatingsCellulosePolymer science

The invention discloses an anti-whitening outer wall real stone paint. The real stone paint is prepared from the following raw materials in parts by weight: 300-350 parts of a basic material, 600-700 parts of quartz sand, 70-80 parts of rock slices, 2-4 parts of a defoaming agent and 2-4 parts of a sterilizing agent; the base material is prepared from the following raw materials in parts by weight: 250 to 350 parts of water, 3 to 7 parts of silica sol, 0.01 to 0.05 part of gamma-glycidyl ether oxypropyl trimethoxy silane, 600 to 800 parts of silicone acrylic emulsion, 30 to 40 parts of a coalescing agent, 2 to 10 parts of a dispersing agent, 10 to 12 parts of a defoaming agent, 2 to 4 parts of hydroxypropyl methyl cellulose ether, 0.5 to 2 parts of a pH regulator, 15 to 20 parts of propylene glycol, 8 to 10 parts of a thickening agent and 10 to 12 parts of a sterilizing agent. The silicone acrylic emulsion and the silica sol are selected, and the raw materials are synergistically matched with the coalescing agent, the dispersing agent of a specific model, the defoaming agent and the like, so that the prepared outer wall real stone paint has excellent whitening resistance and also has relatively good adhesive force, weather resistance and the like.

Owner:QINGDAO HUANGHAI UNIV

External wall paint and preparation method thereof

The invention provides an external wall paint and a preparation method thereof. The paint comprises the following components in parts by weight: 12-30 parts of epoxy resin, 60-70 parts of isopropanol, 3-8 parts of polyacrylamide, 0.1-0.6 part of potassium hydroxide, 30-55 parts of ethanol, 80-120 parts of water, 110-160 parts of titanium white, 1-8 parts of mica powder, 1-7 parts of diethylene glycol butyl ether, 0.2-0.9 part of nano silicon dioxide, 2-11 parts of polyvinyl alcohol, 1-7 parts of kaolin and 5-15 parts of vitrified microbead. The preparation method comprises the following steps: mixing the epoxy resin, isopropanol, polyacrylamide, potassium hydroxide, ethanol and water, stirring uniformly, adding the rest components, stirring uniformly, filtering and standing. The outer wall paint has the advantages of hard paint film, high impact resistance, higher weather resistance and higher abrasion resistance. The paint film has very high stability and density, and thus, has the advantages of high adhesion and no bubble or crack, and is compact and uniform.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com