PE//composite PE novel gravure plastic composite ink and preparation method thereof

A gravure and plastic technology, applied in the field of PE//composite PE new gravure plastic composite ink and its preparation, can solve the problems of toxic and flammable, poor adhesion, poor light fastness, etc., and achieve strong adhesion fastness, enhanced softness performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

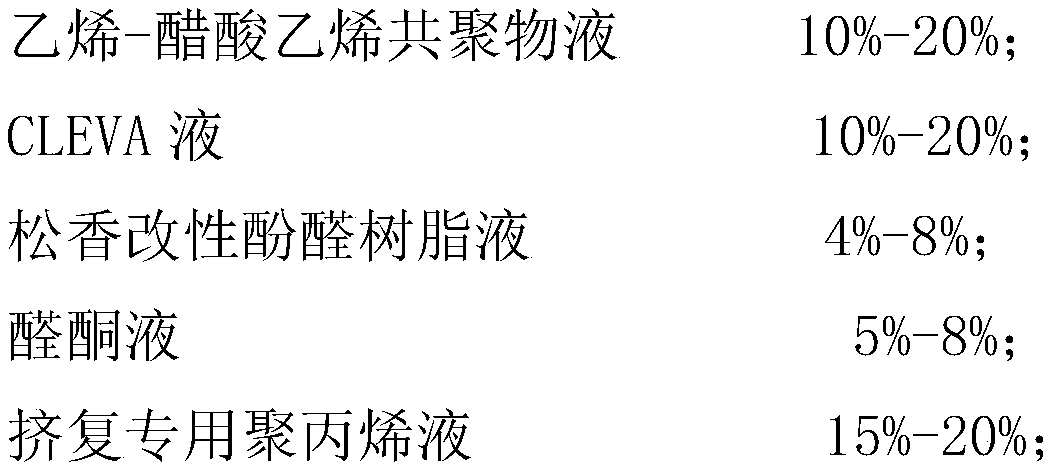

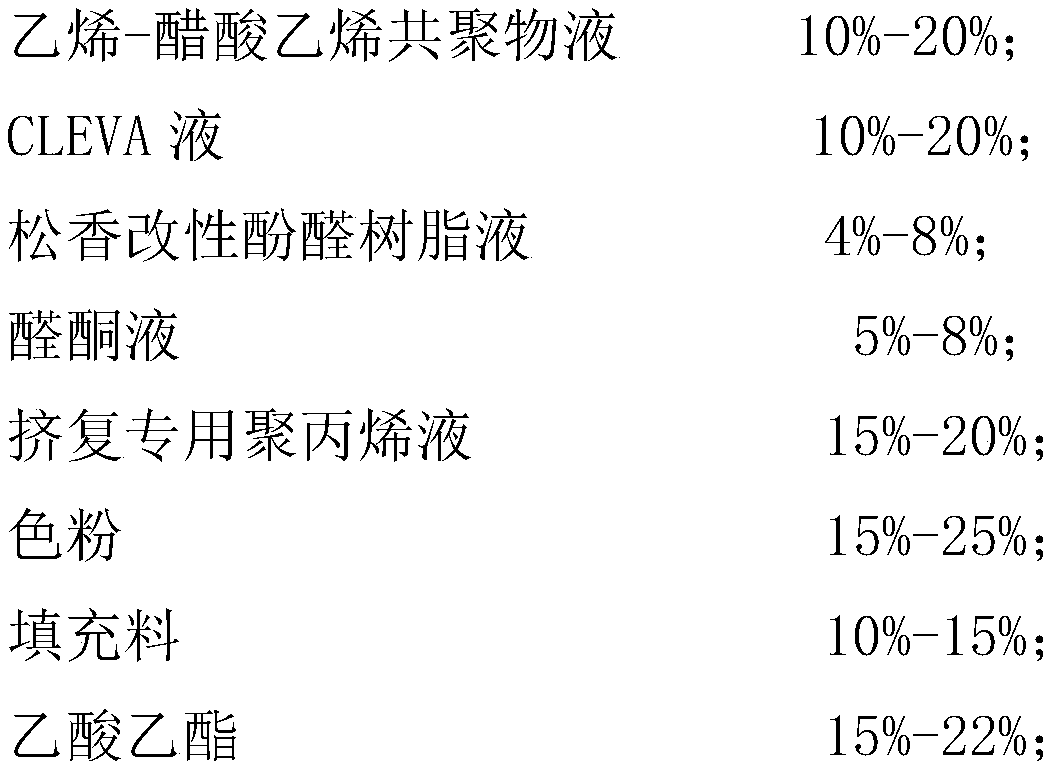

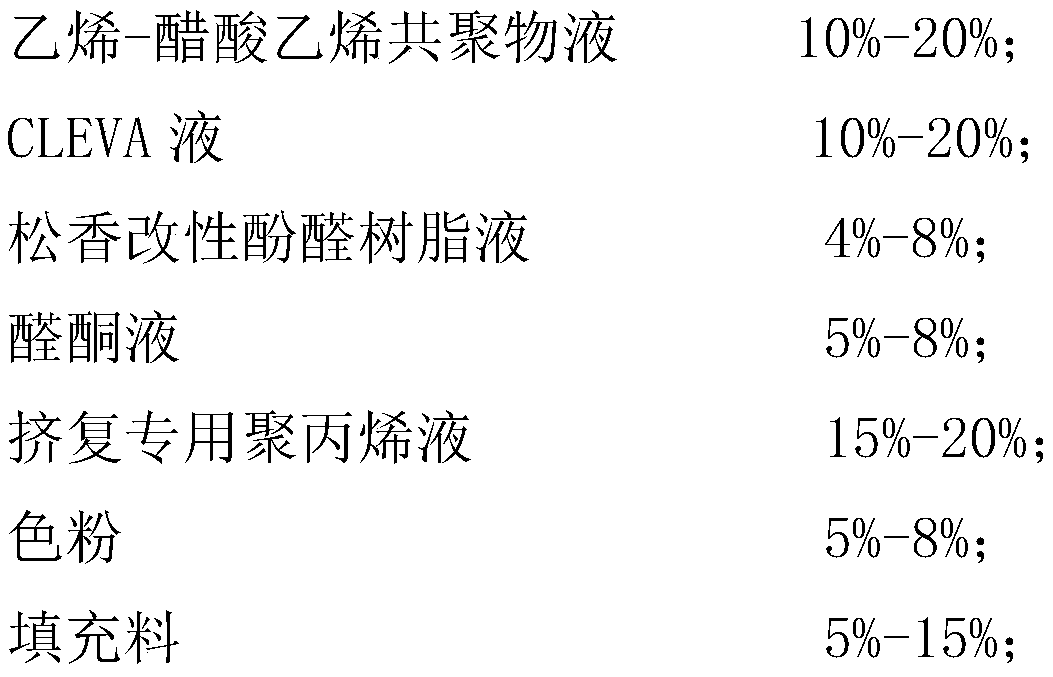

[0064] The dissolution formula ratio table is as follows

[0065]

[0066]

[0067] The preparation process of A, B, C, and D components is the same. Put the solid resin into ethyl ester and n-propyl ester and mix according to the dissolution formula ratio in the above table. Ethylene copolymer liquid, CLEVA liquid, rosin modified phenolic resin liquid, special polypropylene liquid for extrusion and aldehyde and ketone liquid. The resin solvents in traditional gravure plastic composite inks are benzene and ketones, and now they are all replaced by ester solvents.

Embodiment 2

[0069] Get the ethylene-vinyl acetate copolymer solution of 10% by weight prepared in embodiment 1, the CLEVA solution of 10% by weight, the rosin modified phenolic resin solution of 4% by weight and the rutile titanium dioxide of 15% by weight and mix and drop into Mix and stir in the mixer, the stirring temperature is 20-30°C, the dispersion speed is 1000r / min, and the stirring time is 30min to prepare the mixed material;

[0070] The prepared mixed material is placed in a sand mill and ground at a temperature of 20-30 ° C. The grinding time is determined according to the weight of the material to prepare a color paste;

[0071] 15% by weight of the special polypropylene liquid for extrusion, 5% by weight of the aldehyde and ketone solution prepared in Example 1, and 10% by weight of the filler after sanding with a sand mill and 15% by weight of ethyl acetate Put the ester into the color paste, and disperse at a high speed for 30 minutes at a temperature of 20-30°C to prepar...

Embodiment 3

[0073] Get the ethylene-vinyl acetate copolymer liquid of 20% weight portion prepared in embodiment 1, the CLEVA liquid of 20% weight portion, the rosin modified phenolic resin liquid of 8% weight portion and the rutile titanium dioxide of 25% weight portion mix and drop into Mix and stir in the mixer, the stirring temperature is 20-30°C, the dispersion speed is 1000r / min, and the stirring time is 30min to prepare the mixed material;

[0074] The prepared mixed material is placed in a sand mill and ground at a temperature of 20-30 ° C. The grinding time is determined according to the weight of the material to prepare a color paste;

[0075] Get the 20% weight portion of the special polypropylene liquid for extrusion, the 8% weight portion of the aldehyde and ketone liquid prepared in Example 1, and the 15% weight portion of the filler and the 22% weight portion of ethyl acetate after sanding by the sand mill. Put the ester into the color paste, and disperse at a high speed for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com