Anti-whitening outer wall real stone paint and preparation method thereof

A real stone paint, anti-whitening technology, applied in the direction of coating, can solve the problems of whitening of the coating in contact with water, the inability to effectively wrap the emulsion, and the influence of the decorative effect, and achieve the effect of good adhesion and excellent anti-whitening performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

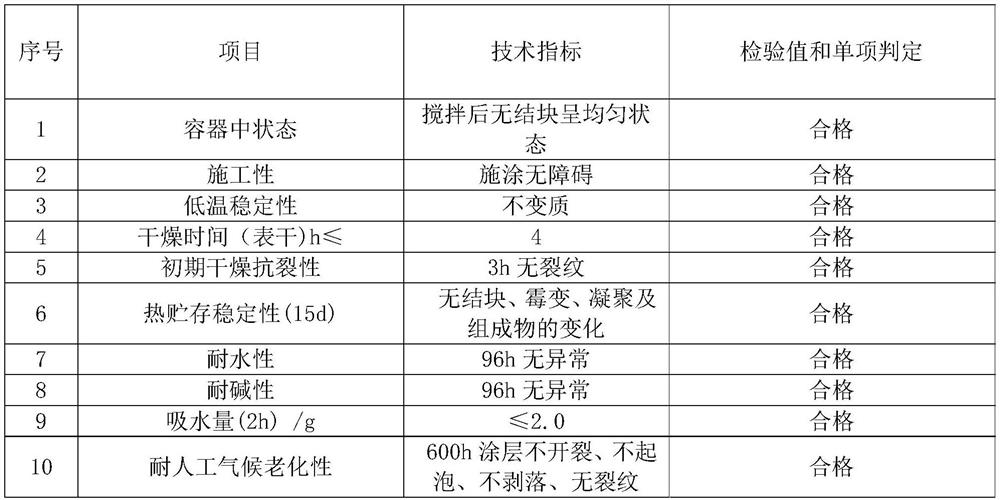

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned anti-whitening exterior wall real stone paint, comprises the following steps:

[0039] (1) Preparation of base material

[0040] Add water into the container, start the high-speed disperser, adjust the speed to 800rpm, and then add silica sol, γ-glycidyl ether oxypropyl trimethoxysilane, silicone acrylic emulsion, film-forming aids, dispersants, and partial defoaming. agent (1 / 2 dosage), hydroxypropyl methylcellulose ether, and dispersed for 20-50min. Then add the pH adjuster, increase the rotation speed to 1000rpm, and continue to disperse for 15-30min. Then reduce the rotation speed to 600rpm, add propylene glycol, the remaining antifoaming agent (1 / 2 amount), and thickener in turn, then increase the rotation speed to 1000rpm, and disperse for 15-30min to prepare the base material.

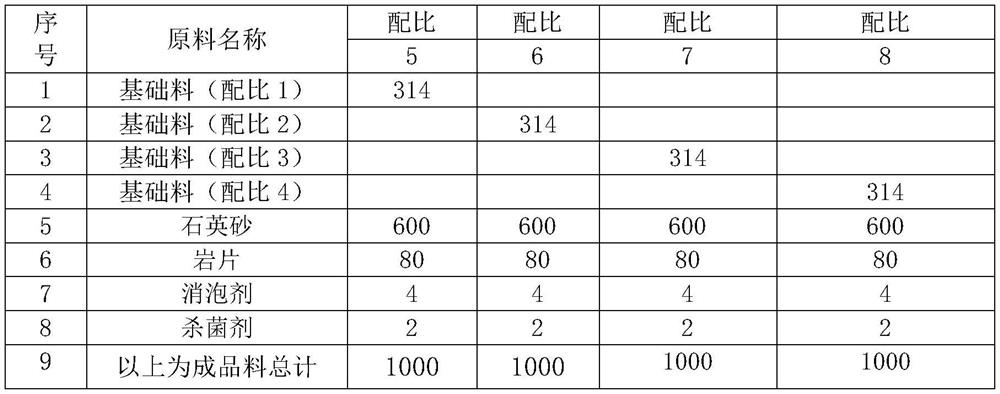

[0041] (2) Preparation of real stone paint

[0042] Add the base material obtained in step (1) into the container, start the high-speed di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com