Cement-free dry powder decorated mortar dedicated cover agent

A decorative mortar and cement-free technology, which is applied to paints containing biocide, anti-fouling/underwater coatings, coatings, etc., can solve problems such as unclear separation joints, poor water whitening resistance, and poor staining resistance, and achieve reduction VOC emission, good yellowing resistance, low gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The content of the invention will be further described below in conjunction with specific embodiments.

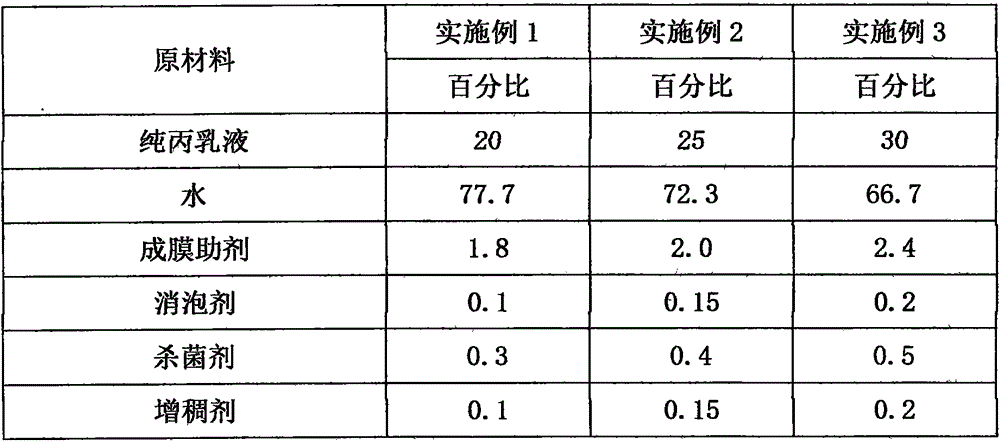

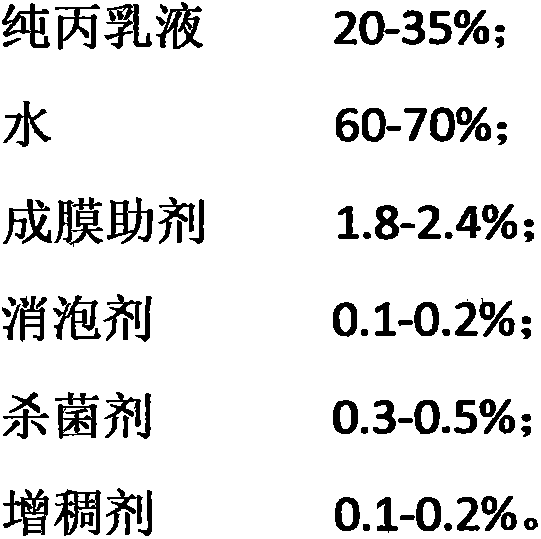

[0012] Each embodiment of the present invention adopts batching weight percent as shown in the following table:

[0013]

[0014] The covering agents of the three embodiments are used in conjunction with cement-free dry powder decorative mortar, and all indicators can meet the requirements of JG / T24-2000 after testing, and the covering agents have been used in the northeast and south since 2014. Customer feedback is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com