Graphene real stone paint and preparation method thereof

A technology of real stone and real stone paint, applied in the field of graphene real stone paint and its preparation, can solve the problems of waste of resources, influence on appearance, peeling and the like, and achieve the effects of low production cost, improved spreadability, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of graphene real stone paint, comprising the steps of:

[0036] S1. Mix cellulose with 50-100 parts of water to prepare a cellulose mixed solution;

[0037] S2. Mix organic bentonite with 40-50 parts to prepare organic bentonite mixed liquid;

[0038] S3. mixing the prepared cellulose homogeneous liquid and the cellulose homogeneous liquid in proportion;

[0039] S4. In the mixed liquor of S3 step, add multifunctional auxiliary agent, pure acrylic emulsion, dispersant, antifreeze agent, film-forming aid, defoamer, preservative, graphene oxide and thickener successively, add each The components need to be mixed evenly before adding the next component to make the base material of real stone paint;

[0040] S5. After transferring the former slurry of the real stone paint base material to the stirring device for pre-stirring, reduce the stirring speed to 200-400 rpm, add natural colored sand, and stop stirring immediately after it is stirred evenly, t...

Embodiment 1

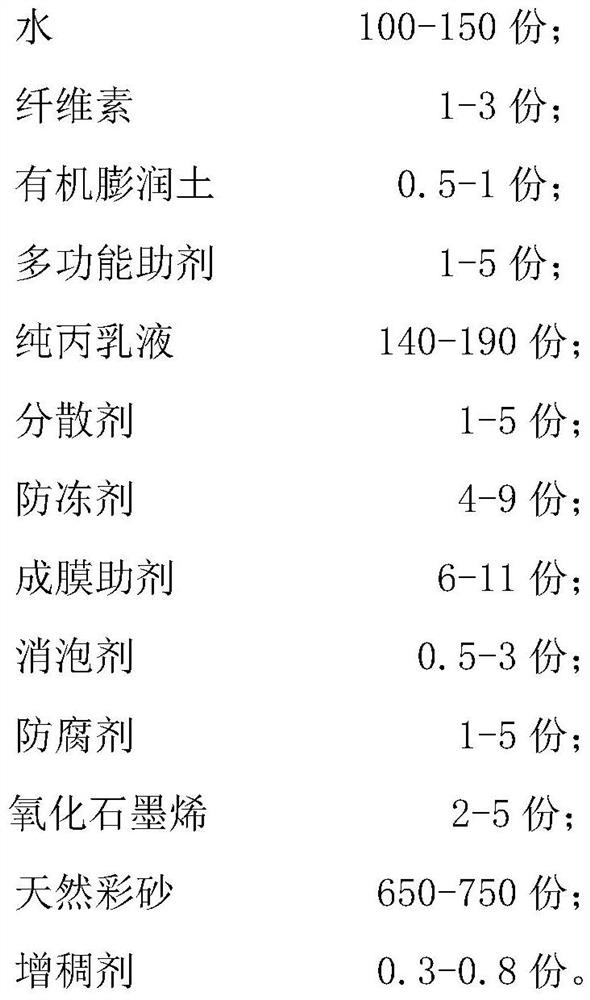

[0047] Real stone paint of the present invention comprises the following components by mass parts:

[0048]

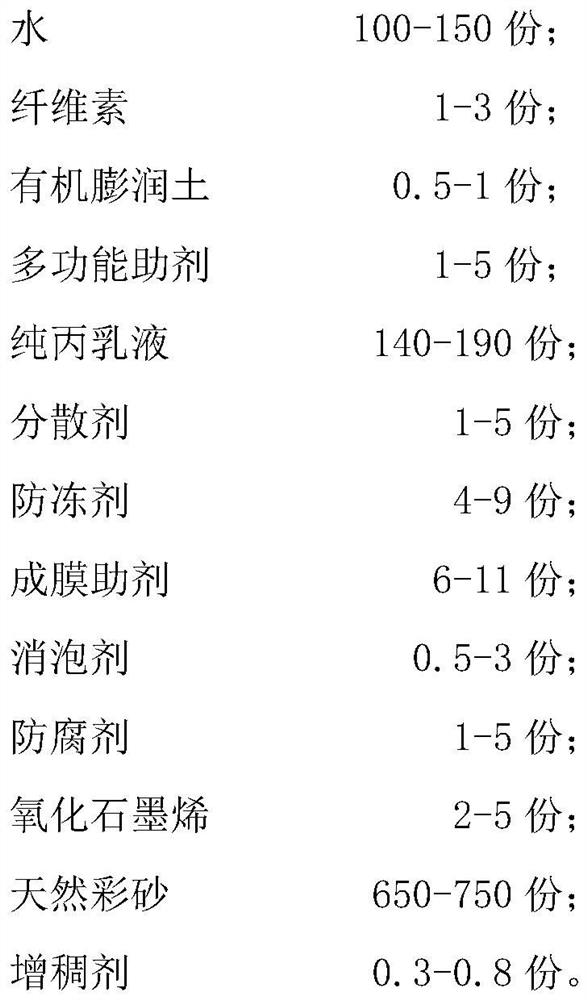

[0049]

[0050] The preparation method of real stone paint described in the present embodiment may further comprise the steps:

[0051] S1. Select a suitable container, weigh 3 parts of high-efficiency hydroxyethyl cellulose, add 50-100 parts of water under stirring, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm until the state is no longer change.

[0052] S2. Weigh 2 parts of organic bentonite and add 40-50 parts of water under stirring state, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm, until the state does not change.

[0053] S3. Mix the prepared cellulose mixed homogenate and bentonite mixed homogenate in proportion, and stir for 10 minutes at a speed of 800-1000 rpm.

[0054] S4. At a speed of 500-1000 rpm, add 1.5 parts of multifunctional additives, 160 parts of pure acrylic emulsion, 2 parts of polyac...

Embodiment 2

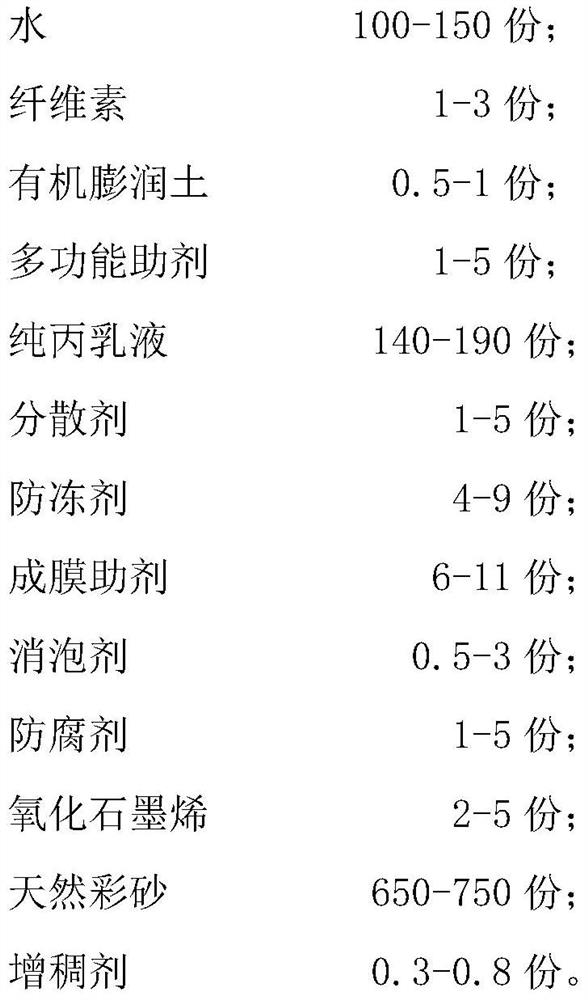

[0057] A novel environment-friendly real stone paint of the present invention comprises the following components in parts by mass:

[0058]

[0059] The preparation method of real stone paint described in the present embodiment may further comprise the steps:

[0060] S1. Select a suitable container, weigh 3 parts of cellulose and add 50-100 parts of water while stirring, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm until the state does not change.

[0061] S2. Weigh 2 parts of organic bentonite and add 40-50 parts of water under stirring state, and stir at room temperature for 20 minutes at a speed of 500-1000 rpm, until the state does not change.

[0062] S3. Mix the prepared cellulose mixed homogenate and bentonite mixed homogenate in proportion, and stir for 10 minutes at a speed of 800-1000 rpm.

[0063] S4. At the speed of 500-1000 rpm, add 1.5 parts of multifunctional additives, 160 parts of pure acrylic emulsion, 2 parts of polyacrylic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com