A kind of real stone paint and preparation method thereof

A technology of real stone paint and lacquer pots, applied in the direction of coating, etc., can solve the problems of low initial viscosity, sand falling, difficult construction, etc., and achieve the effect of good film forming, overcoming phenomenon, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

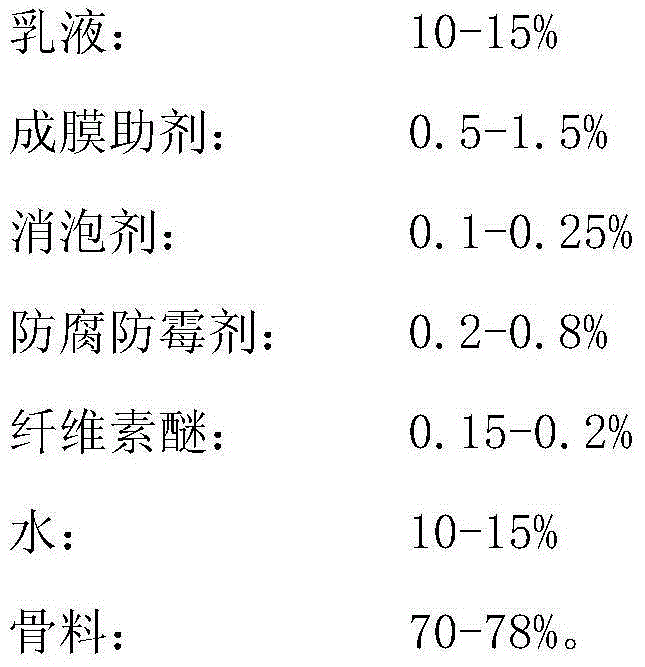

[0026] A real stone paint, its composition and mass percentage are:

[0027]

[0028]

[0029] A method for preparing above-mentioned real stone paint, comprising the following steps:

[0030] (a), put water into the clean paint tank, start the disperser and stir at 500RPM;

[0031] (b), put in dodecyl ester and mineral oil in turn, and disperse at 500RPM for 3 minutes;

[0032] (c), add hydroxyethyl cellulose, and disperse at 500RPM for 3 minutes;

[0033] (d), until the hydroxyethyl cellulose is completely wetted and stirred evenly, adjust the pH to 8.5, and when the viscosity increases, increase the rotation speed to above 1000RPM and disperse for 3 minutes;

[0034] (e), put into water-based acrylate emulsion, and stir at 500RPM for 10 minutes;

[0035] (f), add KathonLEX after stirring evenly, and stir at 500RPM for 3 minutes;

[0036] (g) After mixing the above prepared ingredients and quartz sand, adjust the viscosity to 40000cps / 25℃.

Embodiment 2

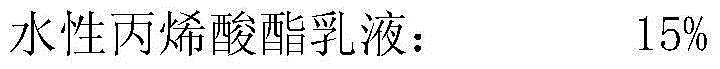

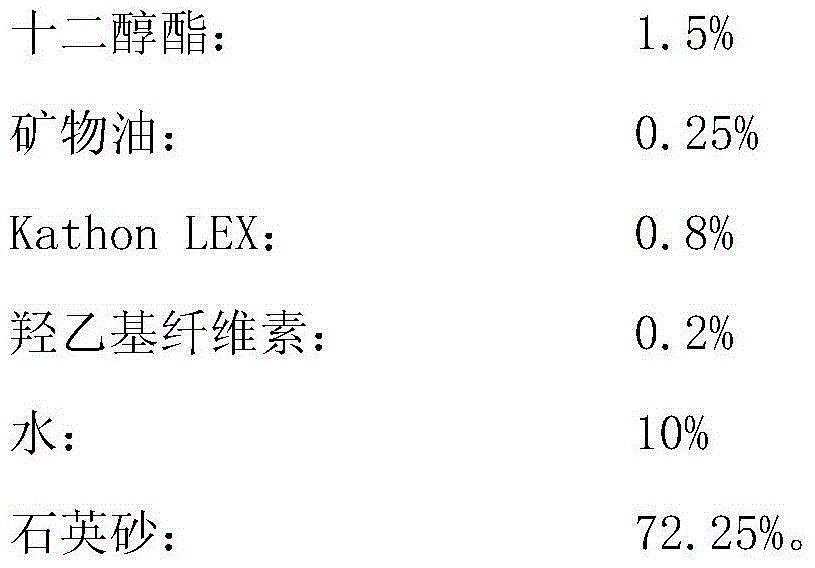

[0038] A real stone paint, its composition and mass percentage are:

[0039]

[0040] A method for preparing above-mentioned real stone paint, comprising the following steps:

[0041] (a), put water into the clean paint tank, start the disperser and stir at 500RPM;

[0042] (b), put in dodecyl ester, mineral oil and propylene glycol in sequence, and disperse at 500RPM for 5 minutes;

[0043] (c), add hydroxyethyl cellulose, and disperse at 500RPM for 5 minutes;

[0044] (d), until the hydroxyethyl cellulose is completely wetted and stirred evenly, adjust the pH to 8.0, when the viscosity increases, increase the rotation speed to above 1000RPM and disperse for 5 minutes, and then add the alkali-swellable thickener ASE60;

[0045] (e), put in silicone modified acrylate emulsion, and stir at 800RPM for 10 minutes;

[0046] (f), add KathonLEX after stirring evenly, and stir at 800RPM for 5 minutes;

[0047] (g) Adjust the viscosity to 45000cps / 25℃ after mixing the above-pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com