A kind of water-based machine spray real stone paint and preparation method thereof

A real stone paint, water-based technology, applied in the field of water-based machine-sprayed real stone paint and its preparation, can solve the problems of low stability and poor atomization effect of water-based real stone paint, and achieve good water whitening resistance, atomization effect and surface texture Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

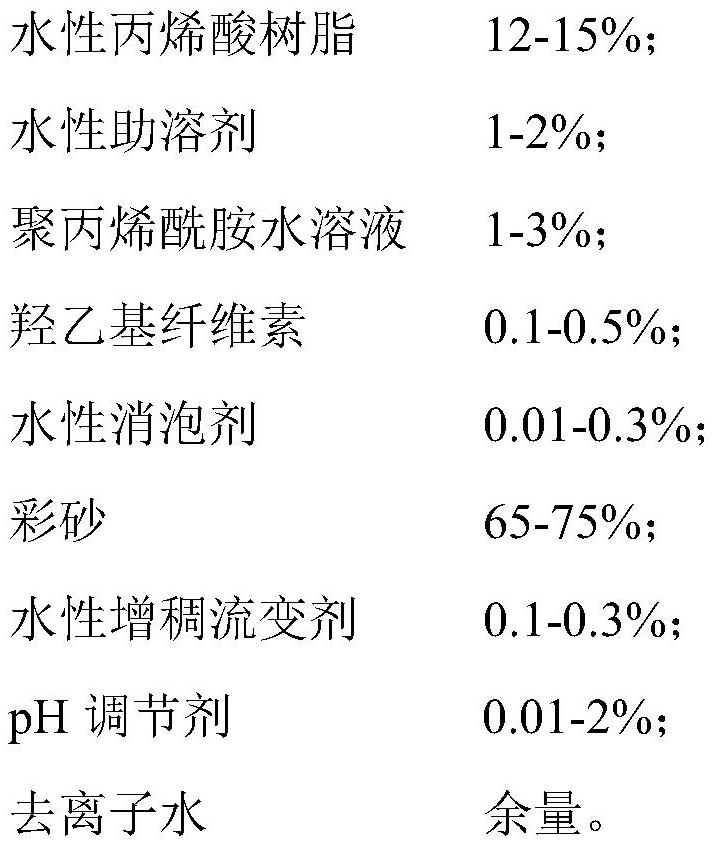

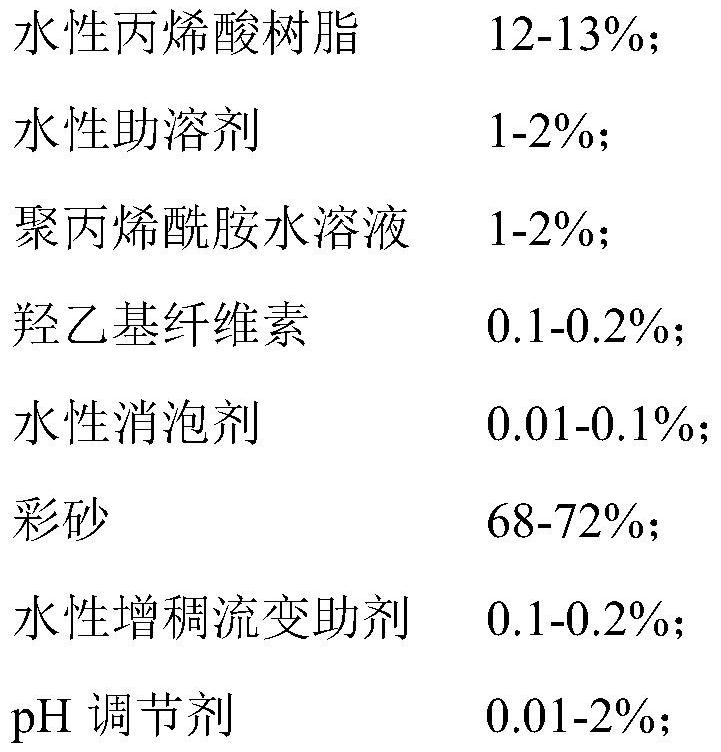

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of machine-sprayed genuine stone paint, comprising the following steps:

[0053] 1) Under the condition of 400r / min stirring, put 13.95kg deionized water into the mixing tank, slowly add 0.15kg hydroxyethyl cellulose (HS30000), then add 0.05kg water-based defoamer (NXZ), increase the stirring speed to 700r / min, stir for 6min, then add 0.1kg pH adjuster (AMP-95), increase the stirring speed to 1000r / min, stir for 7min;

[0054] 2) Reduce the stirring speed to 400r / min, add 1.5kg weight fraction of 0.2% polyacrylamide aqueous solution, then add 1.5kg water-based co-solvent, then add 12.5kg water-based acrylic resin (Badfu RS-706), and then add Stirring speed increased to 1000r / min, stirring for 15min;

[0055] 3) Reduce the stirring speed to 400r / min, add 0.15kg of water-based thickening rheology agent (DR50) and 70kg of colored sand in sequence, and stir for 10 minutes to obtain a water-based machine-sprayed real stone paint.

Embodiment 2

[0057] A preparation method of machine-sprayed genuine stone paint, comprising the following steps:

[0058] 1) Under the stirring condition of 400r / min, put 14kg of deionized water into the mixing tank, slowly add 0.1kg of hydroxyethyl cellulose (HS100000), then add 0.05kg of water-based defoamer (NXZ), increase the stirring speed to 700r / min, stirred for 6min, then added 0.1kg pH regulator (AMP-95), the stirring speed rose to 1000r / min, stirred for 7min;

[0059] 2) Reduce the stirring speed to 400r / min, add 1.5kg weight fraction of 0.2% polyacrylamide aqueous solution, then add 1.5kg water-based co-solvent, then add 12.5kg water-based acrylic resin (Badfu RS-706), and then add Stirring speed increased to 1000r / min, stirring for 20min;

[0060] 3) Reduce the stirring speed to 400r / min, add 0.15kg of water-based thickening rheology agent (DR50), 0.1kg of fungicide (isothiazolinone) and 70kg of colored sand in sequence, and stir for 13min to obtain water-based machine-spraye...

Embodiment 3

[0062] A preparation method of machine-sprayed genuine stone paint, comprising the following steps:

[0063] 1) Under the stirring condition of 400r / min, put 10.95kg of deionized water into the mixing tank, slowly add 0.15kg of hydroxyethyl cellulose (HS30000) and 3kg of magnesium aluminum silicate powder (ATT40), and then add 0.05kg of water-based disinfectant Foaming agent (NXZ), increase the stirring speed to 700r / min, stir for 5min, then add 0.1kg pH regulator (AMP-95), increase the stirring speed to 1000r / min, stir for 8min;

[0064] 2) Reduce the stirring speed to 400r / min, add 1.5kg weight fraction of 0.2% polyacrylamide aqueous solution, then add 1.5kg water-based co-solvent, then add 12.5kg water-based acrylic resin (Badfu RS-706), and then add Stirring speed increased to 1000r / min, stirring for 15min;

[0065] 3) Reduce the stirring speed to 400r / min, add 0.15kg of water-based thickening rheology agent (DR50), 0.1kg of fungicide (isothiazolinone) and 70kg of colored...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com