Radiation-resistant paint and production method thereof

A technology of anti-radiation coatings and production methods, which is applied in the direction of cellulose coatings, etc., can solve the problems that people do not pay enough attention to radiation, and achieve the effects of superior performance, enhanced mechanical properties, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

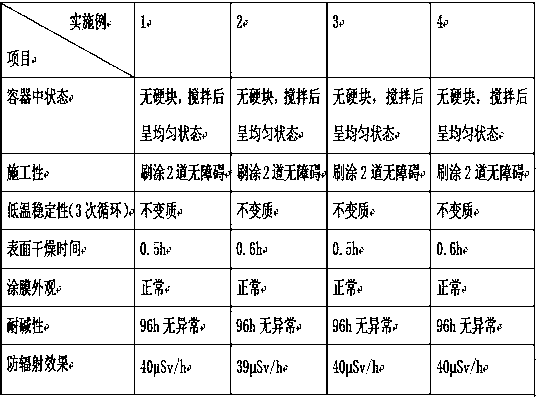

Examples

Embodiment 1

[0063] The production method of the anti-radiation coating, which comprises the following raw materials in parts by weight: 40 parts of polyurethane, 5 parts of emulsion, 20 parts of sisal fiber, 20 parts of water, 2 parts of composite coupling agent, 5 parts of aluminum powder anti-radiation material, flow 1 part of leveling agent, 2 parts of defoamer,

[0064] The production process of the anti-radiation coating comprises the following steps:

[0065] (1) Add the prescribed amount of water, anti-radiation material, leveling agent, and 1 / 2 defoamer in turn into the mixer, stir evenly at a speed of 300 rpm, and stir for 15 minutes to form a colloidal solution;

[0066] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0067] (3) Mix sisal fiber and polyurethane according to the weight ratio of the formula, and the rotating speed is 1000 rpm to obtain a mixed solution;

...

Embodiment 2

[0078] The production method of the anti-radiation coating comprises the following raw materials in parts by weight: 45 parts of polyurethane, 10 parts of emulsion, 25 parts of sisal fiber, 25 parts of water, 3 parts of composite coupling agent, 10 parts of aluminum powder anti-radiation material, flow 2 parts of leveling agent, 3 parts of defoamer,

[0079] The production process of the anti-radiation coating comprises the following steps:

[0080] (1) Add the prescribed amount of water, anti-radiation material, leveling agent, and 1 / 2 defoamer in turn into the mixer, stir evenly, at a speed of 300 rpm, and stir for 20 minutes to form a colloidal solution;

[0081] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0082] (3) Mix sisal fiber and polyurethane according to the weight ratio of the formula, and the speed is 1500 rpm to obtain a mixed solution;

[0083] (4), ...

Embodiment 3

[0093] The production method of anti-radiation coating, which comprises the following raw materials in parts by weight: 50 parts of polyurethane, 15 parts of emulsion, 25 parts of sisal fiber, 25 parts of water, 4 parts of composite coupling agent, 15 parts of silver powder anti-radiation material, leveling 3 parts of agent, 3 parts of defoamer,

[0094] The production process of the anti-radiation coating comprises the following steps:

[0095] (1) Add the prescribed amount of water, anti-radiation material, leveling agent, and 1 / 2 defoamer in turn into the mixer, stir evenly at a speed of 300 rpm, and stir for 25 minutes to form a colloidal solution;

[0096] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0097] (3) Mix sisal fiber and polyurethane according to the weight ratio of the formula, and the speed is 1500 rpm to obtain a mixed solution;

[0098] (4), put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com