Erasable ink printing paper as well as preparation method and application thereof

A technology for printing paper and ink, applied in the field of ink printing, can solve the problems of difficult to remove cleaning process, trouble, etc., and achieve the effect of good water repellency and moisture resistance, speeding up the reaction speed, and excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

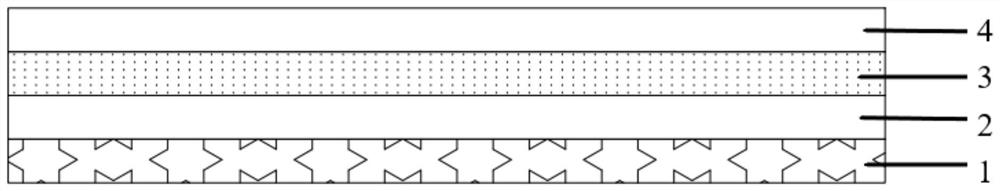

[0043] This embodiment provides a kind of erasable type ink printing paper, described erasable type ink printing paper comprises face liner paper layer, PVP isolation layer, ink layer and coating layer stacked in sequence, and the thickness of described PVP isolation layer is 80 μ m , the ink layer is 0.5 μm, and the coating layer is a PE film with a thickness of 8 μm.

[0044] The raw materials for the preparation of the PVP isolation layer include: polyvinylpyrrolidone K 305%, epoxy acrylate 11.26%, silyl epoxy modified acrylate 11.26%, aliphatic urethane acrylate 33.78%, two Tripropylene glycol diacrylate 18.8%, trimethylolpropane triacrylate 9.3%, photoinitiator (2-hydroxy-2-methyl-1-phenylacetone) 6%, acrylate leveling agent 1.6% , 2% acrylic wetting agent, 1% mineral oil type defoamer, and the balance is water.

[0045] The preparation method of the erasable ink printing paper described in this embodiment is as follows: after coating a PVP isolation layer on the side of...

Embodiment 2

[0047] This embodiment provides a kind of erasable ink printing paper, which includes a liner paper layer, a PVP isolation layer, an ink layer and a film layer stacked in sequence, and the thickness of the PVP isolation layer is 100 μm , the ink layer is 1 μm, and the coating layer is a PE film with a thickness of 10 μm.

[0048] The raw materials for the preparation of the PVP isolation layer include: polyvinylpyrrolidone K 305%, epoxy acrylate 11.26%, silyl epoxy modified acrylate 11.26%, aliphatic urethane acrylate 33.78%, two Tripropylene glycol diacrylate 18.8%, trimethylolpropane triacrylate 9.3%, photoinitiator (2-hydroxy-2-methyl-1-phenylacetone) 6%, acrylate leveling agent 1.6% , 2% acrylic wetting agent, 1% mineral oil type defoamer, and the balance is water.

[0049] The preparation method of the erasable ink printing paper described in this embodiment is as follows: one side of the single paper layer is coated with a PVP isolation layer and then cured under an ult...

Embodiment 3

[0051] This embodiment provides a kind of erasable ink printing paper, which includes a face sheet layer, a PVP isolation layer, an ink layer and a film layer stacked in sequence, and the thickness of the PVP isolation layer is 50 μm , the ink layer is 0.2 μm, and the coating layer is a PE film with a thickness of 10 μm.

[0052] The raw materials for the preparation of the PVP isolation layer include: polyvinylpyrrolidone K 305%, epoxy acrylate 11.26%, silyl epoxy modified acrylate 11.26%, aliphatic urethane acrylate 33.78%, two Tripropylene glycol diacrylate 18.8%, trimethylolpropane triacrylate 9.3%, photoinitiator (2-hydroxy-2-methyl-1-phenylacetone) 6%, acrylate leveling agent 1.6% , 2% acrylic wetting agent, 1% mineral oil type defoamer, and the balance is water.

[0053] The preparation method of the erasable ink printing paper described in this embodiment is as follows: after coating the PVP isolation layer on the side of the single paper layer, curing under the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com