Sound absorption coating and production method thereof

A technology for sound-absorbing coatings and production methods, applied in the direction of anti-corrosion coatings, etc., can solve problems such as lack of sound-absorbing function, sound-absorbing effect, production cost and environmental protection defects, and achieve the effects of prolonging life, improving the acoustic environment, and good sound-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

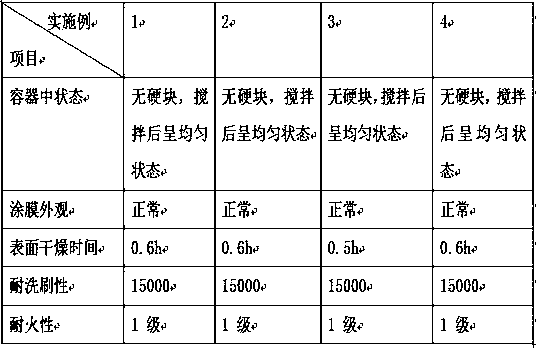

Embodiment 1

[0068] The production method of sound-absorbing coating, which includes the following raw materials in parts by weight: 40 parts of polyurethane, 5 parts of emulsion, 10 parts of slag cotton fiber, 20 parts of water, 2 parts of composite coupling agent, 5 parts of diatom mud, and 5 parts of expanded perlite 1 part, 1 part of leveling agent, 2 parts of defoamer;

[0069] The production process of sound-absorbing coatings includes the following steps:

[0070] (1) Add the prescribed amount of water, diatom mud, leveling agent, and 1 / 2 defoamer in turn into the mixer, stir evenly, at a speed of 300 rpm, and stir for 15 minutes to form a colloidal solution;

[0071] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0072] (3) Mix the slag cotton fiber and polyurethane according to the weight ratio of the formula, and the rotating speed is 1000 rpm to obtain a mixed solution; ...

Embodiment 2

[0083] The production method of sound-absorbing paint, which includes the following raw materials in parts by weight: 45 parts of polyurethane, 10 parts of emulsion, 11 parts of slag cotton fiber, 25 parts of water, 3 parts of composite coupling agent, 7 parts of diatom mud, and 7 parts of expanded perlite 2 parts, 2 parts of leveling agent, 3 parts of defoamer;

[0084] The production process of sound-absorbing coatings includes the following steps:

[0085] (1) Add the prescribed amount of water, diatom mud, leveling agent, and 1 / 2 defoamer in turn into the mixer, stir evenly at a speed of 300 rpm, and stir for 20 minutes to form a colloidal solution;

[0086] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0087] (3) Mix slag cotton fiber and polyurethane according to the formula weight ratio, and the rotating speed is 1200 rpm to obtain a mixed solution;

[0088] (...

Embodiment 3

[0098] The production method of the sound-absorbing coating, which includes the following raw materials in parts by weight: 50 parts of polyurethane, 15 parts of emulsion, 13 parts of slag cotton fiber, 25 parts of water, 4 parts of composite coupling agent, 9 parts of diatom mud, and 9 parts of expanded perlite 3 parts, 3 parts of leveling agent, 3 parts of defoamer;

[0099] The production process of sound-absorbing coatings includes the following steps:

[0100] (1) Add the prescribed amount of water, diatom mud, leveling agent, and 1 / 2 defoamer in turn into the mixer, stir evenly, at a speed of 300 rpm, and stir for 25 minutes to form a colloidal solution;

[0101] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0102] (3) Mix slag wool fiber and polyurethane according to the weight ratio of the formula, and the speed is 1000 rpm to obtain a mixed solution;

[0103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com