Wooden sound-absorbing board coating and production method thereof

A production method and technology of sound-absorbing panels, applied in the field of furniture coatings, can solve the problems of harmfulness to the human body, environmental pollution, inflammability and explosion, etc., and achieve the effect of low cost, strong decoration and hard hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

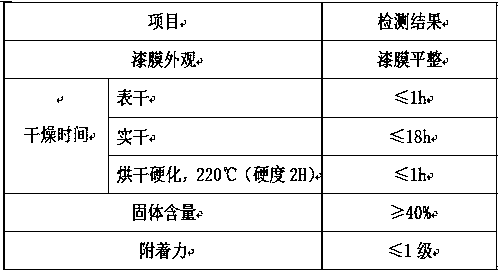

Image

Examples

Embodiment 1

[0084] The production method of wood sound-absorbing board coating, which includes the following raw materials in parts by weight: 40 parts of polyurethane, 30 parts of epoxy resin, 5 parts of emulsion, 10 parts of glass fiber, 2 parts of composite coupling agent, 20 parts of water, expanded perlite 5 parts, 1 part of 3-iodo-2-propynyl butyl carbamate, 1 part of flame retardant, 1 part of hydroxyethyl cellulose thickener, 1 part of silicon carbide anti-wear agent, cellulose acetate butyrate 1 part of plain leveling agent, 2 parts of defoamer;

[0085] Wooden sound-absorbing panel coating, the production process includes the following steps:

[0086] (1) Add formula quantity water, 3-iodo-2-propynyl butyl carbamate, flame retardant, thickener, wear-resistant agent, leveling agent, 1 / 2 Defoamer, stir evenly at 300 rpm, stir for 15 minutes to form a colloidal solution;

[0087] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 mic...

Embodiment 2

[0093] The production method of wood sound-absorbing board coating, which includes the following raw materials in parts by weight: 45 parts of polyurethane, 40 parts of epoxy resin, 10 parts of emulsion, 13 parts of glass fiber, 3 parts of composite coupling agent, 25 parts of water, expanded perlite 7 parts, 2 parts of 3-iodo-2-propynyl butyl carbamate, 2 parts of flame retardant, 2 parts of hydroxyethyl cellulose thickener, 2 parts of mineral powder anti-wear agent, cellulose acetate butyrate 2 parts of plain leveling agent, 3 parts of defoamer;

[0094] Wooden sound-absorbing panel coating, the production process includes the following steps:

[0095] (1) Add formula quantity water, 3-iodo-2-propynyl butyl carbamate, flame retardant, thickener, wear-resistant agent, leveling agent, 1 / 2 Defoamer, stir evenly, at a speed of 300 rpm, stir for 20 minutes to form a colloidal solution;

[0096] (2) Grind the solution obtained in step (1) through a sander until the particle size...

Embodiment 3

[0102]The production method of wood sound-absorbing board coating, which includes the following raw materials in parts by weight: 50 parts of polyurethane, 50 parts of epoxy resin, 15 parts of emulsion, 17 parts of glass fiber, 4 parts of composite coupling agent, 25 parts of water, expanded perlite 9 parts, 2 parts of 3-iodo-2-propynyl butyl carbamate, 3 parts of flame retardant, 3 parts of hydroxyethyl cellulose thickener, 3 parts of mineral powder anti-wear agent, cellulose acetate butyrate 3 parts of plain leveling agent, 3 parts of defoamer;

[0103] Wooden sound-absorbing panel coating, the production process includes the following steps:

[0104] (1) Add formula quantity water, 3-iodo-2-propynyl butyl carbamate, flame retardant, thickener, wear-resistant agent, leveling agent, 1 / 2 Defoamer, stir evenly at 300 rpm, stir for 25 minutes to form a colloidal solution;

[0105] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com