Universal interfacial binding agent

A technology of interfacial adhesive and mass ratio, applied in the directions of adhesives, adhesive types, polymer adhesive additives, etc., can solve problems such as the influence of self-adhesive coil bonding performance, and achieve convenient construction and short drying time. , the effect of good application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

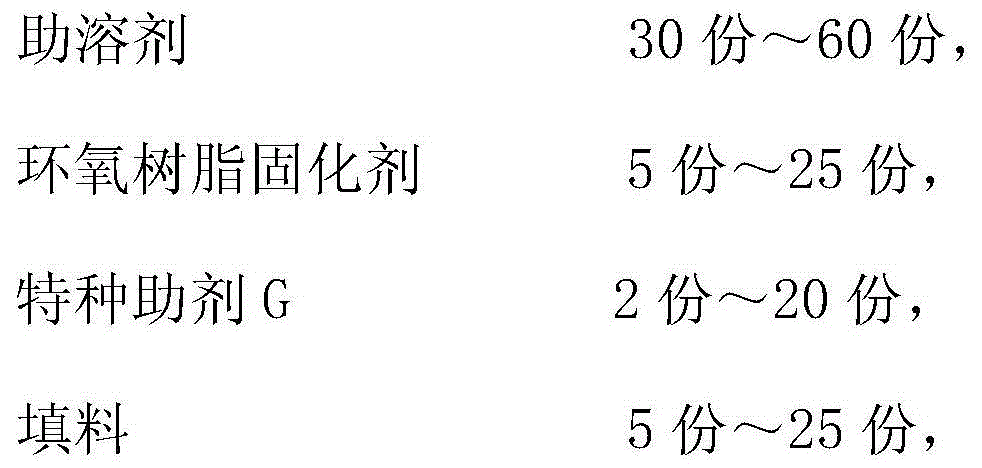

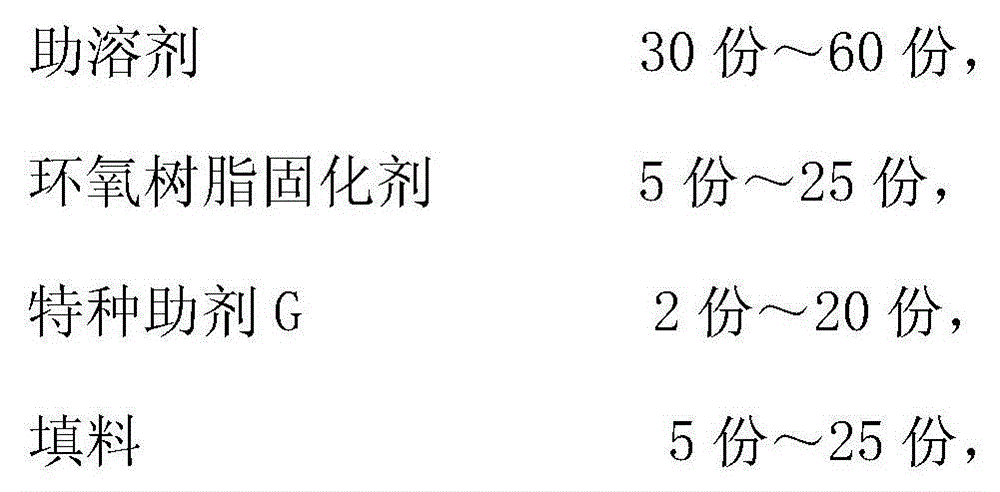

[0021] Accurately weigh 30g of epoxy-based co-solvent, 5g of diethanolamine, 2g of red iron oxide, 3g of precipitated barium sulfate and 2g of ethylene glycol glycidyl ether, add the above materials together into a stirring tank at 60°C, and stir for 1h until the system viscosity Almost uniform, then add 20g of component B to it, mix evenly and cool the resulting mixture to room temperature to obtain a universal interface adhesive.

[0022] When in use, apply the universal interface adhesive on the surface of the treated concrete, and the dosage is 0.3kg / m 2 .

[0023] At room temperature, the viscosity of the universal interface adhesive prepared in Example 1 is 200Cp, and the viscosity is still in a good flow state after an average of 180 minutes.

Embodiment 2

[0025] Accurately weigh 60g of epoxy-based co-solvent, 25g of N-methylolethanolamine, 10g of red iron oxide, 15g of mica powder and 20g of polypropylene glycol diglycidyl ether, and add the above materials together into a stirring tank at 60°C, and stir for 1 hour Until the viscosity of the system is almost uniform, then add 100g of component B to it, mix evenly and cool the resulting mixture to room temperature to obtain a universal interface adhesive.

[0026] When in use, apply the universal interface adhesive on the surface of the treated concrete, and the dosage is 0.3kg / m 2 .

[0027] At room temperature, the viscosity of the universal interface adhesive prepared in Example 2 is 220Cp, and the viscosity is still in a good flow state after an average of 180 minutes.

Embodiment 3

[0029] Accurately weigh 50g of epoxy-based co-solvent, 5g of N-propenyl ethanolamine, 5g of precipitated barium sulfate, 10g of hollow microspheres and 20g of ethylene glycol glycidyl ether, and add the above materials together into a stirring tank at 60°C, and stir for 1h Until the viscosity of the system is almost uniform, then add 16g of component B to it, mix evenly and cool the resulting mixture to room temperature to obtain a universal interface adhesive.

[0030] When in use, apply the universal interface adhesive on the surface of the treated concrete, and the dosage is 0.3kg / m 2 .

[0031] What is the viscosity of the universal interface adhesive prepared in Example 3 at room temperature? 215Cp, the viscosity is still in a good flow state after an average of 180 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com