A kind of oil-based fireproof coating added calcium sulfate whisker and preparation method thereof

A technology of calcium sulfate whiskers and fire-resistant coatings, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor water solubility and aging resistance, affecting material properties, poor thermal stability, etc., and achieve strong adhesion. , Simple operation and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

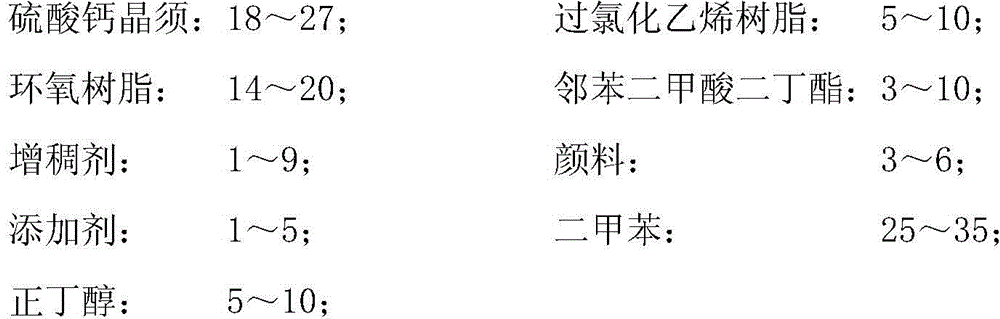

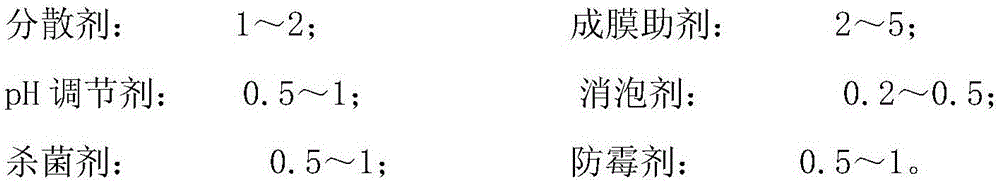

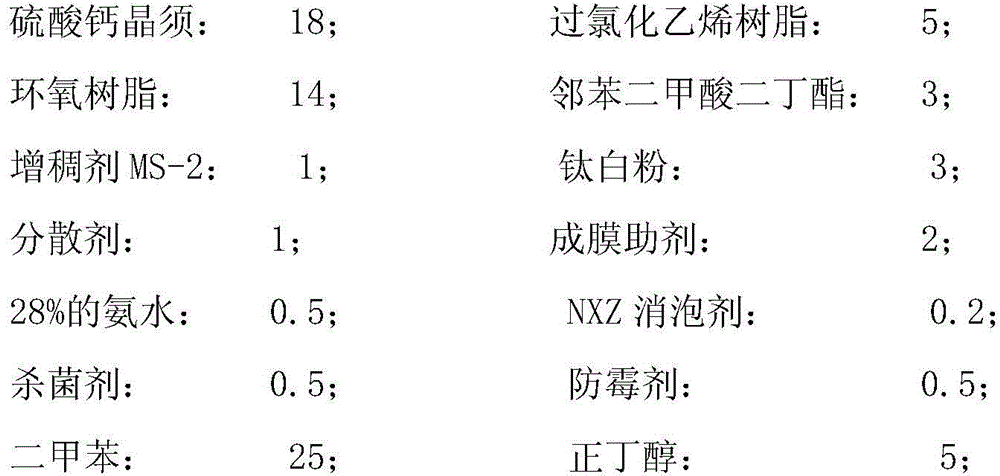

[0025] Embodiment 1: a kind of oily fireproof coating that adds calcium sulfate whisker, it is made up of the raw material of following weight portion:

[0026]

[0027] The above-mentioned preparation method of adding the oily fireproof coating of calcium sulfate whisker, it may further comprise the steps:

[0028] S1. Weighing: Weigh each raw material according to the above ratio, the average length-to-diameter ratio of calcium sulfate whiskers is 50-80, and the diameter is 1-4 μm, and set aside;

[0029] S2. Modification: an aqueous ethanol solution prepared with anhydrous ethanol and deionized water at a volume ratio of 3:1, adding aluminate coupling agent, aluminate coupling agent and calcium sulfate crystals to the ethanol solution The weight ratio of the whiskers is 1:20, stir at 800r / min, add calcium sulfate whiskers, adjust the pH of the solution system to 4 with glacial acetic acid, stir at 2300r / min for 1 hour, and then vacuum dry to obtain modified sulfuric acid...

Embodiment 2

[0031] Embodiment 2: a kind of oily fireproof coating that adds calcium sulfate whisker, it is made up of the raw material of following weight portion:

[0032]

[0033]

[0034] The above-mentioned preparation method of adding the oily fireproof coating of calcium sulfate whisker, it may further comprise the steps:

[0035] S1. Weighing: Weigh each raw material according to the above ratio, the average length-to-diameter ratio of calcium sulfate whiskers is 50-80, and the diameter is 1-4 μm, and set aside;

[0036] S2. Modification: an aqueous ethanol solution prepared with anhydrous ethanol and deionized water at a volume ratio of 3:1, adding aluminate coupling agent, aluminate coupling agent and calcium sulfate crystals to the ethanol solution The weight ratio of the whiskers is 1:30, stir at 1000r / min, add calcium sulfate whiskers, adjust the pH value of the solution system to 5 with glacial acetic acid, stir at 2700r / min for 1 hour, and then vacuum dry to obtain mod...

Embodiment 3

[0038] Embodiment 3: a kind of oily fireproof coating that adds calcium sulfate whisker, it is made up of the raw material of following weight portion:

[0039]

[0040] The above-mentioned preparation method of adding the oily fireproof coating of calcium sulfate whisker, it may further comprise the steps:

[0041] S1. Weighing: Weigh each raw material according to the above ratio, the average length-to-diameter ratio of calcium sulfate whiskers is 50-80, and the diameter is 1-4 μm, and set aside;

[0042] S2. Modification: an aqueous ethanol solution prepared with anhydrous ethanol and deionized water at a volume ratio of 3:1, adding aluminate coupling agent, aluminate coupling agent and calcium sulfate crystals to the ethanol solution The weight ratio of the whiskers is 1:22, stir at a speed of 900r / min, add calcium sulfate whiskers, adjust the pH of the solution system to 4.5 with glacial acetic acid, stir at a speed of 2500r / min for 1 hour, and then vacuum dry to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com