Building coating containing inorganic montmorillonite and production method

A technology of architectural coatings and production methods, applied in the direction of fire-resistant coatings, etc., can solve the problems of fragility, poor air permeability of the coating film, pollution of the environment, etc., and achieve the effect of good stability and superior hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

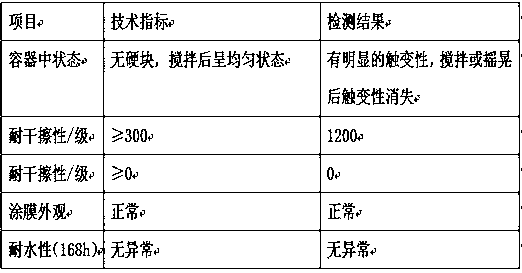

Examples

Embodiment 1

[0070] A kind of production method that contains inorganic montmorillonite architectural paint, it comprises the raw material of following parts by weight: polyurethane 40 parts, emulsion 5 parts, flax fiber 15 parts, inorganic montmorillonite 5 parts, diatom ooze 5 parts, water 20 parts 1 part, 2 parts of composite coupling agent, 1 part of methyl chloroisothiazolinone preservative, 1 part of leveling agent, 2 parts of defoamer,

[0071] The production process of inorganic montmorillonite-containing architectural coatings comprises the following steps:

[0072] (1) Add the formula amount of water, inorganic montmorillonite, diatom ooze, preservative, leveling agent, 1 / 2 defoamer to the mixer in turn, stir evenly, at a speed of 300 rpm, stir for 15 Minutes to form a colloidal solution;

[0073] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0074] (3) Mix flax fiber a...

Embodiment 2

[0085] A method for producing architectural coatings containing inorganic montmorillonite, which comprises the following raw materials in parts by weight: 45 parts of polyurethane, 7 parts of emulsion, 17 parts of flax fiber, 7 parts of inorganic montmorillonite, 7 parts of diatom mud, and 20 parts of water 3 parts, 3 parts of composite coupling agent, 2 parts of methylisothiazolinone preservative, 2 parts of leveling agent, 3 parts of defoamer,

[0086] The production process of inorganic montmorillonite-containing architectural coatings comprises the following steps:

[0087] (1) Add the formula amount of water, inorganic montmorillonite, diatom ooze, preservative, leveling agent, 1 / 2 defoamer to the mixer in turn, stir evenly, at a speed of 300 rpm, stir for 17 Minutes to form a colloidal solution;

[0088] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0089] (3) ...

Embodiment 3

[0100] A method for producing architectural coatings containing inorganic montmorillonite, which comprises the following raw materials in parts by weight: 50 parts of polyurethane, 10 parts of emulsion, 19 parts of flax fiber, 8 parts of inorganic montmorillonite, 8 parts of diatom mud, and 25 parts of water Parts, 4 parts of the composite coupling agent, 1,2 Benzoisothiazoline. 3 parts of 3-ketone preservative, 3 parts of leveling agent, 3 parts of defoamer,

[0101] The production process of inorganic montmorillonite-containing architectural coatings comprises the following steps:

[0102] (1) Add the formula amount of water, inorganic montmorillonite, diatom ooze, preservative, leveling agent, 1 / 2 defoamer to the mixer in turn, stir evenly, at a speed of 300 rpm, stir for 20 Minutes to form a colloidal solution;

[0103] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com