Patents

Literature

46results about How to "Sufficient elongation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

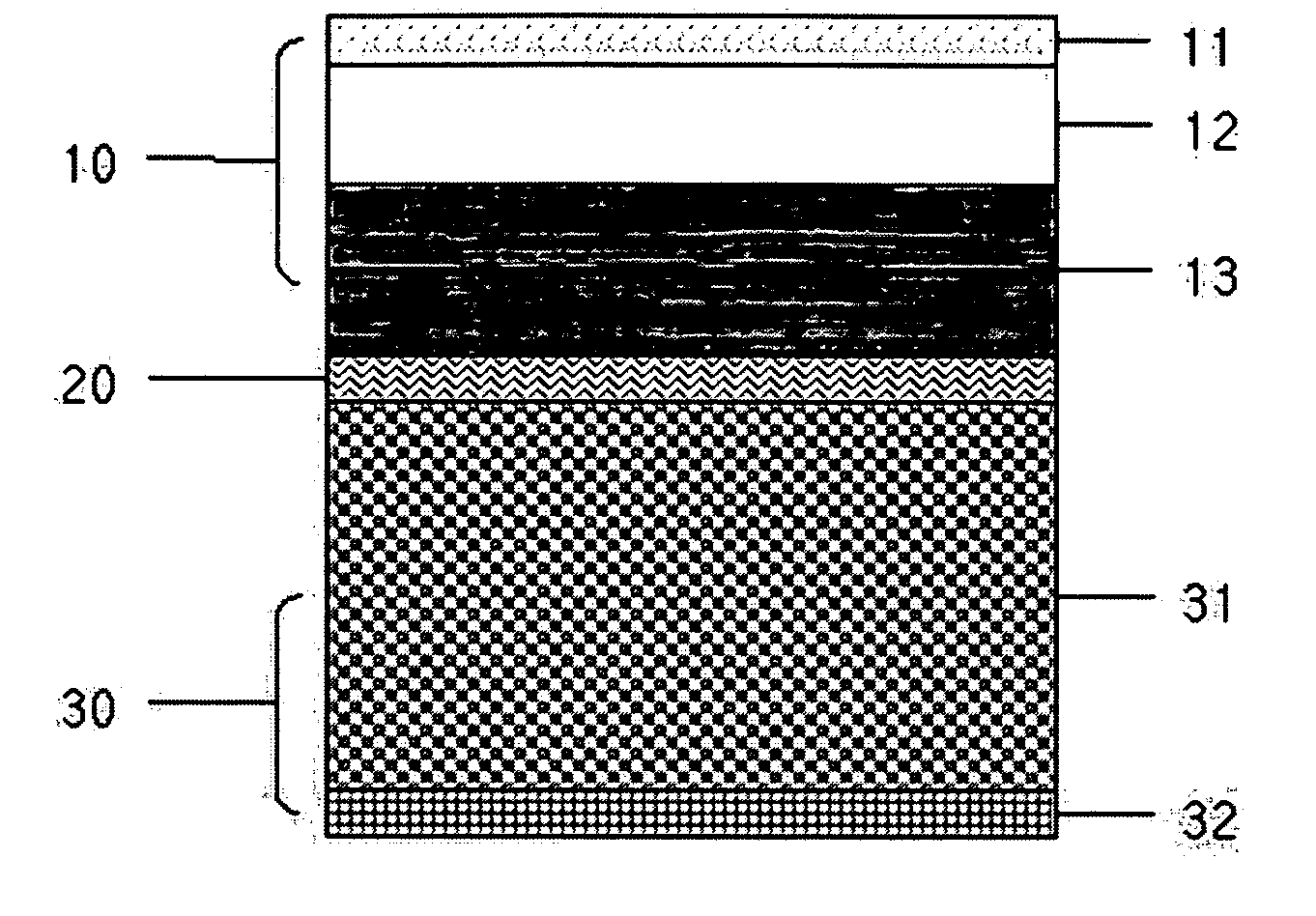

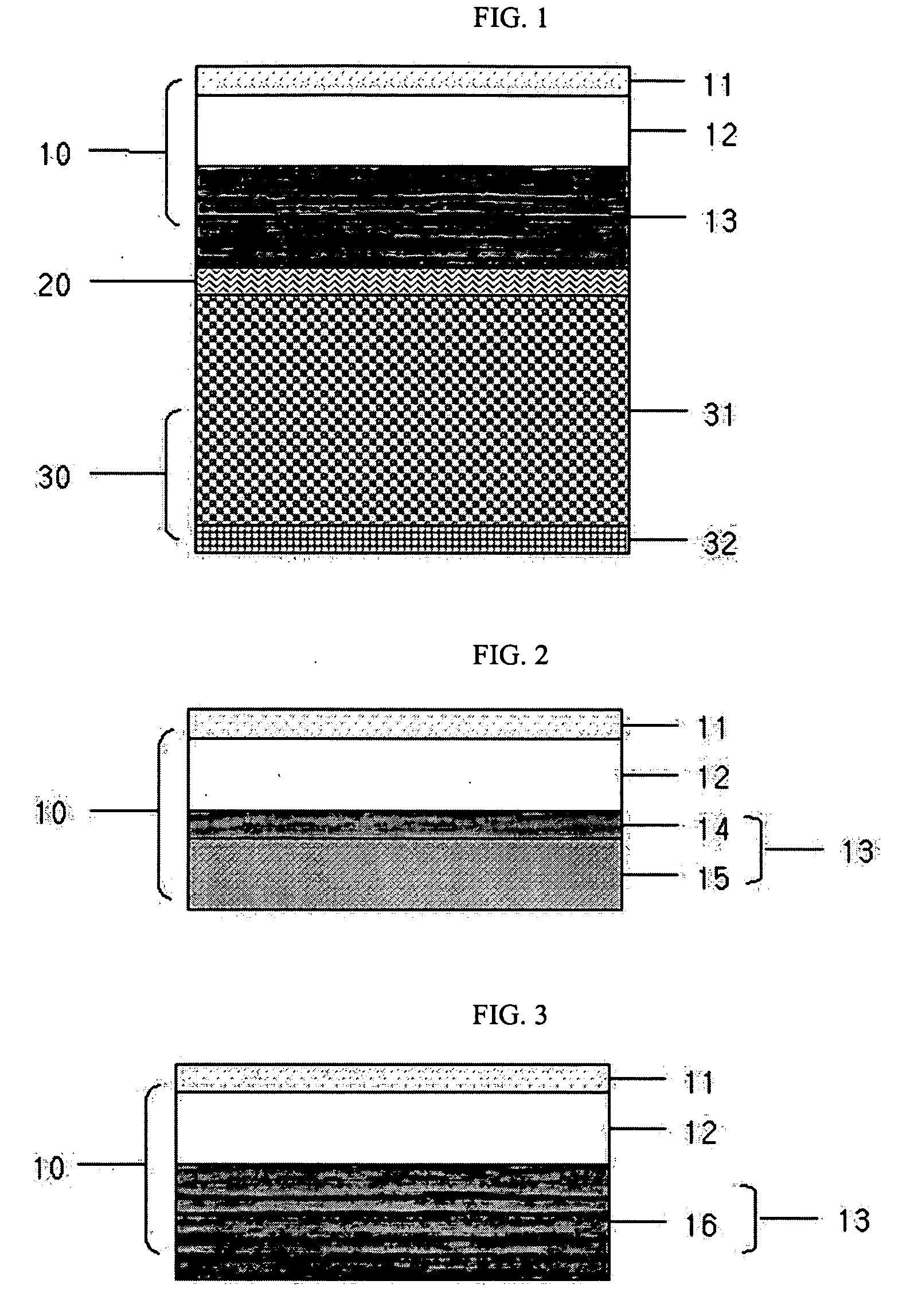

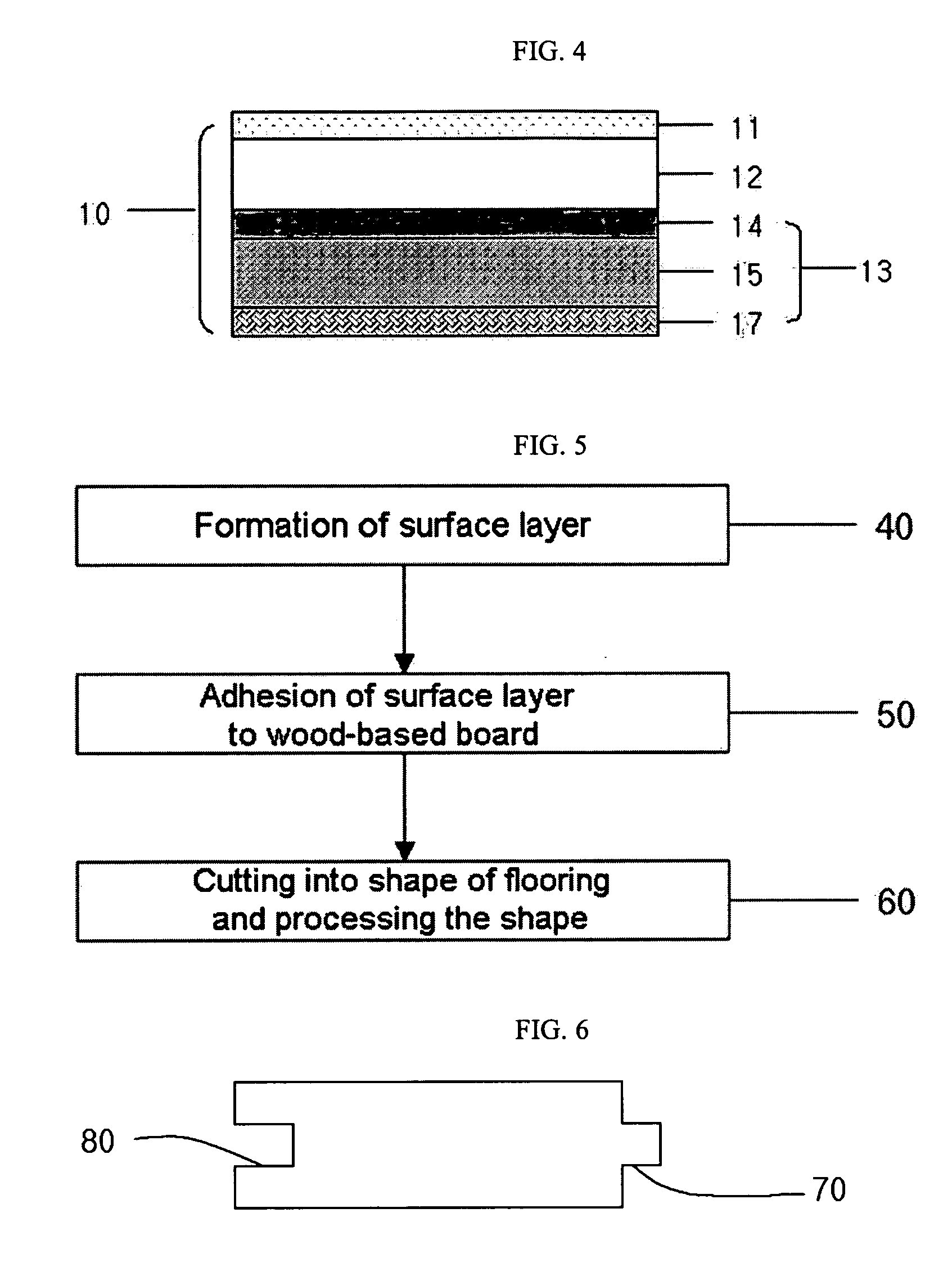

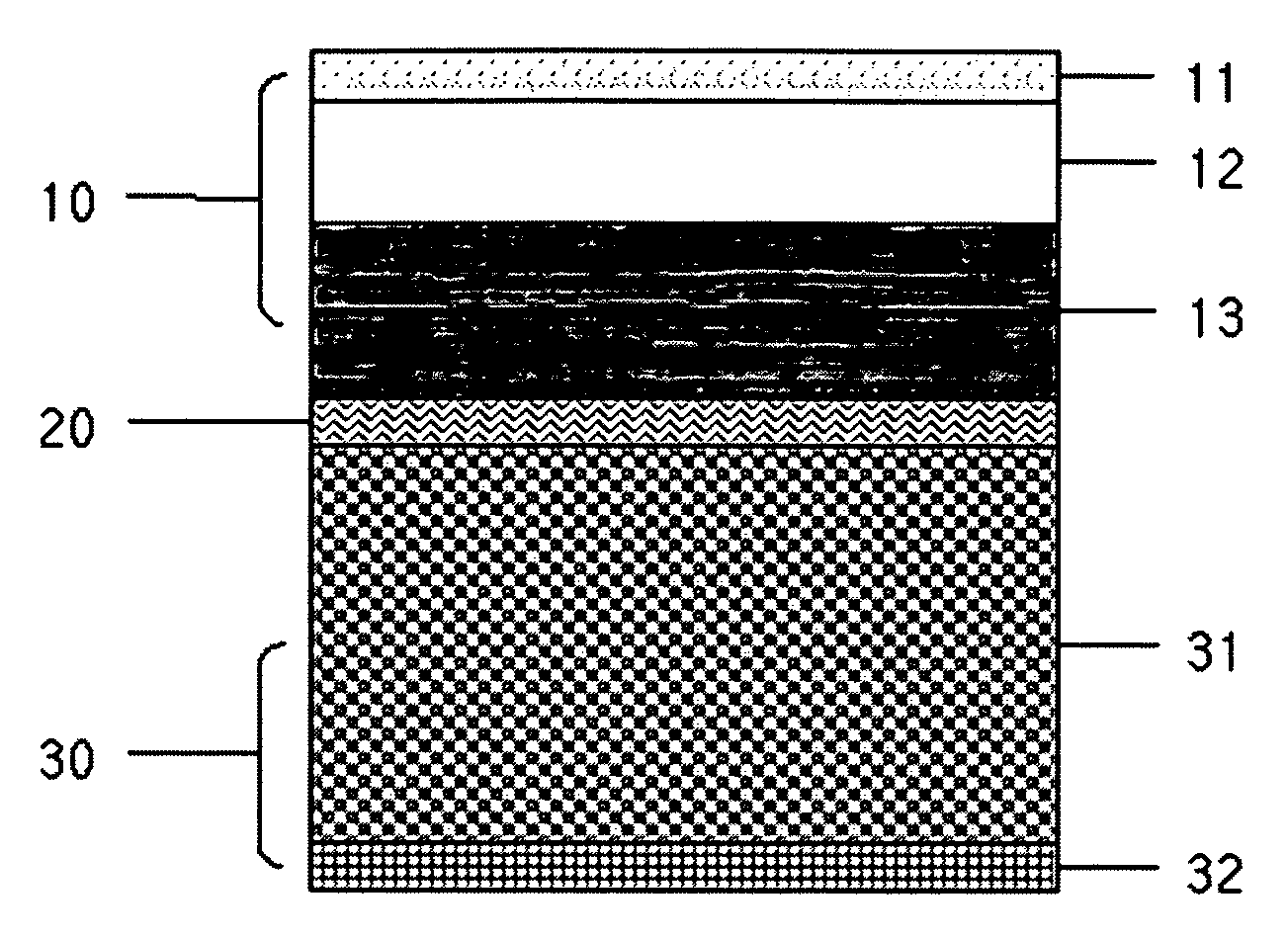

Flooring having surface layer of synthetic resin and wood-based board

InactiveUS20050281986A1Improve surface physical propertiesProtect the surfaceCovering/liningsSynthetic resin layered productsDigital printingTongue and groove

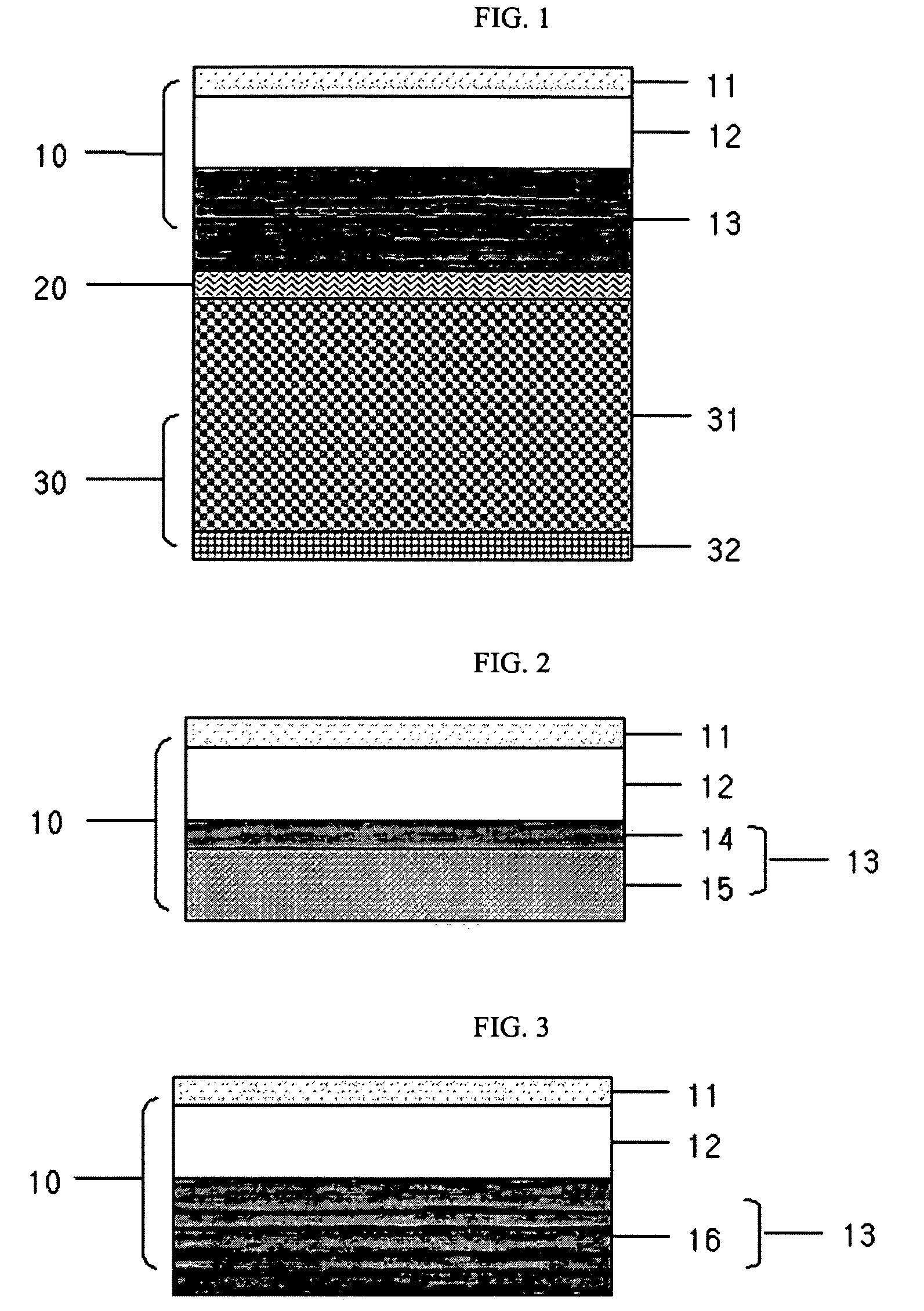

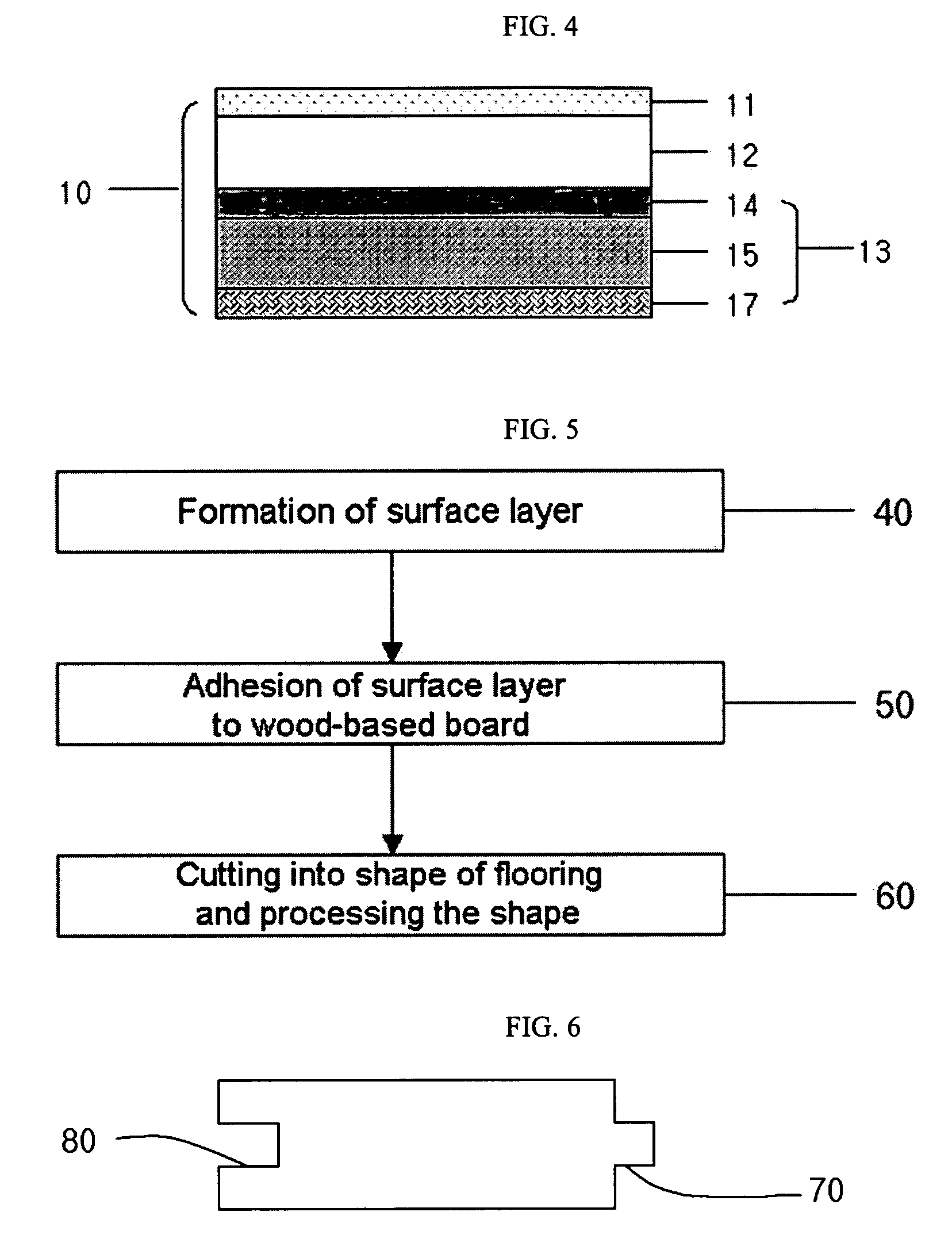

Disclosed herein is a flooring comprising a surface layer made of a synthetic resin, and a wood-based board as a base. Preferably, the surface layer includes a printed layer formed by general gravure, transfer, heat-sublimation, silk screen or digital printing using a printer, a protective made of a synthetic resin, and a UV-curable or heat-curable surface treatment layer. The wood-based board is selected from plywood, medium-density fiberboard (MDF), high-density fiberboard (HDF), particle board, and resin-wood flour composite board. The flooring may further comprise a bottom layer laminated under the wood-based board for protecting the flooring against moisture from the bottom. The flooring is cut into pieces having an appropriate size, and the pieces are processed into a finished product in a tongue and groove (T & G) shape.

Owner:LG CHEM LTD

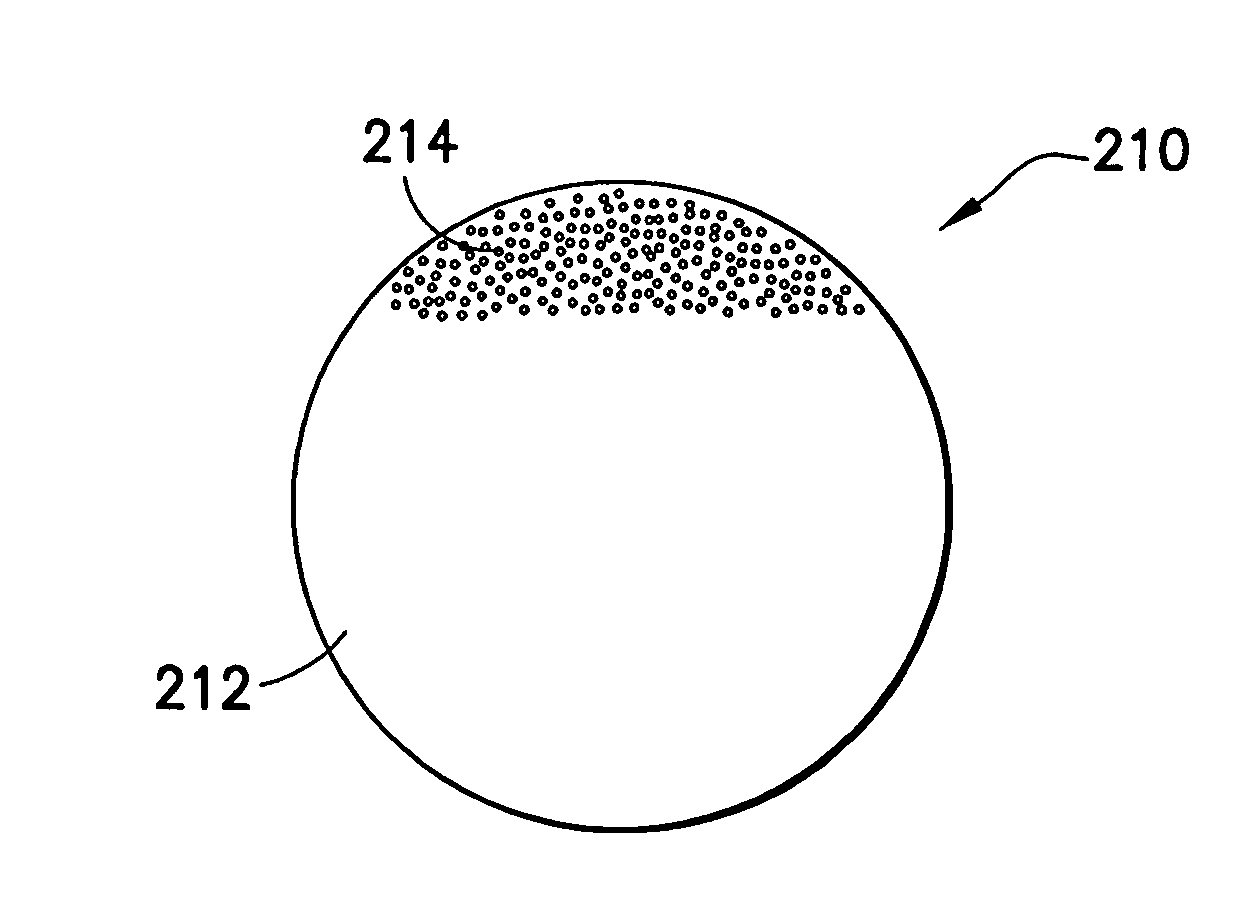

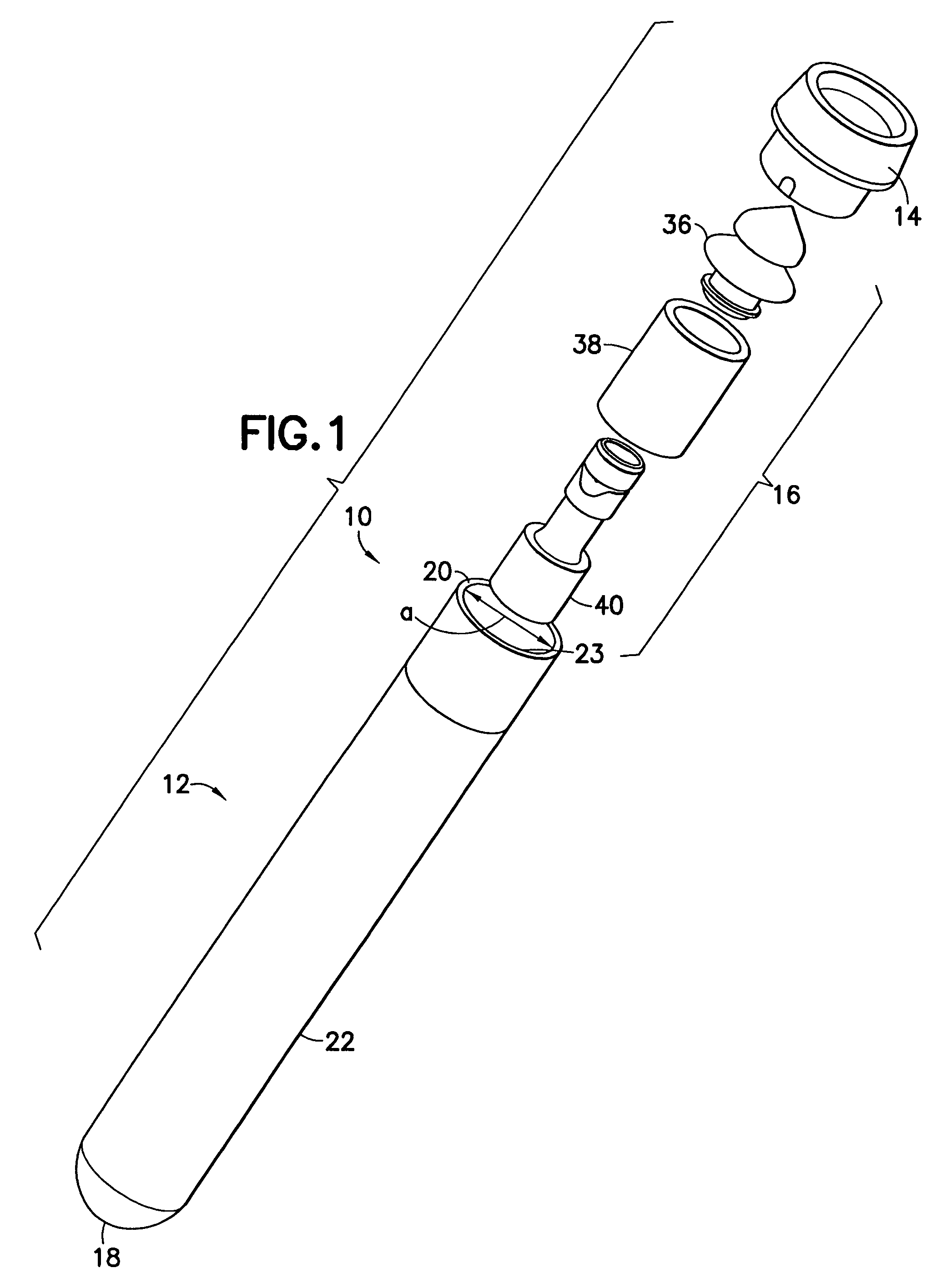

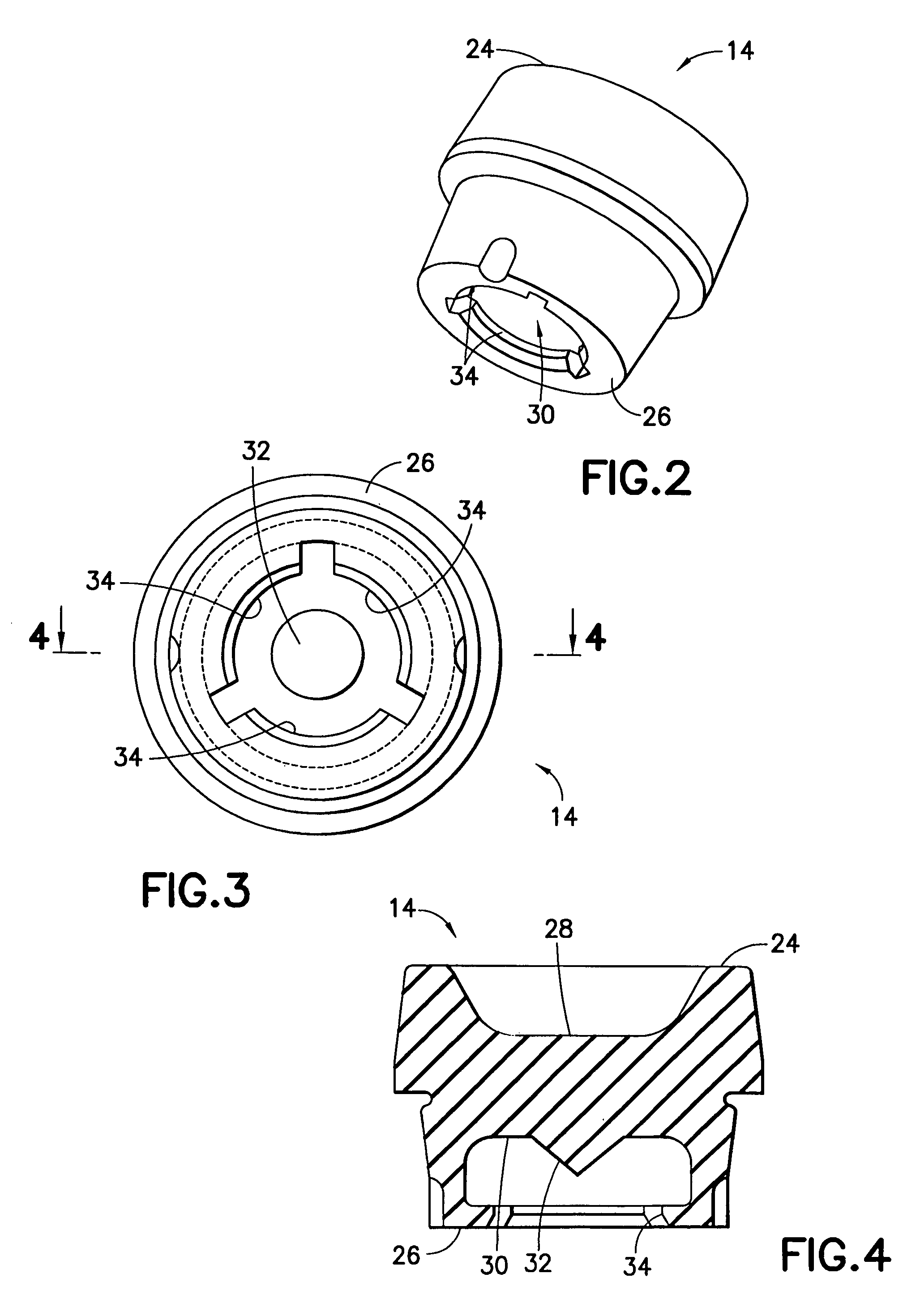

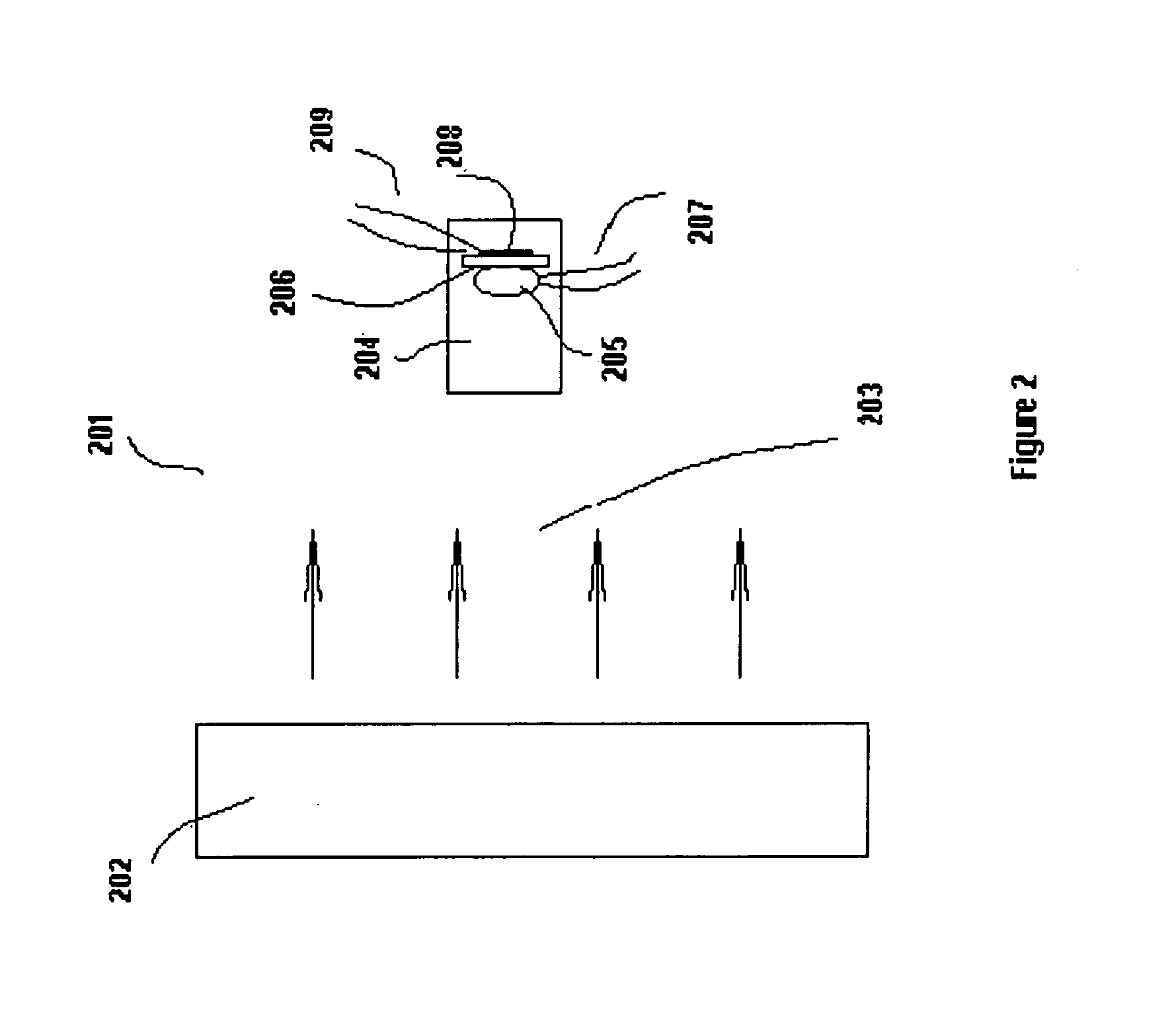

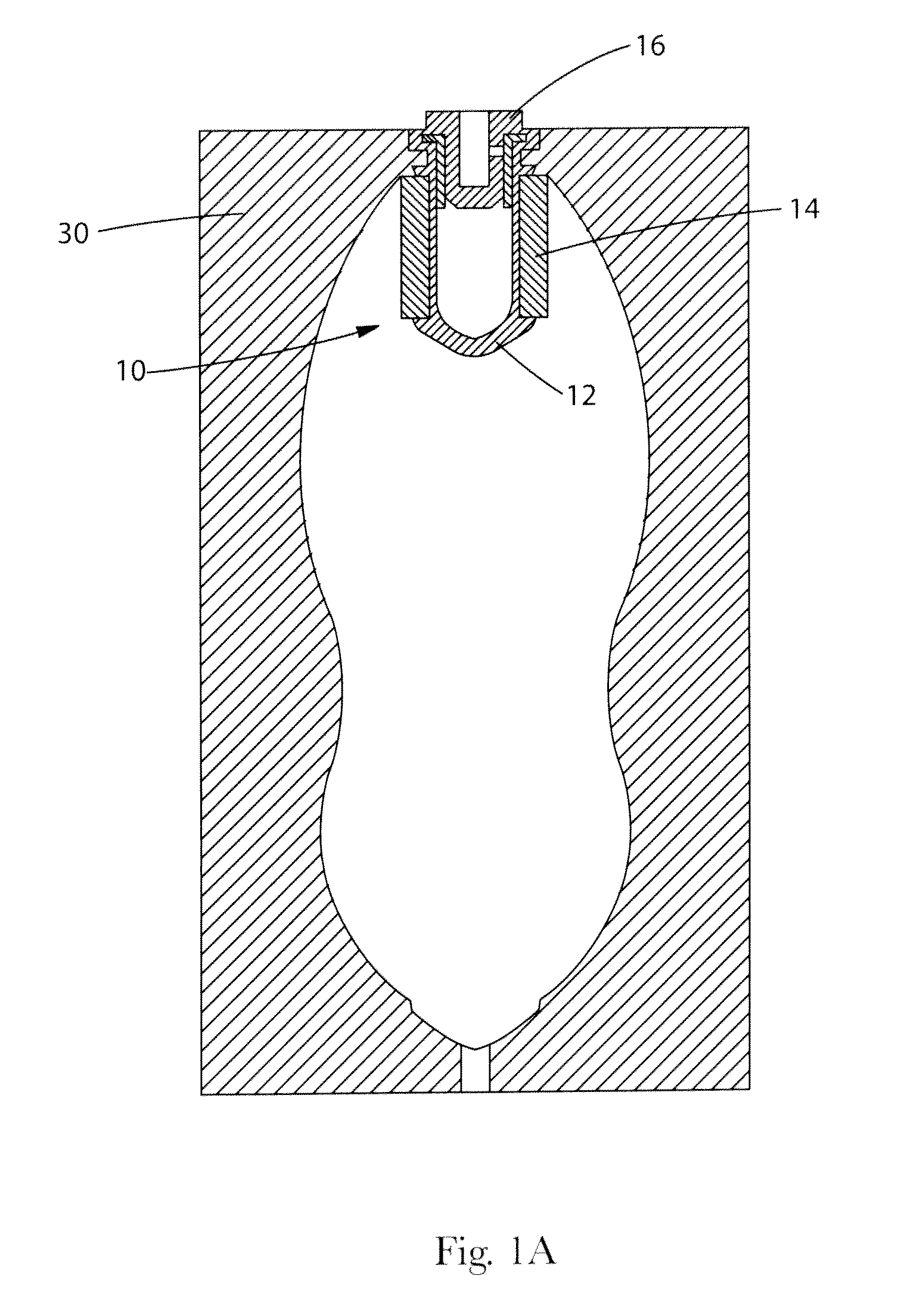

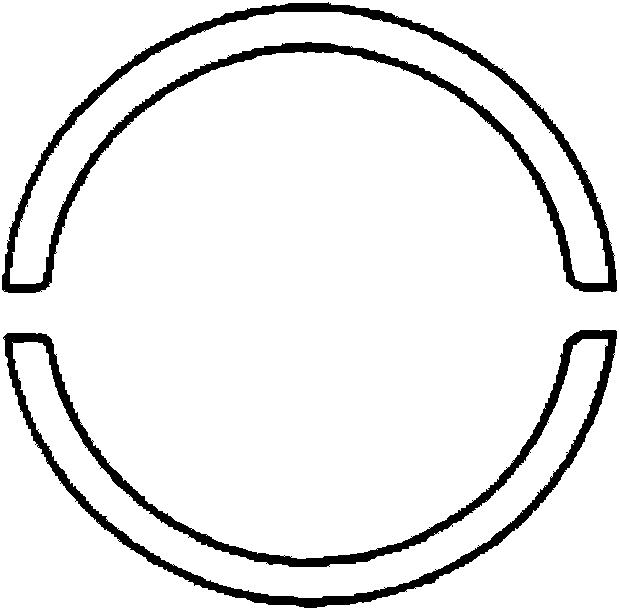

Device for separating components of a fluid sample

ActiveUS7947236B2Reduce overall outer diameterSmall overall deformationAnalysis using chemical indicatorsDispersed particle separationCentrifugationVolumetric Mass Density

A device for separating heavier and lighter fractions of a fluid sample is provided, the device including a container and a unitary separator located therein, the separator having an overall density between the heavier and light fractions. The separator is capable of moving between the fractions upon centrifugation, and sealing the fractions from one another when centrifugation ends.

Owner:BECTON DICKINSON & CO

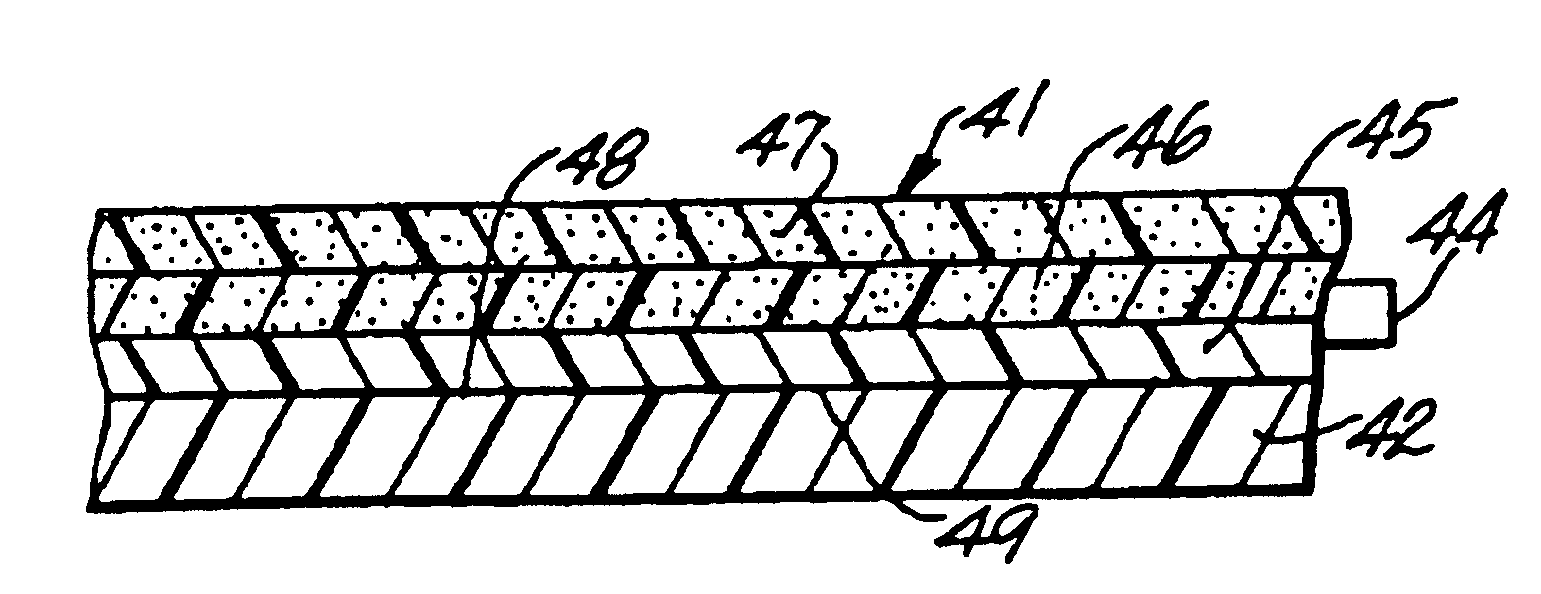

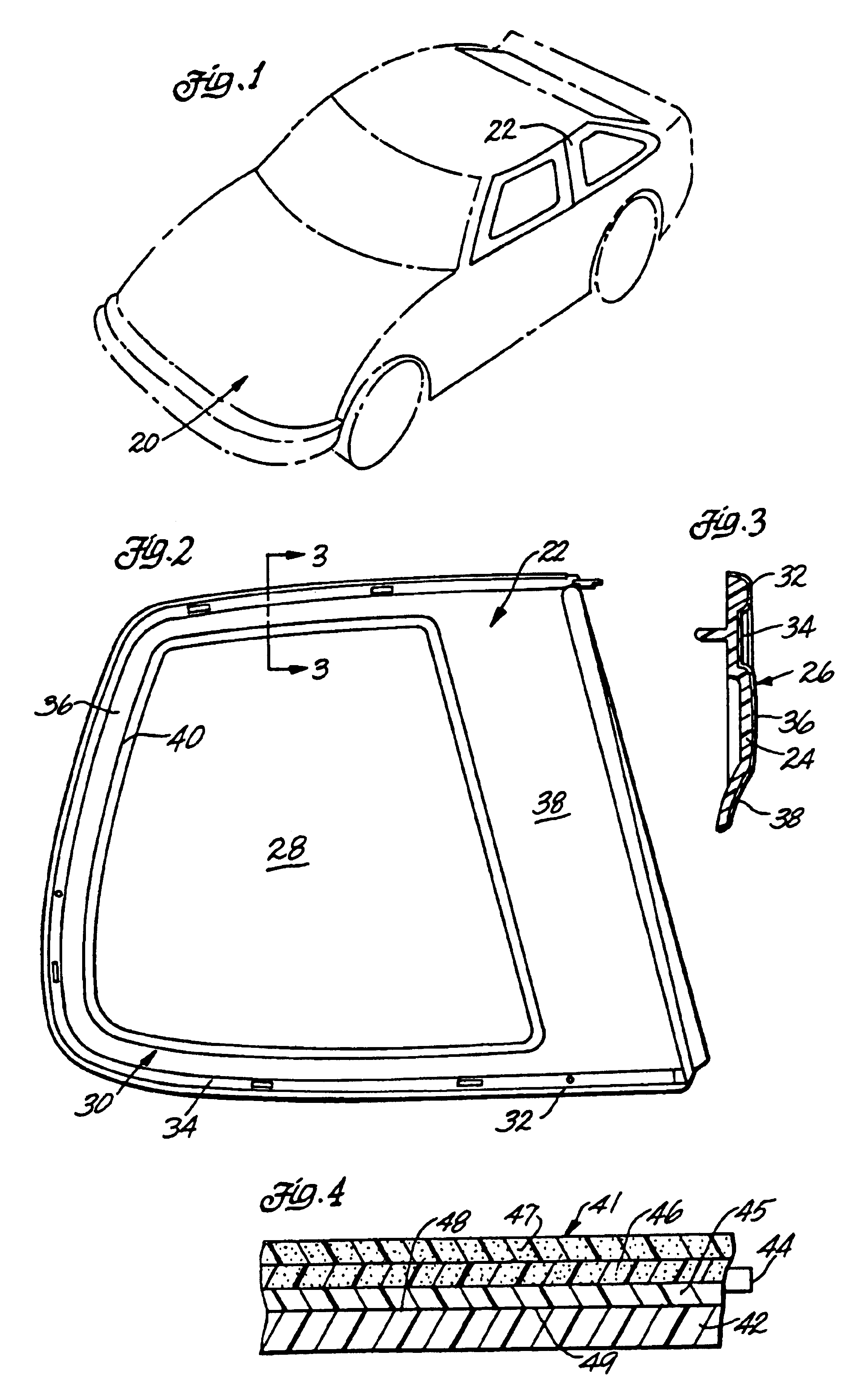

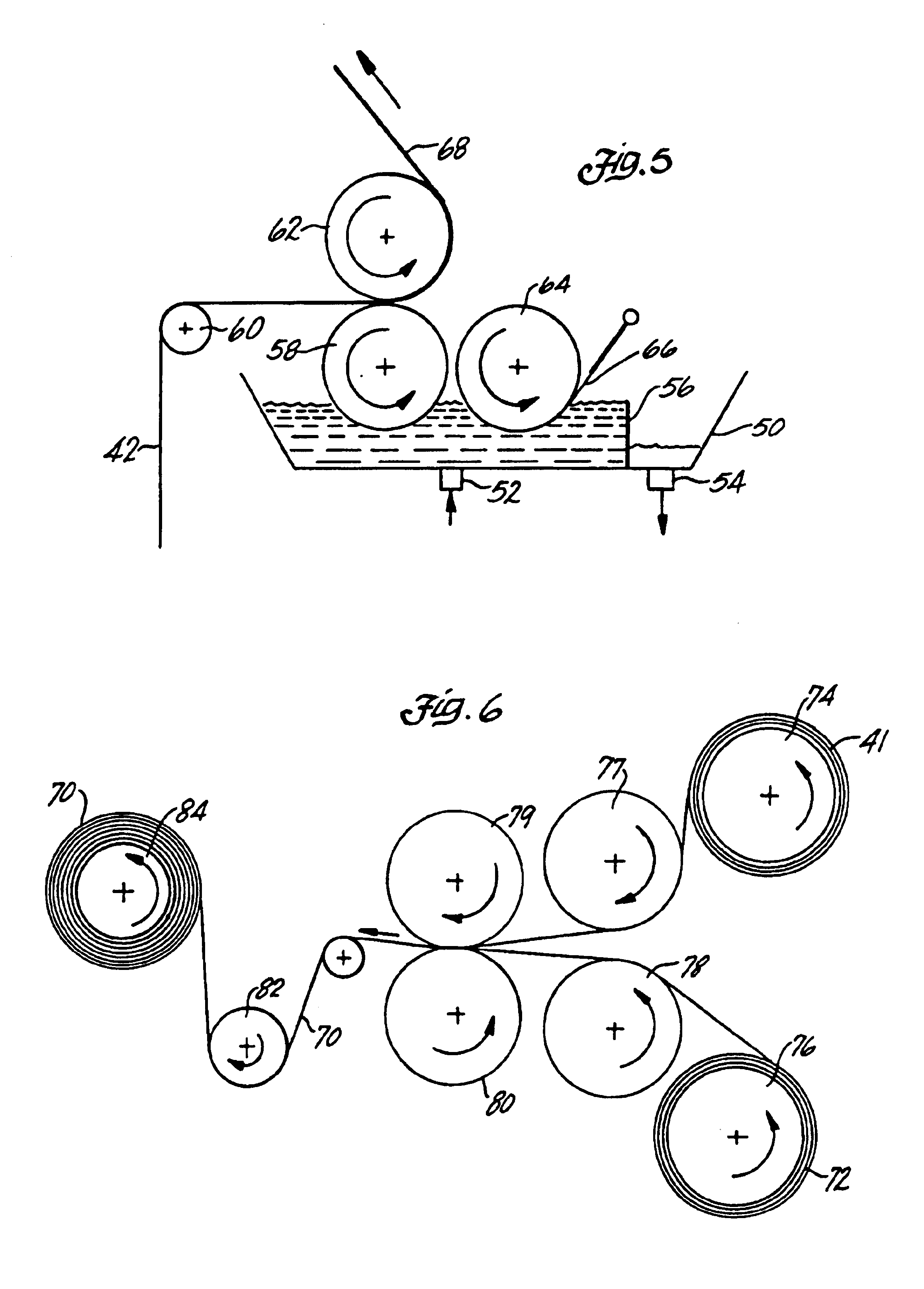

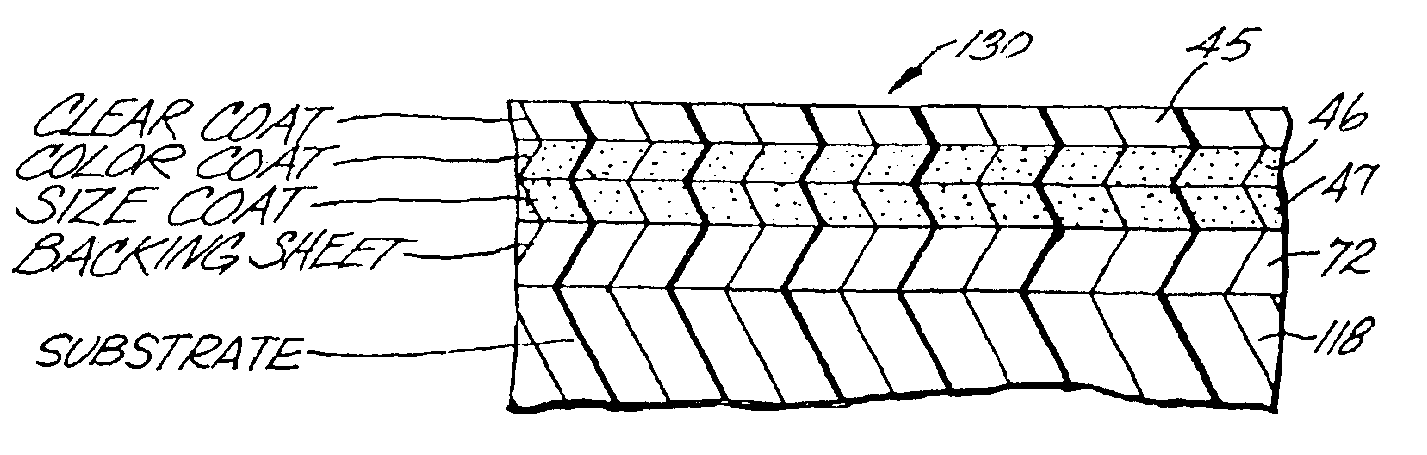

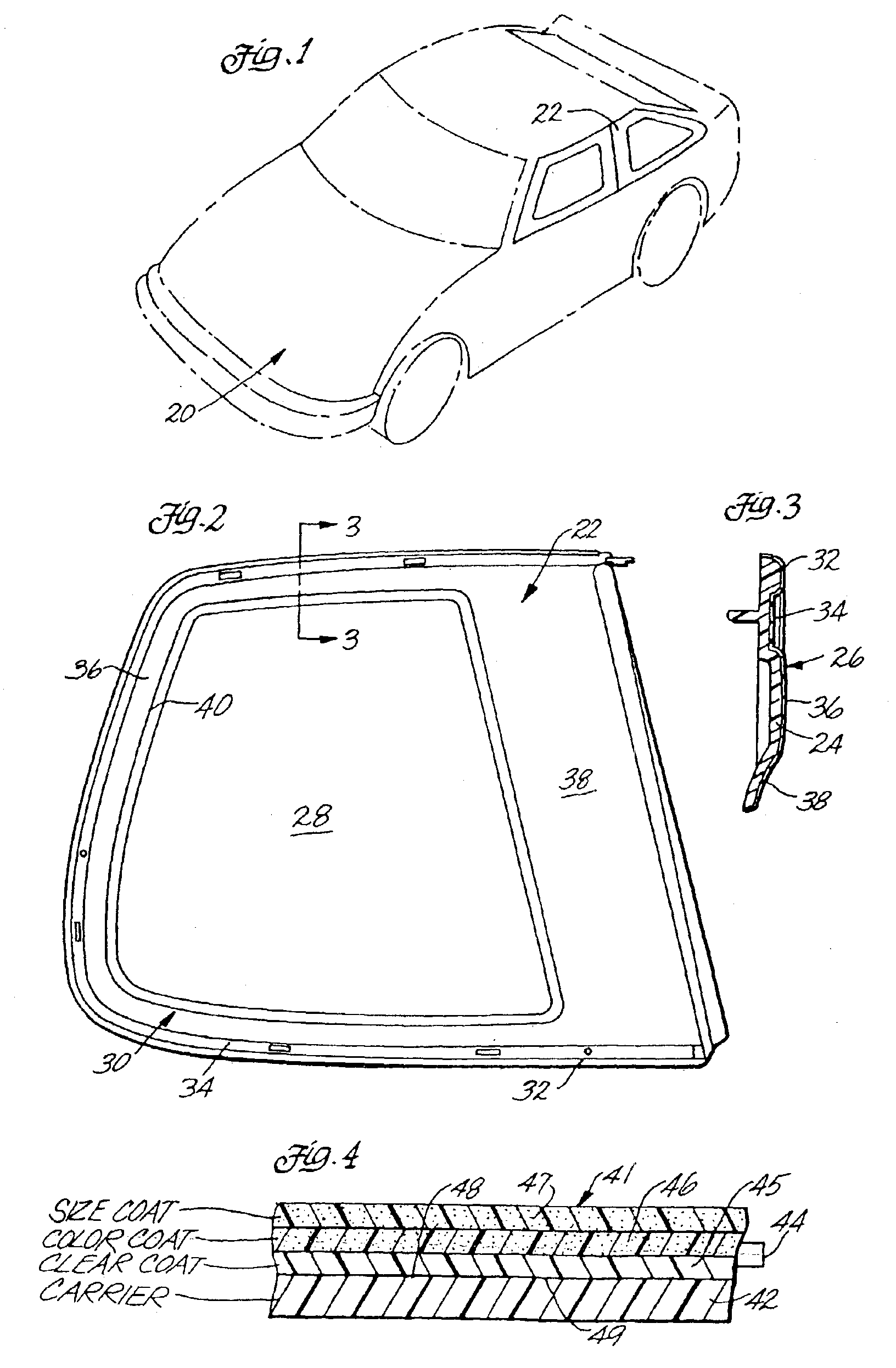

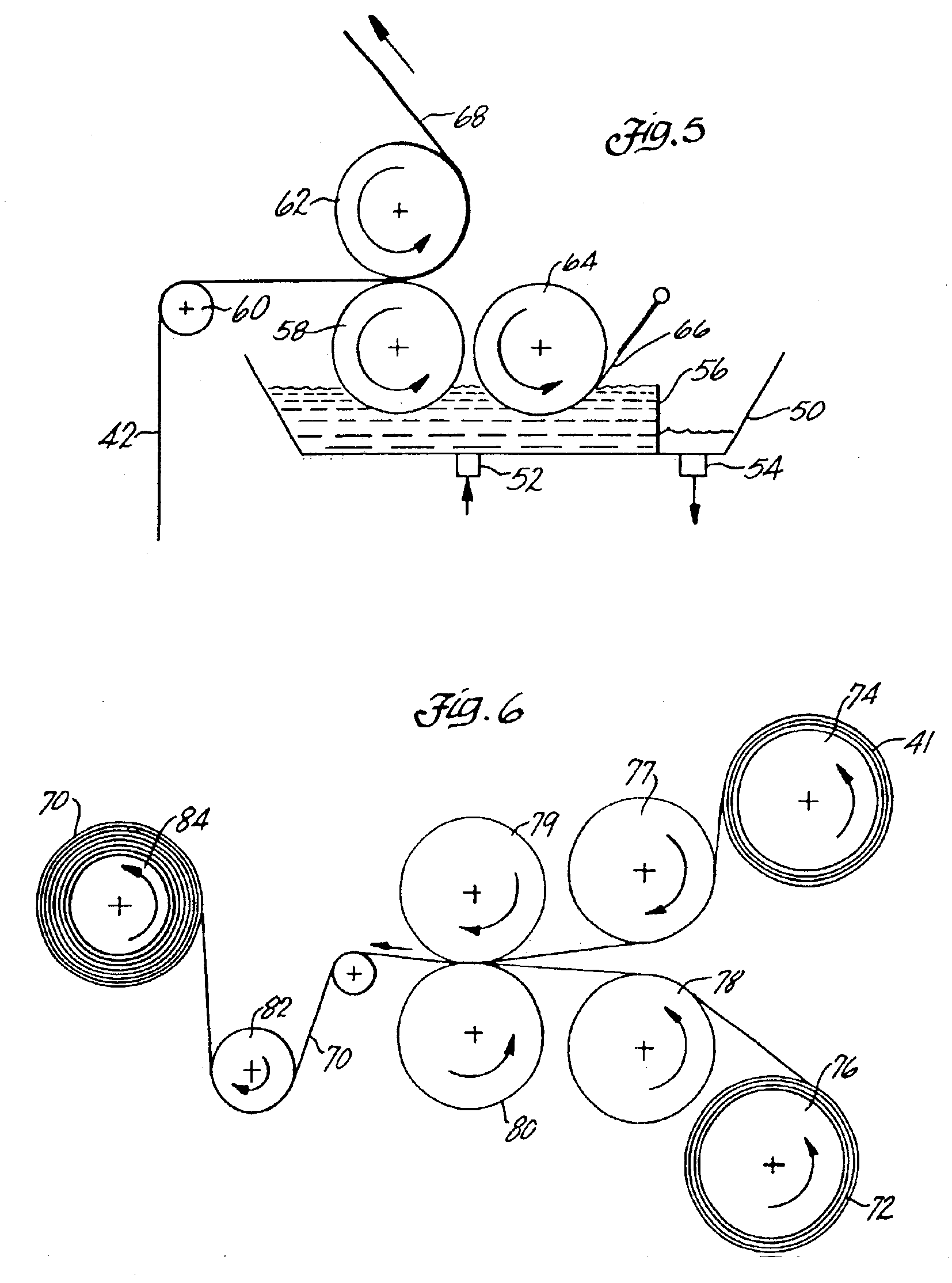

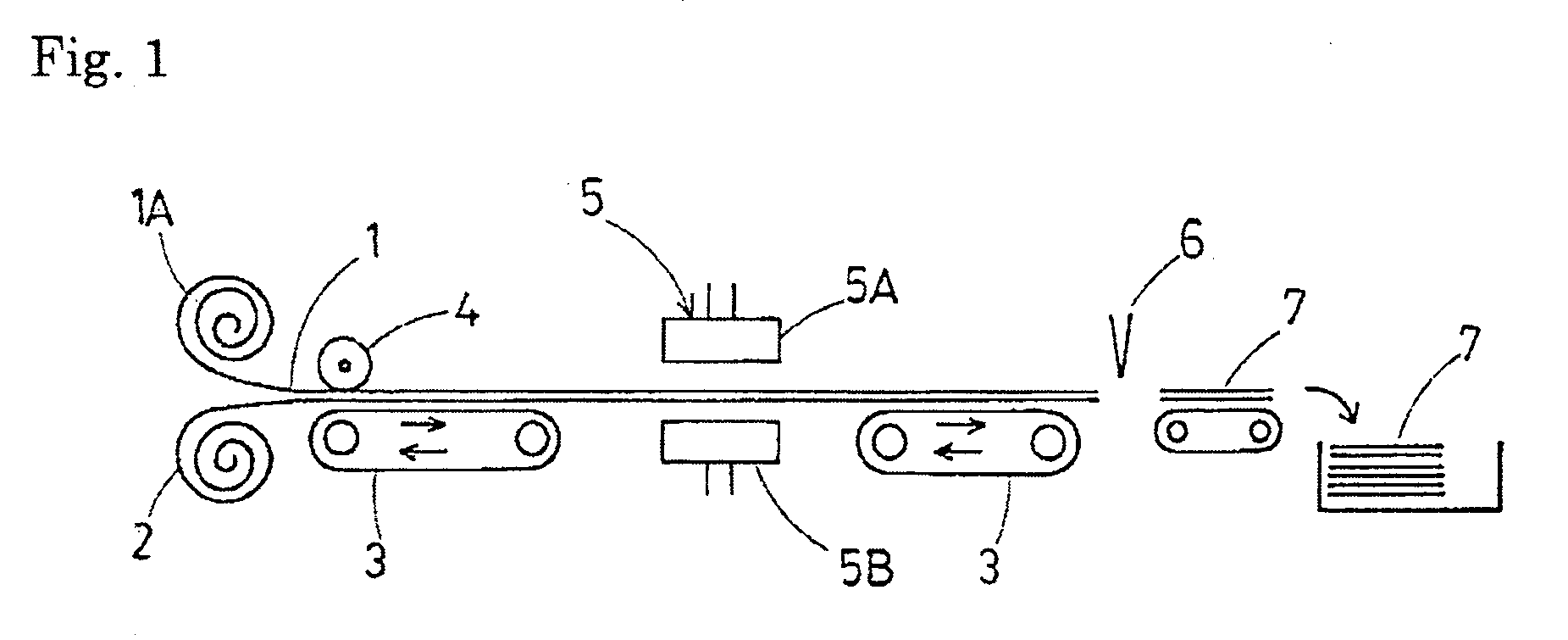

Dry paint transfer process and product

InactiveUS6838130B1Sufficient level of resistanceSufficient elongationLiquid surface applicatorsElectrical controlShell moldingLacquer

An automotive quality paint coat (44) is laminated to the exterior surface of a molded plastic car body member or panel (118). In one embodiment, the paint coat (44) includes an exterior clear coat (45) above a color coat (46). During processing, the clear coat (45) and color coat (46) are each coated on a temporary flexible casting sheet (42) and dried. A high gloss surface is transferred to the clear coat (45) from the casting sheet (42). The paint coat (44) is then transferred from the casting sheet (42) to a thin, semi-flexible thermoformable plastic backing sheet (72) by dry paint transfer-laminating techniques. The resulting laminate (70) is thermoformed into a complex three-dimensional shape of the car body member or panel. The preformed laminate (116) is then bonded to an underlying plastic substrate material, by injection-cladding techniques, for example, to form the finished article. The paint coat (44) has sufficient elongation to retain exterior automotive appearance and durability properties during thermoforming without deglossing. The backing sheet (72) absorbs defects in the substrate material so the paint coat retains its appearance and durability properties during the injection-cladding step. The finished article comprises a high gloss, defect-free paint coat on the exterior of a molded plastic car body member or panel. Solution-form polyvinylidene fluoride / acrylic paint systems have remarkably high combined gloss and distinctiveness-of-image levels, together with durability properties required for exterior automotive use.

Owner:CCL LABEL INC

Dry paint transfer-lamination process for making high DOI automotive body panels

InactiveUS6966962B2Sufficient level of resistanceSufficient elongationLiquid surface applicatorsElectrical controlShell moldingLacquer

Owner:CCL LABEL INC

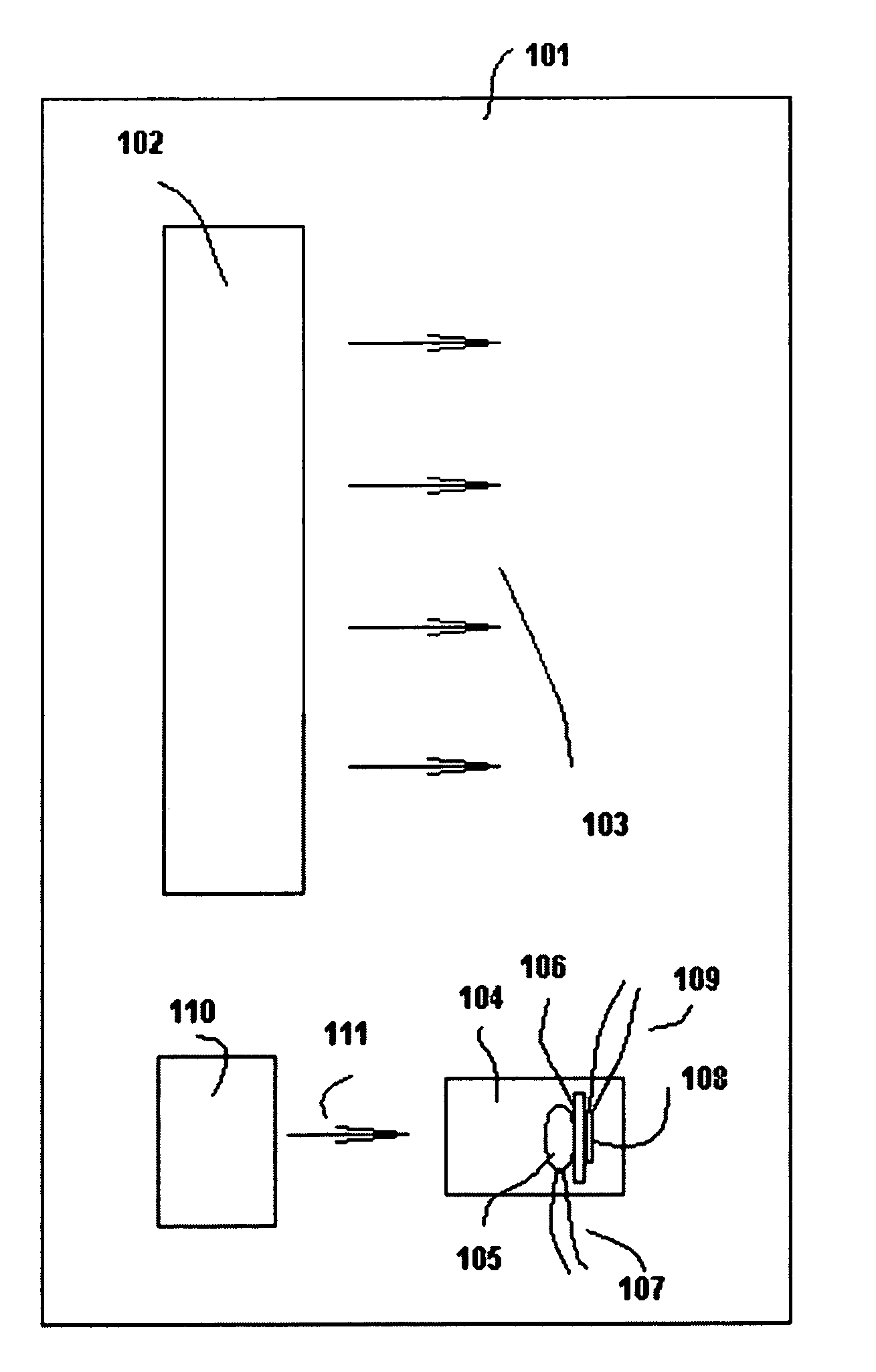

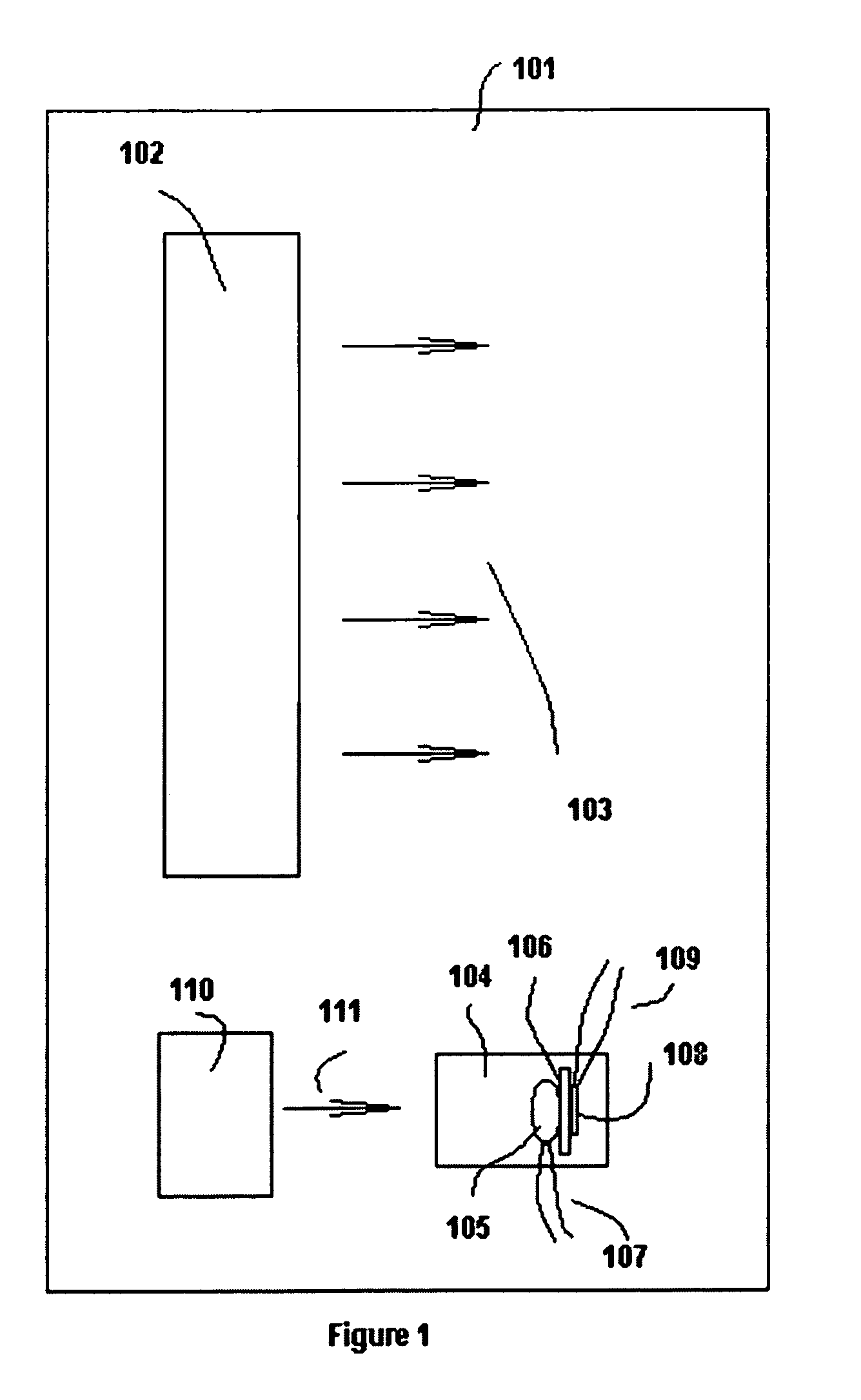

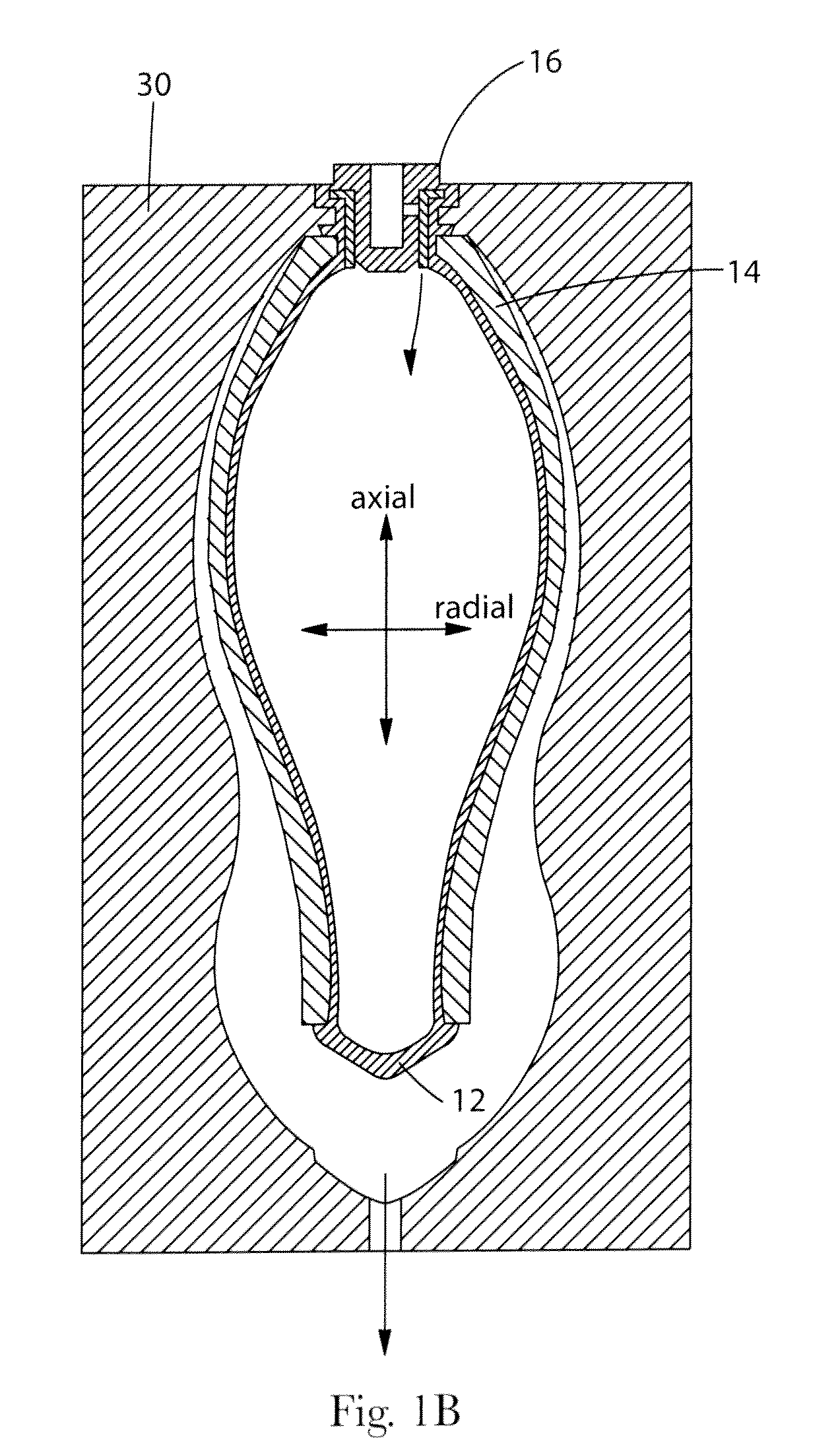

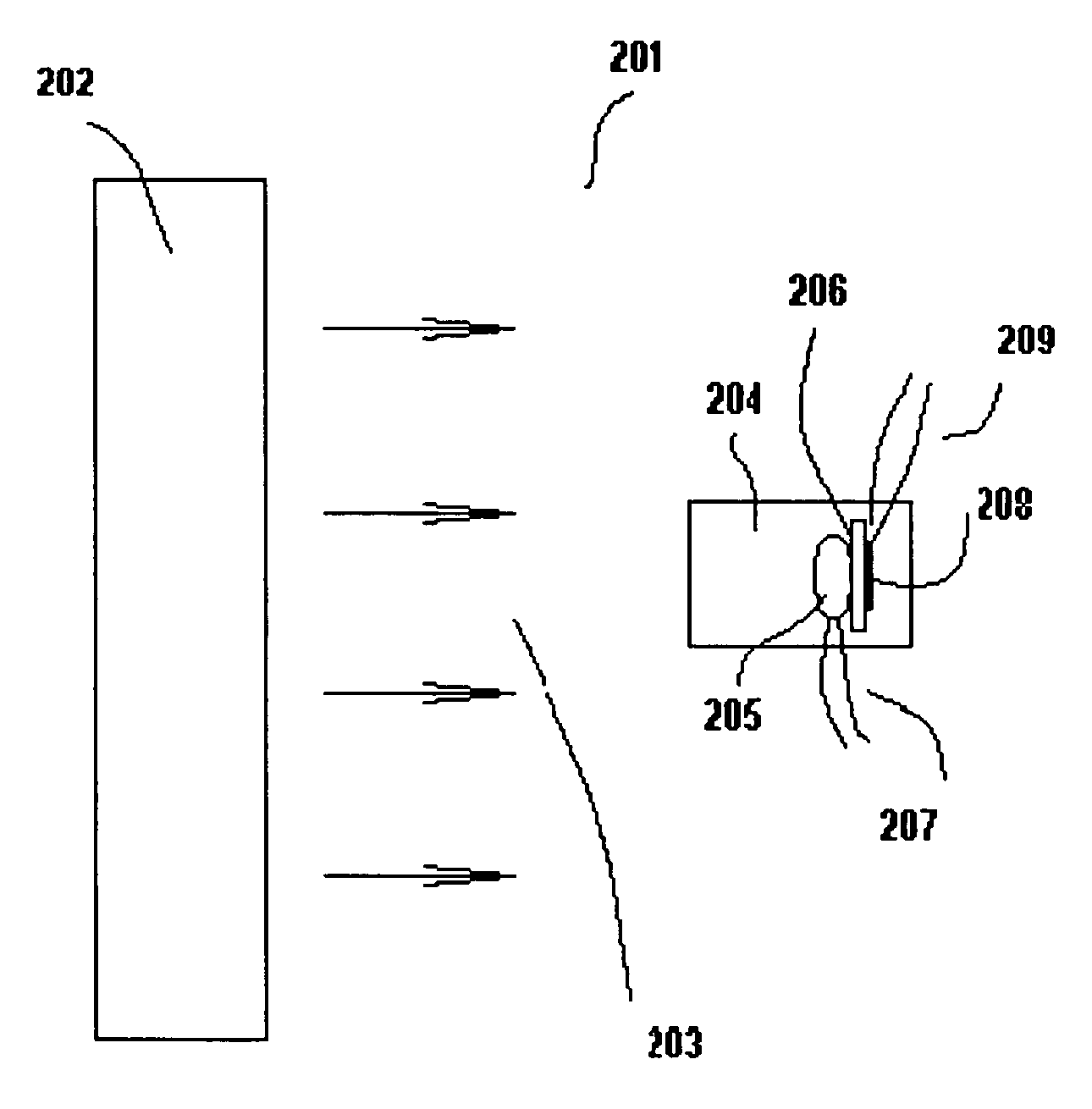

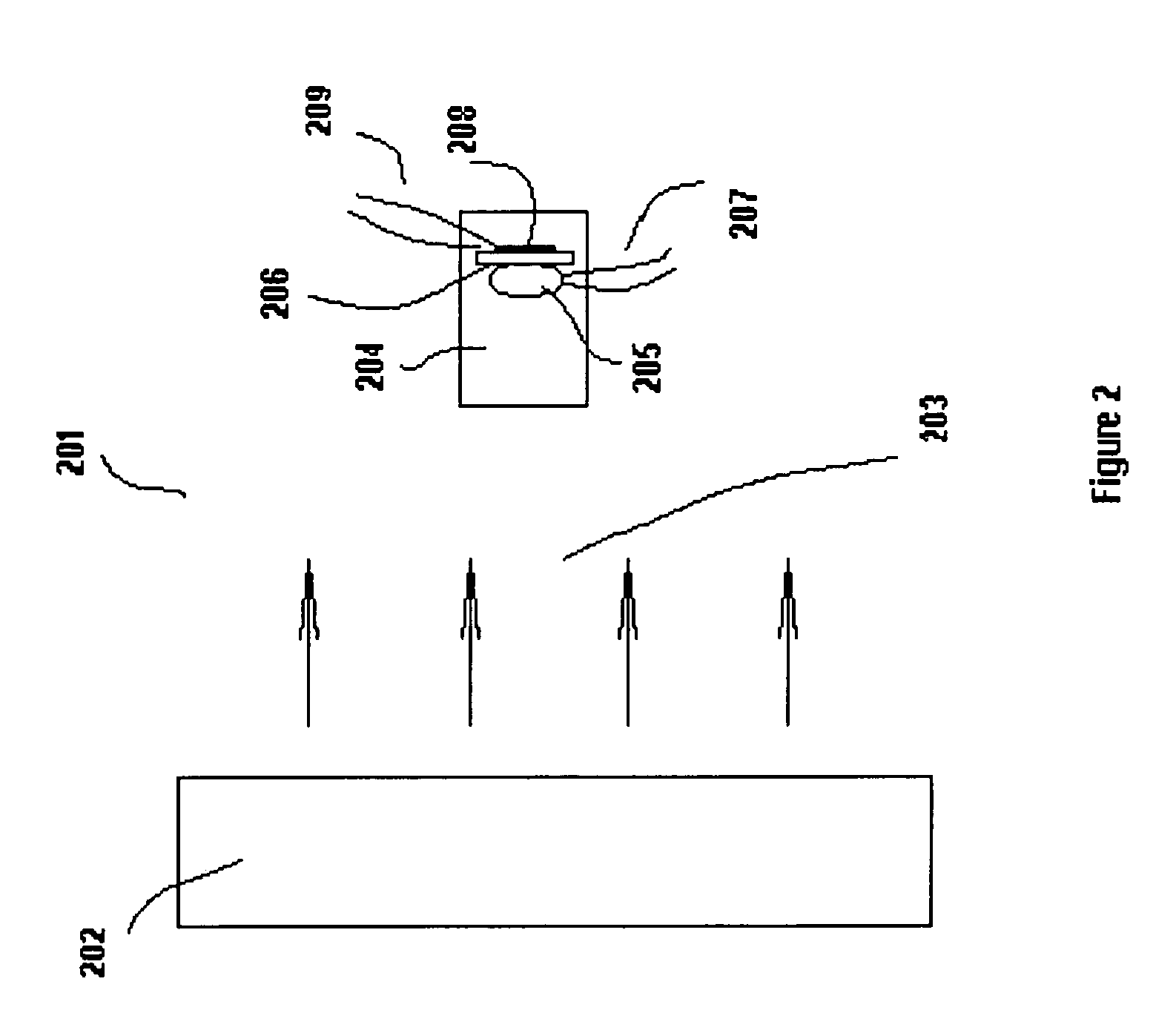

Electrostatic fluid accelerator for and method of controlling a fluid flow

InactiveUS20060226787A1Increase diameterPrevent sagSamples introduction/extractionElectrostatic separationElectrode arrayEngineering

An electrostatic fluid accelerator includes an electrode array including an array of corona discharge electrodes and an array of accelerating electrodes. A detector is configured to sense a constituent component of the fluid as present in an output from the electrode array. A control circuit supplies power to the electrode array, the control circuit being responsive to an output from the detector for operating the electrode array responsive a level of the constituent component.

Owner:TESSERA INC

Multi-chamber material dispensing system and method for making same

Material dispensing systems and methods for make such systems are described. The material dispensing systems employ a collapsible container having at least two distinct chambers, and is at least partially surrounded by an elastically deformable band. The band stretches as the container is filled with a flowable composition, thereby creating potential energy which can then be used to dispense the composition in lieu of a propellant and / or pressurized container.

Owner:THE PROCTER & GAMBLE COMPANY

Method of controlling a fluid flow

InactiveUS7410532B2Prevents the corona wires from saggingIncrease the diameterSamples introduction/extractionElectrostatic separationEngineeringElectrode array

An electrostatic fluid accelerator includes an electrode array including an array of corona discharge electrodes and an array of accelerating electrodes. A detector is configured to sense a constituent component of the fluid as present in an output from the electrode array. A control circuit supplies power to the electrode array, the control circuit being responsive to an output from the detector for operating the electrode array responsive a level of the constituent component.

Owner:TESSERA INC

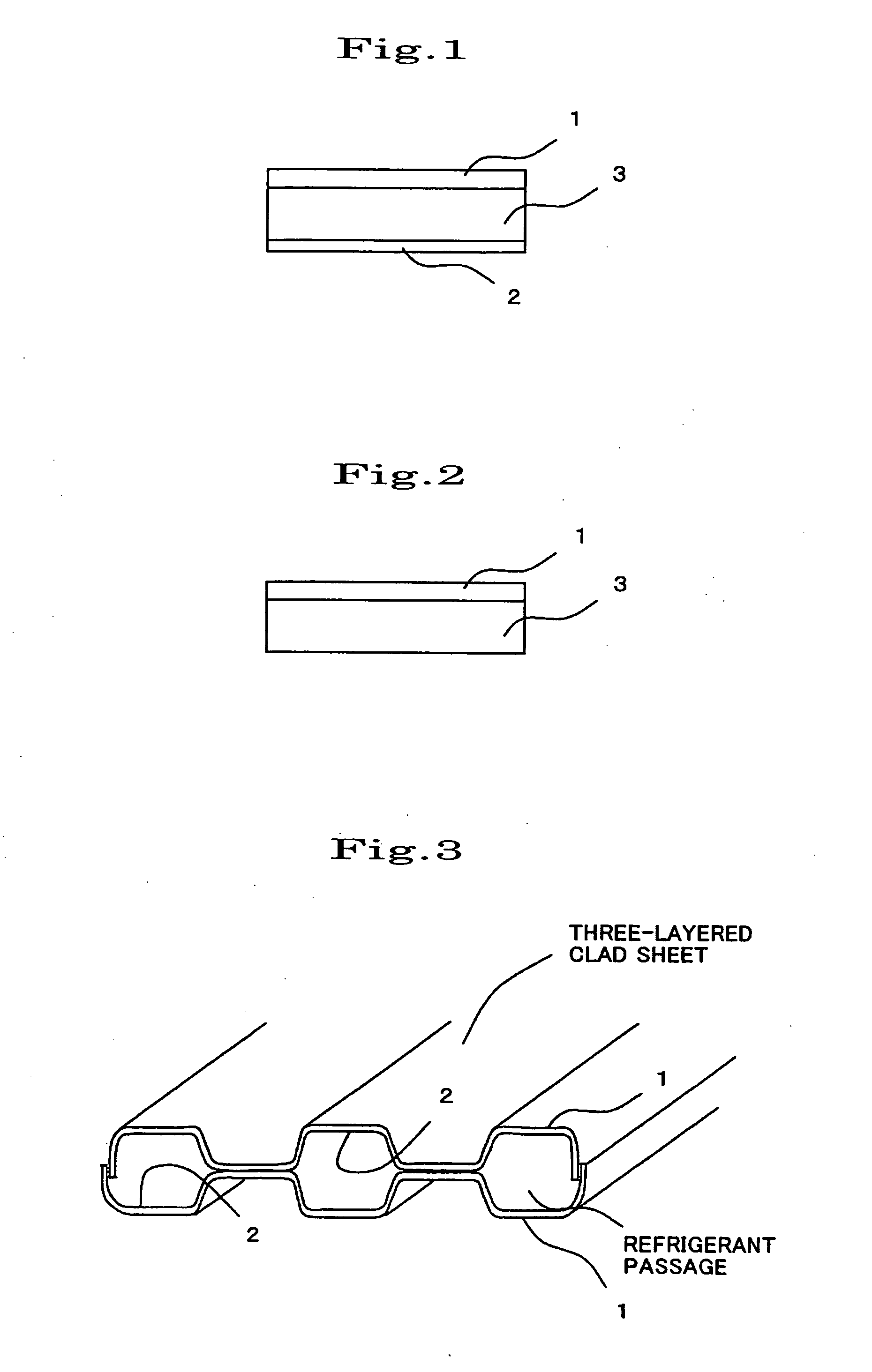

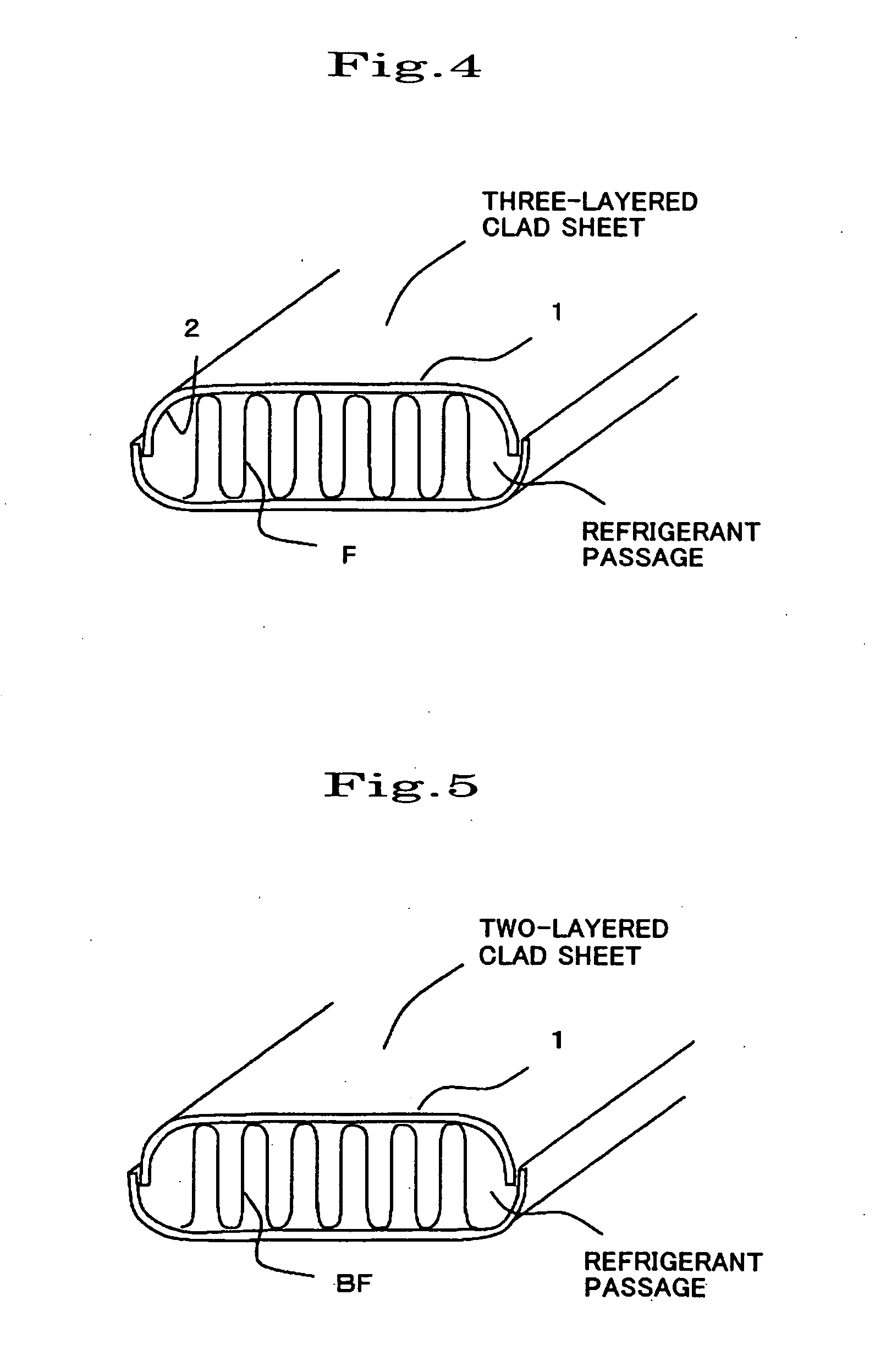

Aluminum alloy clad sheet for heat exchangers and method of producing the same

InactiveUS20100263768A1Excellent brazeabilitySufficient elongationWelding/cutting media/materialsMetal working apparatusPlate heat exchangerImpurity

An aluminum alloy clad sheet for heat exchangers includes a core material, a cladding material 1, and a cladding material 2, one side and the other side of the core material being respectively clad with the cladding material 1 and the cladding material 2, the core material containing 0.5 to 1.2% of Si, 0.2 to 1.0% of Cu, and 1.0 to 1.8% of Mn, with the balance being Al and unavoidable impurities, the cladding material 1 containing 3 to 6% of Si, 2 to 8% of Zn, and at least one of 0.3 to 1.8% of Mn and 0.05 to 0.3% of Ti, with the balance being Al and unavoidable impurities, and the cladding material 2 containing 6 to 13% of Si, with the balance being Al and unavoidable impurities, the cladding material 1 being positioned on the outer side of the aluminum alloy clad sheet during use.

Owner:SUMITOMO LIGHT METAL INDS LTD

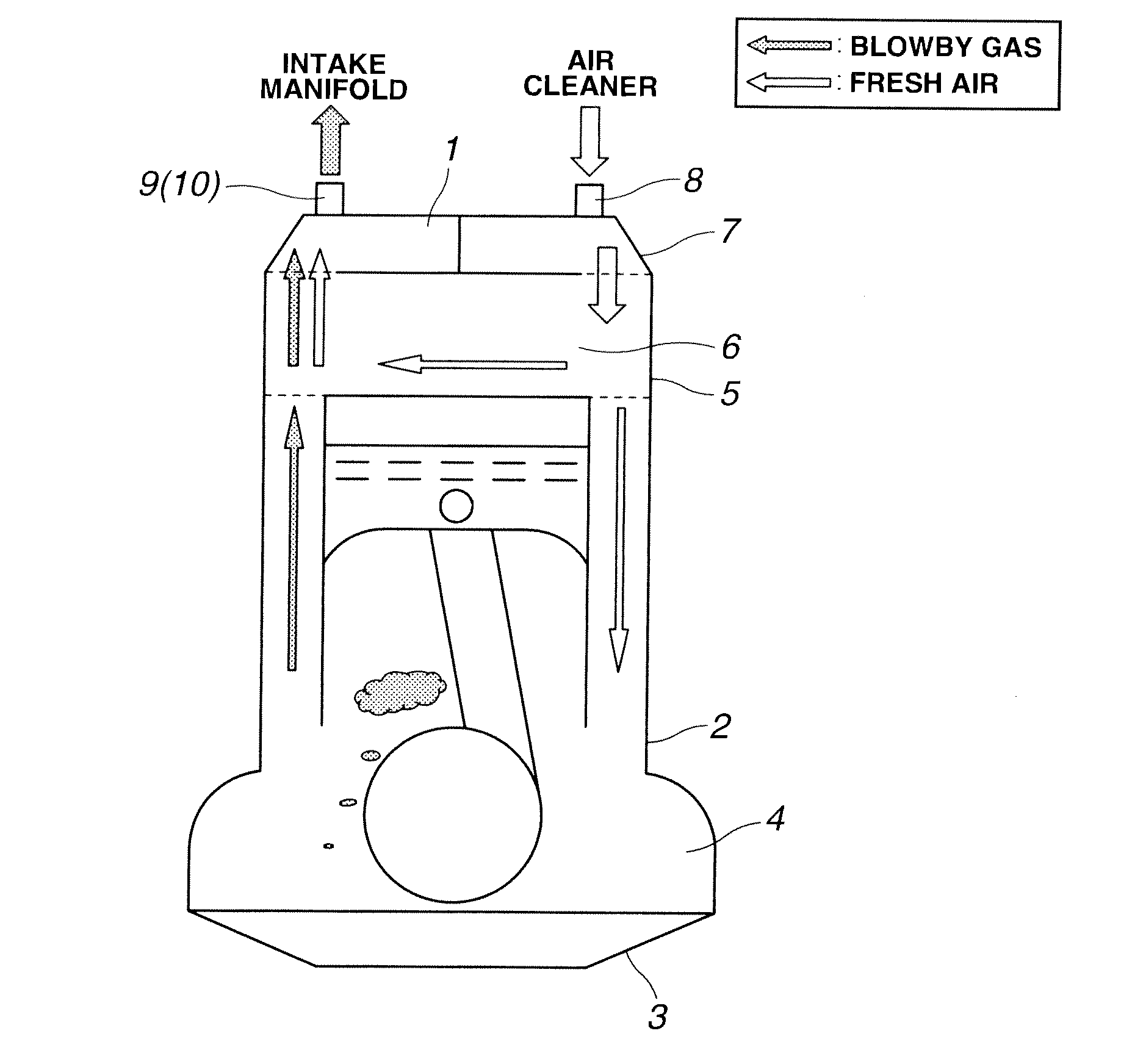

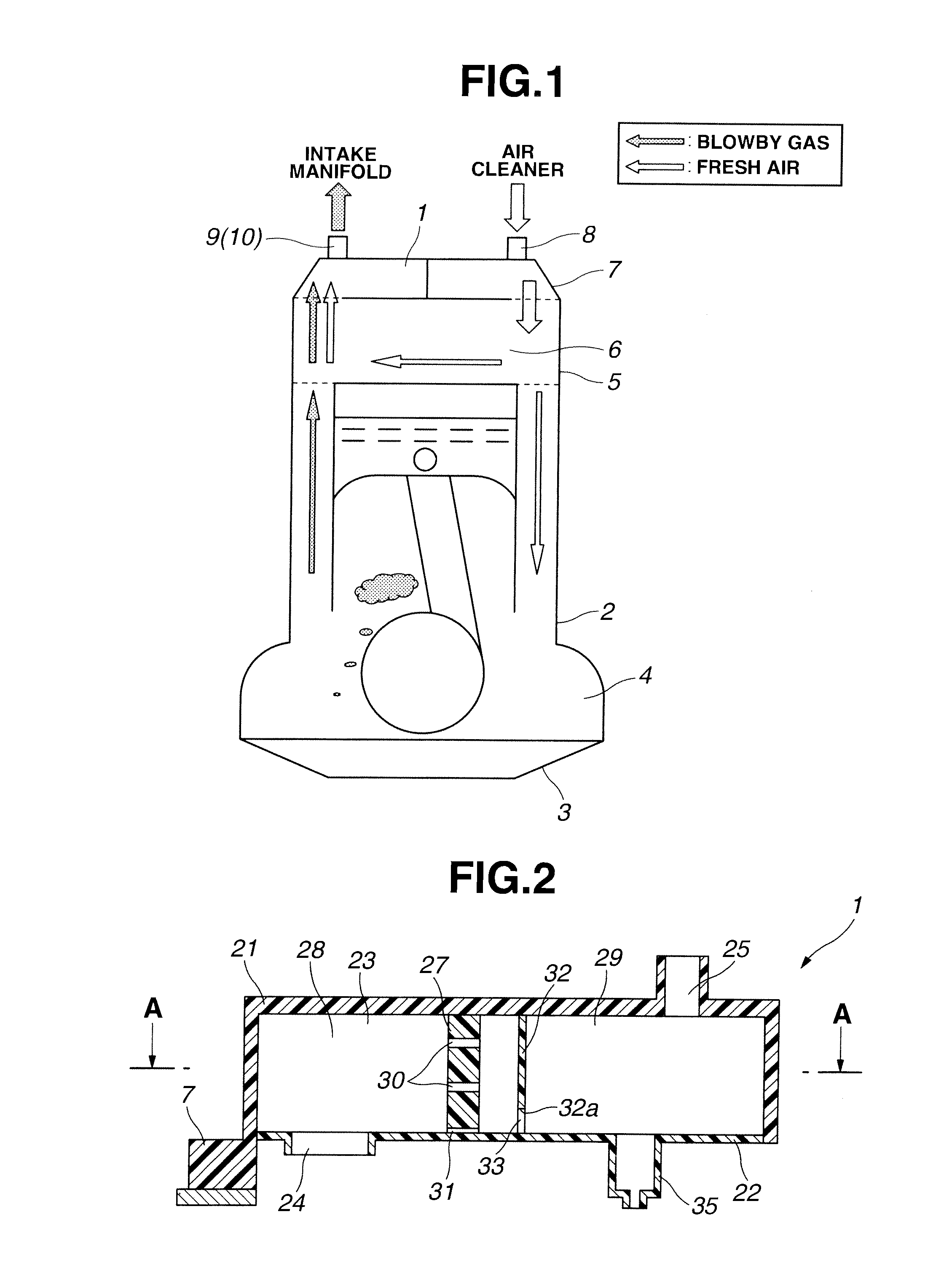

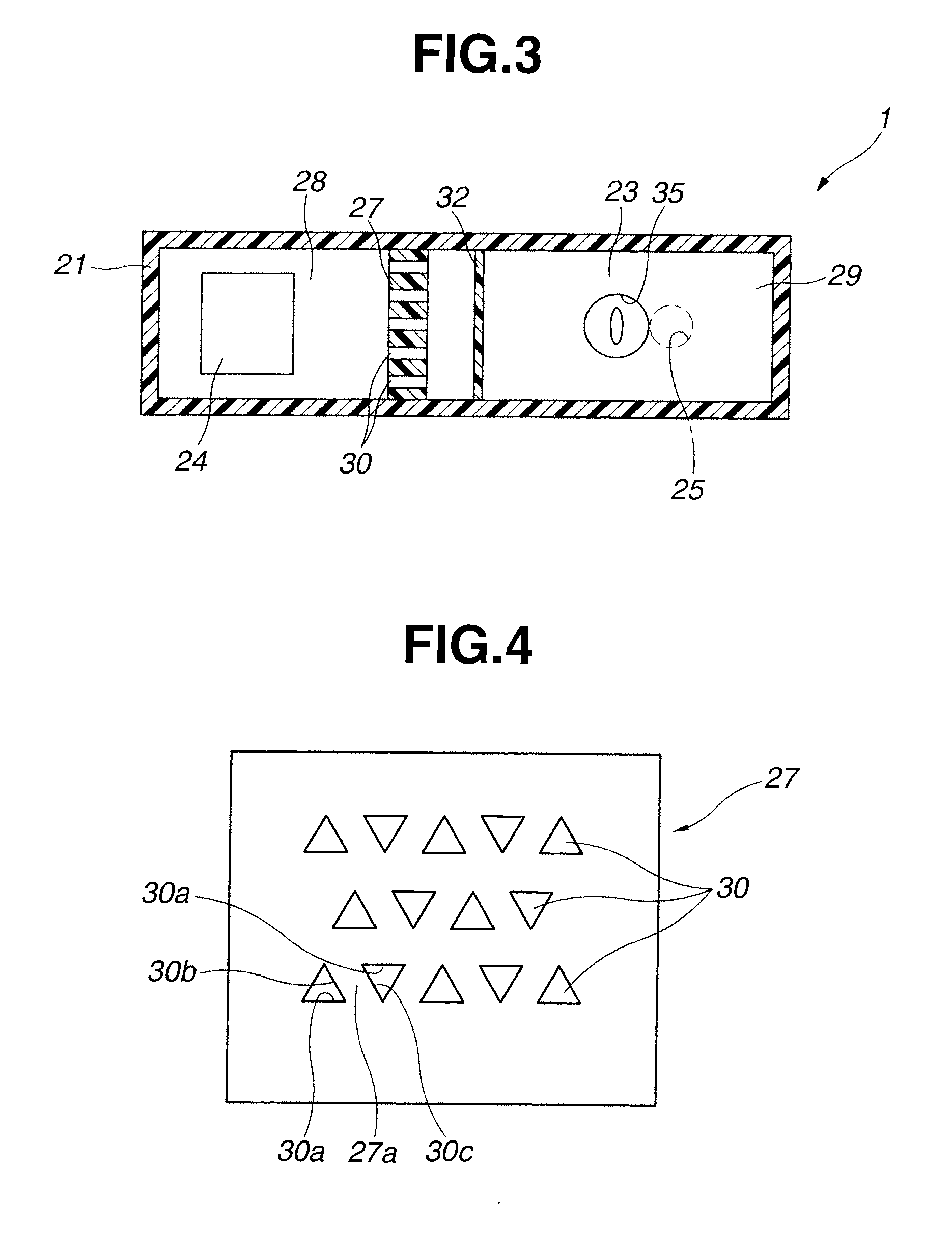

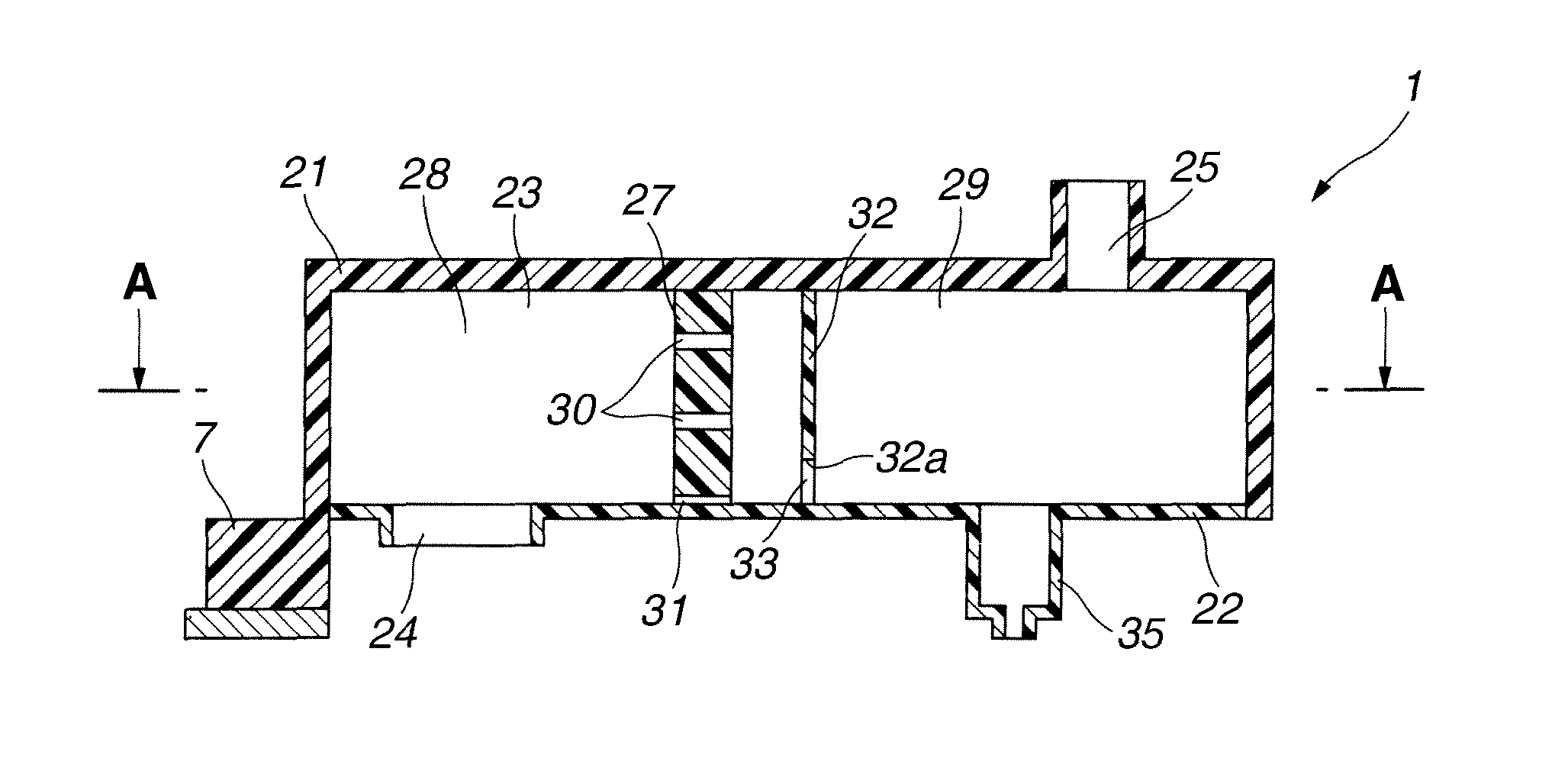

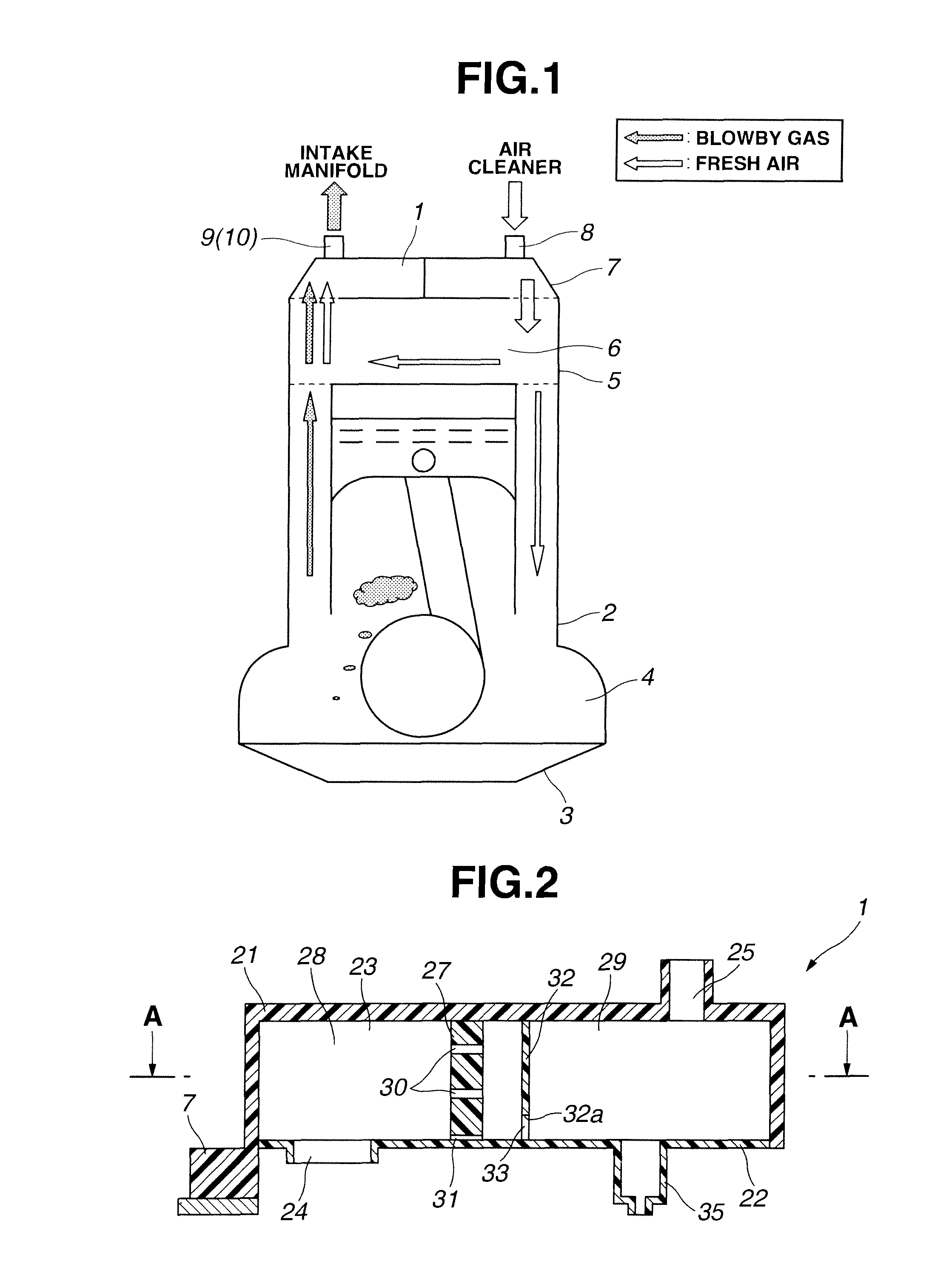

Oil separator for internal combustion engine

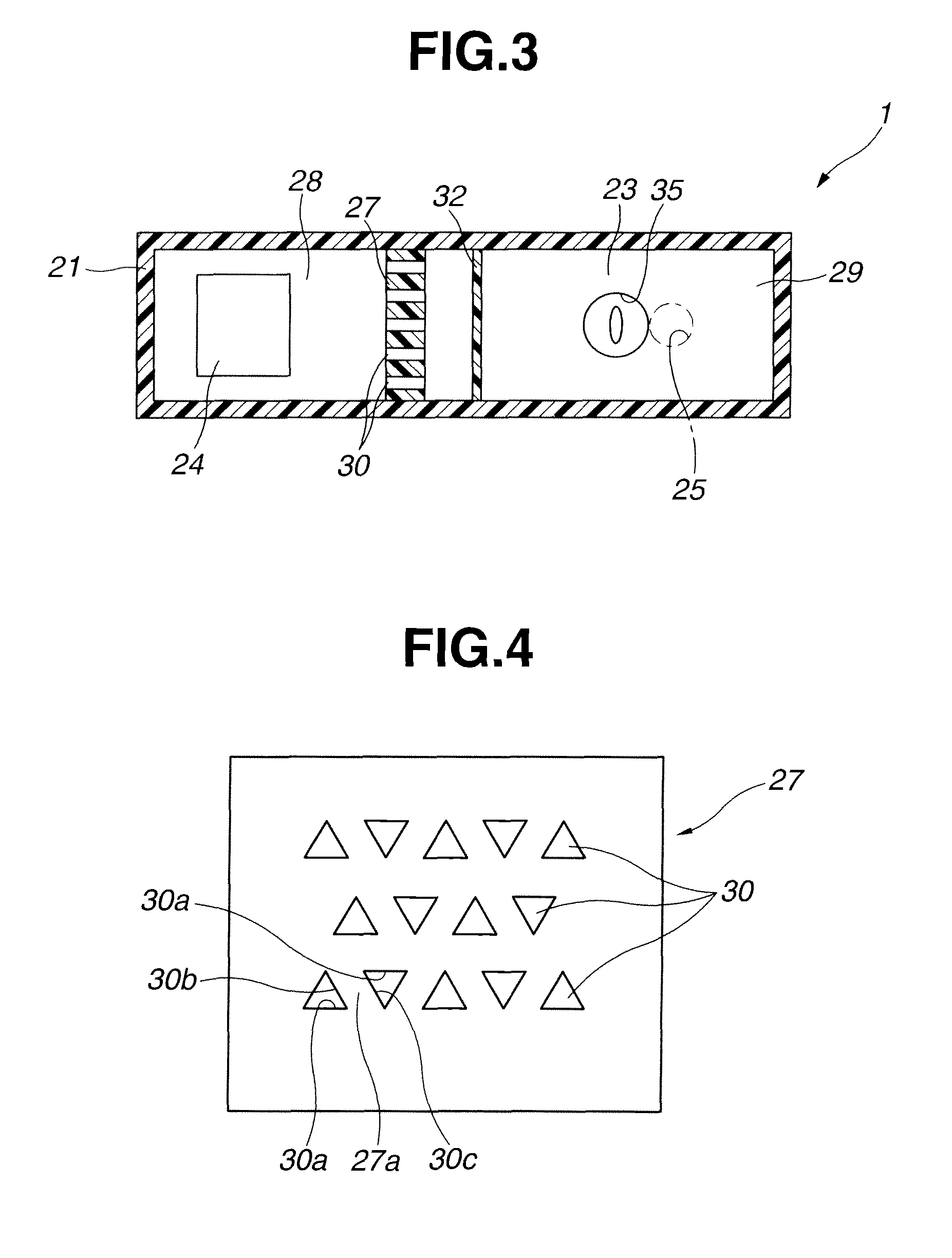

InactiveUS20130125865A1Facilitate flow velocityReduce the cross-sectional areaCombustion enginesCrankcase ventillationCylinder headExternal combustion engine

An oil separator disposed inside a cylinder head cover of an internal combustion engine. The oil separator includes a body section defining an elongate separator chamber and having a blowby gas inlet and a blowby gas outlet. A partition wall is disposed to divide the separator chamber into an inlet chamber at side of the blowby gas inlet and an outlet chamber at side of the blowby gas outlet. The partition wall is formed with a plurality of passage holes each of which is triangular in cross-section. A collision plate is disposed inside the outlet chamber and located opposite to the passage holes of the partition wall. A slit-like opening is defined by a lower section of the collision plate and communicated with a drain section for discharging oil separated from blowby gas into a valve operating chamber.

Owner:MAHLE FILTER SYST JAPAN CORP

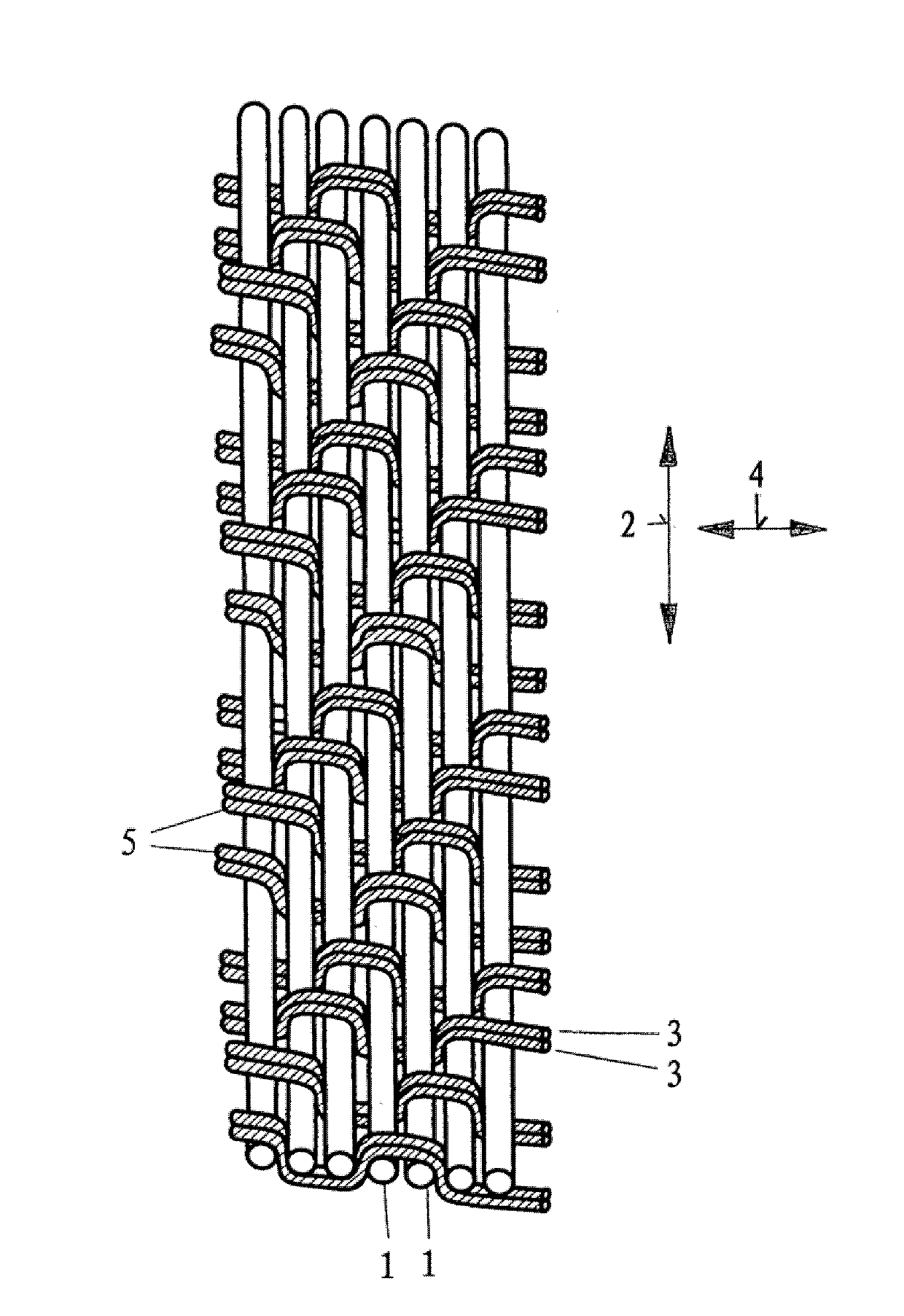

Compound centrifugal manufacturing method for sink roller or stabilizing roller

InactiveCN101596584AImprove corrosion resistanceImprove wear resistanceHot-dipping/immersion processesSlagCobalt based alloy

The invention discloses a compound centrifugal manufacturing method for a sink roller or stabilizing roller, which comprises the following steps: smelting molten metal of an iron-based material and molten metal of a cobalt-base alloy in two smelting furnaces respectively; performing deslagging and deoxidation treatment after the melting down of the molten metal of the iron-based material and the molten metal of the cobalt-base alloy; performing centrifugal casting on the outer layer molten metal of the cobalt-base alloy first, and adding an acid slag protective agent along with the outer layer molten metal of the cobalt-base alloy when the outer layer molten metal of the cobalt-base alloy is cast to 20 to 30 percent of the gross weight of the outer layer molten metal of the cobalt-base alloy needing to be cast; after the outer layer molten metal of the cobalt-base alloy is cast and the outer layer molten metal of the cobalt-base alloy is solidified, casting the inner layer molten metal of the iron-based material until finishing; and under the action of centrifugal force, cooling and solidifying the inner layer molten metal and the outer layer molten metal into a blank of a compound centrifugal sink roller or a stabilizing roller.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Oil separator for internal combustion engine

InactiveUS8726876B2Velocity increasesReduce the cross-sectional areaCombustion enginesPressure lubricationCylinder headExternal combustion engine

An oil separator disposed inside a cylinder head cover of an internal combustion engine. The oil separator includes a body section defining an elongate separator chamber and having a blowby gas inlet and a blowby gas outlet. A partition wall is disposed to divide the separator chamber into an inlet chamber at side of the blowby gas inlet and an outlet chamber at side of the blowby gas outlet. The partition wall is formed with a plurality of passage holes each of which is triangular in cross-section. A collision plate is disposed inside the outlet chamber and located opposite to the passage holes of the partition wall. A slit-like opening is defined by a lower section of the collision plate and communicated with a drain section for discharging oil separated from blowby gas into a valve operating chamber.

Owner:MAHLE FILTER SYST JAPAN CORP

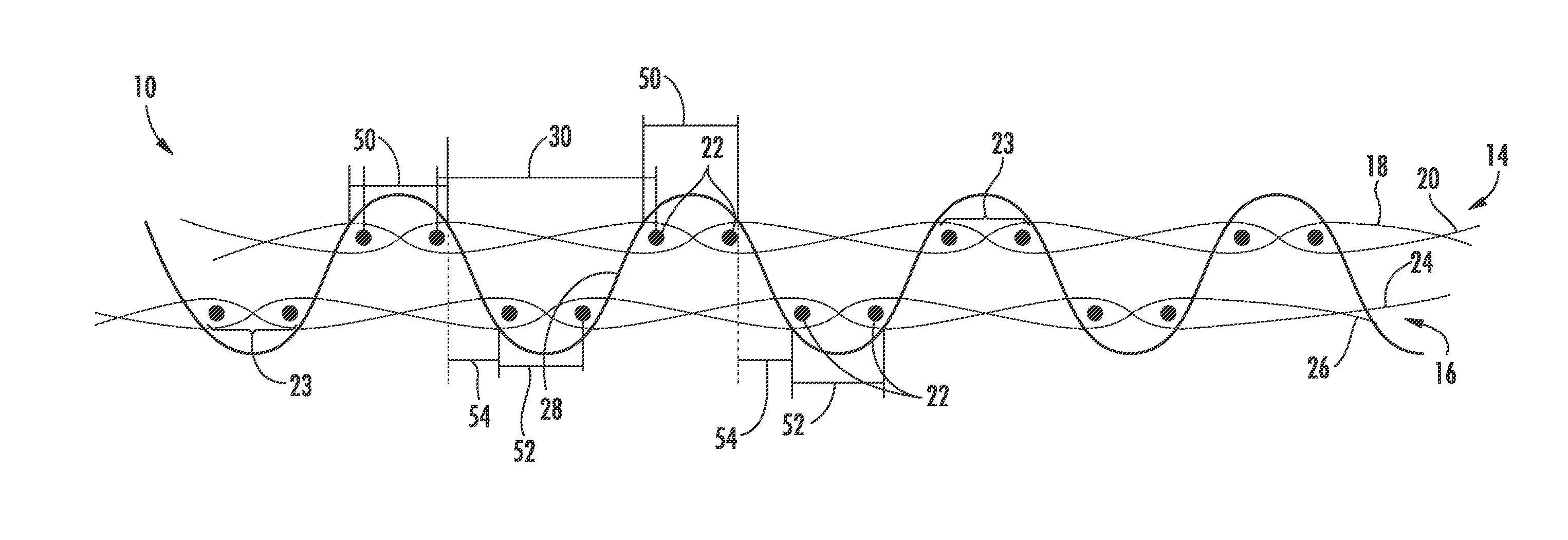

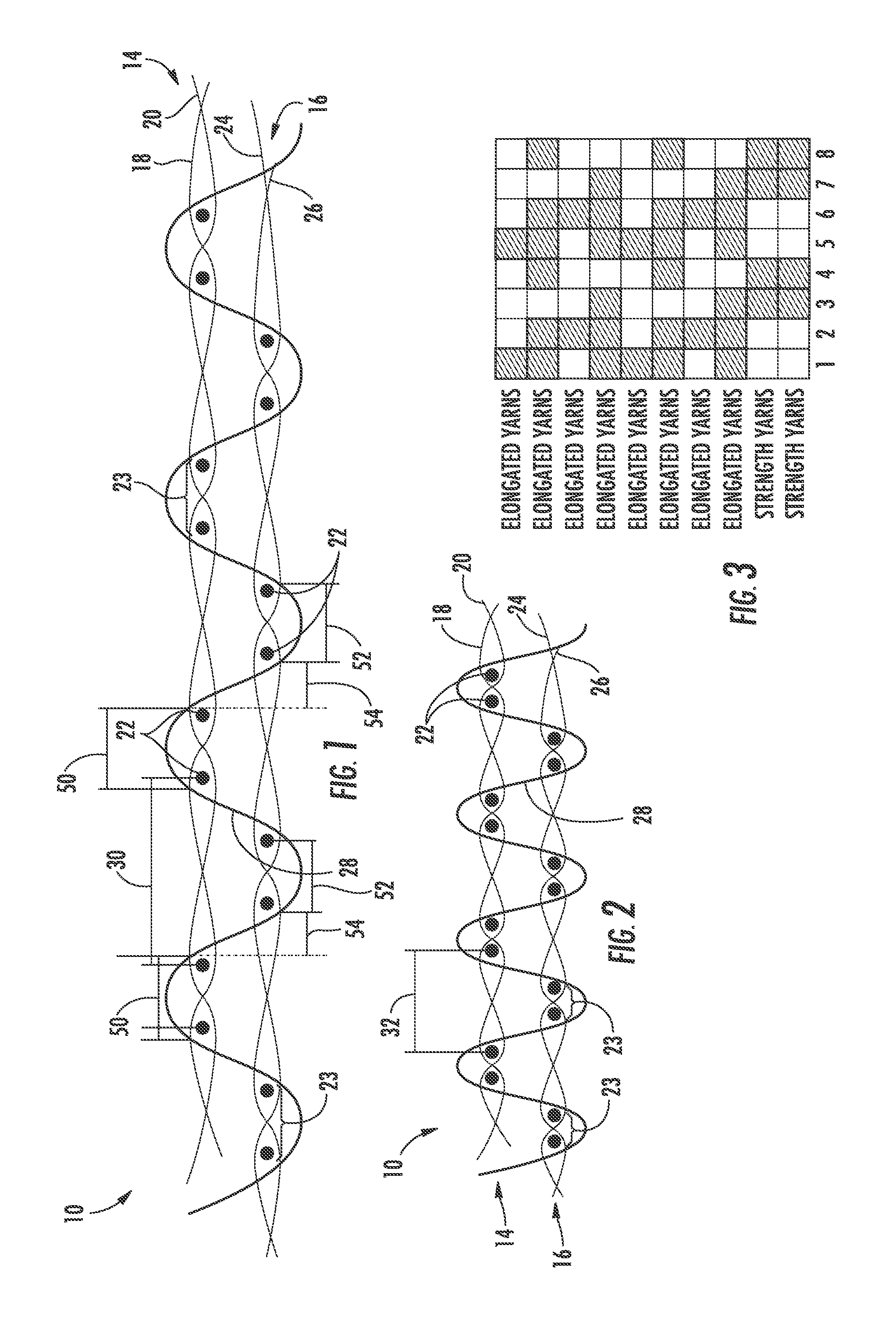

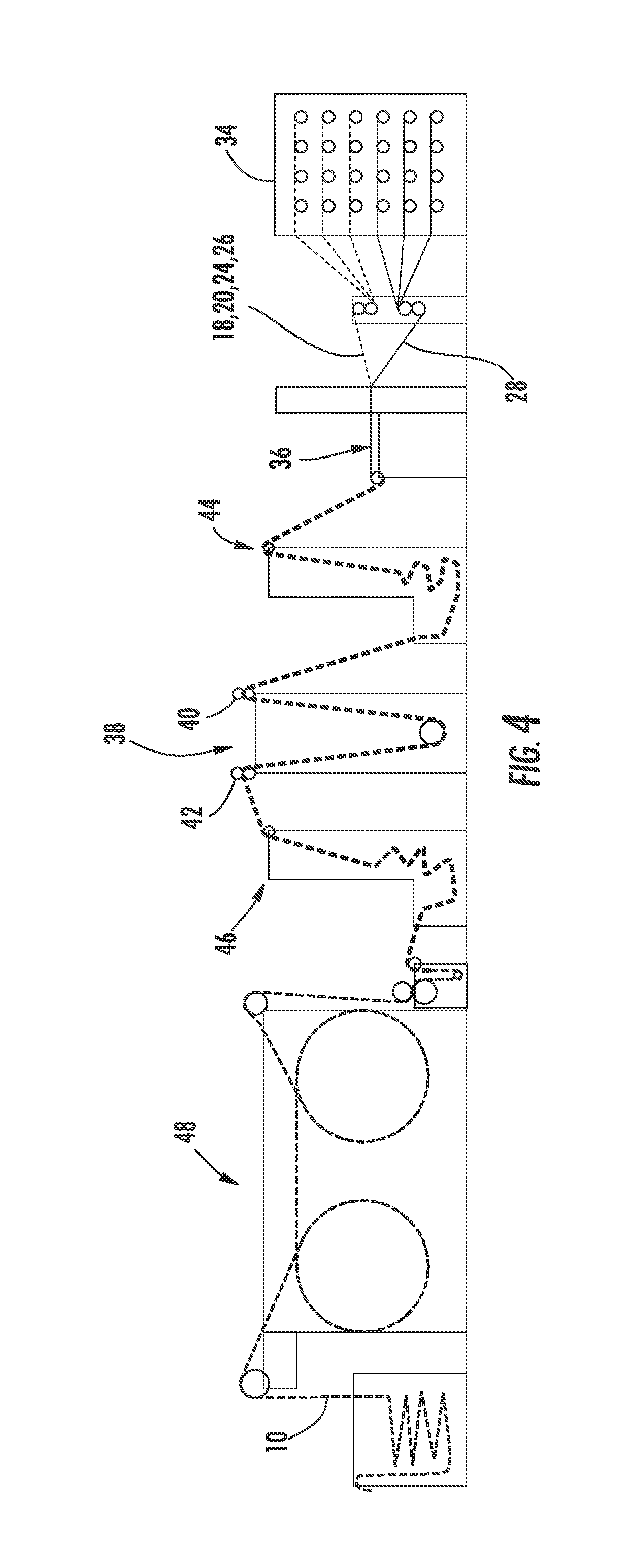

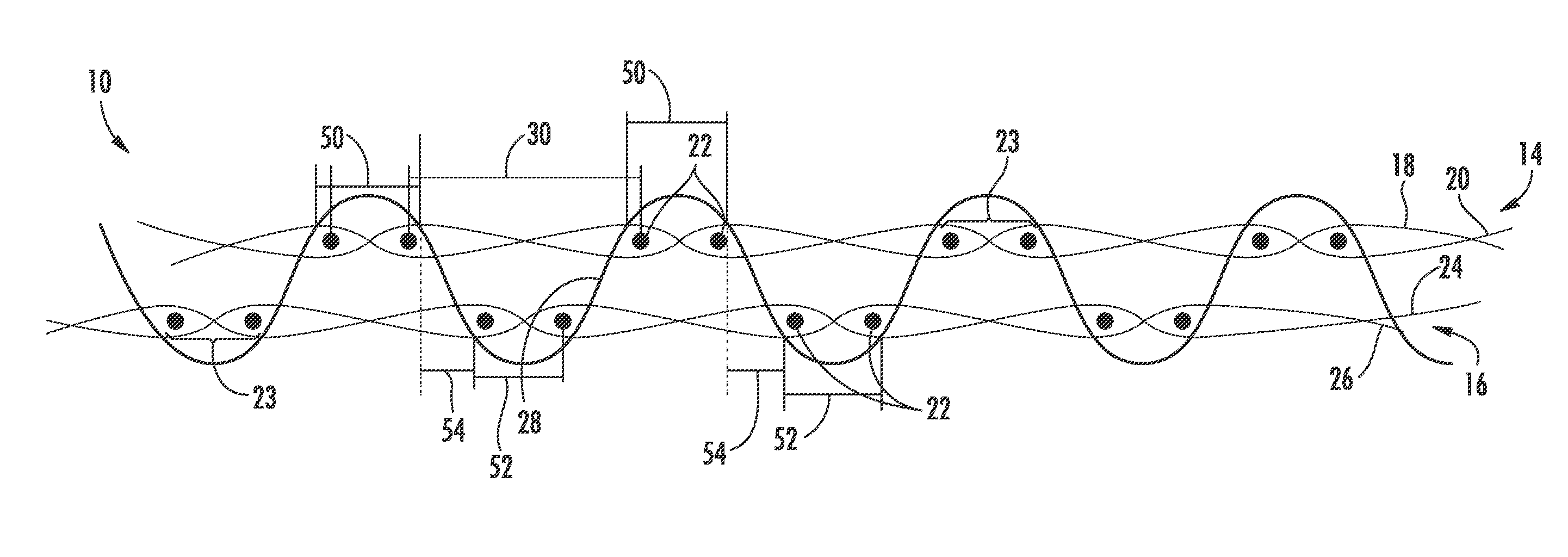

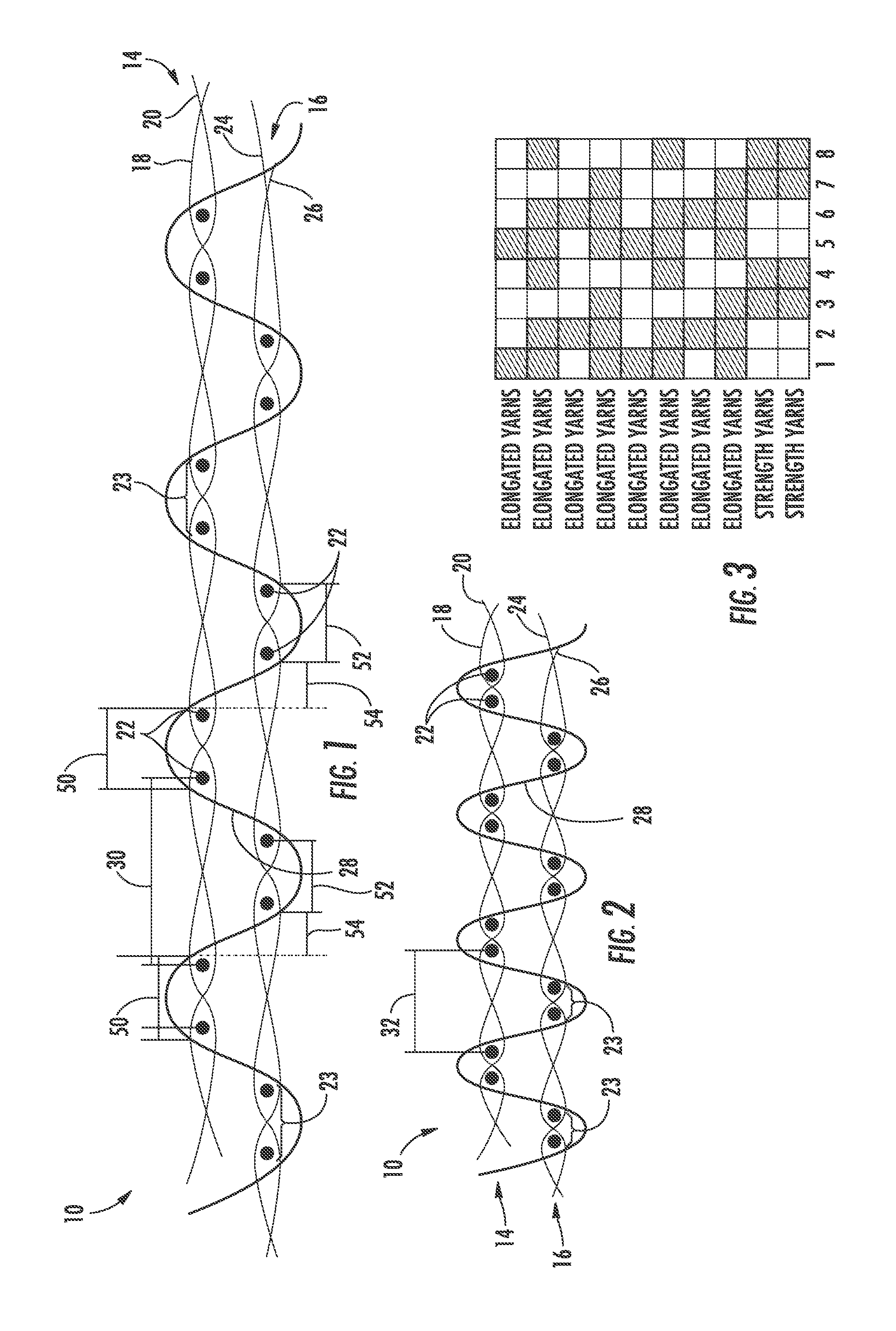

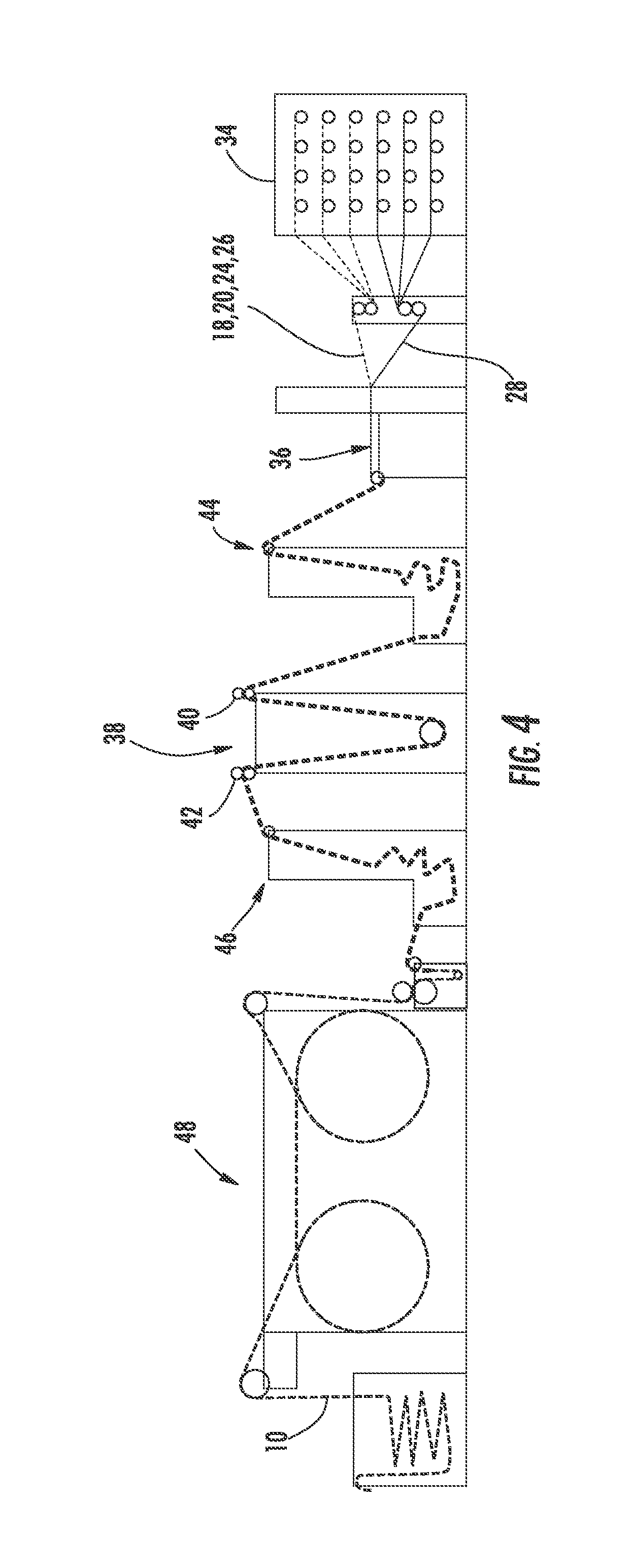

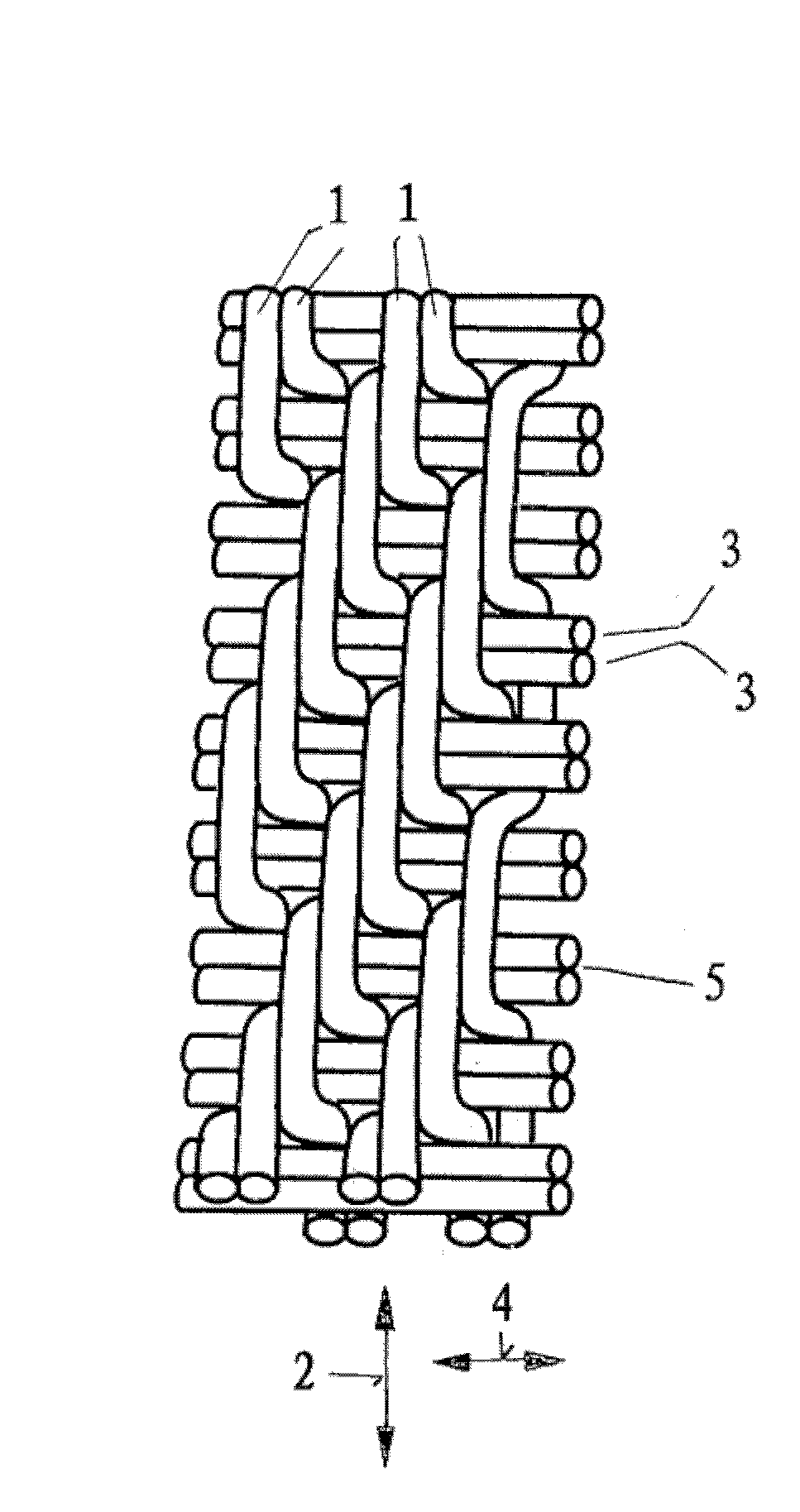

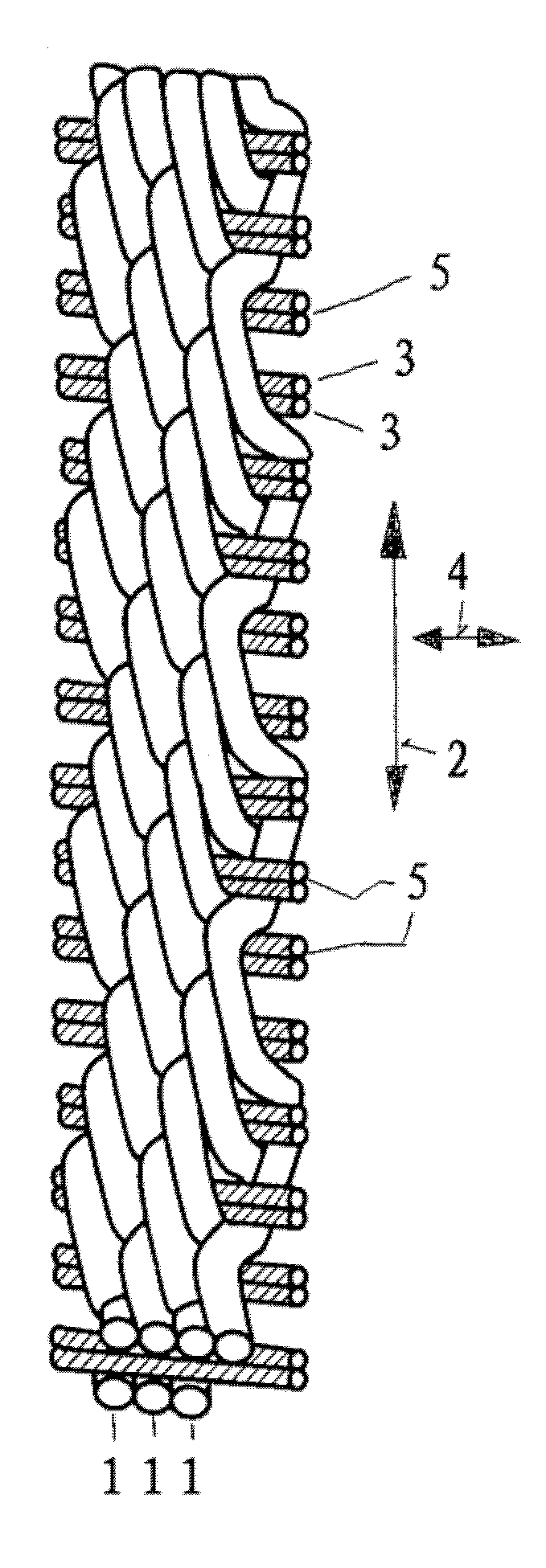

Energy absorbing fabric and method of manufacturing same

Energy absorbing fabrics that are generally flat and that have a controllable and significant elongation distance. The fabrics are comprised of elongation yarns, such as partially oriented yarns (POY), and binder yarns, where the elongation yarns and the binder yarns have various weave-in percentages depending on the desired amount of elongation. In certain embodiments, because they are generally flat, the energy absorbing fabrics are suitable for use in retractors. Also provided are processes of manufacturing generally flat, energy absorbing fabrics.

Owner:YKK CORP OF AMERICA

Compound centrifugal manufacturing method for axial sleeve of bushing

InactiveCN101596583AImprove corrosion resistanceImprove wear resistanceHot-dipping/immersion processesSlagCentrifugal force

The invention discloses a compound centrifugal manufacturing method for an axial sleeve of a bushing, which comprises the following steps: smelting molten metal of an iron-based material and molten metal of a cobalt-base alloy in two smelting furnaces respectively; performing deslagging and deoxidation treatment after the melting down of the molten metal of the iron-based material and the molten metal of the cobalt-base alloy; performing centrifugal casting on the outer layer molten metal of the cobalt-base alloy first, and adding an acid slag protective agent along with the outer layer molten metal of the cobalt-base alloy when the outer layer molten metal of the cobalt-base alloy is cast to 20 to 30 percent of the gross weight of the outer layer molten metal of the cobalt-base alloy needing to be cast; passing 3 to 5 minutes after the outer layer molten metal is cast, and after solidifying the outer layer molten metal of the cobalt-base alloy, casting the inner layer molten metal of the iron-based material until finishing; and under the action of centrifugal force, cooling and solidifying the inner layer molten metal and the outer layer molten metal into a blank of a compound centrifugal axial sleeve of a bushing, and assembling and processing the blank.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

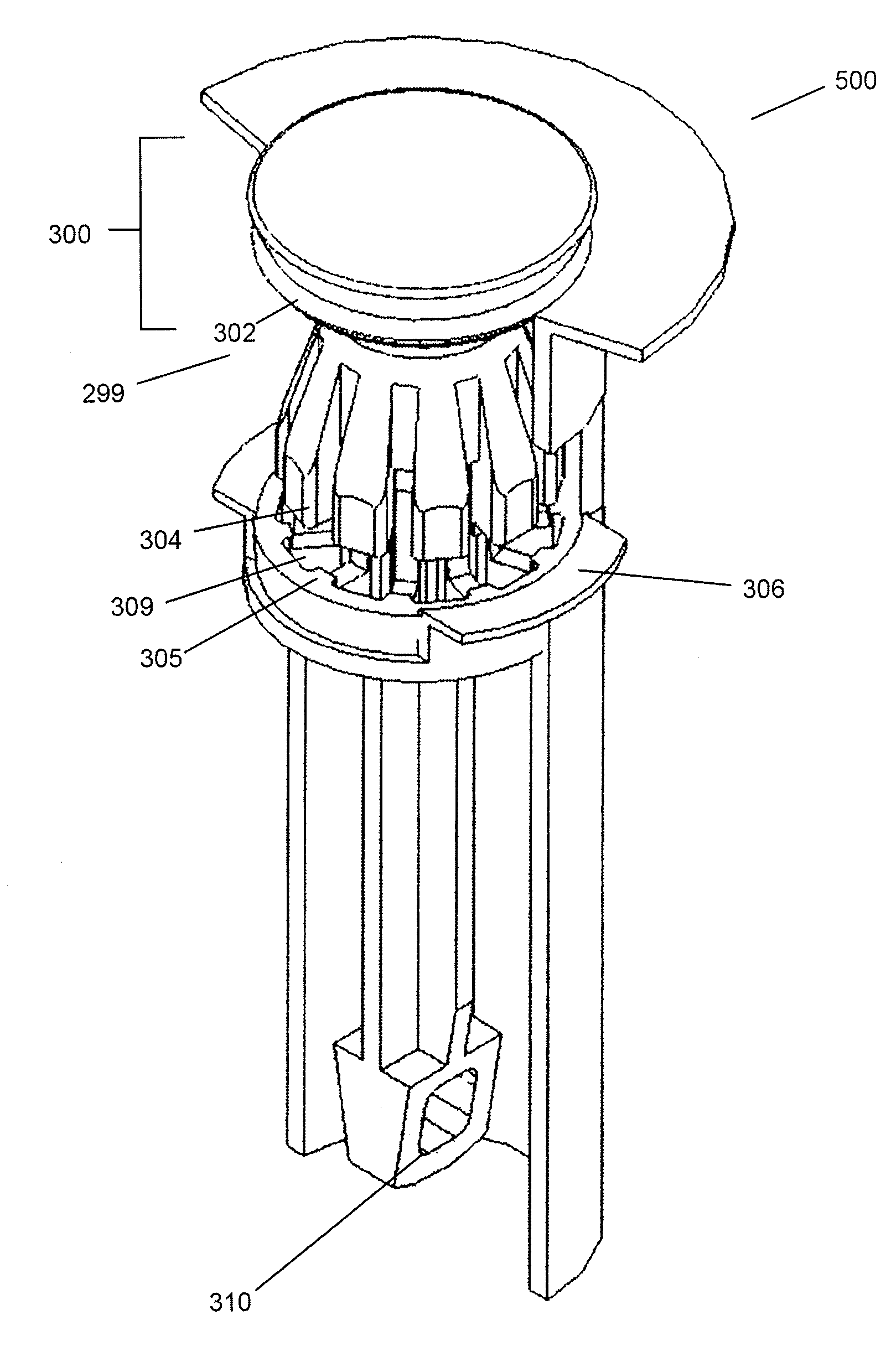

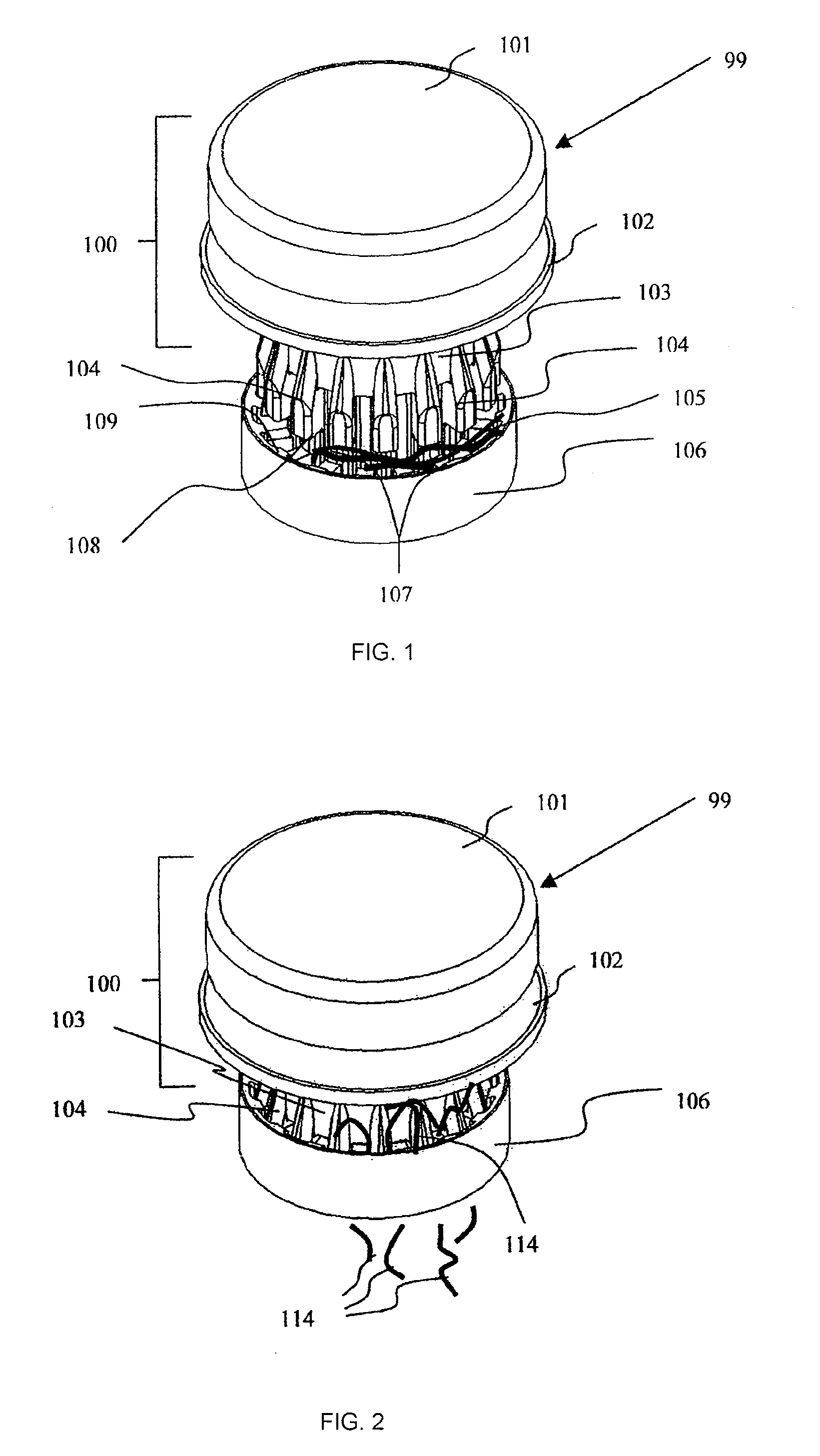

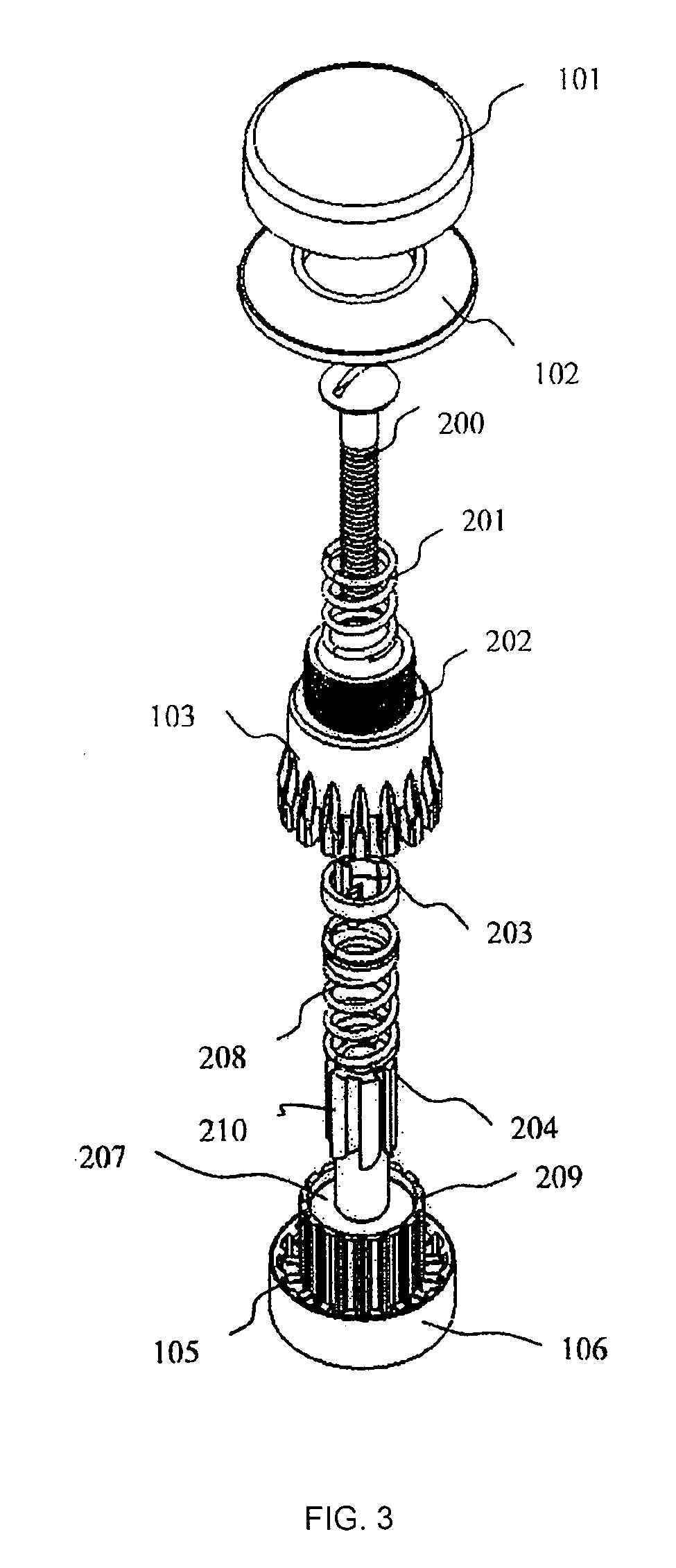

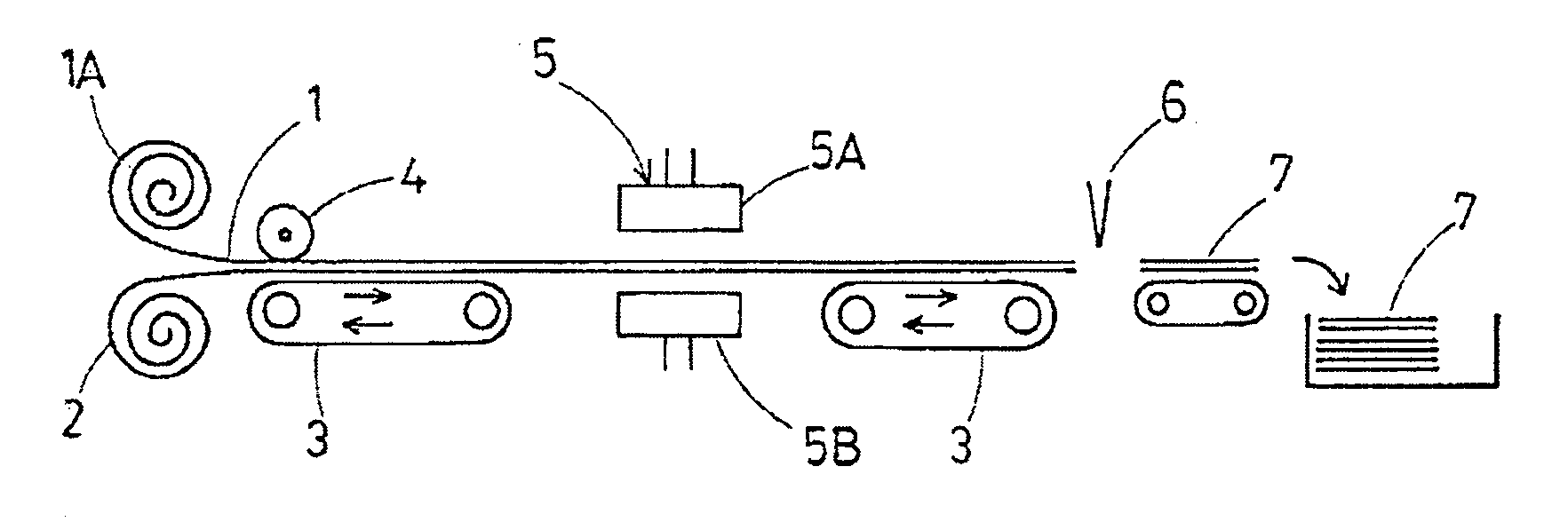

Manually Operable Drain Device

A method for preventing waste materials from clogging a household drain, the method comprising: a) receiving a quantity of waste material contained in a flow of liquid toward a drain receptacle; b) guiding the flow of liquid to a predetermined position adjacent a part of a manually operable device mounted within the drain receptacle and gathering the quantity of the waste material from the flow of liquid in a first location adjacent a member of the manually operable device located in the drain receptacle; c) maintaining the quantity of waste material generally perpendicular to the vertical motion of a manually moving size reduction assembly; d) manually moving the size reduction assembly portion of the device so as to subject the quantity of waste material to abrading action, thereby producing an abraded portion of waste material as a plurality of smaller pieces; and e) carrying the abraded pieces away from the drain receptacle and through a drain conduit in the flow of water.

Owner:DYNAMIC DRAIN SOLUTIONS

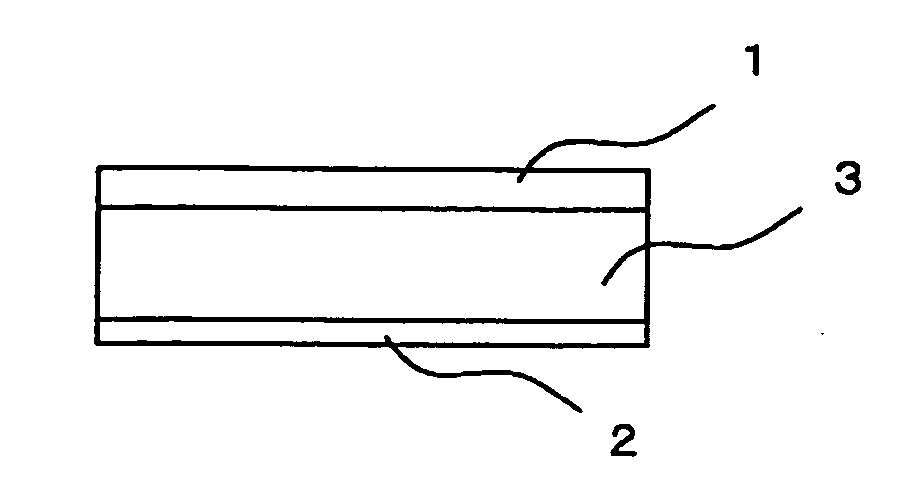

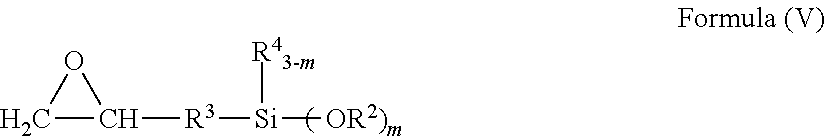

Formable Sheet and Interior Finishing Material

InactiveUS20090311510A1Prevent dry stateSufficient elongationSynthetic resin layered productsThin material handlingSynthetic resinMoisture

The object of the present invention is to provide a moldable sheet which maintains good moldability even in a case where the moldable sheet is kept at a low temperature and a low humidity.The moldable sheet comprises a porous material which a synthetic resin is coated on or impregnated into, the porous material being further impregnated with a water retention agent.The water retention agent in the porous material retains moisture in the porous material, maintaining the good moldability of the moldable sheet, even at a low temperature and a low humidity.

Owner:NAGOYA OIL CHEM CO LTD

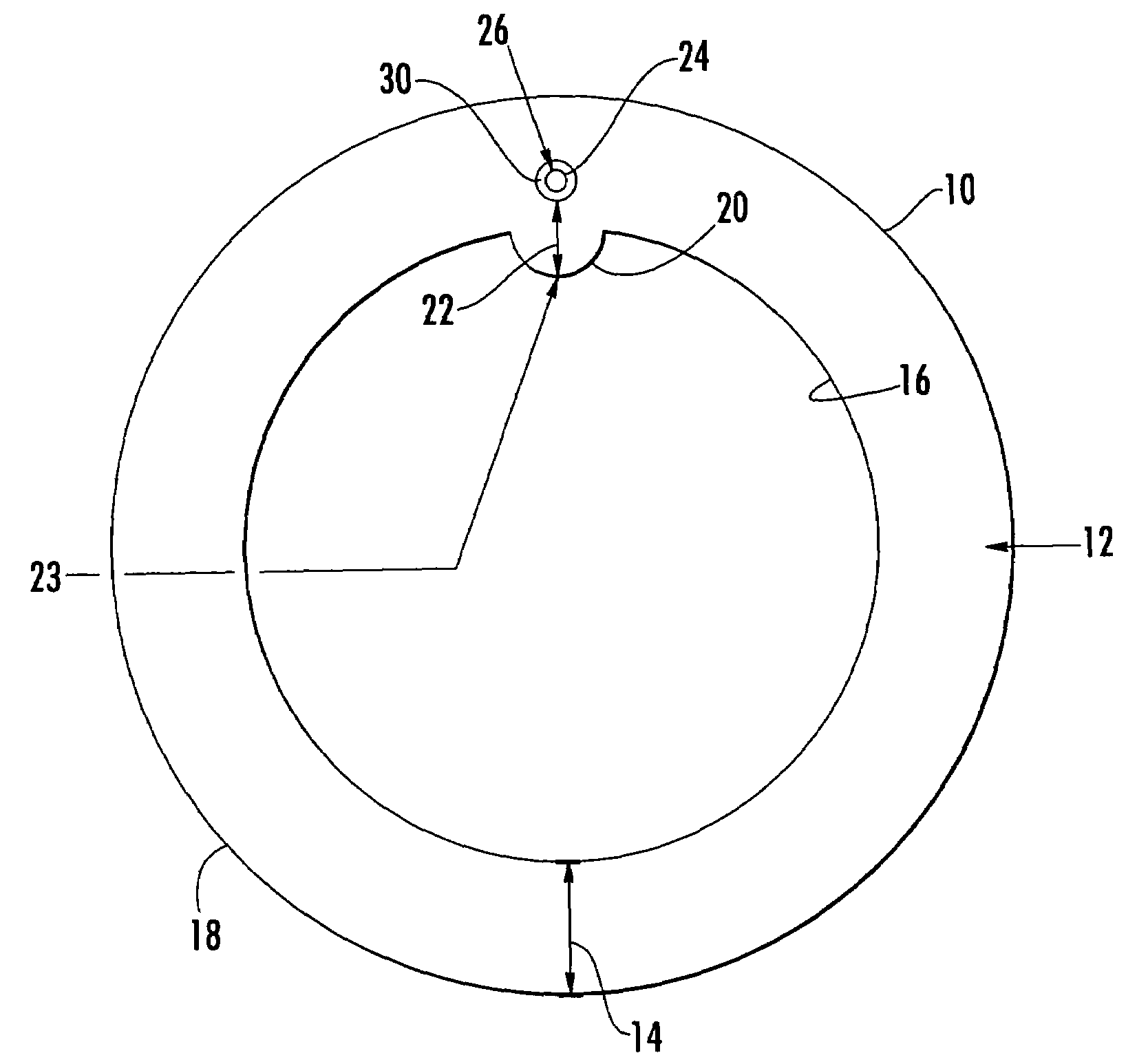

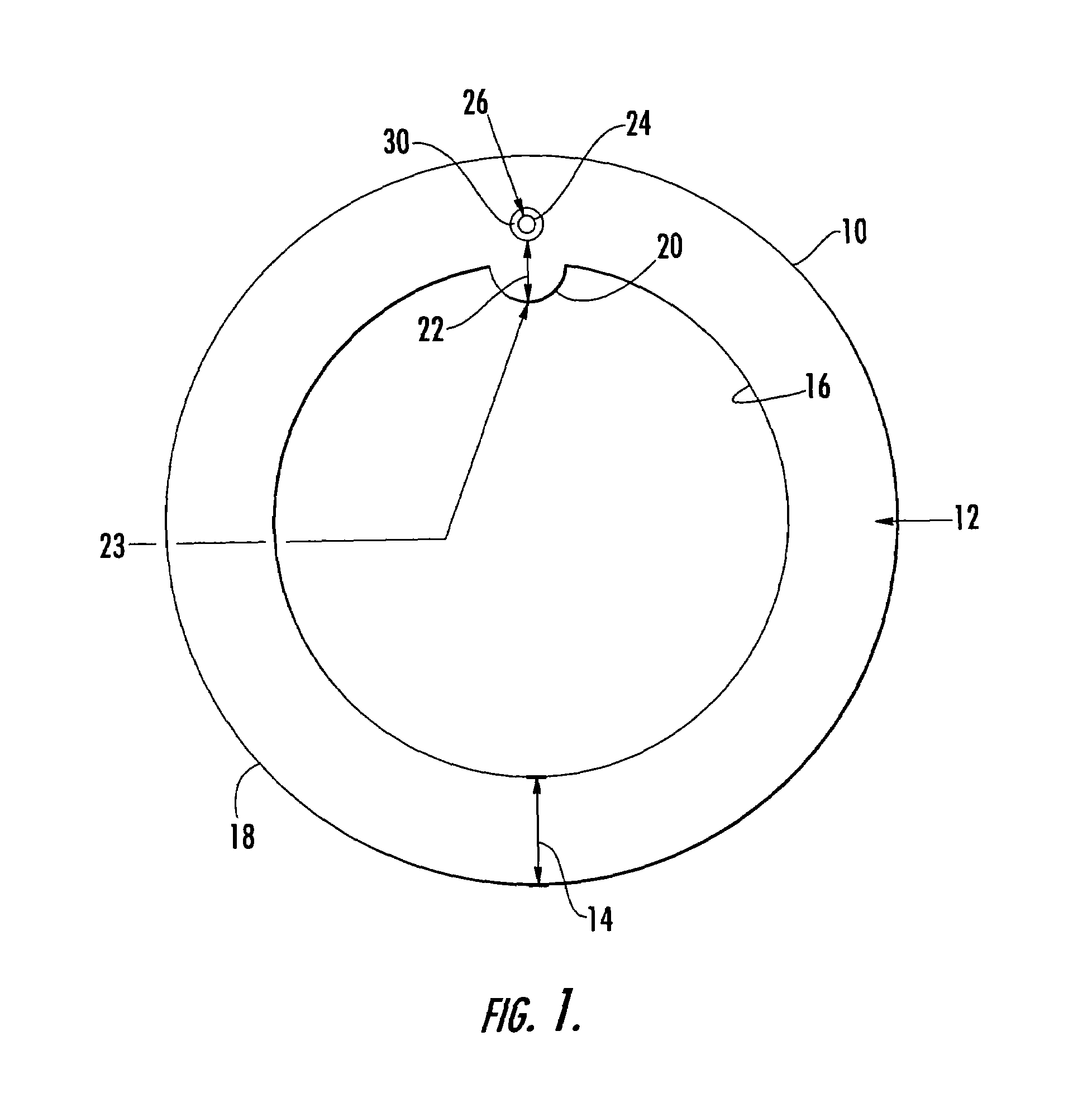

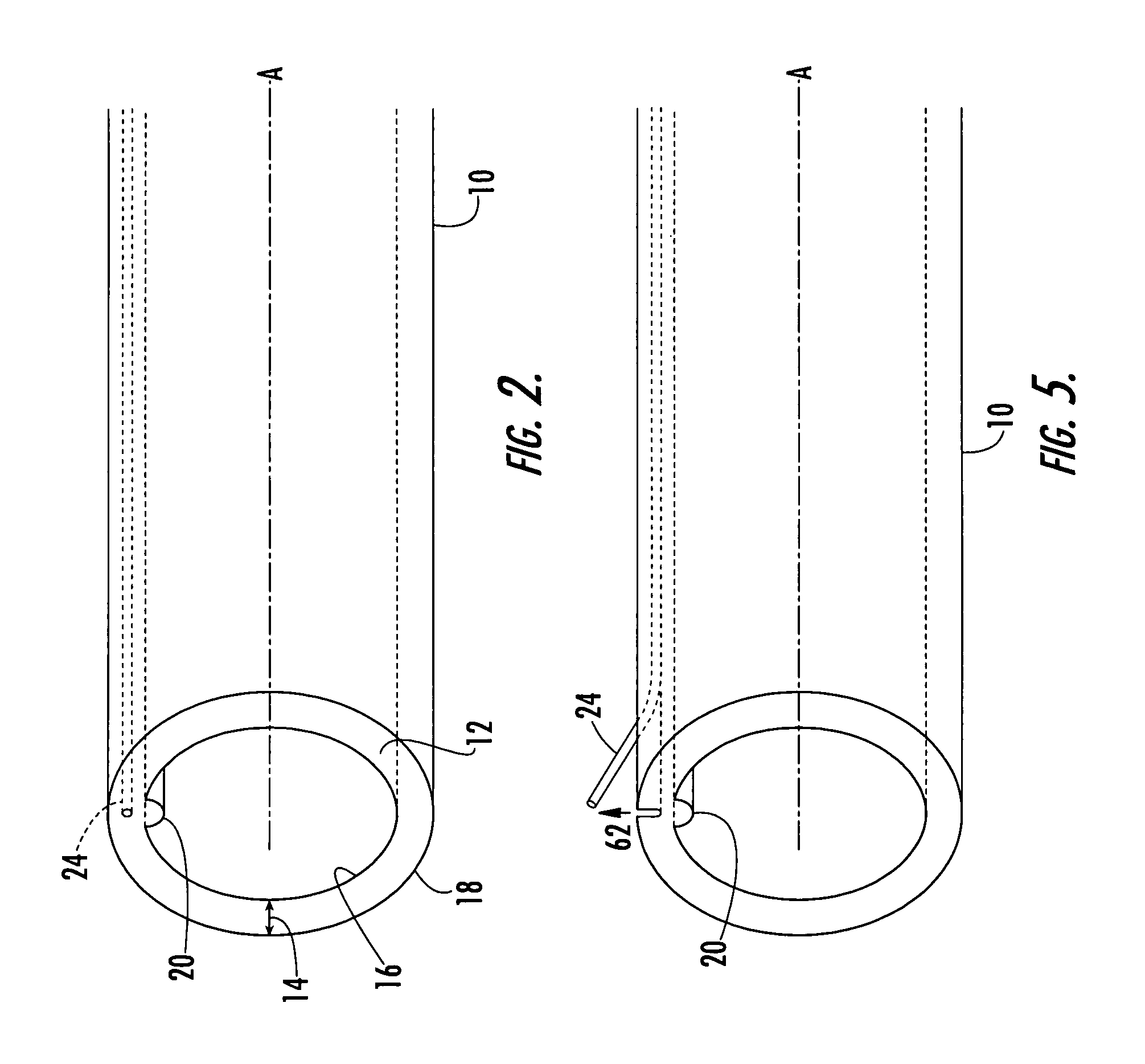

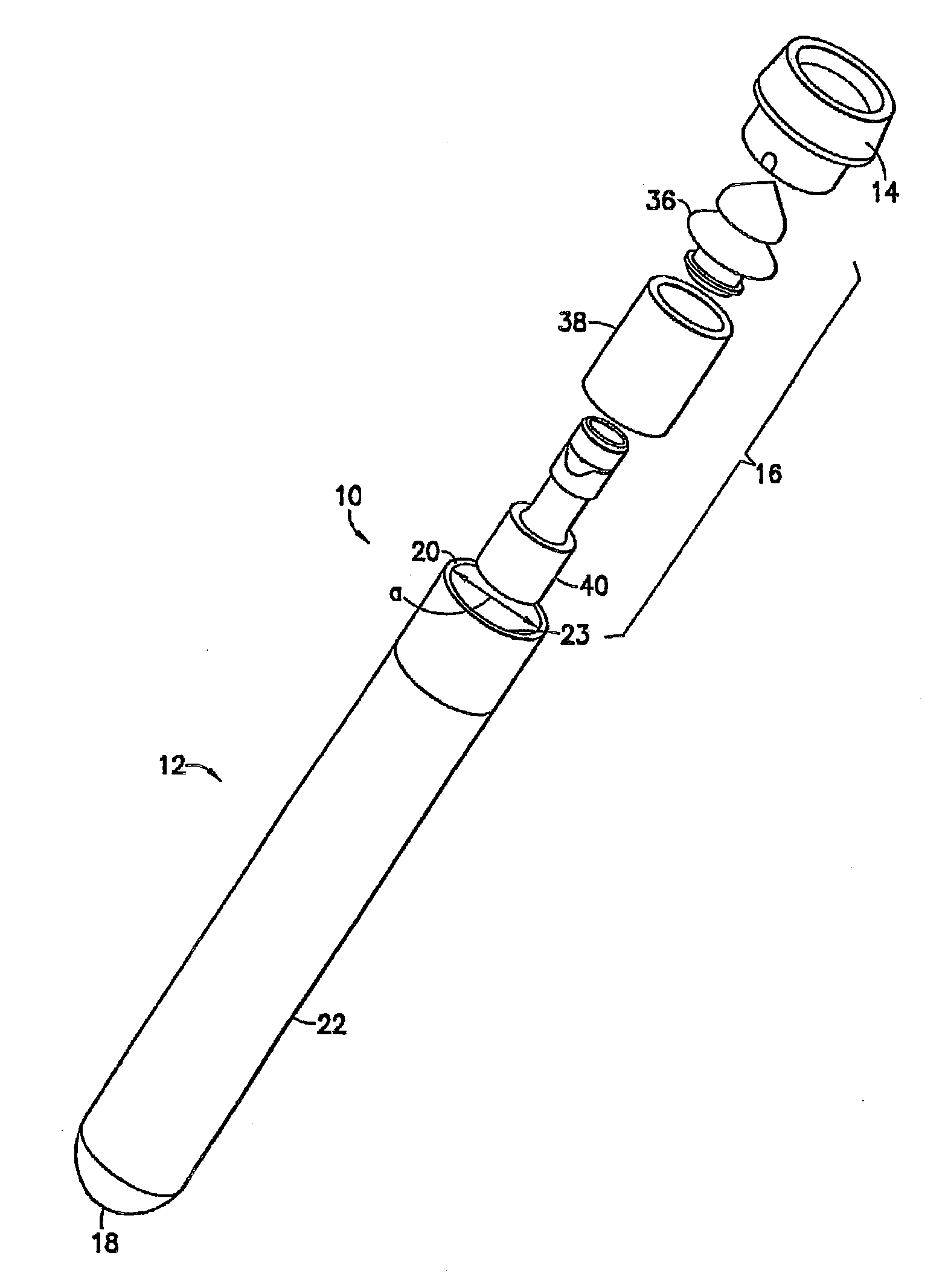

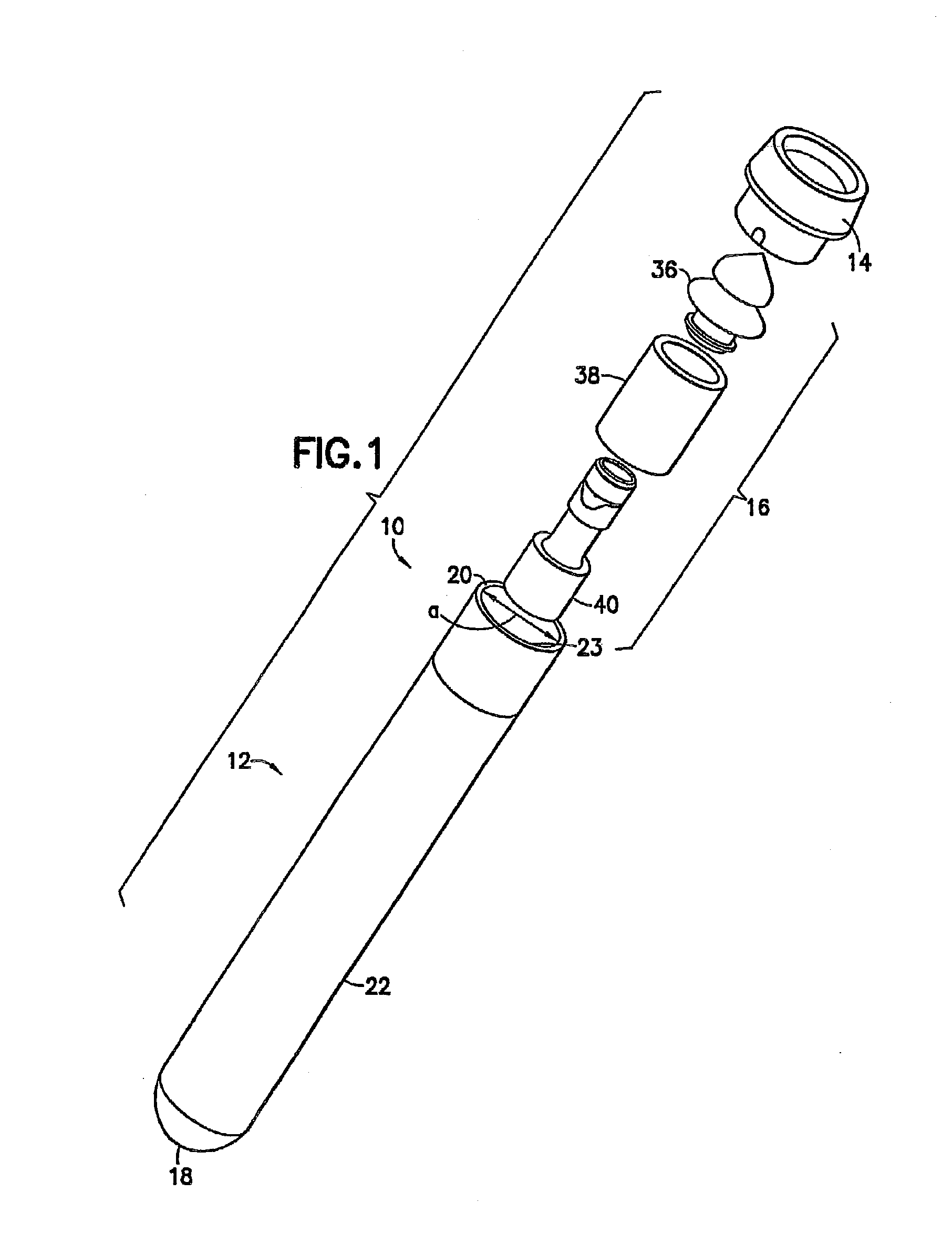

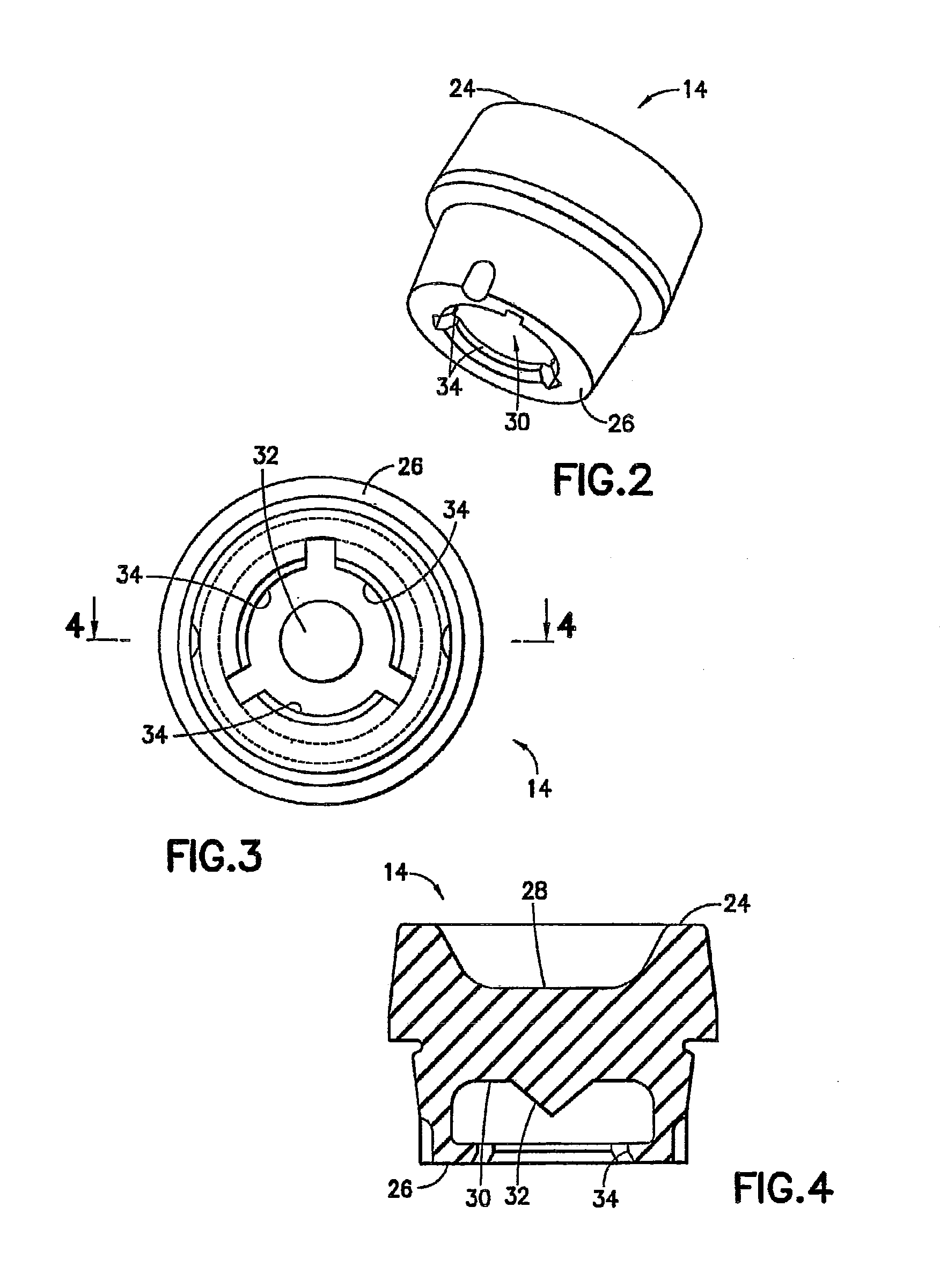

Toneable conduit and method of preparing same

InactiveUS7361835B2Easy to detectSufficient elongationPipe laying and repairPipe elementsEngineeringCatheter

The present invention is a toneable conduit that can transmit a signal and that can therefore be readily detected by toning equipment. In addition, the conduit of the invention can be readily coupled with other conduit to provide extended lengths of conduit. The toneable conduit includes an elongate polymeric tube having a wall with an interior surface, an exterior surface, and a predetermined wall thickness. A channel extends longitudinally within the wall of the elongate polymeric tube and a stabilizing rib extends longitudinally along the interior surface of the wall of the elongate polymeric tube and is located radially inward from the channel. A continuous, coated, high elongation wire is coincident with the channel in the elongate polymeric tube and is coated with a coating composition that prevents the wire from adhering to the polymer melt used to form the elongate polymeric tube. The present invention further includes methods of making the toneable conduit and methods of coupling a first toneable conduit with a second toneable conduit.

Owner:DURA LINE CORP A CORP OF KY

Energy absorbing fabric and method of manufacturing same

Energy absorbing fabrics that are generally flat and that have a controllable and significant elongation distance. The fabrics are comprised of elongation yarns, such as partially oriented yarns (POY), and binder yarns, where the elongation yarns and the binder yarns have various weave-in percentages depending on the desired amount of elongation. In certain embodiments, because they are generally flat, the energy absorbing fabrics are suitable for use in retractors. Also provided are processes of manufacturing generally flat, energy absorbing fabrics.

Owner:YKK CORP OF AMERICA

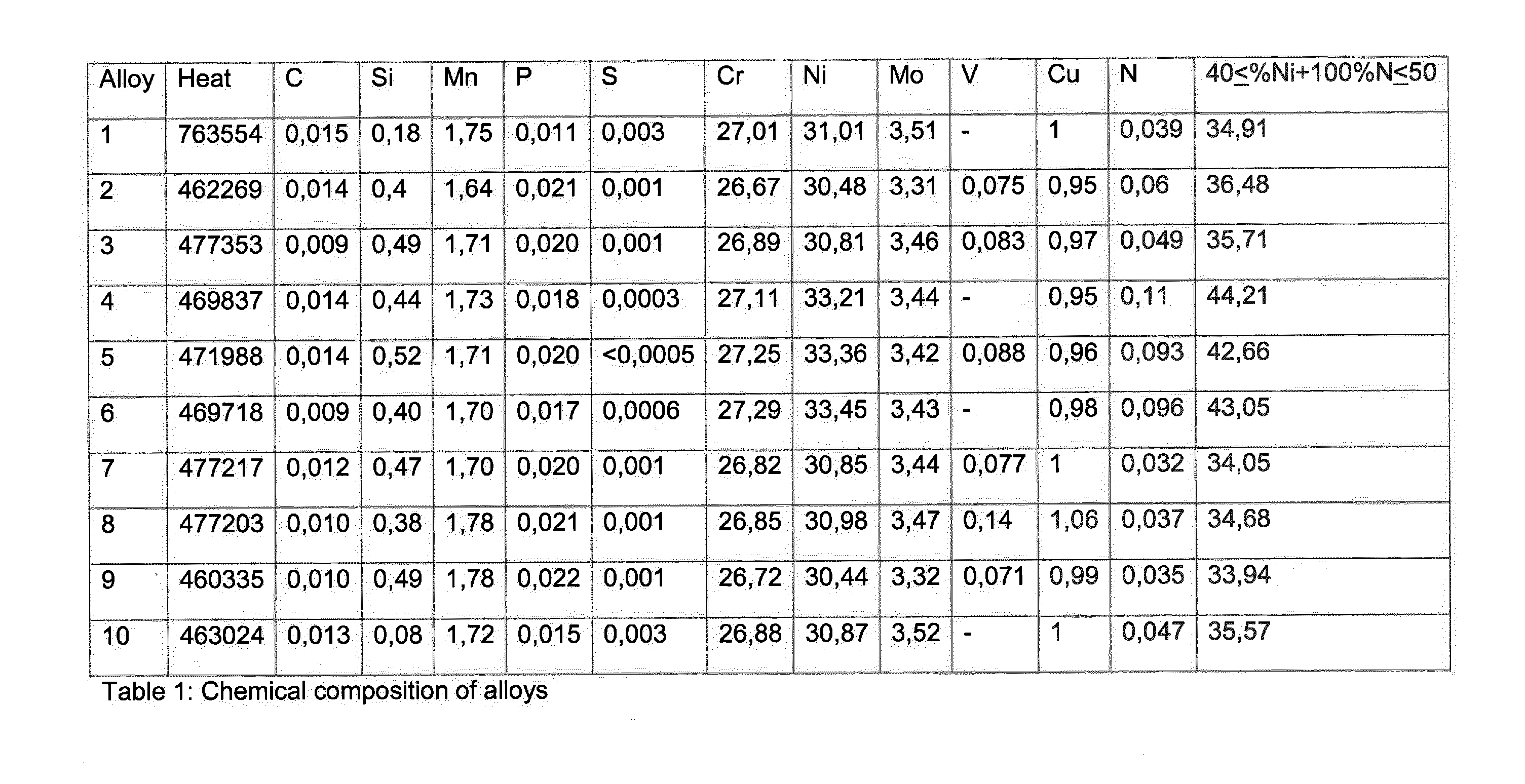

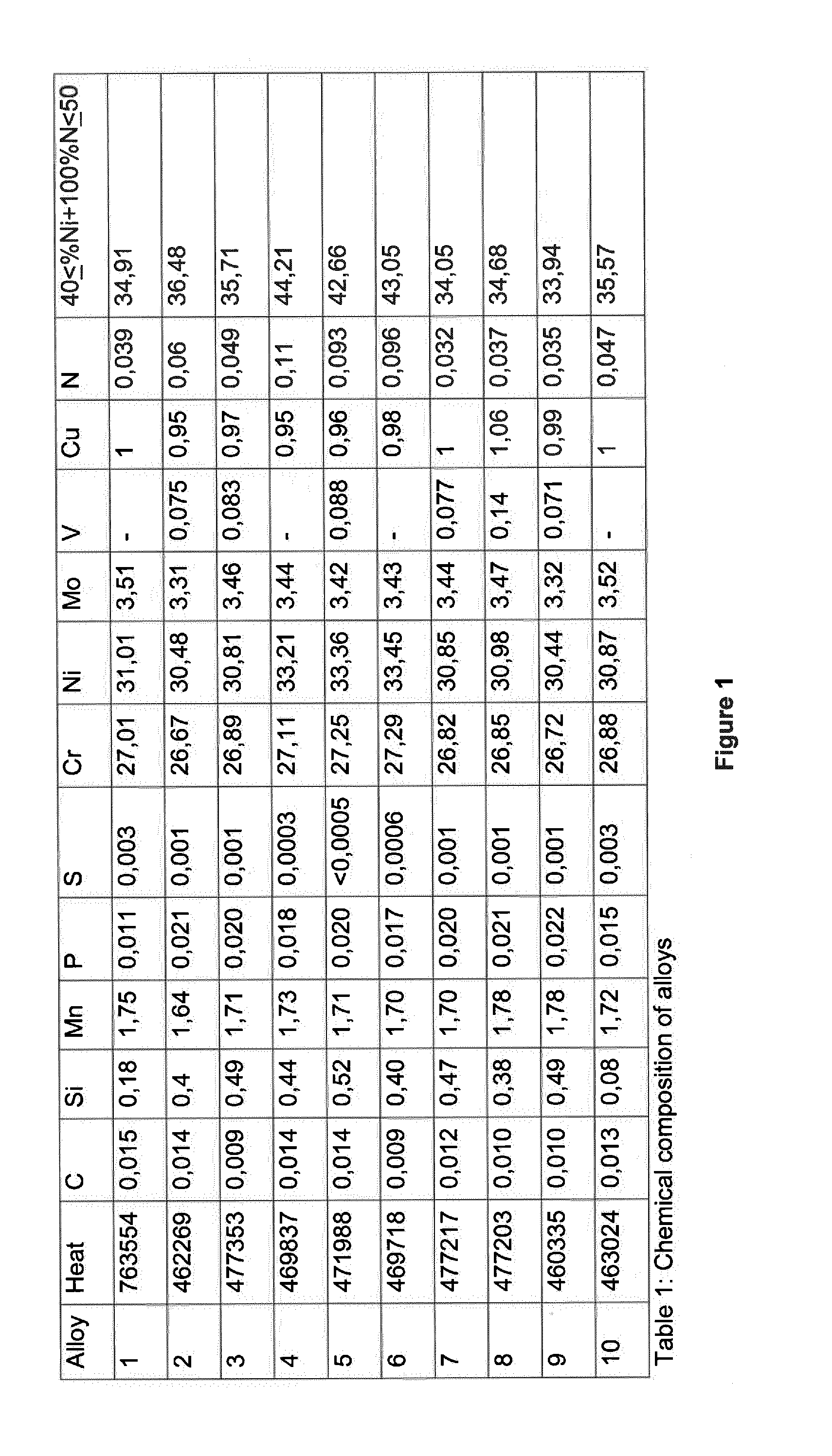

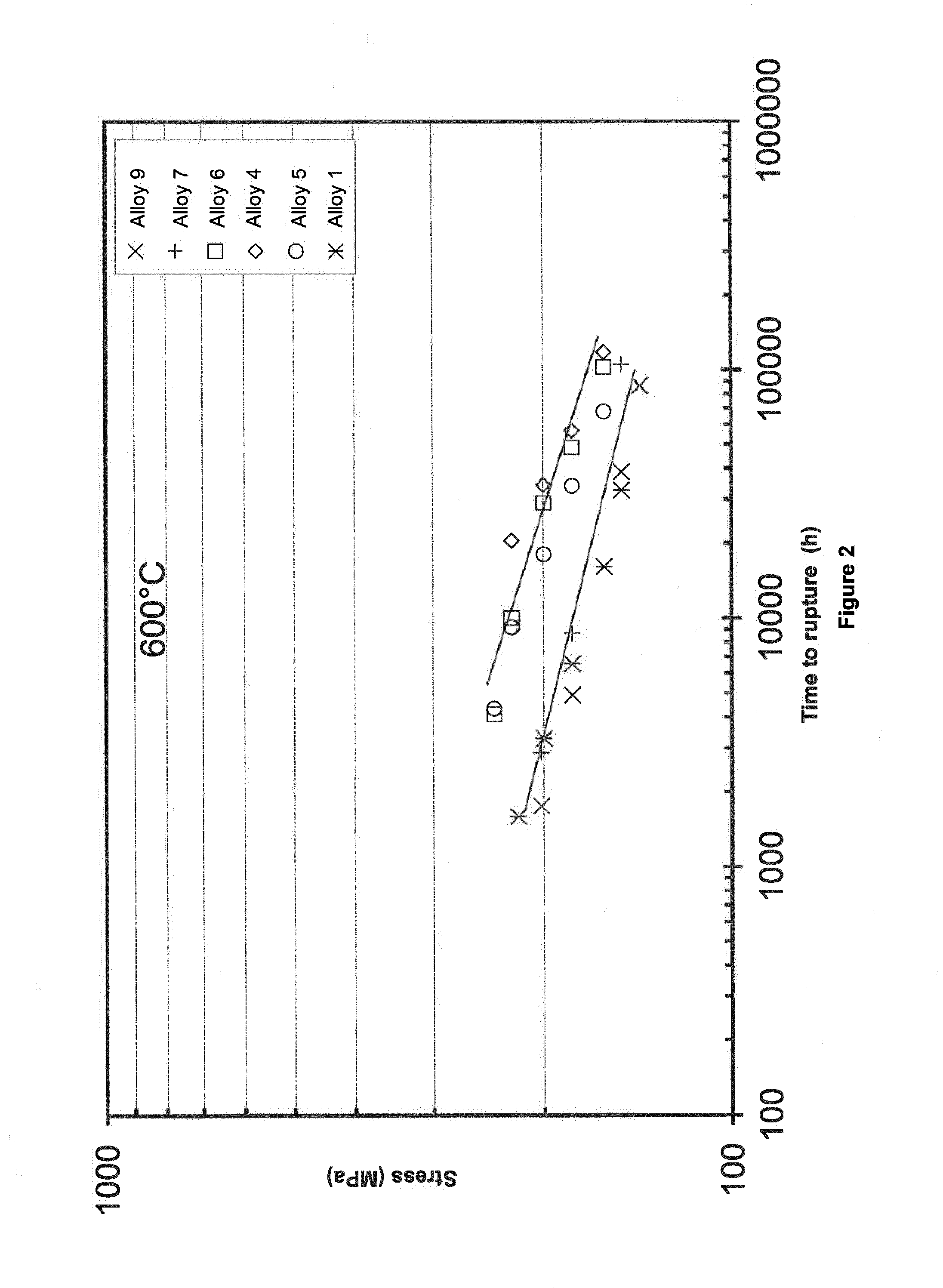

Austenitic alloy

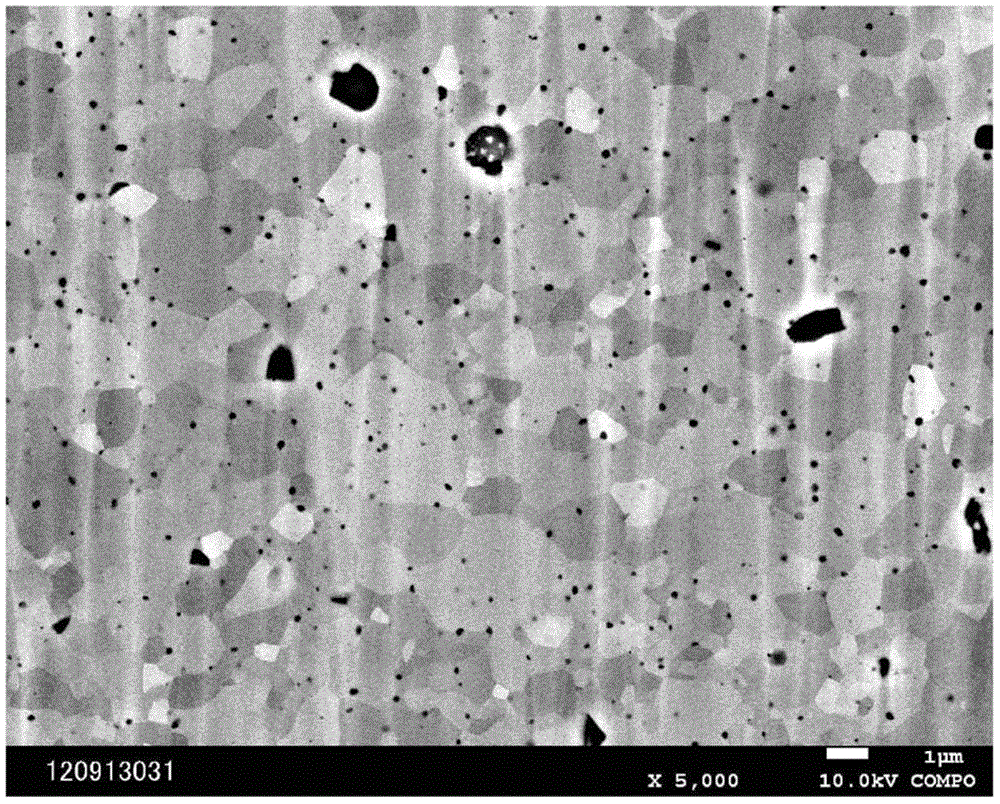

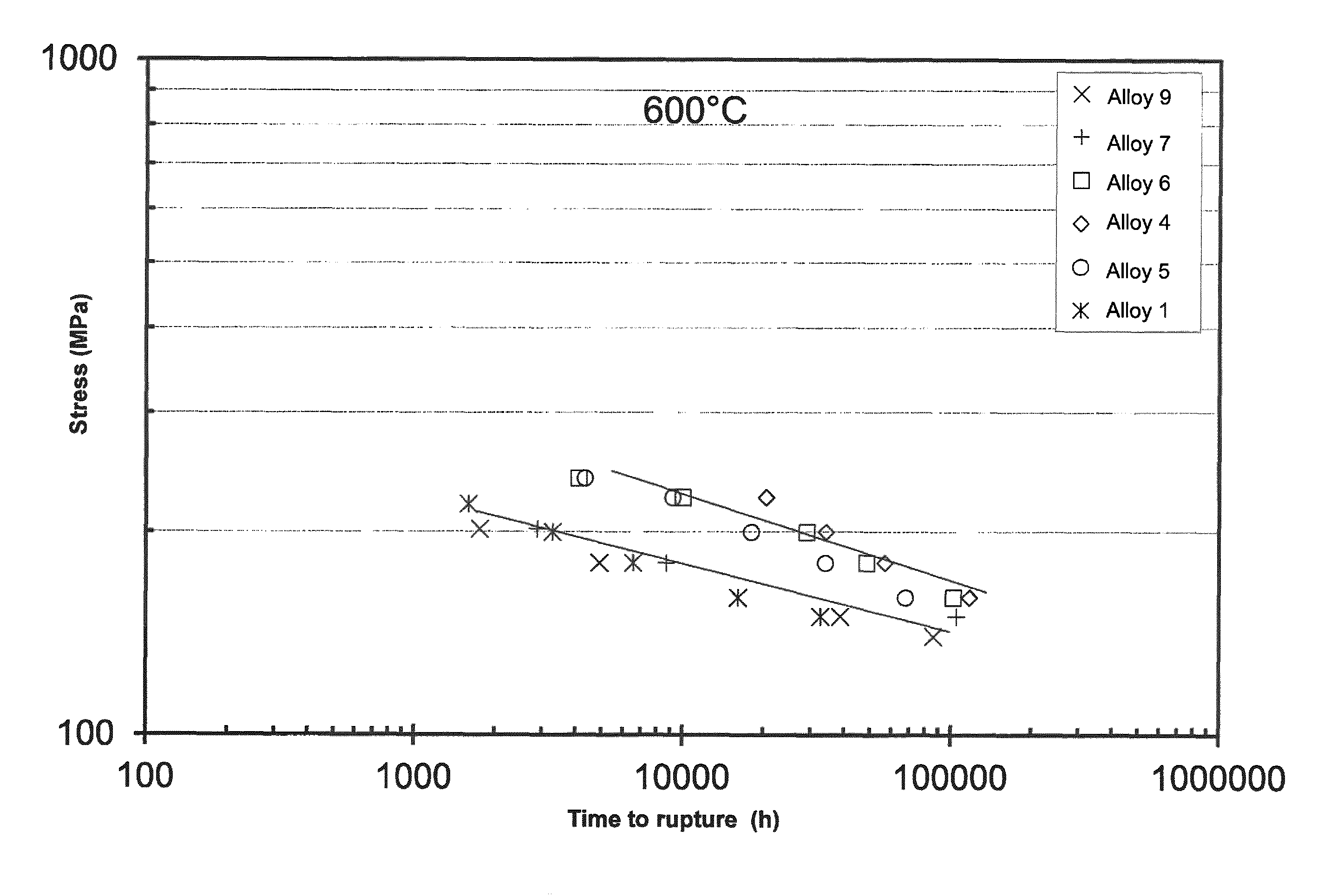

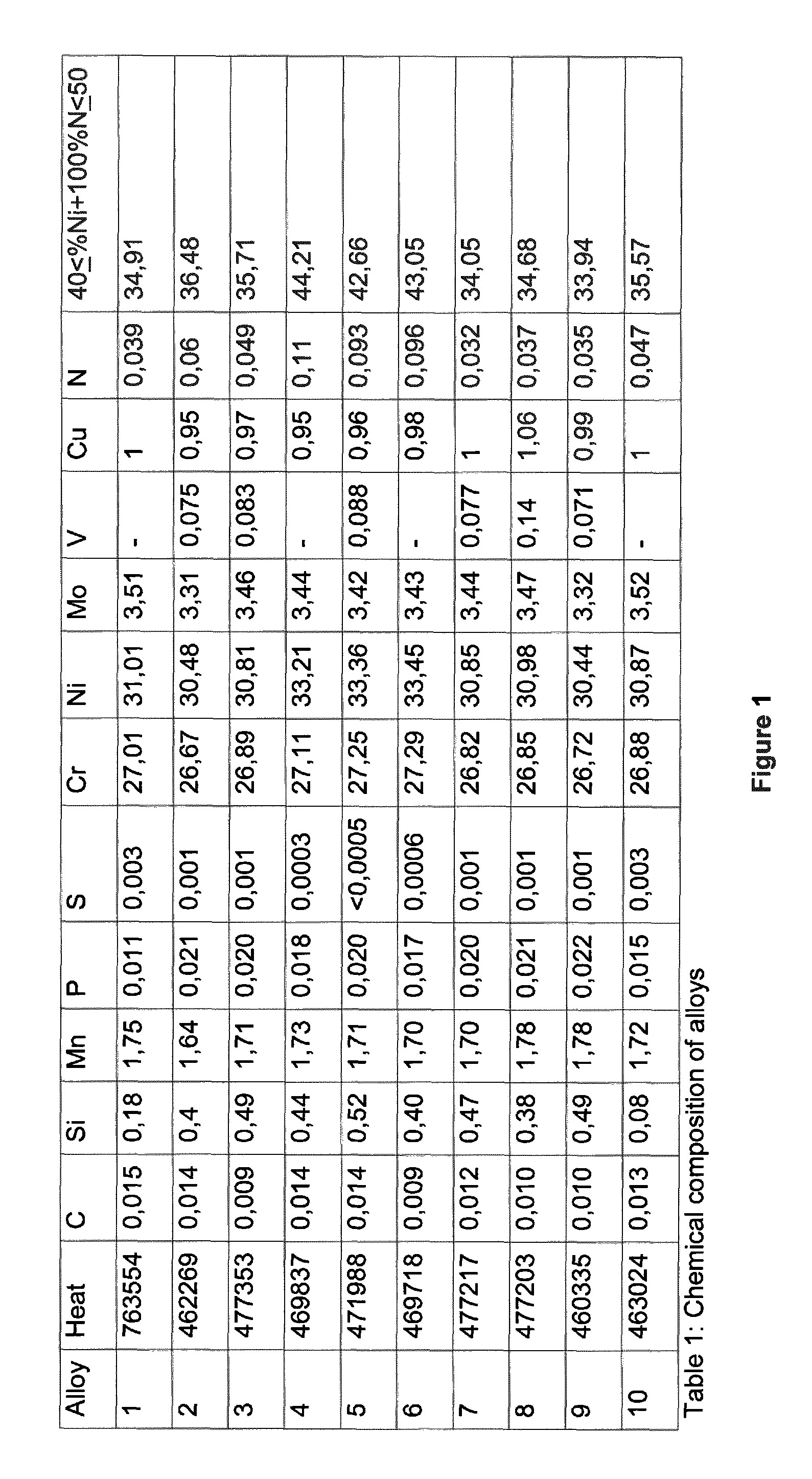

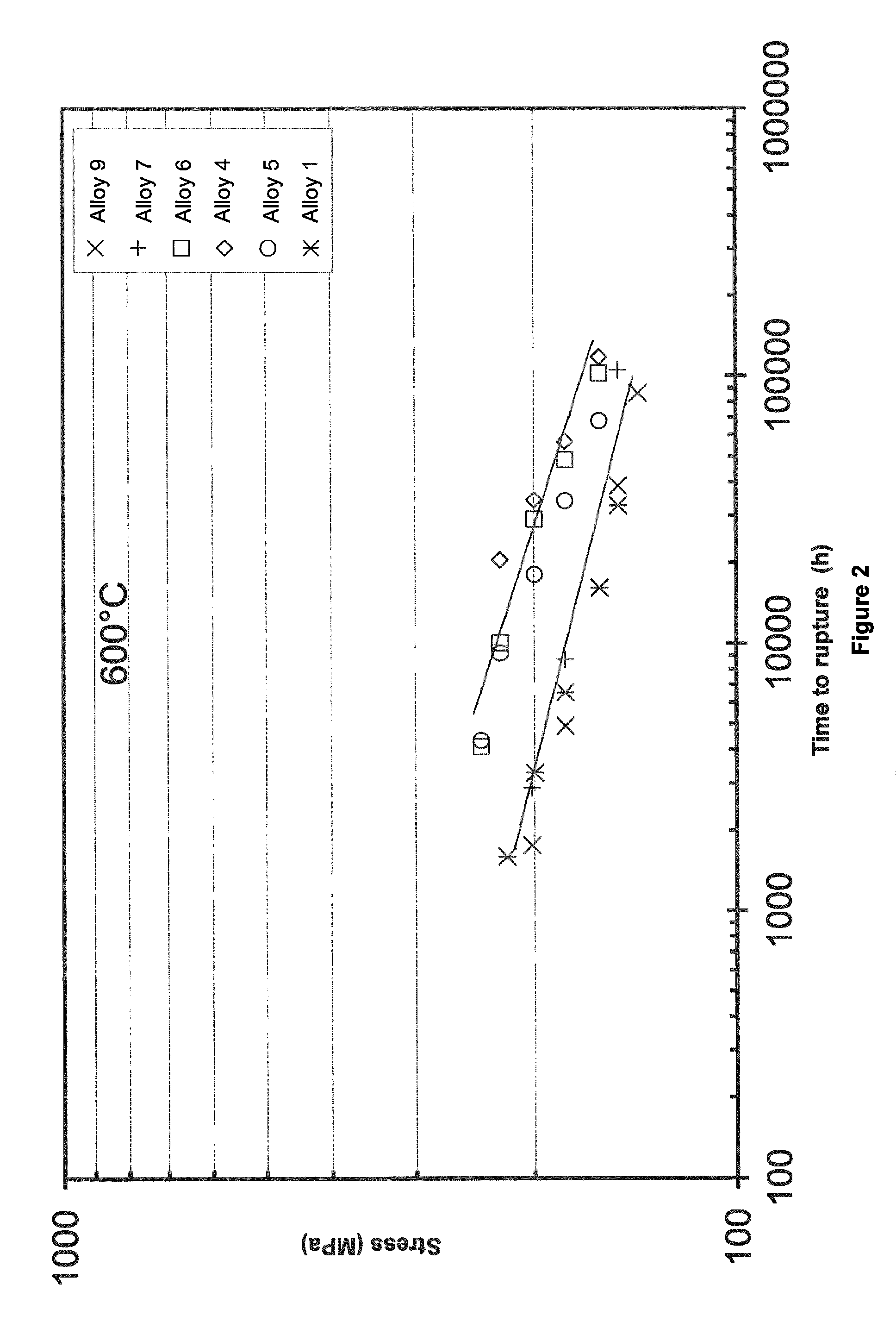

ActiveUS20140348699A1Stable structureImpact of ductility and elongationSteam boilersSteam boilers componentsAlloyImpurity

An austenitic alloy comprising (in weight %):C: 0.01-0.05Si: 0.05-0.80Mn: 1.5-2Cr: 26-34.5Ni: 30-35Mo: 3-4Cu: 0.5-1.5N: 0.05-0.15V: <0.15the balance being Fe and unavoidable impurities, wherein 40<% Ni+100*% N<50.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Device For Separating Components of a Fluid Sample

InactiveUS20110187021A1Reduce overall outer diameterSmall overall deformationLaboratory glasswaresSedimentation separationCentrifugationVolumetric Mass Density

A device for separating heavier and lighter fractions of a fluid sample is provided, the device including a container and a unitary separator located therein, the separator having an overall density between the heavier and light fractions. The separator is capable of moving between the fractions upon centrifugation, and sealing the fractions from one another when centrifugation ends.

Owner:BECTON DICKINSON & CO

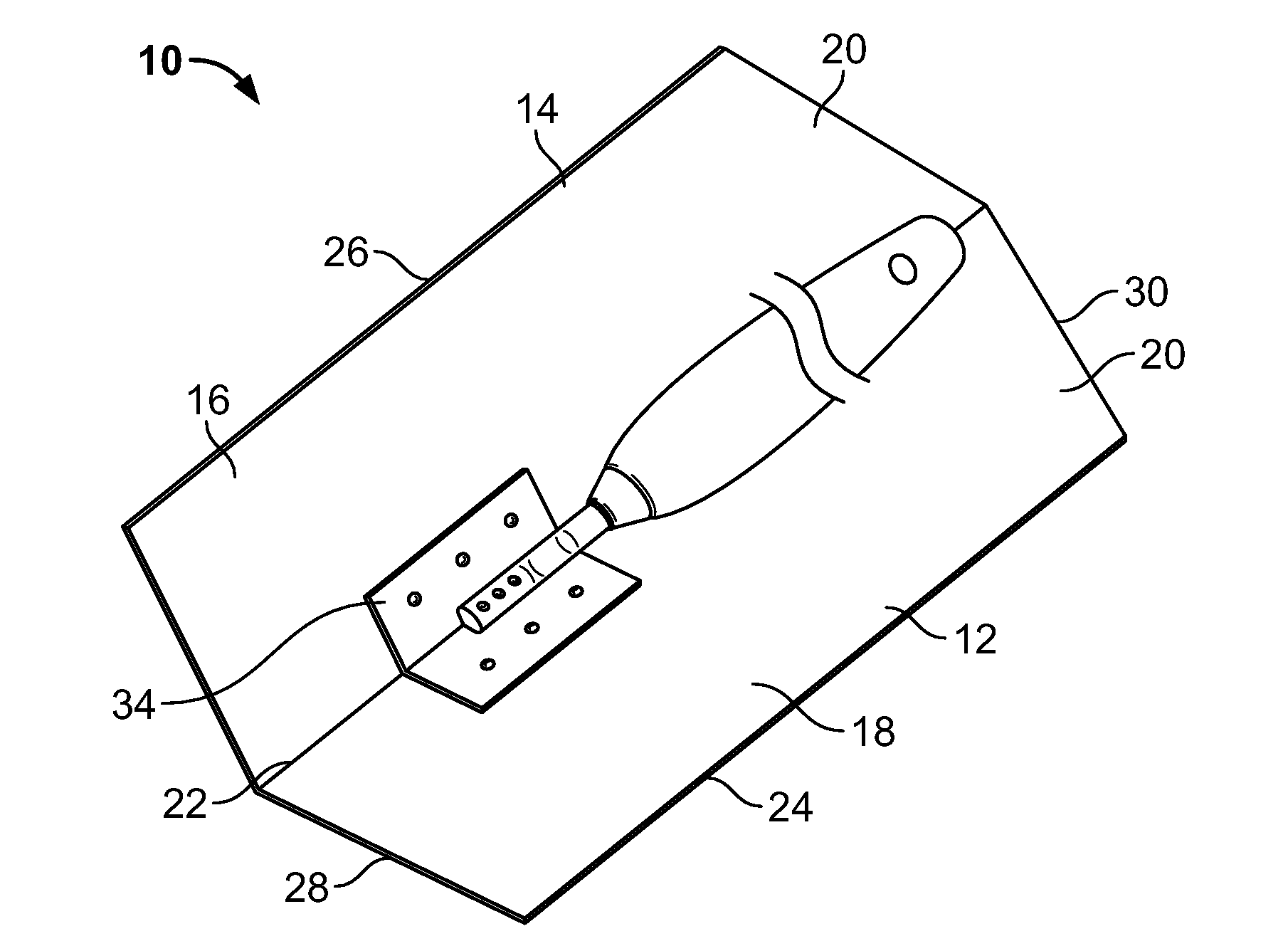

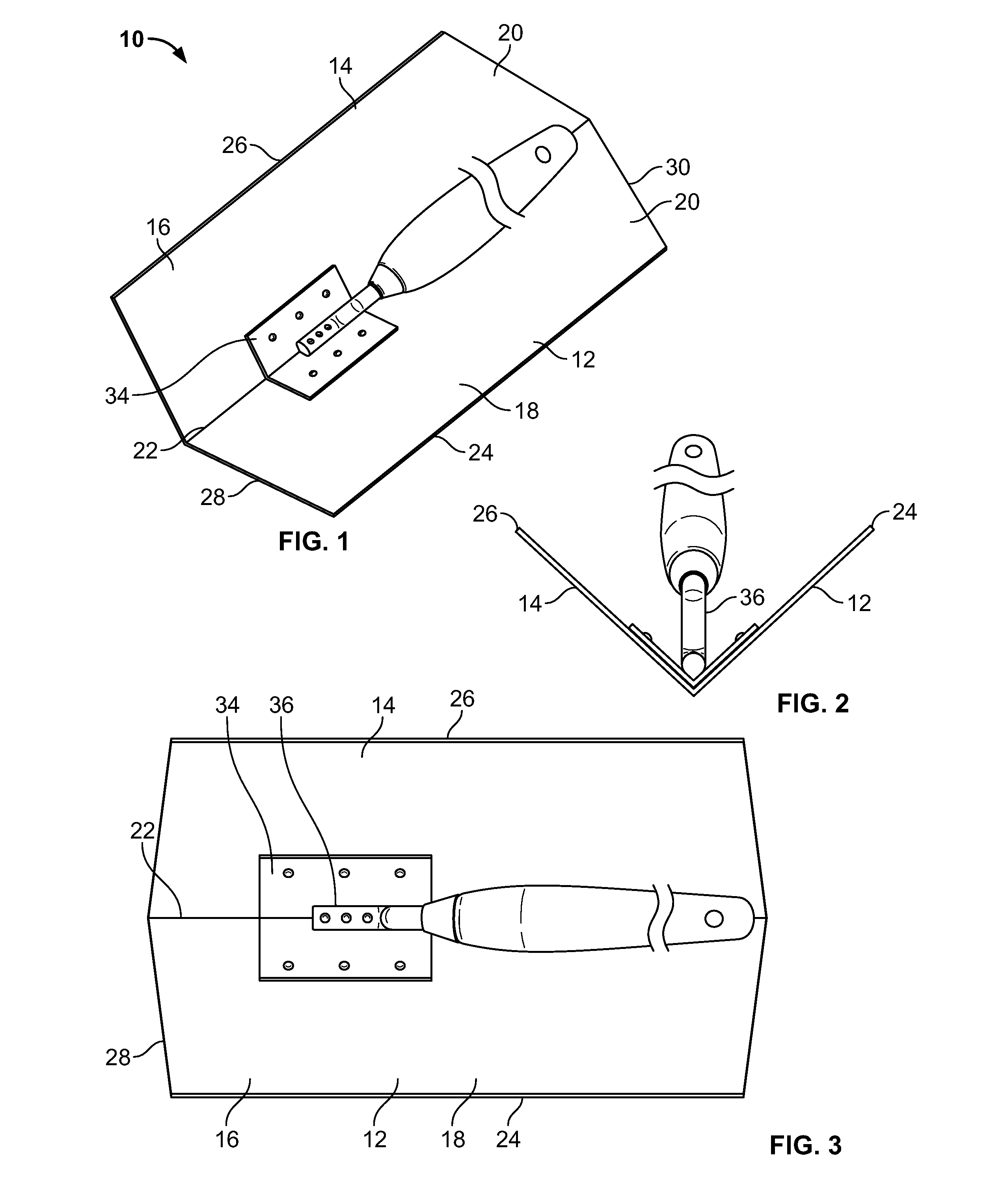

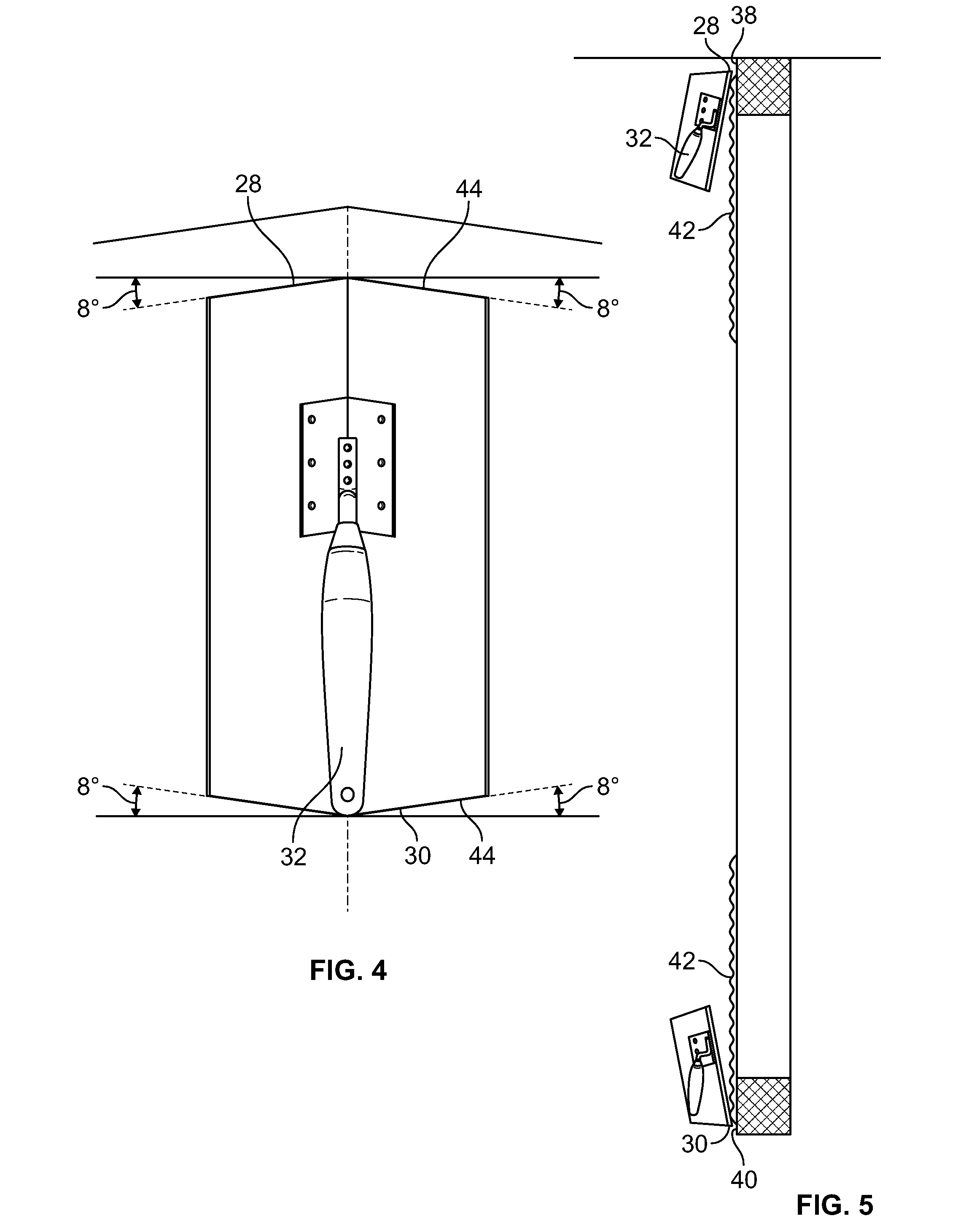

Tool for Finishing Drywall Corners with Elongated Blade Members and Extended Handle

InactiveUS20090031518A1Efficiently manipulatedSufficient elongationLiquid surface applicatorsBuilding constructionsJoint compoundEngineering

A tool for finishing viscous masses, such as joint compound and tape, to inside and outside corners of drywall edges includes elongated blade members with an elongated handle. The elongated blade members and elongated handle provide for the effective manipulation of the tool while moving upwardly or downwardly in a corner without the requirement of changing the tool to another hand of the user or inverting it to complete the finishing the corner.

Owner:SALVINO LARRY

Flooring having surface layer of synthetic resin and wood-based board

InactiveUS7678466B2Improve surface physical propertiesProtect the surfaceConstruction materialCovering/liningsEngineeringParticle board

Disclosed herein is a flooring comprising a surface layer made of a synthetic resin, and a wood-based board as a base. Preferably, the surface layer includes a printed layer formed by general gravure, transfer, heat-sublimation, silk screen or digital printing using a printer, a protective made of a synthetic resin, and a UV-curable or heat-curable surface treatment layer. The wood-based board is selected from plywood, medium-density fiberboard (MDF), high-density fiberboard (HDF), particle board, and resin-wood flour composite board. The flooring may further comprise a bottom layer laminated under the wood-based board for protecting the flooring against moisture from the bottom. The flooring is cut into pieces having an appropriate size, and the pieces are processed into a finished product in a tongue and groove (T & G) shape.

Owner:LG CHEM LTD

Al-mg-si-based, casting aluminum alloy with excellent yield strength and cast member made thereof

ActiveUS20120034128A1Sufficient elongationHigh yield strengthUltimate tensile strengthAluminium alloy

Owner:HITACHI METALS LTD

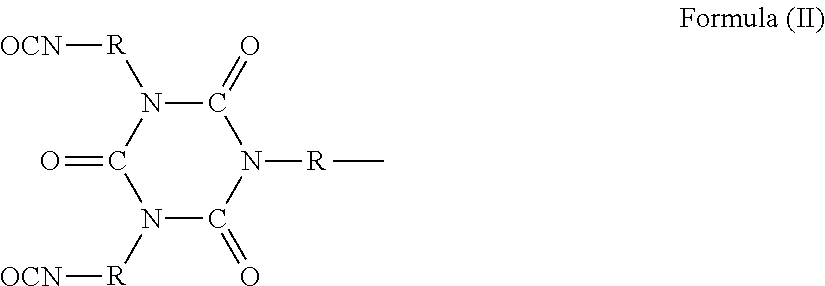

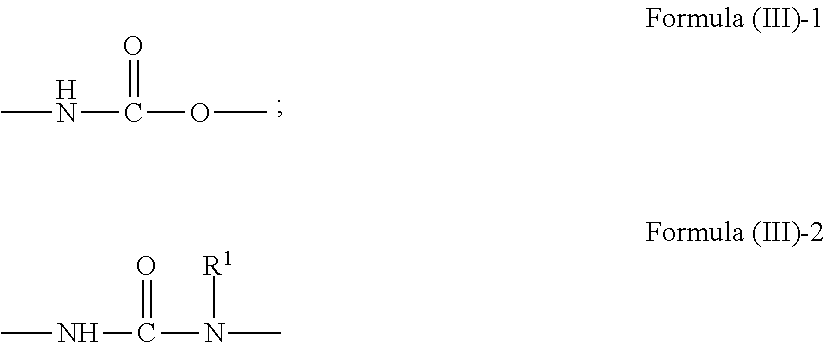

Composition for dip forming and molding obtained by dip forming

A dip-forming composition of the present invention comprises a dip-forming latex containing a copolymer obtained by copolymerizing 100 parts by weight of a monomer mixture containing 70 to 85 parts by weight of a conjugated diene monomer, 10 to 28 parts by weight of an aromatic vinyl monomer, 2 to 5 parts by weight of an ethylenically unsaturated acid monomer and 0 to 18 parts by weight of other monomer copolymerizable with these monomers, said copolymer having a toluene insoluble content of 30% by weight or more and a toluene swelling degree of 70 times or less; and a vulcanizing agent, a vulcanization accelerator and zinc oxide which are blended in said latex in amounts of 0.5 to 2 parts by weight, 0.25 to 1 part by weight and 0.5 to 1 part by weight, respectively, on the basis of 100 parts by weight of a solid content of the latex. There can be provided a dip-formed article exhibiting an excellent touch and feel, sufficient tensile strength and elongation at break and an excellent persistence of close fitting, as well as a dip-forming composition capable of providing such a dip-formed article.

Owner:ZEON CORP

Belt

Owner:E OPPERMANN EINBECK MECHANISCHE GURT & BANDWEBEREI

Polymer mixture, multilayer article containing the same, and process of preparing the multilayer article

ActiveUS11098219B2Sufficient elongationHigh strengthSynthetic resin layered productsGround pavingsPolymer sciencePolymer chemistry

Owner:DOW GLOBAL TECH LLC

930MPa-grade anti-corrosion Ti-Al-V-Zr-Ru titanium alloy pipe material and preparation method thereof

The invention discloses a 930MPa-grade anti-corrosion Ti-Al-V-Zr-Ru titanium alloy pipe material and a preparation method thereof and belongs to the technical field of petroleum and natural gas industry oil well pipe manufacturing. The 930MPa-grade anti-corrosion Ti-Al-V-Zr-Ru titanium alloy pipe material is composed of, by mass, 5.8-6.5% of Al, 2.0-3.0% of V, 1.0-1.7% of Zr, 0.5-1.0% of Mo, 0.1-0.3% of Ru and the balance Ti and inevitable impurities. The preparation method comprises the steps of smelting, casting, forging, extruding, rolling, annealing treatment, solid solution treatment, pre-stretching treatment and aging treatment. According to a titanium alloy drill stem obtained through the above process route, the yield strength is larger than 930 MPa, and the corrosion resistance isgood.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Nuclear radiation resistant vulcanized rubber and preparation method thereof

The invention belongs to the technical field of special rubber, and particularly relates to nuclear radiation resistant vulcanized rubber and a preparation method thereof. The radiation-resistant rubber composition comprises the following raw material components in parts by weight: 80-90 parts of EPM rubber, 30-50 parts of a radiation-resistant auxiliary agent, 40-60 parts of a filling agent, 3-8 parts of a vulcanizing agent, 1.5-3.0 parts of an accelerant, 10-20 parts of a plasticizer and 2-5 parts of an anti-aging agent, and is characterized in that the radiation-resistant auxiliary agent comprises lead oxide, bismuth oxide, barium sulfate and / or antimony trioxide. The nuclear radiation resistant vulcanized rubber obtained according to the preparation method has stable protection and shielding performance on nuclear radiation in the actual use process, also has excellent comprehensive physical performance, and has the advantages of stable performance, safety and reliability.

Owner:河北宇通特种胶管有限公司

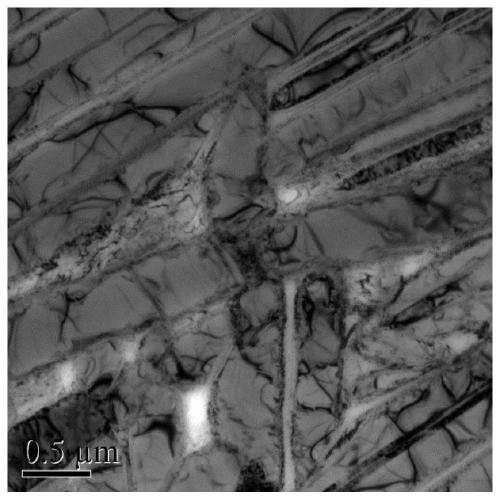

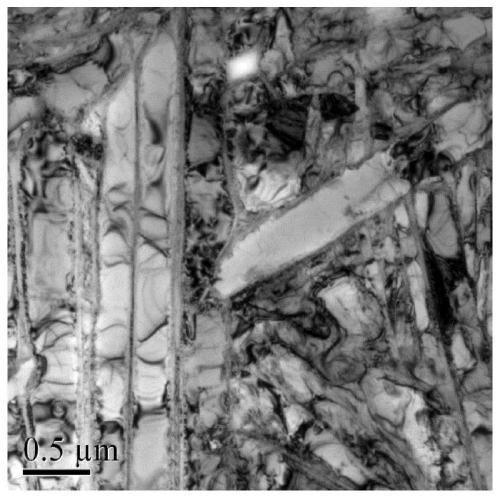

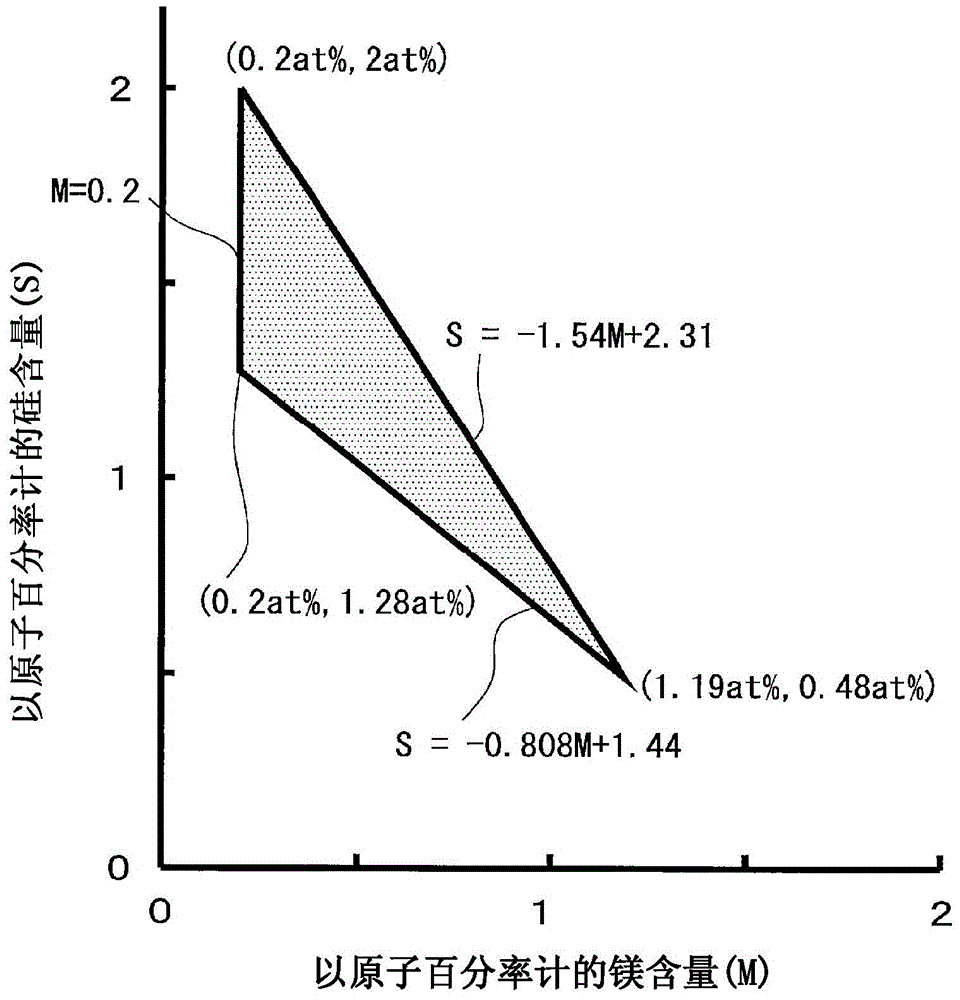

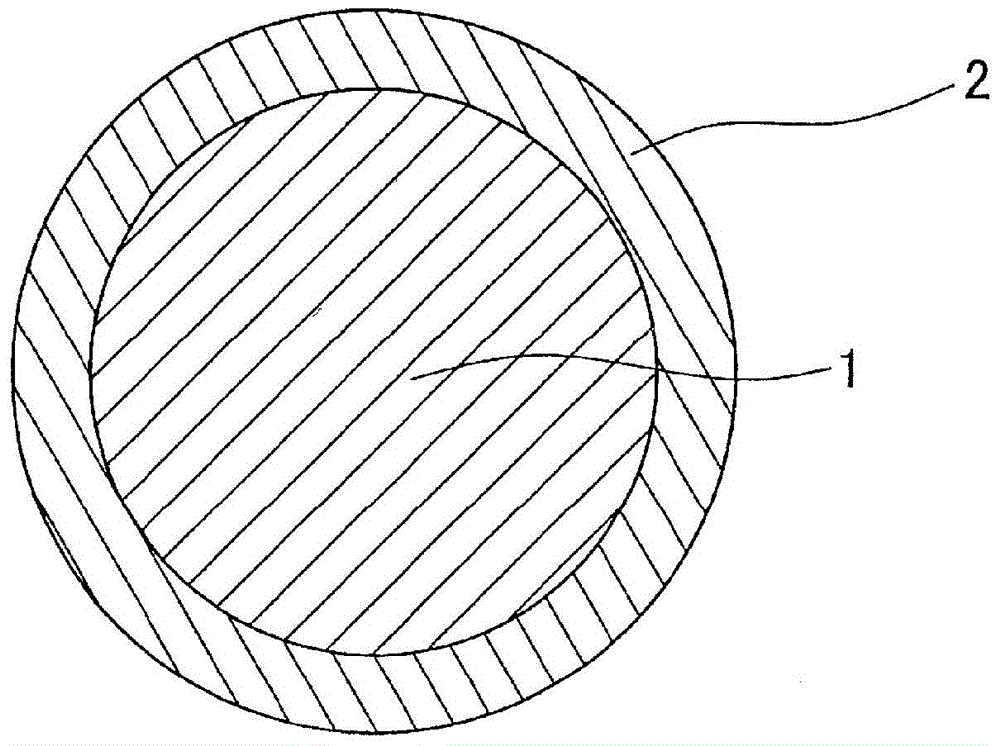

Aluminum alloy wire, electric wire, cable and wire harness

InactiveCN104968816AStrong enoughSufficient elongationSingle bars/rods/wires/strips conductorsConductive materialElectrical conductorNumber density

Provided is an aluminum alloy wire which satisfies all the requirements necessary as a thin conductor for an automotive wire, namely, sufficient strength, sufficient elongation and sufficient conductivity. An aluminum alloy wire in which: the magnesium atomic content (M) (at%) and the silicon (Si) atomic content (S) (at%) fall respectively within the ranges represented by formulae (1) and (2) with the balance being composed of aluminum and unavoidable impurities; the mean grain size in the metallographic structure observed in a cross section is 3 to 20μm; the precipitate size in the metallographic structure observed in the cross the section is 100nm or less; and the number density of precipitates in the cross section is 1 / μm2 or more. [Numerical formula 1] 0.2 ≤ M ≤ 1.19 ··· (1) -0.81M + 1.44 ≤ S ≤ -1.54M + 2.31 ··· (2)

Owner:YAZAKI CORP

Austenitic alloy

ActiveUS9587295B2Improve corrosion resistanceSolve the lack of resistanceSteam boilersSteam boilers componentsAlloyCopper

An austenitic alloy comprising (in weight %):C: 0.01-0.05Si: 0.05-0.80Mn: 1.5-2Cr: 26-34.5Ni: 30-35Mo: 3-4Cu: 0.5-1.5N: 0.05-0.15V: <0.15the balance being Fe and unavoidable impurities, wherein 40<% Ni+100*% N<50.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Copper, copper alloy, and manufacturing method therefor

InactiveUS20080277032A1Improve bending performanceImprove ductilityMetal rolling arrangementsTensile testingCopper alloy

Copper and copper alloy comprises: a structure having fine crystal grains with grain size of 1 μm or less after a final cold rolling with a reduction η, wherein η is expressed in the following formula and satisfying η≧3; and an elongation of 2% or more in a tensile test.η=ln(T0 / T1)T0: plate thickness before rolling, T1: plate thickness after rolling.

Owner:JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com