Compound centrifugal manufacturing method for sink roller or stabilizing roller

A technology of centrifugal compounding and manufacturing method, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of spray coating failure, cracks, non-densification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

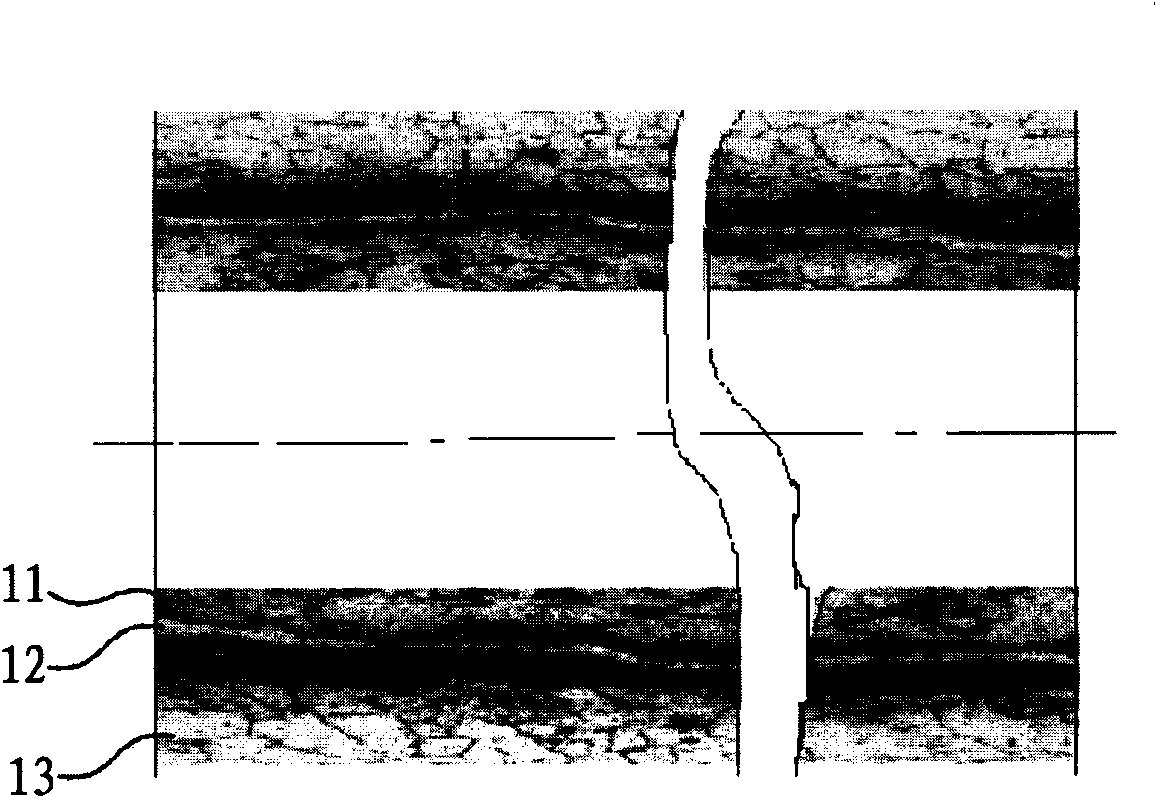

[0034] The submerged substrate of the sinking roller manufactured by centrifugal compounding is made of 00Cr17Ni14Mo2 stainless steel, and its chemical composition is C≤0.03wt%, Cr 16wt%~18wt%, Ni 10wt%~14wt%, Mo 2.00wt%~3.00wt%, Mn≤2.00wt% %, Si≤1.00wt%; its working surface layer is a cobalt-based alloy, and the composition of the cobalt-based alloy is: Cr 25wt%, Ni 5wt%, W 3wt%, Mo 3wt%, V 0.1wt%, Ti 0.1wt%, C 0.6wt%, Fe 6wt%, Si 0.5wt%, Mn 0.3wt%, Al 0.5wt%, Nb 1.5wt%, P<0.07wt%, S<0.07wt%, and the rest is Co.

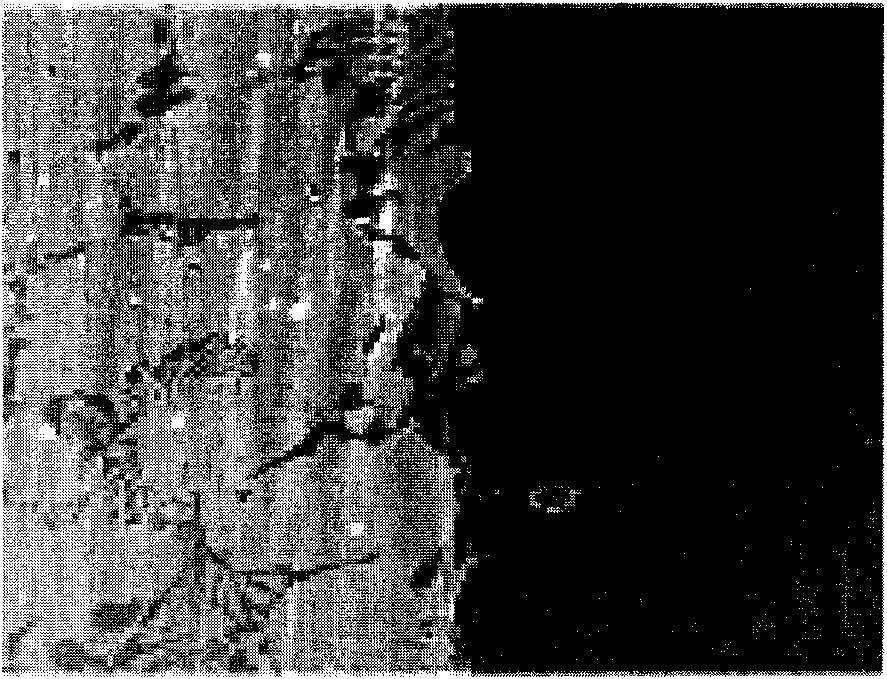

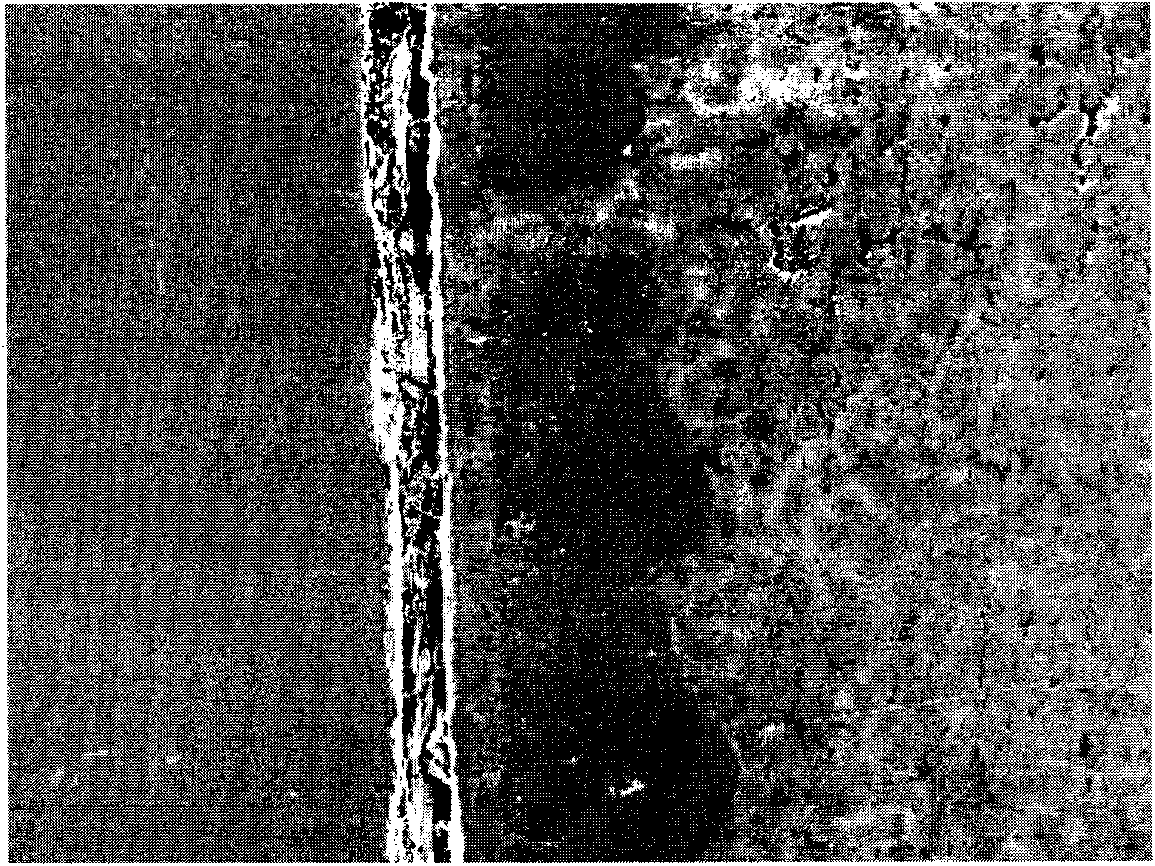

[0035] The manufacturing steps are as follows: ① Smelt 00Cr17Ni14Mo2 raw material molten iron with an electric arc furnace, then use an AOD refining furnace first, and then use a VOD refining furnace to smelt qualified 00Cr17Ni14Mo2 molten metal; use an induction furnace to smelt the chemical composition of Cr 25wt%, Ni 5wt%, W 3wt%, Mo 3wt%, V 0.1wt%, Ti 0.1wt%, C 0.6wt%, Fe 6wt%, Si 0.5wt%, Mn 0.3wt%, Al 0.5wt%, Nb 1.5wt%, P<0.07wt% %, S<0.07wt%, and the rest is ...

Embodiment 2

[0038] The submerged substrate of the sinking roller made by centrifugal compounding is austenitic heat-resistant stainless steel SUS316, and its chemical composition is C≤0.08wt%, Cr 16wt%~18wt%, Ni 10wt%~14wt%, Mo 2.00wt%~3.00wt%, Mn≤2.00wt%, Si≤1.00wt%; the working surface layer is a cobalt-based alloy, and the composition of the cobalt-based alloy is: Cr 20wt%, Ni 3wt%, W 5wt%, Mo 2wt%, V 0.2wt%, Ti 0.2wt%, C 0.6wt%, Fe 12wt%, Al 0.5wt%, Mn 0.7wt%, Nb 1.0wt%, Si 0.4wt%, P<0.07wt%, S<0.07wt%, the rest is Co.

[0039] The manufacturing steps are as follows: ① smelt SUS316 raw material molten iron with electric arc furnace, and then smelt qualified SUS316 molten metal with AOD refining furnace; 0.2wt%, Ti 0.2wt%, C 0.6wt%, Fe 12wt%, Al 0.5wt%, Mn 0.7wt%, Nb 1.0wt%, Si 0.4wt%, P<0.07wt%, S<0.07wt%, The rest is a qualified cobalt-based alloy metal liquid of Co. ②Centrifugally cast the outer layer of cobalt-based alloy metal liquid with a centrifugal casting machine, and when ...

Embodiment 3

[0042] The bottom substrate of the stabilizing roller manufactured by centrifugal compounding is heat-resistant stainless steel ZG07Cr19Ni9, and its chemical composition is C 0.07wt%, Cr 18%-21wt%, Ni 8.0wt%-11.0wt%, Mn 1.5wt%, Si1.5wt%, P ≤0.040wt%, S≤0.030wt%; the working surface layer is a cobalt-based alloy, and the composition of the cobalt-based alloy is: Cr 26wt%, Ni 3wt%, W 5wt%, Mo 2wt%, V 0.2wt%, Ti 0.2 wt%, C 1.5wt%, Fe 12wt%, Al 0.8wt%, Mn 0.7wt%, Nb 1.0wt%, Si 1.0wt%, P<0.07wt%, S<0.07wt%, and the rest is Co.

[0043]The manufacturing steps are as follows: ① use electric arc furnace to smelt ZG07Cr19Ni9 raw material molten iron, and then use ladle refining furnace to smelt qualified ZG07Cr19Ni9 molten metal; use vacuum induction furnace to smelt chemical composition of Cr26wt%, Ni 3wt%, W 5wt%, Mo 2wt%, V 0.2wt%, Ti 0.2wt%, C 1.5wt%, Fe 12wt%, Al 0.8wt%, Mn 0.7wt%, Nb 1.0wt%, Si1.0wt%, P<0.07wt%, S<0.07wt%, The rest is a qualified cobalt-based alloy metal liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com