930MPa-grade anti-corrosion Ti-Al-V-Zr-Ru titanium alloy pipe material and preparation method thereof

A titanium alloy and pipe technology, which is applied in the field of oil well pipe manufacturing in the oil and gas industry, can solve the problems of high operating cost of deep wells in marine engineering, failure accidents of oil pipes, shortening the service life of pipes, etc., so as to reduce the operating cost of deep wells and improve the yield strength. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

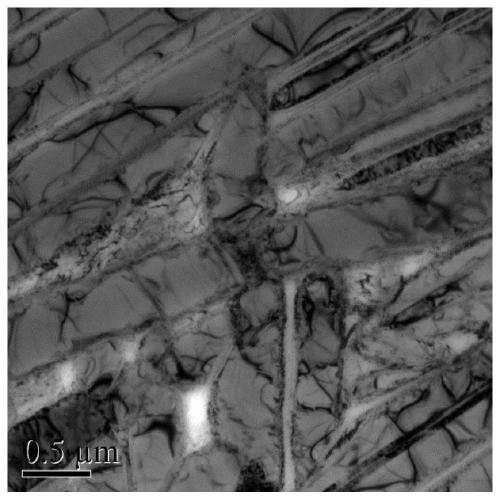

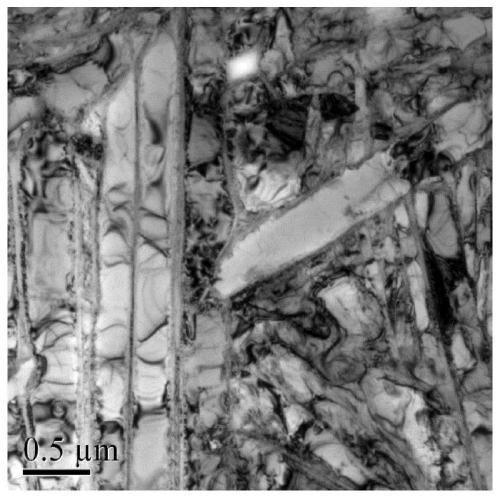

Image

Examples

Embodiment 1

[0031] A method for manufacturing a 930MPa grade Ti-Al-V-Zr-Ru corrosion-resistant titanium alloy pipe, comprising the steps of:

[0032] S1: According to the mass percentage Al: 5.85%, V: 2.35%, Zr: 1.2%, and the balance is Ti, weigh the raw materials, place them in a vacuum consumable furnace for smelting and casting, and obtain a tube blank;

[0033] S2: hot-forging the tube blank obtained in the above S1 in advance, that is, placing it in a furnace at 1000°C for 1 hour;

[0034] S3: Squeeze and deform the hot-forged tube billet of S2 with an extrusion ratio of 15 and an extrusion speed of 85mm / s; then place it in a furnace at 470°C for 1.0h to obtain a semi-finished pipe;

[0035] S4: Anneal the semi-finished pipe product after S3 rolling, that is, keep it at 700°C for 1h; Insulate at 915°C for 2 hours, and air cool to obtain titanium alloy pipes;

[0036]S5: pre-stretch the titanium alloy pipe prepared in S4, and apply 1.0% pre-stretch deformation; then artificially age...

Embodiment 2

[0039] A method for manufacturing a 930MPa grade Ti-Al-V-Zr-Ru corrosion-resistant titanium alloy pipe, comprising the steps of:

[0040] S1: According to the mass percentage Al: 5.8%, V: 3.0%, Zr: 1.7%, Ru: 0.1%, weigh the raw materials, place them in a vacuum consumable furnace for smelting and casting, and obtain a tube blank;

[0041] S2: hot-forging the tube blank obtained in the above S1 in advance, that is, placing it in a furnace at 980°C for 1.5 hours;

[0042] S3: Squeeze and deform the hot-forged tube billet of S2 with an extrusion ratio of 30 and an extrusion speed of 95mm / s; then place it in a furnace at 400°C for rolling for 1.5 hours to obtain a semi-finished pipe;

[0043] S4: Anneal the semi-finished pipe after S3 rolling, that is, keep it at 650°C for 1.2h; Insulate at 910°C for 2 hours, and air-cool to obtain titanium alloy pipes;

[0044] S5: pre-stretch the titanium alloy pipe produced in S4, and apply a pre-stretch deformation of 1.5%; then artificially...

Embodiment 3

[0047] A method for manufacturing a 930MPa grade Ti-Al-V-Zr-Ru corrosion-resistant titanium alloy pipe, comprising the steps of:

[0048] S1: According to the mass percentage Al: 6.5%, V: 2.0%, Zr: 1.0%, Ru: 0.3%, weigh the raw materials, place them in a vacuum consumable furnace for smelting and casting, and obtain the tube blank;

[0049] S2: hot-forging the tube blank obtained in the above S1 in advance, that is, placing it in a furnace at 1050°C for 0.8h;

[0050] S3: Squeeze and deform the tube billet after hot forging in S2, the extrusion ratio is 45, and the extrusion speed is 110mm / s; then place it in a furnace at 500°C for rolling for 0.5h to obtain a semi-finished pipe;

[0051] S4: Perform annealing treatment on the semi-finished pipe product after S3 rolling, that is, keep it at 750°C for 0.8h; Insulate at 920°C for 2 hours, and air-cool to obtain titanium alloy pipes;

[0052] S5: pre-stretch the titanium alloy pipe produced in S4, and apply 2.0% pre-stretch def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com