Manually Operable Drain Device

a man-operated, drain device technology, applied in water installations, washstands, constructions, etc., can solve problems such as difficulty or inability to meet, complex apparatus, and difficulty in providing various man-operated drain strainers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

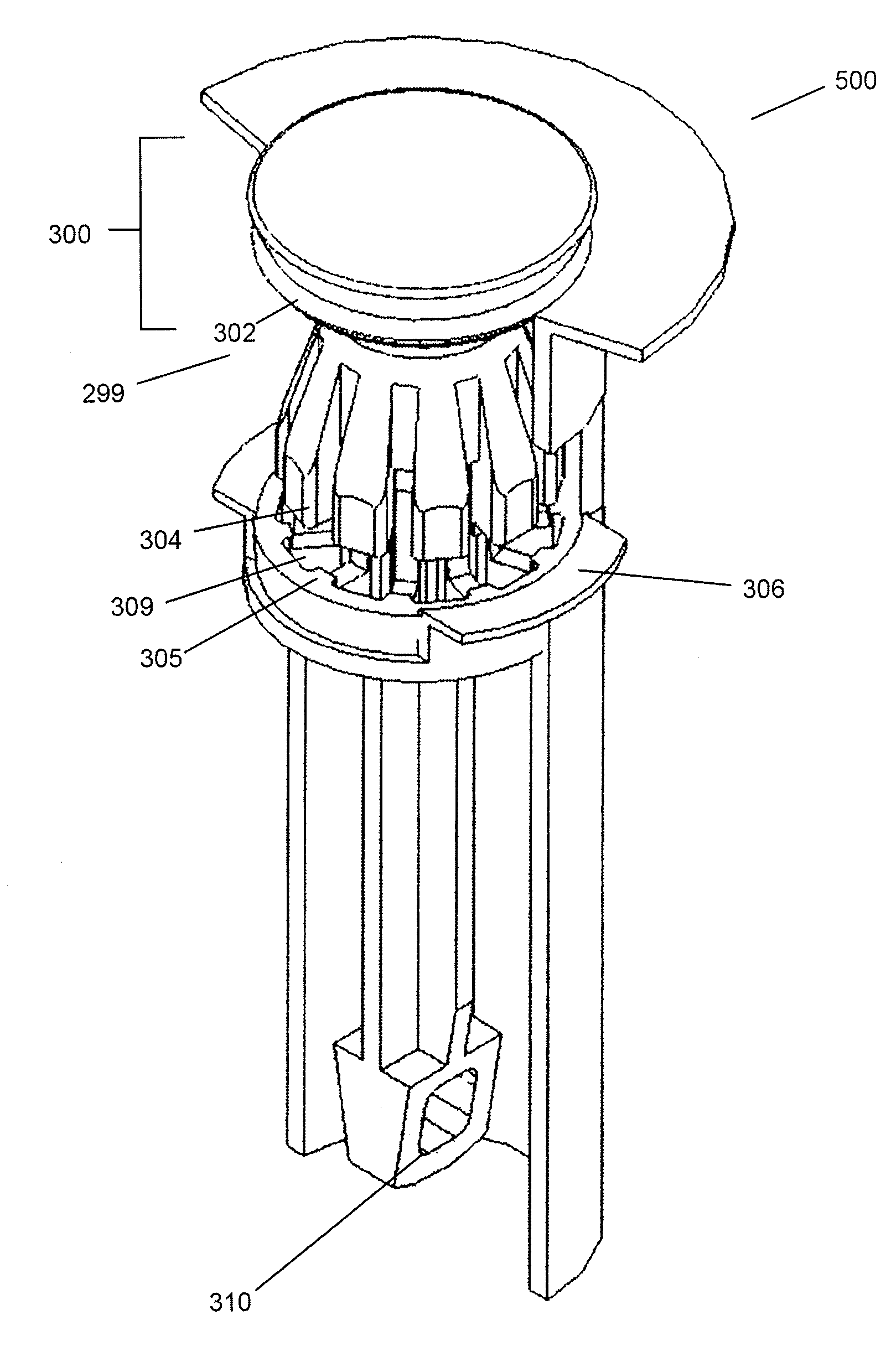

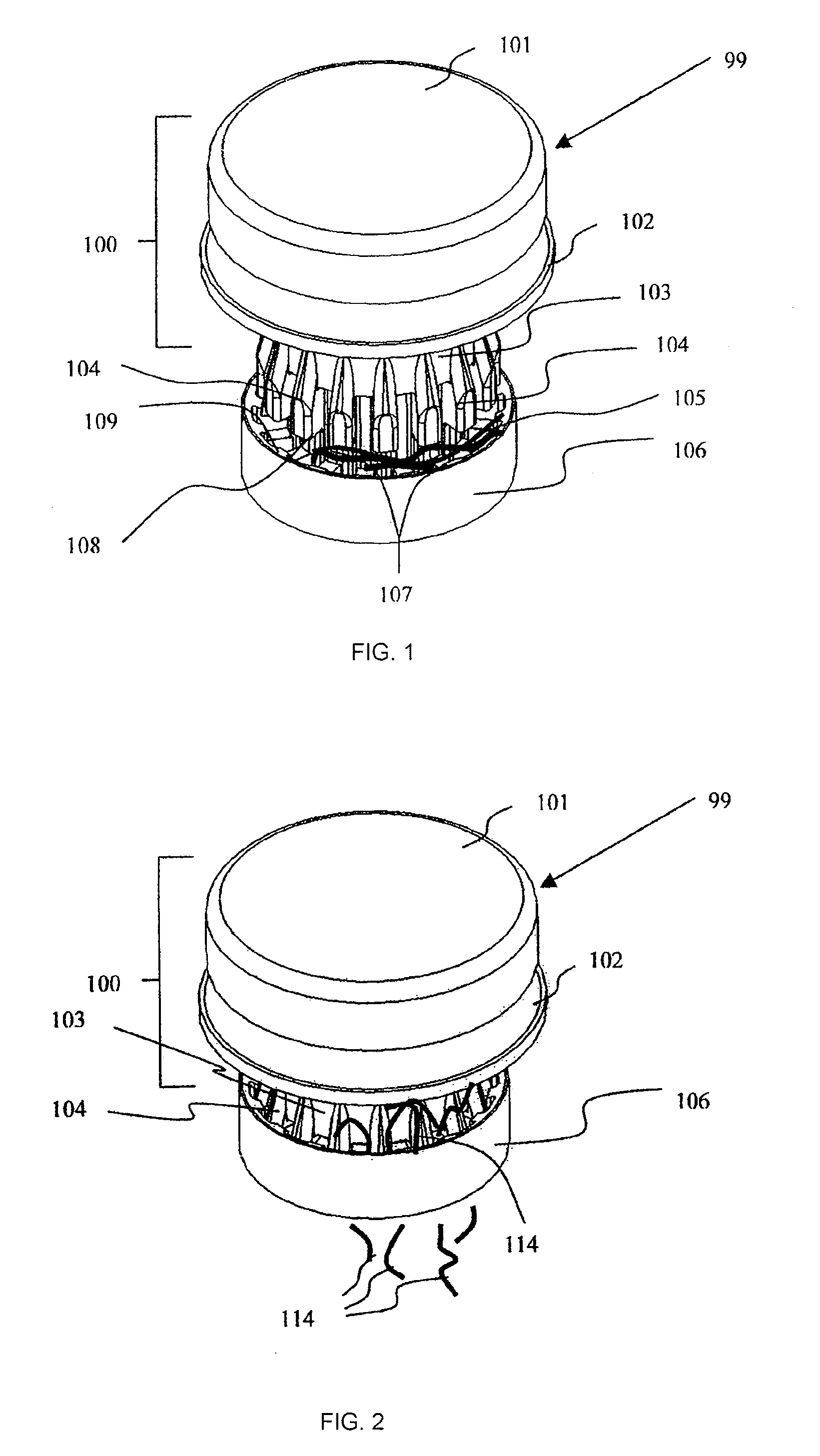

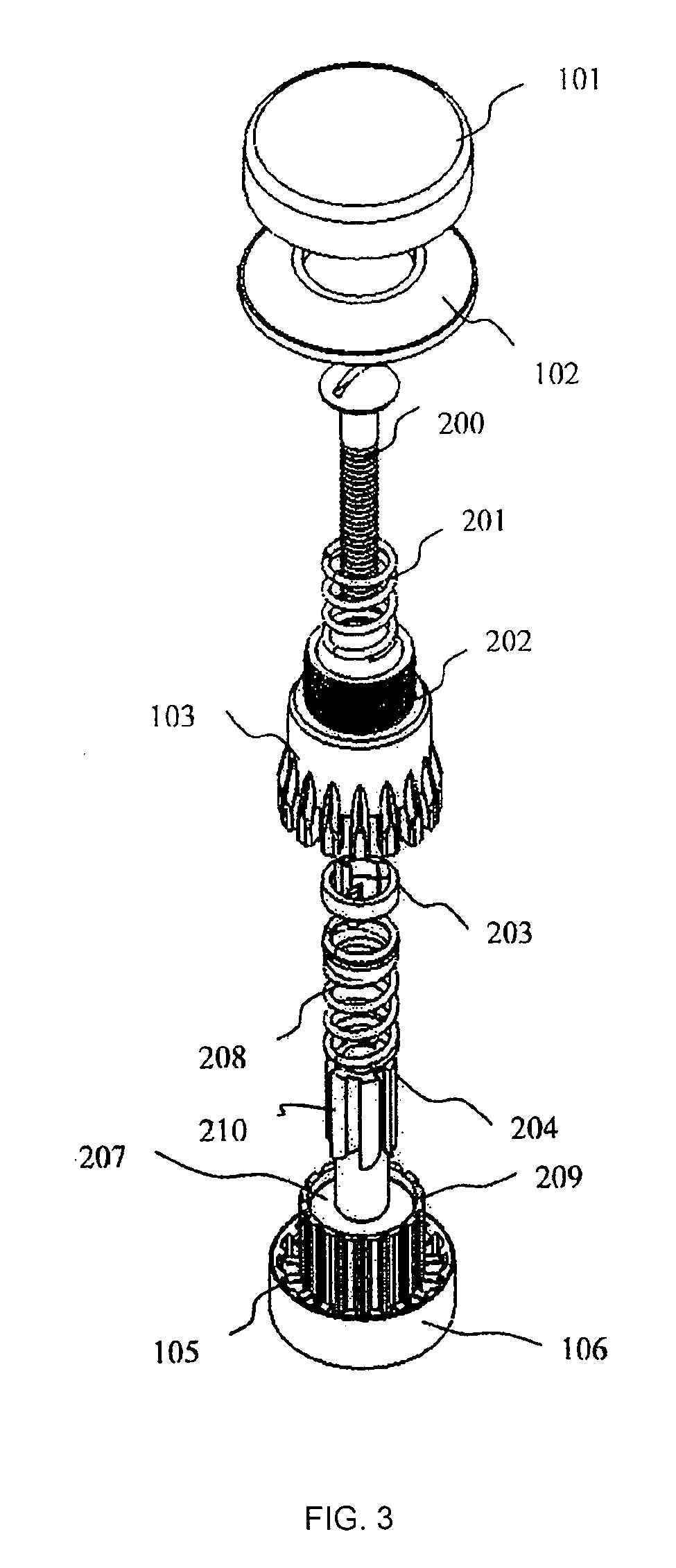

[0042]Referring first to FIGS. 1-4, a manually operable dram mounted device 99 shown assembled in FIG. 1 may be installed in an open drain receptacle (as typified in FIG. 13 and seen in sink, bathtub, or shower drains) (add picture of common drain receptacle and label it FIG. 13) for disposal of solid materials commonly encountered in a household or office, other than in a kitchen, such as hair, thread, fingernails, soapy residues, and so forth.

[0043]Referring to FIG. 1, the device 99 is in a ready condition, before operation, fitted for a typical drain receptacle. The device 99 may be manufactured in a size appropriate to fit snugly within the receptacle of a conventional drain for a tub, shower, or sink, in which the receptacle portion includes a horizontal bottom support cross member defining a threaded hole centered within the strainer bottom.

[0044]The device 99 includes a perforated strainer and ripping cutting plate 106 which is stationary and may be supported by a small dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com